Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

ADP3820

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1999

Lithium-Ion

Battery Charger

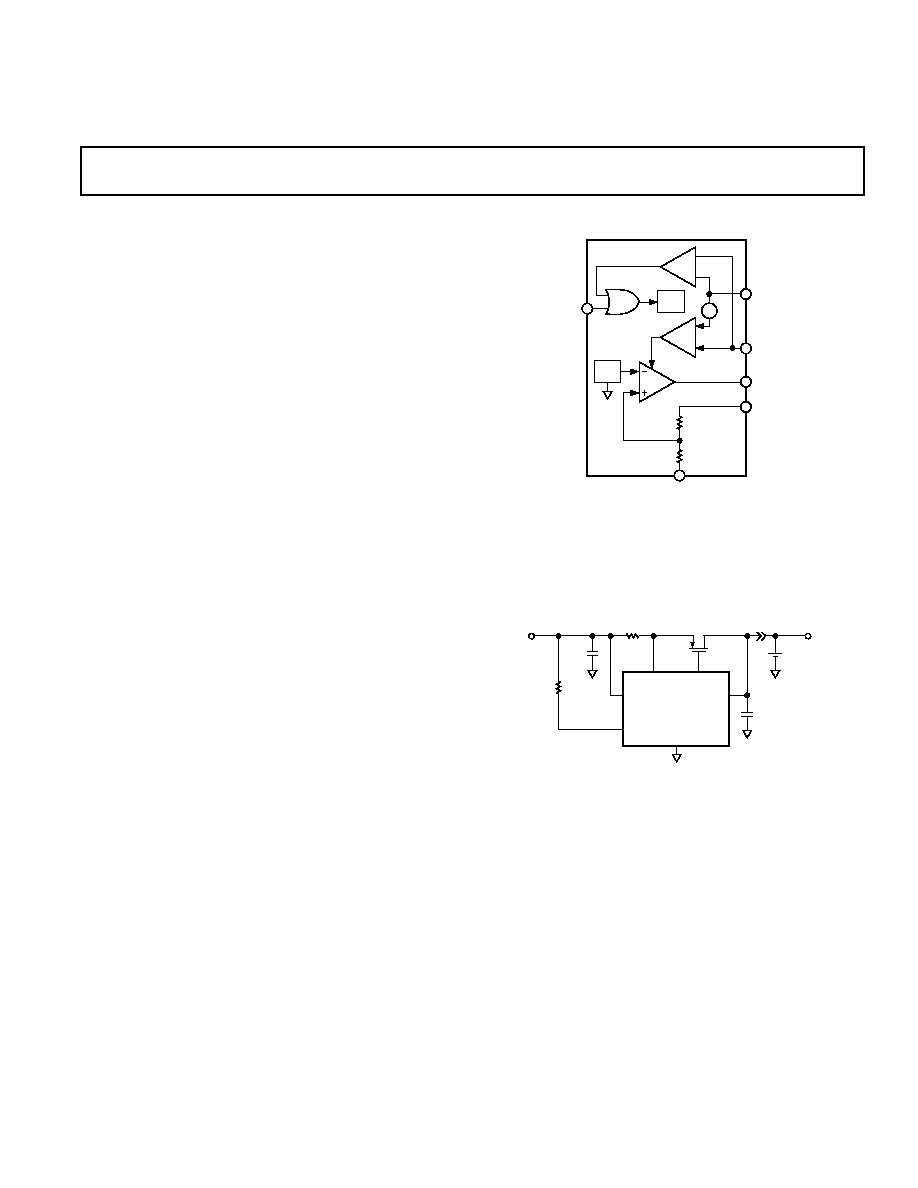

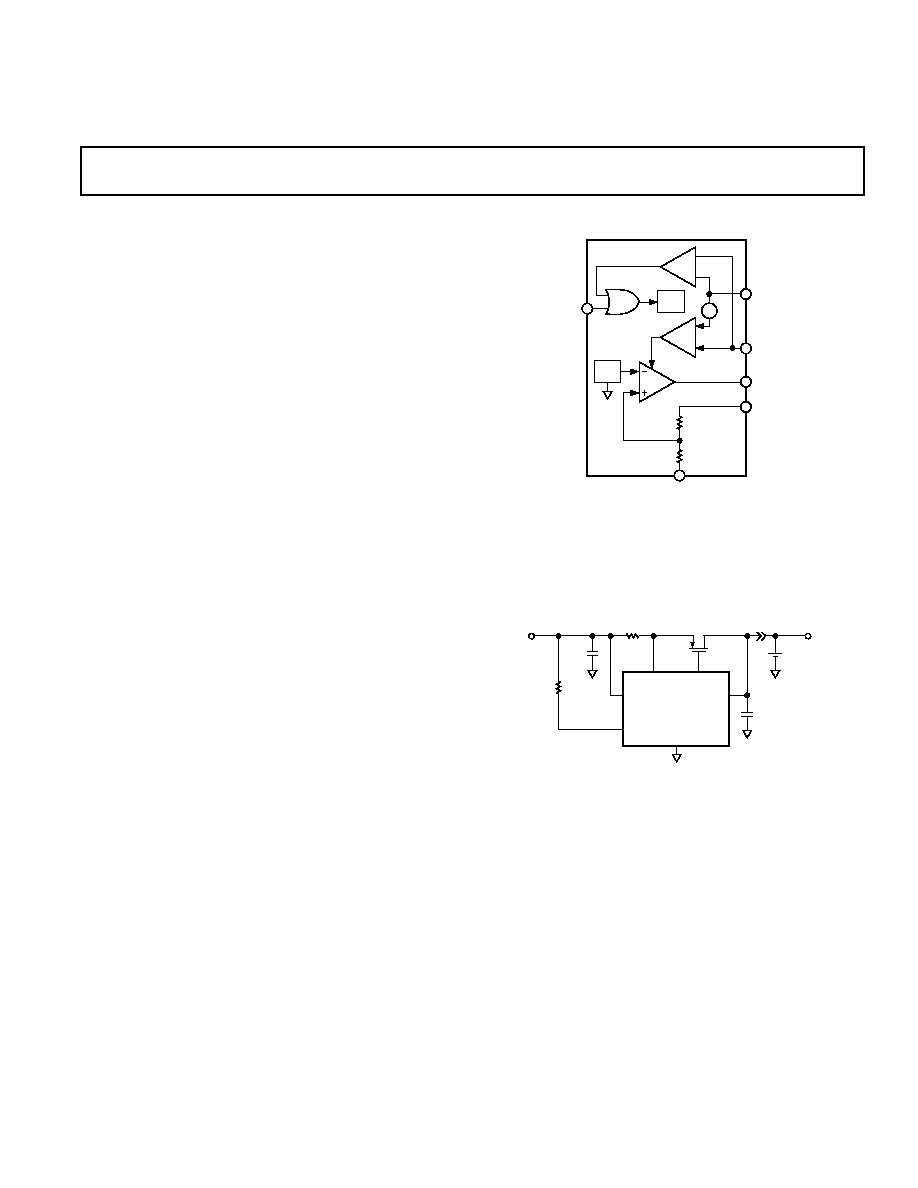

FUNCTIONAL BLOCK DIAGRAM

V

IN

IS

GATE

V

OUT

SD

50mV

+

BIAS

V

REF

ADP3820

GND

FEATURES

1% Total Accuracy

630 A Typical Quiescent Current

Shutdown Current: 1 A (Typical)

Stable with 10 F Load Capacitor

4.5 V to 15 V Input Operating Range

Integrated Reverse Leakage Protection

6-Lead SOT-23-6 and 8-Lead SO-8 Packages

Programmable Charge Current

20 C to +85 C Ambient Temperature Range

Internal Gate-to-Source Protective Clamp

APPLICATIONS

Li-Ion Battery Chargers

Desktop Computers

Hand-Held Instruments

Cellular Telephones

Battery Operated Devices

GENERAL DESCRIPTION

The ADP3820 is a precision single cell Li-Ion battery charge

controller that can be used with an external Power PMOS de-

vice to form a two-chip, low cost, low dropout linear battery

charger. It is available in two voltage options to accommodate

Li-Ion batteries with coke or graphite anodes. The ADP3820's

high accuracy (

±

1%) low shutdown current (1

µ

A) and easy

charge current programming make this device especially attrac-

tive as a battery charge controller.

Charge current can be set by an external resistor. For example,

50 m

of resistance can be used to set the charge current to

1 A. Additional features of this device include foldback current

limit, overload recovery, and a gate-to-source voltage clamp to

protect the external MOSFET. The proprietary circuit also

minimizes the reverse leakage current from the battery if the

input voltage of the charger is disconnected. This feature elimi-

nates the need for an external serial blocking diode.

The ADP3820 operates with a wide input voltage range from

4.5 V to 15 V. It is specified over the industrial temperature

range of 20

°

C to +85

°

C and is available in the ultrasmall

6-lead surface mount SOT-23-6 and 8-lead SOIC packages.

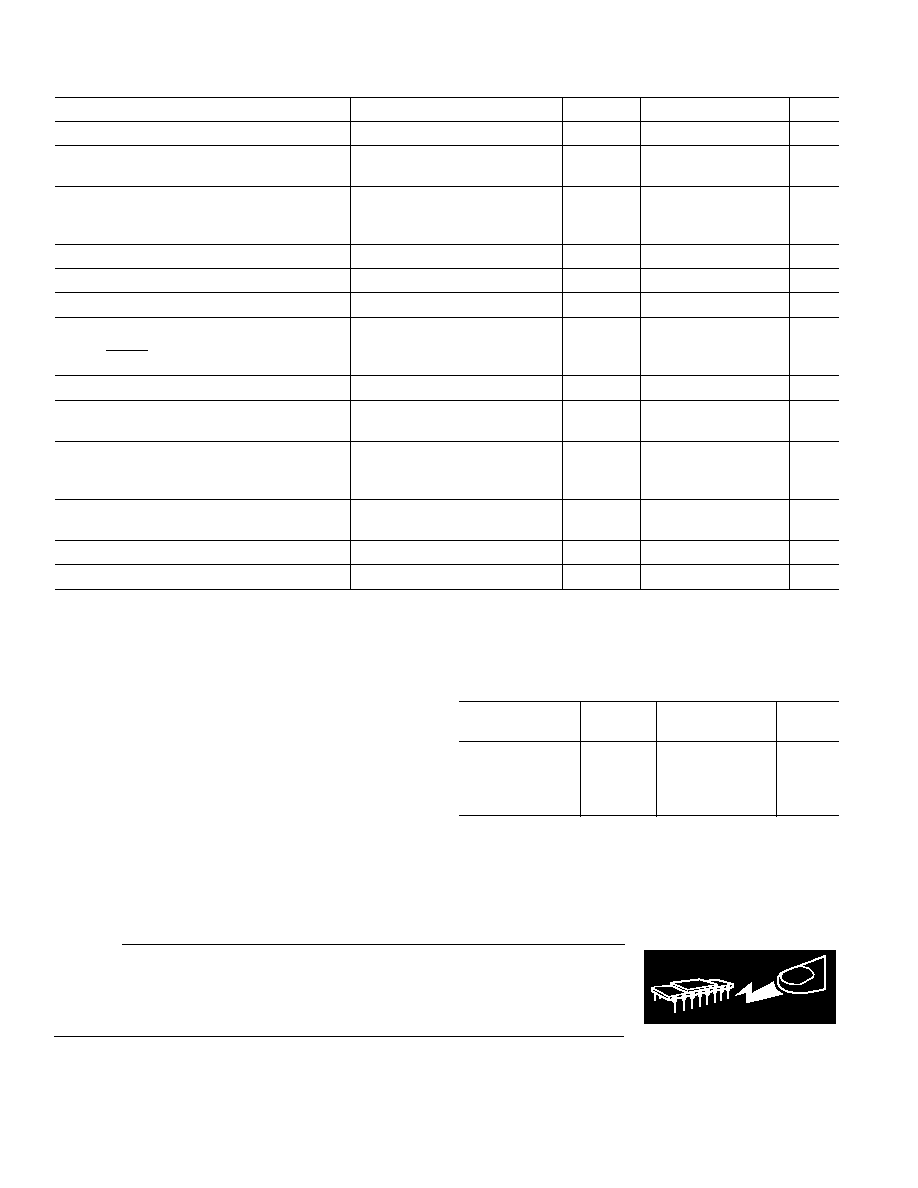

C1

10 F

+

R1

10k

V

IN

+5V

R

S

50m

22 F

V

OUT

Li-Ion

BATTERY

I

O

= 1A

NDP6020P

GND

IS

GATE

V

IN

SD

V

OUT

ADP3820-xx

Figure 1. Li-Ion Charger Application Circuit

2

REV. A

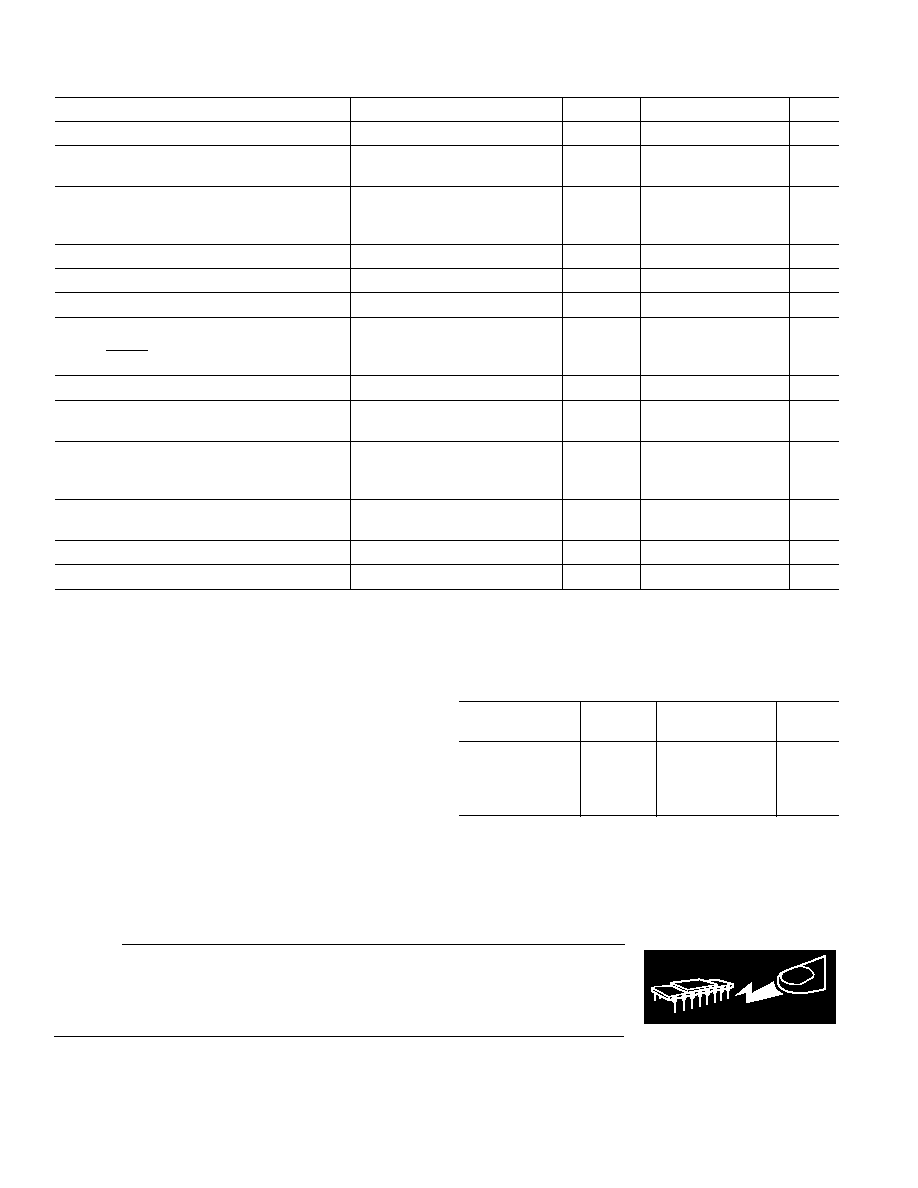

ADP3820SPECIFICATIONS

1

Parameter

Conditions

Symbol

Min

Typ

Max

Units

INPUT VOLTAGE

V

IN

4.5

15

V

OUTPUT VOLTAGE ACCURACY

V

IN

= V

OUT

+ 1 V to 15 V

V

OUT

1

+1

%

V

SD

= 2 V

QUIESCENT CURRENT

Shutdown Mode

V

SD

= 0 V

I

GND

1

15

µ

A

Normal Mode

V

SD

= 2 V

I

GND

630

800

µ

A

GATE TO SOURCE CLAMP VOLTAGE

6

10

V

GATE DRIVE MINIMUM VOLTAGE

2

0.7

V

GATE DRIVE CURRENT (SINK/SOURCE)

1

mA

GAIN

V

V

GS

OUT

80

dB

CURRENT LIMIT THRESHOLD VOLTAGE

V

IN

V

IS

40

75

mV

LOAD REGULATION

I

OUT

= 10 mA to 1 A,

Circuit of Figure 1

10

+10

mV

LINE REGULATION

V

IN

= V

OUT

+ 1 V to 15 V

I

OUT

= 0.1 A

Circuit of Figure 1 (No Battery)

10

+10

mV

SD INPUT VOLTAGE

V

IH

V

SD

2.0

V

V

IL

0.4

V

SD INPUT CURRENT

V

SD

= 0 V to 5 V

I

SD

15

+15

µ

A

OUTPUT REVERSE LEAKAGE CURRENT

V

IN

= Floating

I

DISCH

3

5

µ

A

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC).

2

Provided gate-to-source clamp voltage is not exceeded.

Specifications subject to change without notice.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADP3820 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Input Voltage, V

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 V

Enable Input Voltage . . . . . . . . . . . . . . . 0.3 V to (V

IN

+ 0.3 V)

Operating Ambient Temperature Range . . . . 20

°

C to +85

°

C

Storage Temperature Range . . . . . . . . . . . . 65

°

C to +150

°

C

JA

, SO-8 Package . . . . . . . . . . . . . . . . . . . . . . . . 150

°

C/W

JA

, SOT-23-6 Package . . . . . . . . . . . . . . . . . . . . 230

°

C/W

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300

°

C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . +215

°

C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . .+220

°

C

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 kV

*This is a stress rating only; operation beyond these limits can cause the device

to be permanently damaged.

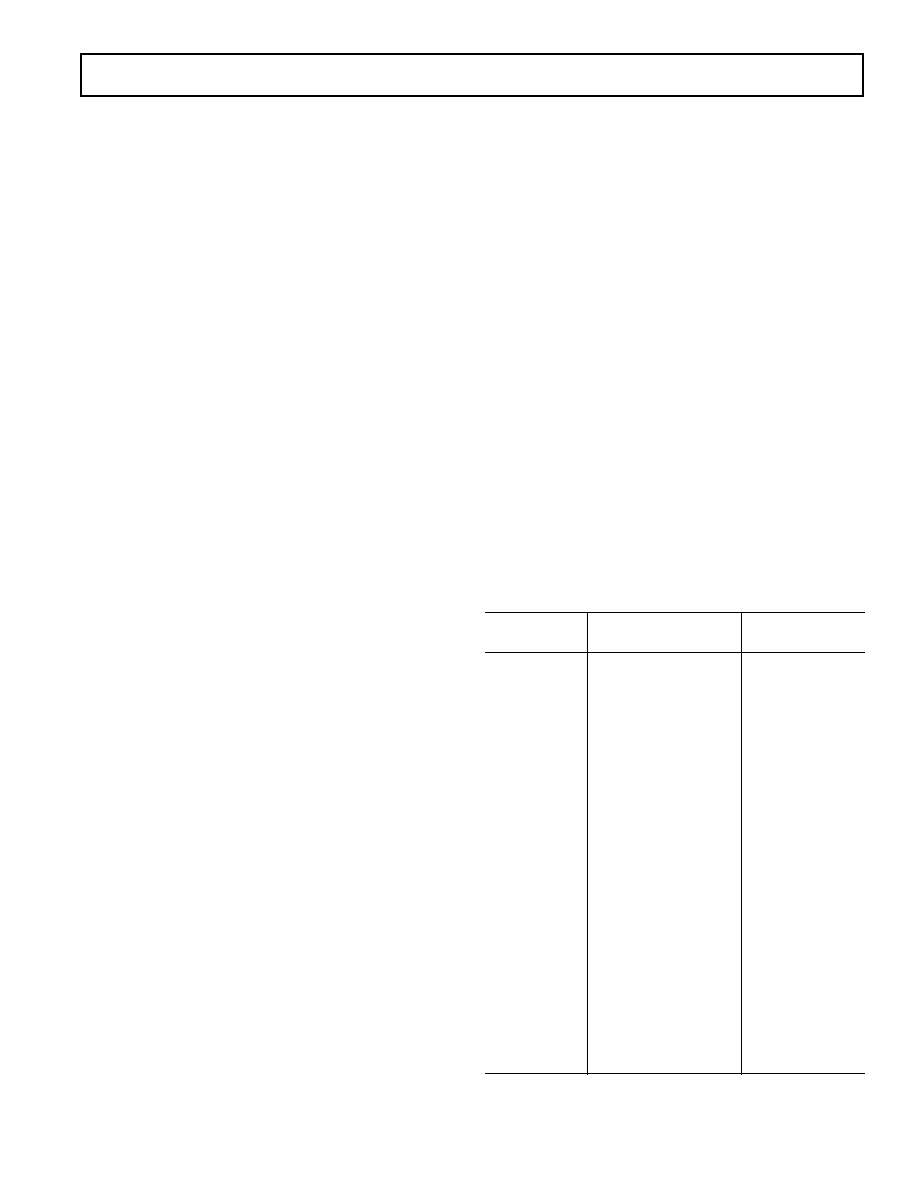

ORDERING GUIDE

Voltage

Package

Marking

Model

Output

Option*

Code

ADP3820ART-4.1

4.1 V

RT-6 (SOT-23-6) BAC

ADP3820ART-4.2

4.2 V

RT-6 (SOT-23-6) BBC

ADP3820AR-4.1

4.1 V

SO-8

ADP3820AR-4.2

4.2 V

SO-8

*SOT = Surface Mount Package. SO = Small Outline.

Contact the factory for availability of other output voltage options.

(V

IN

= [V

OUT

+ 1 V] T

A

= 20 C to +85 C, unless otherwise noted)

ADP3820

3

REV. A

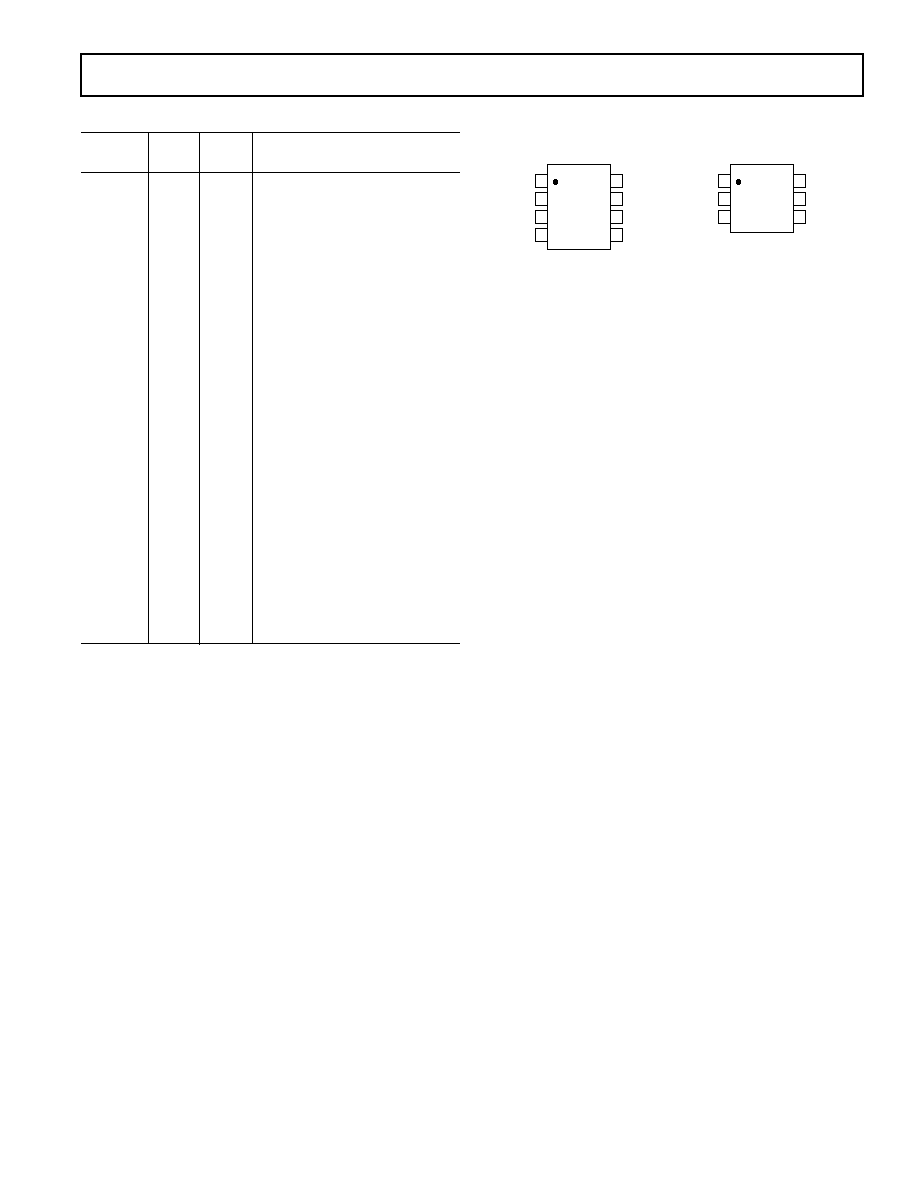

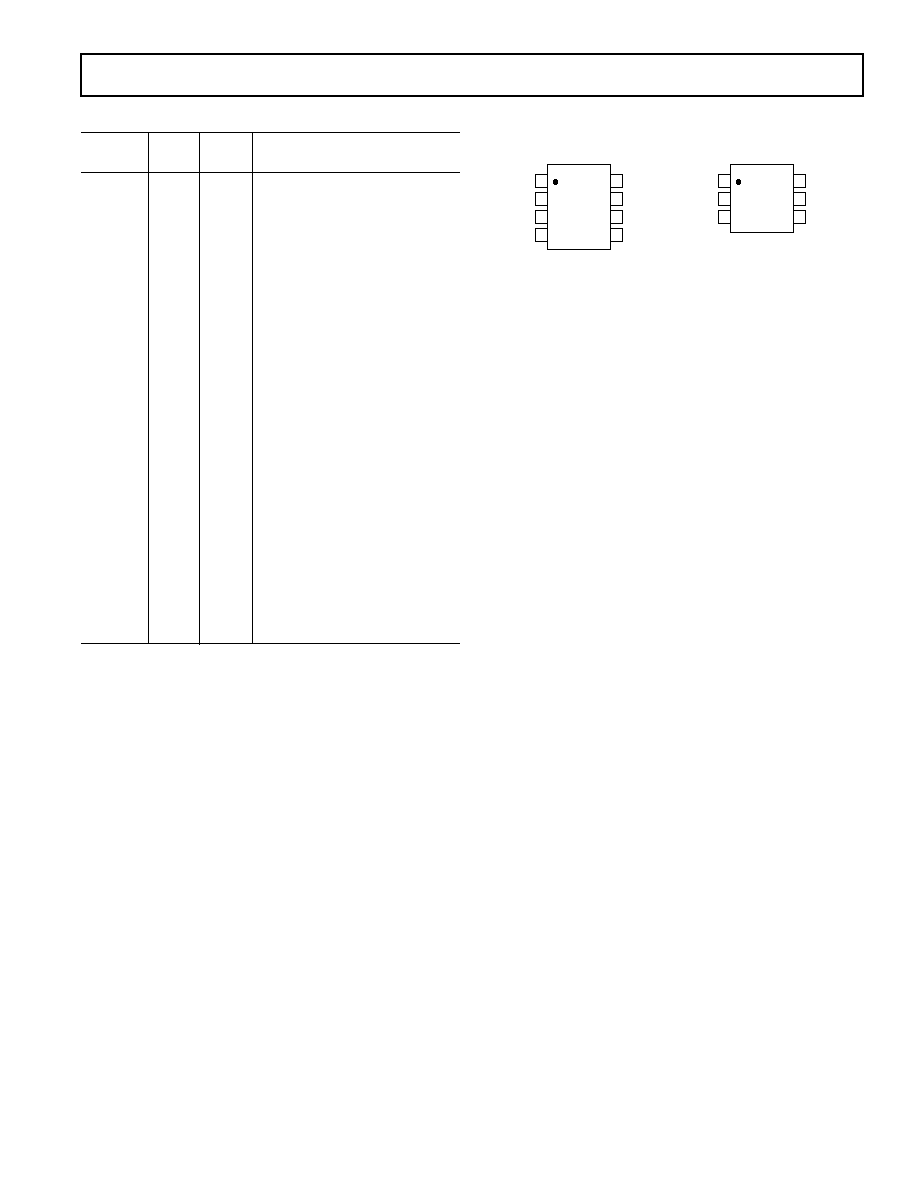

PIN FUNCTION DESCRIPTIONS

Pin

Pin

SOT-23-6 SO-8

Name

Function

1

8

SD

Shutdown. Pulling this pin low

will disable the output.

2

7

GND

Device Ground. This pin should

be tied to system ground closest

to the load.

3

5

V

OUT

Output Voltage Sense. This pin

is connected to the MOSFET's

drain and directly to the load for

optimal load regulation. Bypass

to ground with a 10

µ

F or larger

capacitor.

4

3

GATE

Gate drive for the external

MOSFET.

5

4

V

IN

Input Voltage. This is also the

positive terminal connection of

the current sense resistor.

6

1

IS

Current Sense. Used to sense the

input current by monitoring the

voltage across the current sense

resistor. It is connected to the

more negative terminal of the

resistor as well as the power

MOSFET's source pin. IS pin

should be tied to the V

IN

pin if

the current limit feature is not

used.

2, 6

NC

No Connect.

PIN CONFIGURATIONS

SO-8

RT-6 (SOT-23-6)

TOP VIEW

(Not to Scale)

8

7

6

5

1

2

3

4

NC = NO CONNECT

IS

NC

GATE

V

IN

SD

GND

NC

V

OUT

ADP3820

TOP VIEW

(Not to Scale)

6

5

4

1

2

3

SD

GND

V

OUT

IS

V

IN

GATE

ADP3820

ADP3820

4

REV. A

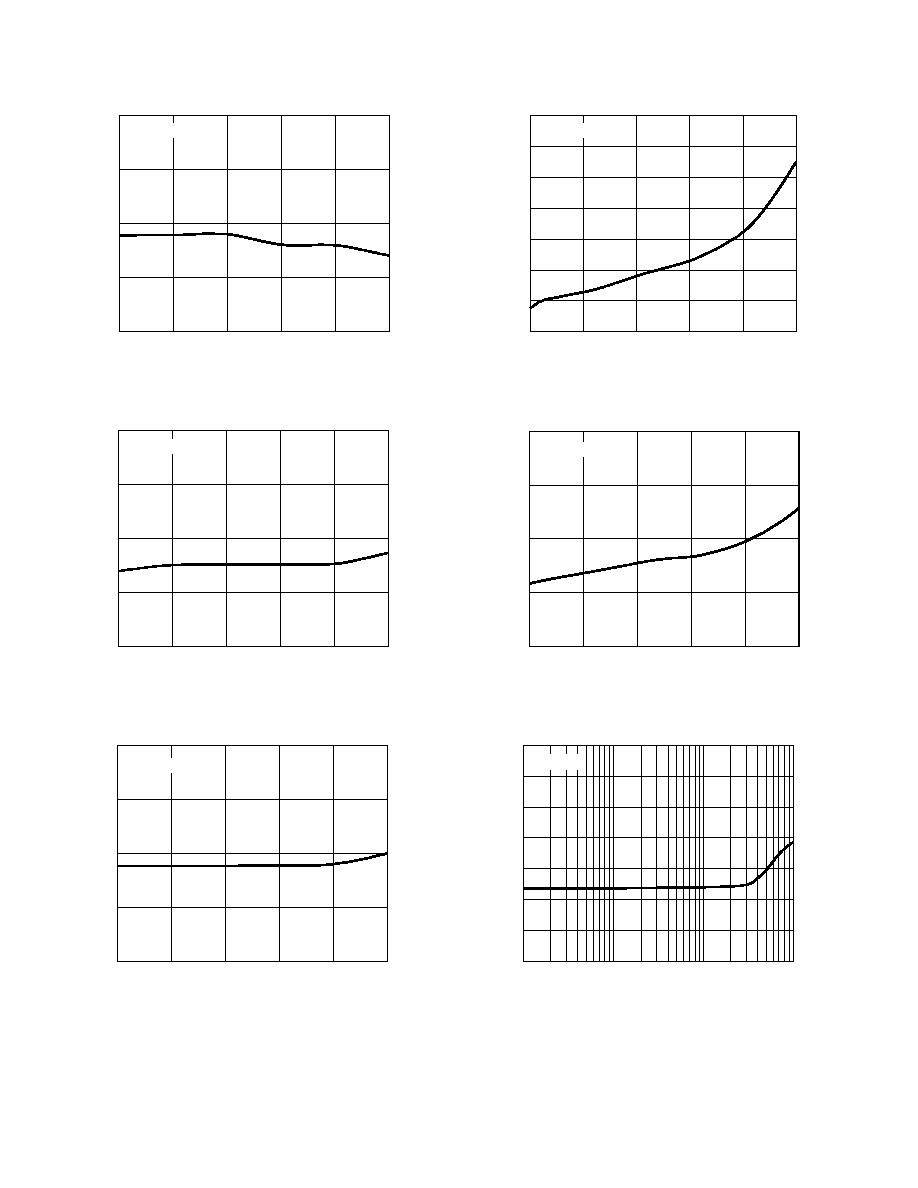

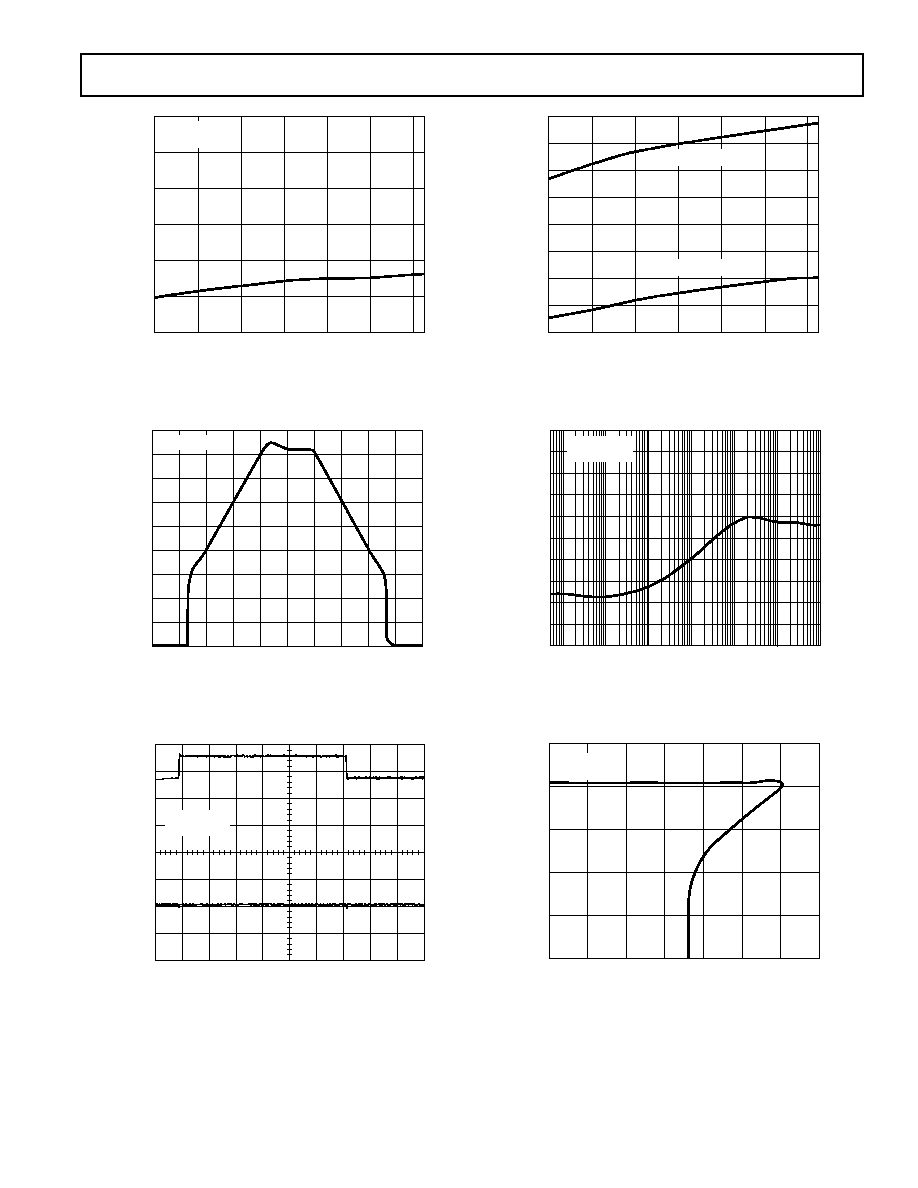

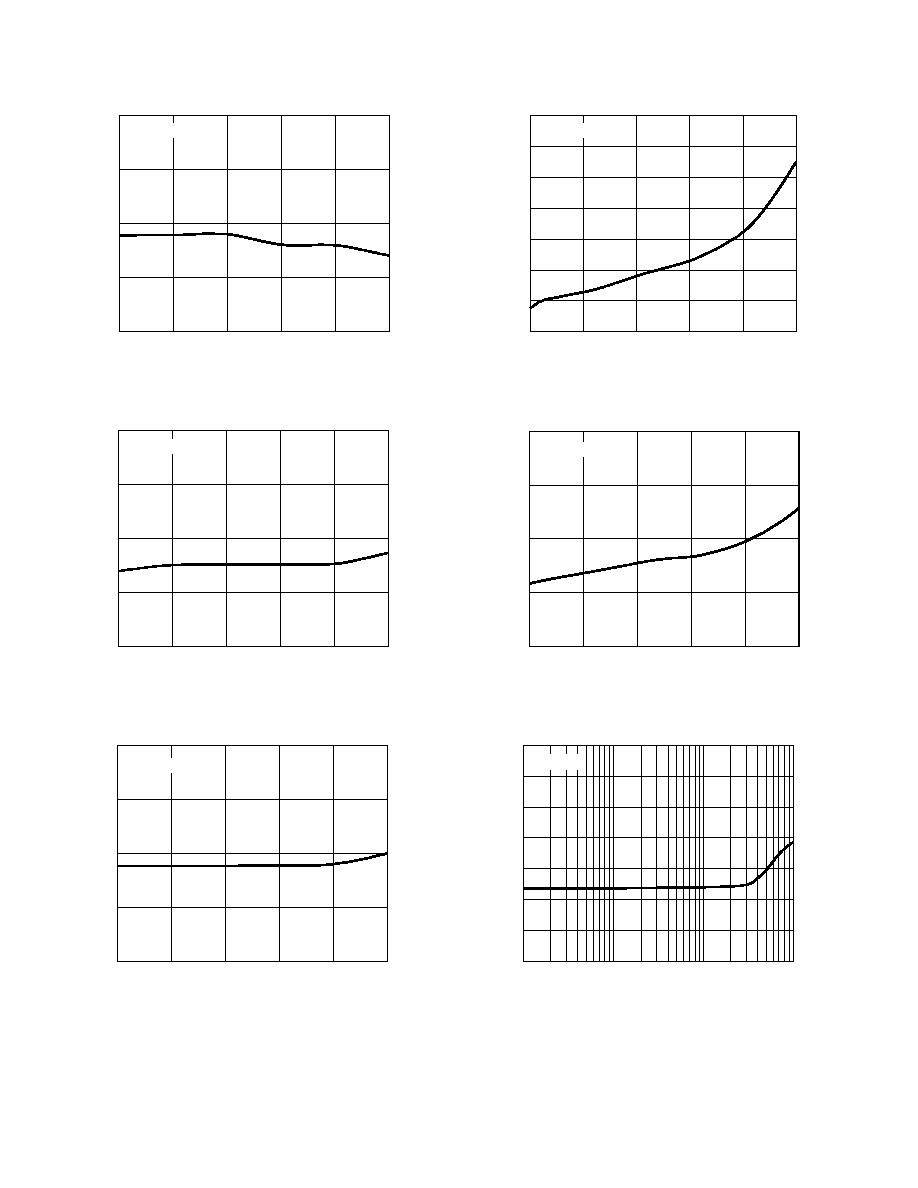

Typical Performance Characteristics

I

LOAD

mA

4.110

4.105

4.090

0

1000

200

OUTPUT VOLTAGE V

400

600

800

4.100

4.095

V

IN

= 5.1V

Figure 2. V

OUT

vs. I

LOAD

(V

IN

= 5.1 V)*

4.110

4.105

4.090

5

15

7

OUTPUT VOLTAGE V

9

11

13

4.100

4.095

INPUT VOLTAGE V

I

LOAD

= 1A

Figure 3. V

OUT

vs. V

IN

(I

LOAD

= 1 A)*

4.110

4.105

4.090

5

15

7

OUTPUT VOLTAGE V

9

11

13

4.100

4.095

INPUT VOLTAGE V

I

LOAD

= 10mA

Figure 4. V

OUT

vs. V

IN

(I

LOAD

= 10 mA)*

INPUT VOLTAGE V

0.760

0.740

0.680

5

15

7

I

GND

mA

9

11

13

0.720

0.700

0.660

0.640

0.620

I

LOAD

= 10mA

Figure 5. I

GND

vs. V

IN

(I

LOAD

= 10 mA)*

INPUT VOLTAGE V

0.900

0.850

0.700

5

15

7

I

GND

mA

11

13

0.800

0.750

I

LOAD

= 1A

9

Figure 6. I

GND

vs. V

IN

(I

LOAD

= 1 A)*

I

LOAD

mA

1.200

0.500

0.001

1000

I

GND

mA

1.100

10

0.1

1.000

0.900

0.800

0.700

0.600

V

IN

= 5.1V

Figure 7. I

GND

vs. I

LOAD

(V

IN

= 5.1 V)*

*Reference Figure 1.

ADP3820

5

REV. A

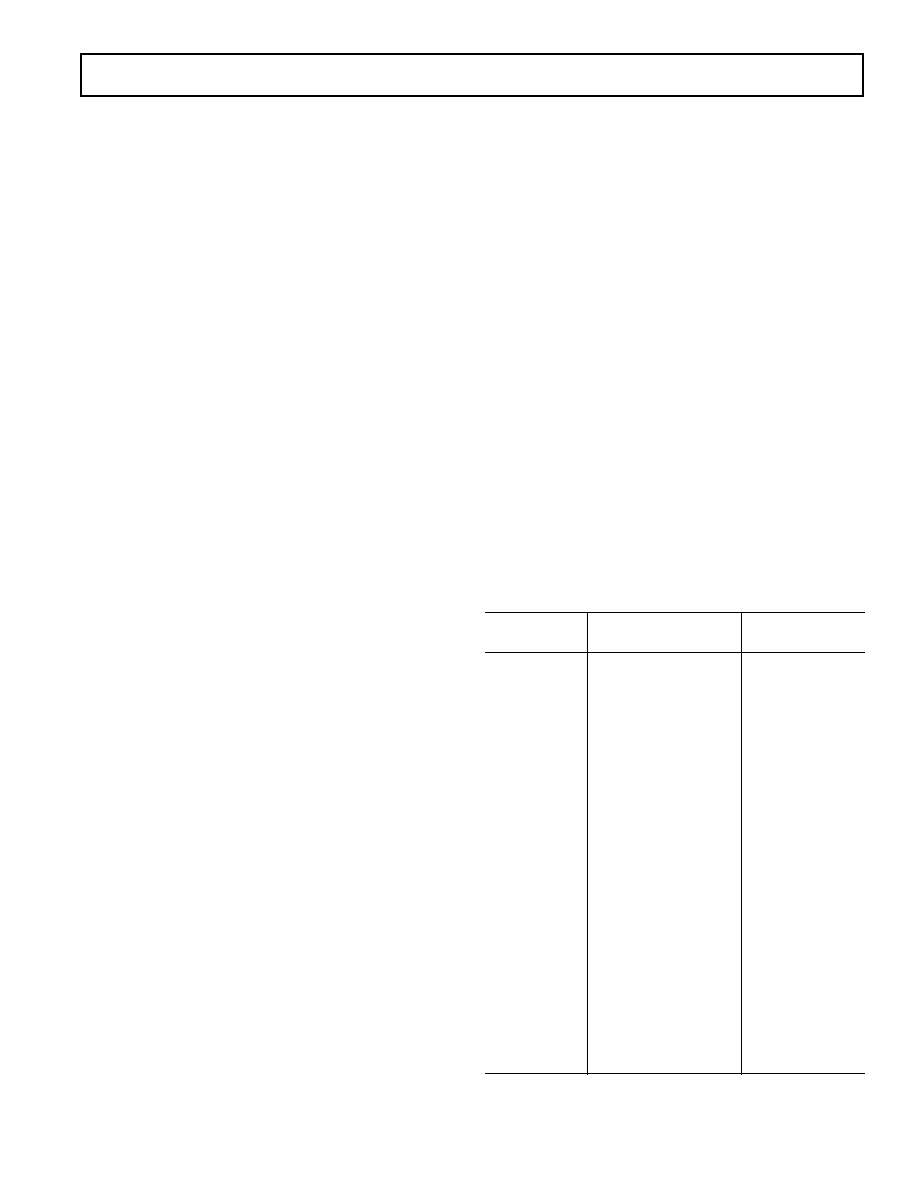

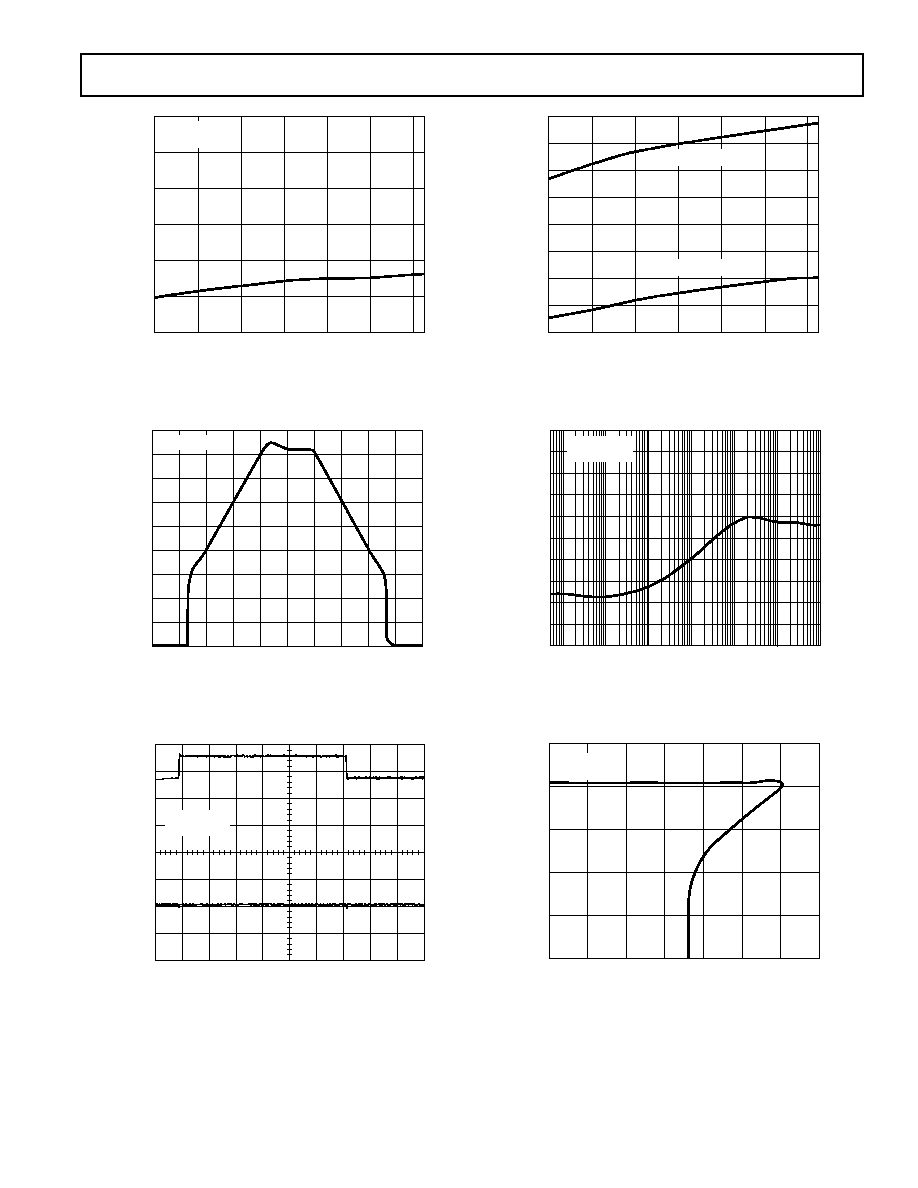

TEMPERATURE C

1.100

0.500

40

80

20

I

GND

mA

0

20

40

60

1.000

0.900

0.800

0.700

0.600

V

IN

= 5.1V

I

LOAD

= 10mA

Figure 8. Quiescent Current vs. Temperature*

INPUT VOLTAGE V

0

0

1

2

3

4

5

4

3

2

1

4.5

4.0

0

OUTPUT VOLTAGE V

2.0

1.5

1.0

0.5

3.0

2.5

3.5

I

LOAD

= 10mA

Figure 9. Power-Up/Power-Down*

4.2

4.1

4.0

5.5

7.0

I

LOAD

= 10mA

C

OUT

= 10 F

OUTPUT

VOLTAGE V

INPUT

VOLTAGE V

Figure 10. Line Transient Response (10

µ

F Output Cap)*

TEMPERATURE C

4.230

4.110

40

80

20

OUTPUT VOLTAGE V

0

20

40

60

4.210

4.190

4.170

4.150

4.130

4.090

4.070

V

OUT

= 4.2V

V

OUT

= 4.1V

Figure 11. V

OUT

vs. Temperature, V

IN

= 5.1 V, I

LOAD

= 10 mA*

FREQUENCY Hz

0

100

10

1M

PSRR dB

50

100

1k

10k

100k

10

20

30

40

60

70

80

90

10M

C

LOAD

= 10 F

I

LOAD

= 1mA

Figure 12. Ripple Rejection*

I

LOAD

mA

5.000

4.000

0.000

0

140

20

OUTPUT VOLTAGE V

40

60

80

100

120

3.000

2.000

V

IN

= 5.1V

R

S

= 0.5

1.000

Figure 13. Current Limit Foldback*

ADP3820

6

REV. A

APPLICATION INFORMATION

The ADP3820 is very easy to use. A P-channel power MOS-

FET and a small capacitor on the output is all that is needed to

form an inexpensive Li-Ion battery charger. The advantage of

using the ADP3820 controller is that it can directly drive a

PMOS FET to provide a regulated output current until the

battery is charged. When the specified battery voltage is reached,

the charge current is reduced and the ADP3820 maintains the

maximum specified battery voltage accurately.

When fully charged, the circuit in Figure 1 works like a well

known linear regulator, holding the output voltage within the

specified accuracy as needed by single cell Li-Ion batteries. The

output is sensed by the V

OUT

pin. When charging a discharged

battery, the circuit maintains a set charging current determined

by the current sense resistor until the battery is fully charged,

then reduces it to a trickle charge to keep the battery at the

specified voltage. The voltage drop across the R

S

current sense

resistor is sensed by the IS input of the ADP3820. At minimum

battery voltage or at shorted battery, the circuit reduces this

current (foldback) to limit the dissipation of the FET (see Fig-

ure 13). Both the V

IN

input and V

OUT

sense pins of the IC need

to be bypassed by a suitable bypass capacitor.

A 6 V gate-to-source voltage clamp is provided by the ADP3820

to protect the MOSFET gates at higher source voltages. The

ADP3820 also has a TTL

SD input, which may be connected to

the input voltage to enable the IC. Pulling it to low or to

ground will disable the FET-drive.

Design Approach

Due to the lower efficiency of Linear Regulator Charging, the

most important factor is the thermal design and cost, which is

the direct function of the input voltage, output current and

thermal impedance between the MOSFET and the ambient

cooling air. The worse-case situation is when the battery is

shorted since the MOSFET has to dissipate the maximum power.

A tradeoff must be made between the charge current, cost and

thermal requirements of the charger. Higher current requires a

larger FET with more effective heat dissipation leading to a

more expensive design. Lowering the charge current reduces

cost by lowering the size of the FET, possibly allowing a smaller

package such as SOT-23-6. The following designs consider both

options. Furthermore, each design is evaluated under two input

source voltage conditions.

Regarding input voltage, there are two options:

A. The input voltage is preregulated, e.g., 5 V

±

10%

B. The input voltage is not a preregulated source, e.g., a wall

plug-in transformer with a rectifier and capacitive filter.

Higher Current Option

A. Preregulated Input Voltage (5 V 10%)

For the circuit shown in Figure 1, the required

JA

thermal

impedance can be calculated as follows: if the FET data sheet

allows a max FET junction temperature of T

JMAX

= 150

°

C, then

at 50

°

C ambient and at convection cooling, the maximum al-

lowed

T junction temperature rise is thus, T

JMAX

T

AMAX

=

150

°

C 50

°

C = 100

°

C.

The maximum current for a shorted or discharged battery is

reduced from the set charge current by a multiplier factor shown

in Figure 13 due to the foldback current limiting feature of the

ADP3820. This k factor between V

O

of 0 V to about 2.5 V is:

k ~ 0.65.

JA

=

T/(I

O

×

k

×

V

IN

) = 100/(1

×

0.65

×

5) = 30.7

°

C/W

This thermal impedance can be realized using the transistor

shown in Figure 1 when surface mounted to a 40

×

40 mm

double-sided PCB with many vias around the tab of the surface-

mounted FET to the backplane of the PCB. Alternatively, a

TO-220 packaged FET mounted to a heatsink could be used.

The

or thermal impedance of a suitable heatsink is calculated

below:

< (

JA

JC

) = 30.7 2 = +28.7

°

C/W

Where the

JC

, or junction-to-case thermal impedance of the

FET can be read from the FET data sheet. A low cost such

heatsink is type PF430 made by Thermalloy, with a

=

+25.3

°

C/W.

The current sense resistor for this application can be simply

calculated:

R

S

= V

S

/I

O

= 0.05/1 = 50 m

Where V

S

is specified on the data sheet as current limit threshold

voltage at 40 mV75 mV. For battery charging applications, it

is adequate to use the typical 50 mV midvalue.

B. Nonpreregulated Input Voltage

If the input voltage source is, for example, a rectified and

capacitor-filtered secondary voltage of a small wall plug-in

transformer, the heatsinking requirement is more demanding.

The V

INMIN

should be specified 5 V, but at the lowest line volt-

age and full load current. The required thermal impedance can

be calculated the same way as above, but here we have to use

the maximum output rectified voltage, which can be substan-

tially higher than 5 V, depending on transformer regulation and

line voltage variation. For example, if V

INMAX

is 10 V

JA

=

T/(I

O

×

k

×

V

INMAX

) = 100/(1

×

0.65

×

10) = +15.3

°

C/W

The

suitable heatsink thermal impedance:

<

JA

JC

= 15.3 2 = 13.3

°

C/W

A low cost heatsink is Type 6030B made by Thermalloy, with a

= +12.5

°

C/W.

Lower Current Option

A. Preregulated Input Voltage (5 V 10%)

If lower charging current is allowed, the

JA

value can be increased,

and the system cost decreased. The lower cost is assured by

using an inexpensive MOSFET with, for example, a NDT452P

in a SOT-23-6 package mounted on a small 40

×

40 mm area

on double-sided PCB. This provides a convection cooled ther-

mal impedance of

JA

= +55

°

C/W, presuming many vias are

used around the FET to the backplane. Allowing a maximum

FET junction temperature of +150

°

C, at +50

°

C ambient, and

at convection cooling the maximum allowed heat rise is thus

150

°

C50

°

C = 100

°

C.

The maximum foldback current allowed:

I

FB

=

T/(

×

V

IN

) = 100/(55

×

5) = 0.33 A

Thus the full charging current:

I

OUTMAX

= I

FB

/k = 0.5 A

k is calculated in the above example.

ADP3820

7

REV. A

The current sense resistor for this application:

R

S

= V

S

/I

O

= 0.05/0.5 = 100 m

FET Selection

The type and size of the pass transistor are determined by the

threshold voltage, input-output voltage differential and load

current. The selected PMOS must satisfy the physical and ther-

mal design requirements. To ensure that the maximum V

GS

provided by the controller will turn on the FET at worst case

conditions, (i.e., temperature and manufacturing tolerances) the

maximum available V

GS

must be determined. Maximum V

GS

is

calculated as follows:

V

GS

= V

IN

V

BE

I

OUTMAX

×

R

S

where

I

OUTMAX

= Maximum Output Current

R

S

= Current Sense Resistor

V

BE

~ 0.7 V (Room Temperature)

~ 0.5 V (Hot)

~ 0.9 V (Cold)

For example:

V

IN

= 5 V, and I

OUTMAX

= 1 A,

V

GS

= 5 V 0.7 V 1 A

×

50 m

= 4.25 V

If V

GS

< 5 V, logic level FET should be considered.

If V

GS

> 5 V, either logic level or standard MOSFET can be

used.

The difference between V

IN

and V

O

(V

DS

) must exceed the

voltage drop due to the sense resistor plus the ON-resistance

of the FET at the maximum charge current. The selected

MOSFET must satisfy these criteria; otherwise, a different pass

device should be used.

V

DS

= V

IN

V

O

= 5 V 4.2 V = 0.8 V

The maximum R

DS(ON)

required at the available gate drive (V

DR

)

and Drain-to-Source voltage (V

DS

) is:

R

DS(ON)

= V

DS

/I

OUTMAX

From the Drain-to Source current vs. Drain-to-Source voltage

vs. gate drive graph off the MOSFET data sheet, it can be de-

termined if the above calculated R

DS(ON)

is higher than the graph

indicates. However, the value read from the MOSFET data

sheet graph must be adjusted based on the junction temperature

of the MOSFET. This adjustment factor can be obtained from

the normalized R

DS(ON)

vs. junction temperature graph in the

MOSFET data sheet.

External Capacitors

The ADP3820 is stable with or without a battery load, and

virtually any good quality output filter capacitors can be used

(anyCAPTM), independent of the capacitor's minimum ESR

(Effective Series Resistance) value. The actual value of the

capacitor and its associated ESR depends on the g

m

and capaci-

tance of the external PMOS device. A 10

µ

F tantalum or alumi-

num electrolytic capacitor at the output is sufficient to ensure

stability for up to a 10 A output current.

Shutdown Mode

Applying a TTL high signal to the

SD pin or tying it to the

input pin will enable the output. Pulling this pin low or tying

it to ground will disable the output. In shutdown mode, the

controller's quiescent current is reduced to less than 1

µ

A.

Gate-to-Source Clamp

A 6 V gate-to-source voltage clamp is provided by the ADP3820 to

protect most MOSFET gates in the event the V

IN

> V

GS

allowed

and the output is suddenly shorted to ground. This allows use of

the new, low R

DS(ON)

MOSFETs.

Short Circuit Protection

The power FET is protected during short circuit conditions

with a foldback type of current limiting that significantly re-

duces the current. See Figure 13 for foldback current limit

information.

Current Sense Resistor

Current limit is achieved by setting an appropriate current sense

resistor (R

S

) across the current limit threshold voltage. Current

limit sense resistor, R

S

, is calculated as shown above. Proper

derating is advised to select the power dissipation rating of the

resistor.

The simplest and cheapest sense resistor for high current appli-

cations, (i.e., Figure 1) is a PCB trace. However, the tempera-

ture dependence of the copper trace and the thickness tolerances of

the trace must be considered in the design. The resistivity of

copper has a positive temperature coefficient of +0.39%/

°

C.

Copper's Tempco, in conjunction with the proportional-to-

absolute temperature (

±

0.3%) current limit voltage, can provide

an accurate current limit. Table I provides the typical resistance

values for PCB copper traces. Alternately, an appropriate sense

resistor, such as surface mount sense resistors, available from

KRL, can be used.

Table I. Printed Circuit Copper Resistance

Conductor

Conductor

Resistance

Thickness

Width/Inch

m /In

1/2oz/ft

2

(18

µ

m)

0.025

39.3

0.050

19.7

0.100

9.83

0.200

4.91

0.500

1.97

1oz/ft

2

(35

µ

m)

0.025

19.7

0.050

9.83

0.100

4.91

0.200

2.46

0.500

0.98

2oz/ft

2

(70

µ

m)

0.025

9.83

0.050

4.91

0.100

2.46

0.200

1.23

0.500

0.49

3oz/ft

2

(106

µ

m)

0.025

6.5

0.050

3.25

0.100

1.63

0.200

0.81

0.500

0.325

anyCAP is a trademark of Analog Devices, Inc.

ADP3820

8

REV. A

C2986a29/99

PRINTED IN U.S.A.

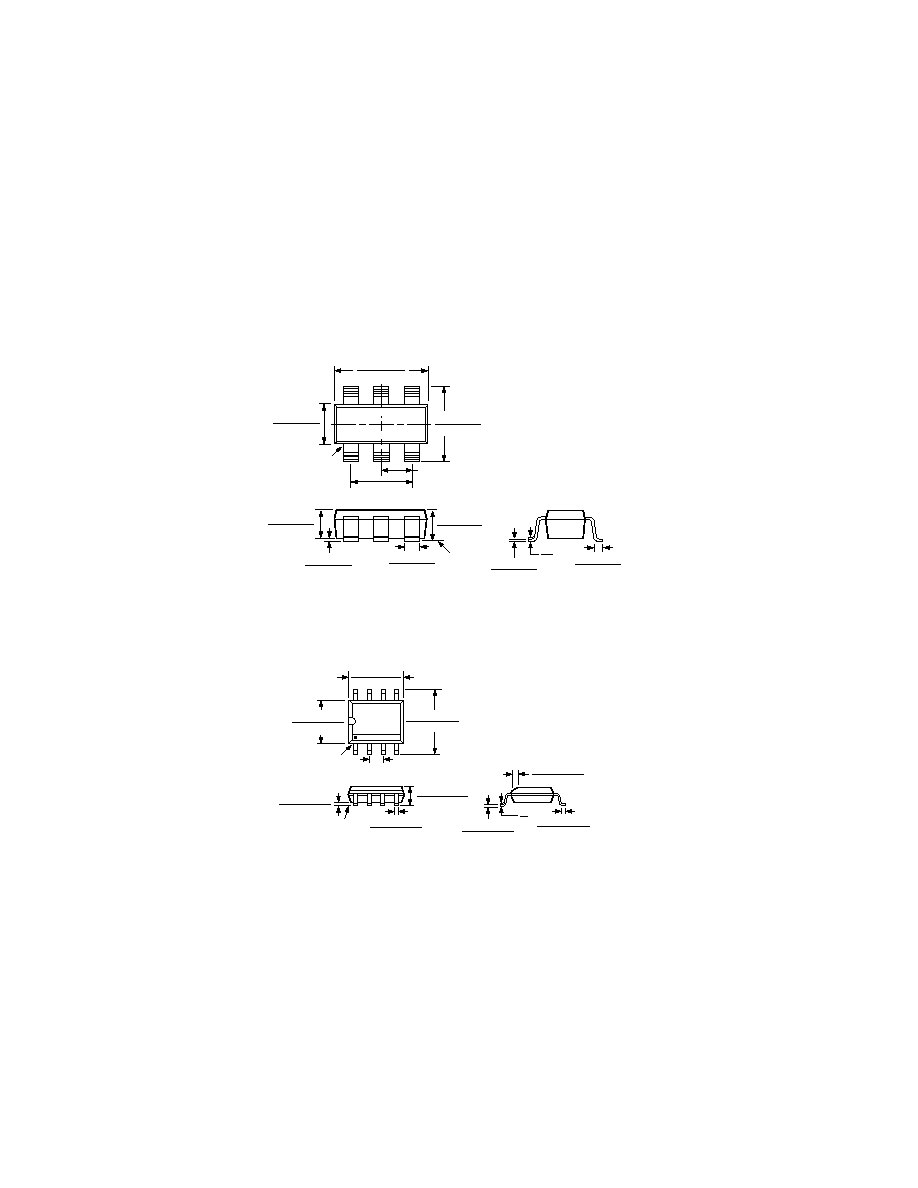

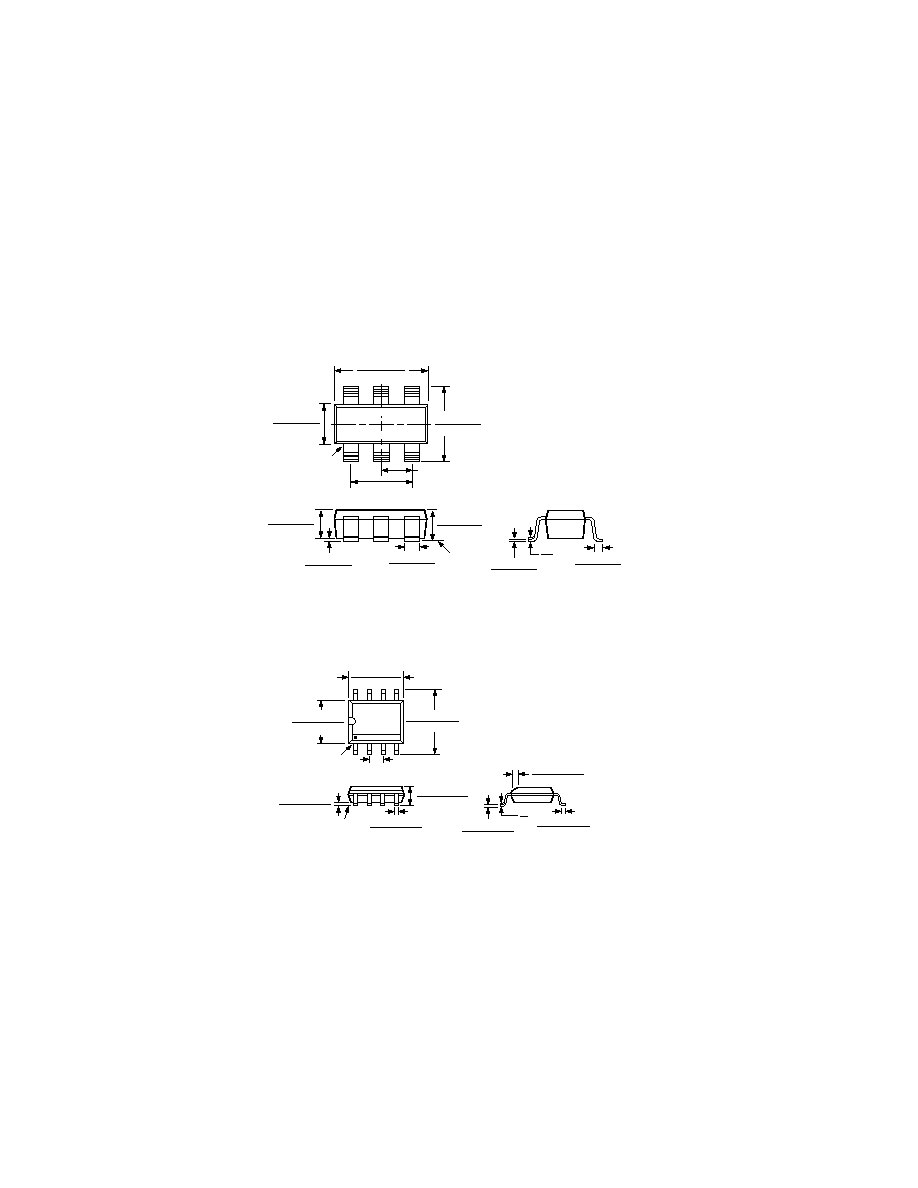

6-Lead Plastic Surface Mount Package

RT-6 (SOT-23-6)

0.122 (3.10)

0.106 (2.70)

PIN 1

0.118 (3.00)

0.098 (2.50)

0.075 (1.90)

BSC

0.037 (0.95) BSC

1

3

4

5

6

2

0.071 (1.80)

0.059 (1.50)

0.009 (0.23)

0.003 (0.08)

0.022 (0.55)

0.014 (0.35)

10

0

0.020 (0.50)

0.010 (0.25)

0.006 (0.15)

0.000 (0.00)

0.051 (1.30)

0.035 (0.90)

SEATING

PLANE

0.057 (1.45)

0.035 (0.90)

8-Lead Narrow Body Package

SO-8

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8

0

0.0196 (0.50)

0.0099 (0.25)

45

8

5

4

1

0.1968 (5.00)

0.1890 (4.80)

0.2440 (6.20)

0.2284 (5.80)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.0500 (1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0.0098 (0.25)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

PCB Layout Issues

For optimum voltage regulation, place the load as close as pos-

sible to the device's V

OUT

and GND pins. It is recommended to

use dedicated PCB traces to connect the MOSFET's drain to

the positive terminal and GND to the negative terminal of the

load to avoid voltage drops along the high current carrying PCB

traces.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

If PCB layout is used as heatsink, adding many vias around the

power FET helps conduct more heat from the FET to the back-

plane of the PCB, thus reducing the maximum FET junction

temperature.