©

Semiconductor Components Industries, LLC, 2001

June, 2001 Rev. 3

1

Publication Order Number:

CS2844/D

CS2844, CS3844, CS2845,

CS3845

Current Mode PWM

Control Circuit with

50% Max Duty Cycle

The CS3844/45 provides all the necessary features to implement

offline fixed frequency currentmode control with a minimum

number of external components.

T h e C S 3 8 4 4 f a m i l y i n c o r p o r a t e s a n e w p r e c i s i o n

temperaturecontrolled oscillator to minimize variations in frequency.

An internal toggle flipflop, which blanks the output every other clock

cycle, limits the dutycycle range to less than 50%. An undervoltage

lockout ensures that V

REF

is stabilized before the output stage is

enabled. In the CS2844/CS3844 turn on occurs at 16 V and turn off at

10 V. In the CS2845/CS3845 turn on is at 8.4 V and turn off at 7.6 V.

Other features include low startup current, pulsebypulse current

limiting, and a highcurrent totem pole output for driving capacitive

loads, such as gate of a power MOSFET. The output is low in the off

state, consistent with Nchannel devices.

Features

·

Optimized for OffLine Control

·

Temp. Compensated Oscillator

·

50% Max DutyCycle Clamp

·

V

REF

Stabilized Before Output Stage Is Enabled

·

Low StartUp Current

·

PulseByPulse Current Limiting

·

Improved Undervoltage Lockout

·

Double Pulse Suppression

·

1.0% Trimmed Bandgap Reference

·

High Current Totem Pole Output

http://onsemi.com

x

= 2 or 3

y

= 4 or 5

A

= Assembly Location

WL, L

= Wafer Lot

YY, Y

= Year

WW, W = Work Week

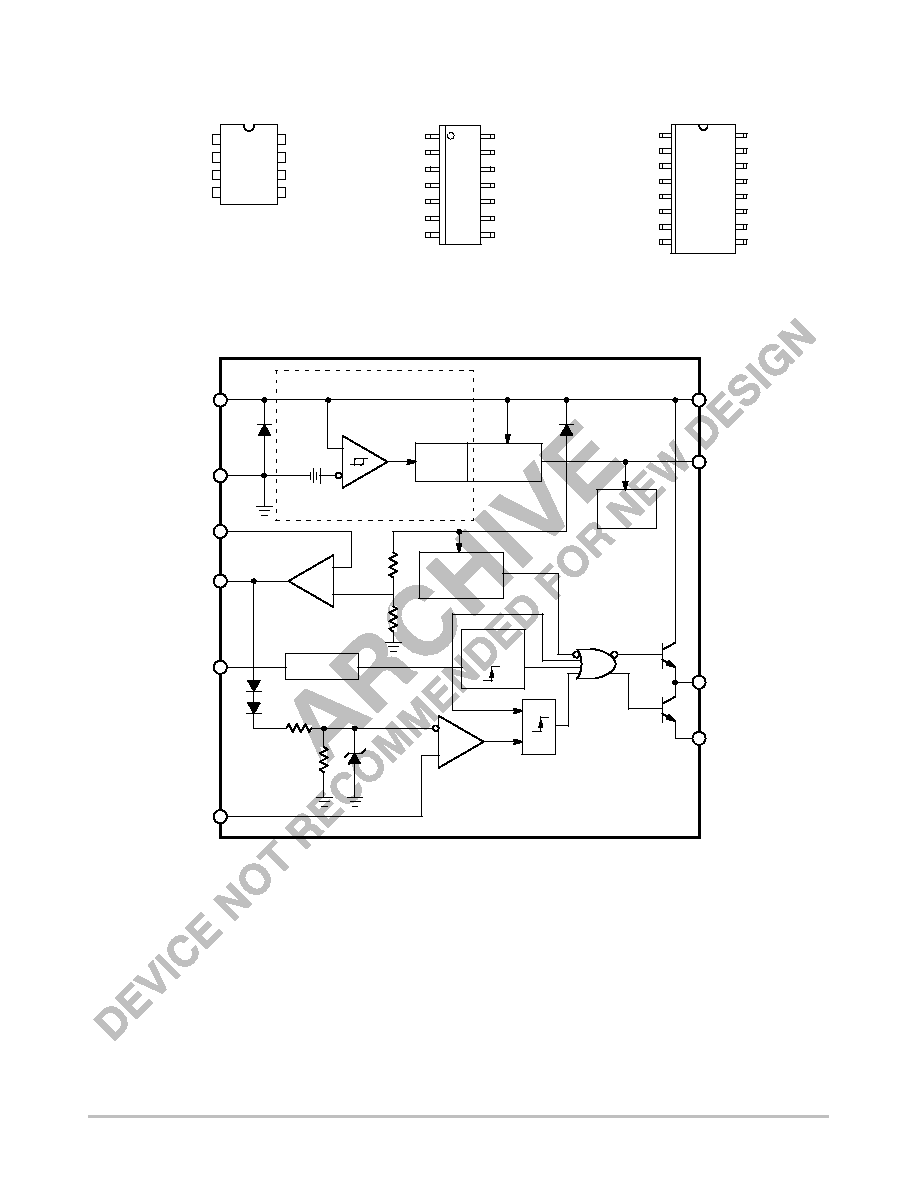

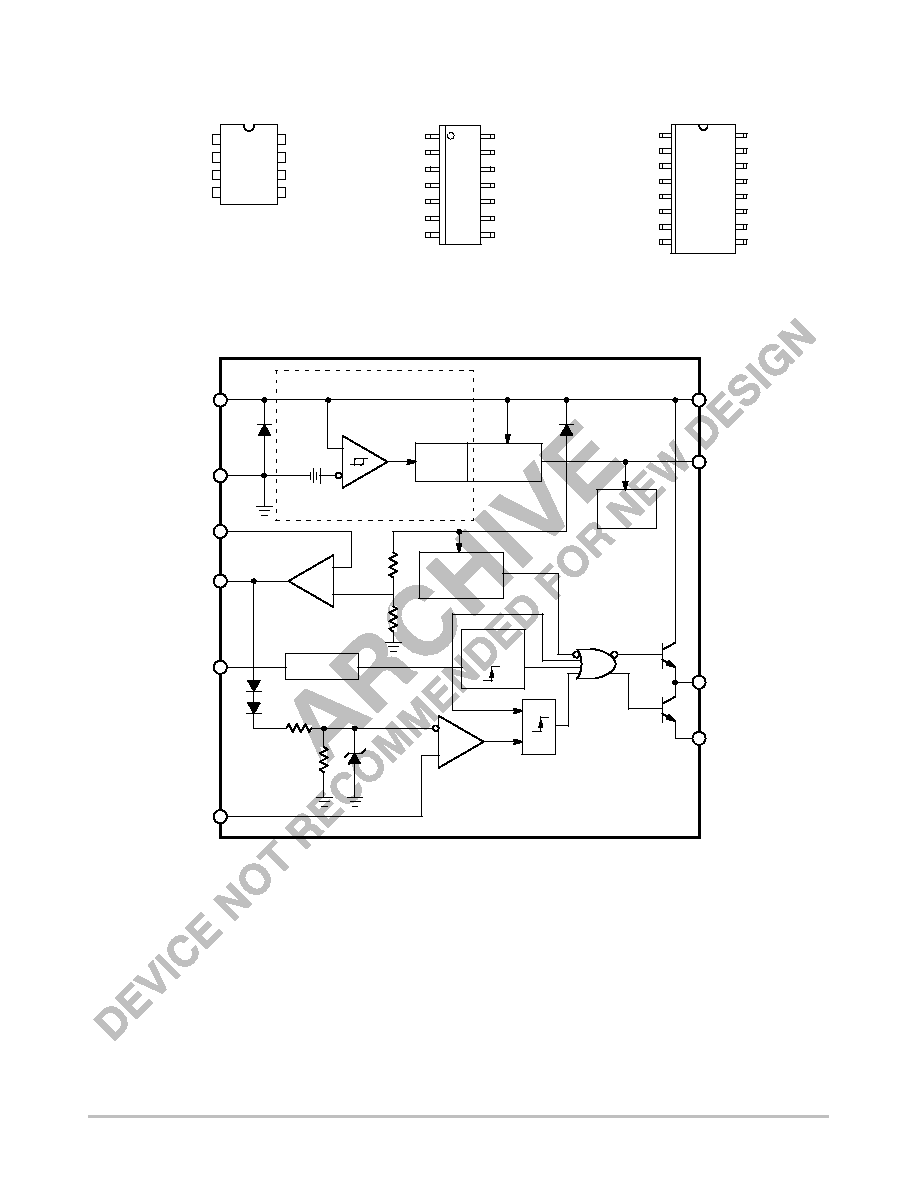

DIP8

N SUFFIX

CASE 626

1

8

SO8

D SUFFIX

CASE 751

1

8

SO14

D SUFFIX

CASE 751A

1

14

1

8

CSx84yN

AWL

YYWW

MARKING

DIAGRAMS

1

384yD

ALYW

8

1

CSx84yD14

AWLYWW

14

See detailed ordering and shipping information in the package

dimensions section on page 7 of this data sheet.

ORDERING INFORMATION

SO16L

DW SUFFIX

CASE 751G

1

16

1

CSx84yDW

AWLYYWW

16

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

2

PIN CONNECTIONS

GND

OSC

V

OUT

Sense

V

CC

V

FB

V

REF

COMP

1

Pwr GND

OSC

GND

NC

V

OUT

Sense

V

CC

Pwr

NC

1

14

V

CC

V

FB

NC

NC

V

REF

COMP

8

NC

NC

1

16

Pwr GND

NC

GND

OSC

V

OUT

Sense

V

CC

Pwr

V

FB

V

CC

COMP

V

REF

NC

NC

NC

DIP8 & SO8

SO14

SO16L

Figure 1. Block Diagram

Set/

Reset

5.0 V

Reference

V

CC

Undervoltage Lockout

16 V/10 V

(8.4 V/7.6 V)

34 V

V

CC

GND

Internal

Bias

Oscillator

OSC

2.50 V

V

CC

Pwr

V

REF

V

OUT

+

V

FB

COMP

Error

Amplifier

S

R

2R

R

1.0 V

Sense

Current

Sensing

Comparator

PWM

Latch

Pwr GND

( ) Indicates CS2845/3845

NOR

V

REF

Undervoltage

Lockout

R

R

Toggle

FlipFlop

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

3

MAXIMUM RATINGS*

Rating

Value

Unit

Supply Voltage (I

CC

< 30 mA)

Self Limiting

Supply Voltage (Low Impedance Source)

30

V

Output Current

±

1.0

A

Output Energy (Capacitive Load)

5.0

µ

J

Analog Inputs (V

FB

, Sense)

0.3 to + 5.5

V

Error Amp Output Sink Current

10

mA

Package Thermal Resistance, PDIP8

JunctiontoCase, R

JC

JunctiontoAmbient, R

JA

52

100

°

CW

°

CW

Package Thermal Resistance, SO8

JunctiontoCase, R

JC

JunctiontoAmbient, R

JA

45

165

°

CW

°

CW

Package Thermal Resistance, SO14

JunctiontoCase, R

JC

JunctiontoAmbient, R

JA

30

125

°

CW

°

CW

Package Thermal Resistance, SO16L

JunctiontoCase, R

JC

JunctiontoAmbient, R

JA

23

105

°

CW

°

CW

Lead Temperature Soldering:

Wave Solder (through hole styles only) (Note 1)

Reflow (SMD styles only) (Note 2)

260 peak

230 peak

°

C

°

C

1. 10 second maximum.

2. 60 second maximum above 183

°

C.

*The maximum package power dissipation must be observed.

ELECTRICAL CHARACTERISTICS

(25

°

T

A

85

°

for CS2844/2845, 0

°

T

A

70

°

for CS3844/CS3845.

V

CC

= 15 V*; R

T

= 10 k

, C

T

= 3.3 nF for sawtooth mode; unless otherwise stated.)

CS2844/CS2845

CS3844/CS3845

Characteristic

Test Conditions

Min

Typ

Max

Min

Typ

Max

Unit

Reference Section

Output Voltage

T

J

= 25

°

C, I

REF

= 1.0 mA

4.95

5.00

5.05

4.90

5.00

5.10

V

Line Regulation

12

V

CC

25 V

6.0

20

6.0

20

mV

Load Regulation

1.0

I

REF

20 mA

6.0

25

6.0

25

mV

Temperature Stability

Note 3.

0.2

0.4

0.2

0.4

mV/

°

C

Total Output Variation

Line, Load, Temperature. Note 3.

4.90

5.10

4.82

5.18

V

Output Noise Voltage

10 Hz

f

10 kHz, T

J

= 25

°

C. Note 3.

50

50

µ

V

Long Term Stability

T

A

= 125

°

C, 1000 Hrs. Note 3.

5.0

25

5.0

25

mV

Output Short Circuit

T

A

= 25

°

C

30

100

180

30

100

180

mA

Oscillator Section

Initial Accuracy

Sawtooth Mode, T

J

= 25

°

C

47

52

57

47

52

57

kHz

Voltage Stability

12

V

CC

25 V

0.2

1.0

0.2

1.0

%

Temperature Stability

Sawtooth Mode T

MIN

T

A

T

MAX

. Note 3.

5.0

5.0

%

Amplitude

V

OSC

(peak to peak)

1.7

1.7

V

3. These parameters, although guaranteed, are not 100% tested in production.

*Adjust V

CC

above the start threshold before setting at 15 V.

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

4

ELECTRICAL CHARACTERISTICS (continued)

(25

°

T

A

85

°

for CS2844/2845, 0

°

T

A

70

°

for CS3844/CS3845.

V

CC

= 15 V*; R

T

= 10 k

, C

T

= 3.3 nF for sawtooth mode; unless otherwise stated.)

CS2842A/CS2843A

CS3842A/CS3843A

Characteristic

Test Conditions

Min

Typ

Max

Min

Typ

Max

Unit

Error Amp Section

Input Voltage

V

COMP

= 2.5 V

2.45

2.50

2.55

2.42

2.50

2.58

V

Input Bias Current

V

FB

= 0

0.3

1.0

0.3

2.0

µ

A

A

VOL

2.0

V

OUT

4.0 V

65

90

65

90

dB

Unity Gain Bandwidth

Note 4.

0.7

1.0

0.7

1.0

MHz

PSRR

12

V

CC

25 V

60

70

60

70

dB

Output Sink Current

V

FB

= 2.7 V, V

COMP

= 1.1 V

2.0

6.0

2.0

6.0

mA

Output Source Current

V

FB

= 2.3 V, V

COMP

= 5.0 V

0.5

0.8

0.5

0.8

mA

V

OUT

High

V

FB

= 2.3 V, R

L

= 15 k

to GND

5.0

6.0

5.0

6.0

V

V

OUT

Low

V

FB

= 2.7 V, R

L

= 15 k

to V

REF

0.7

1.1

0.7

1.1

V

Current Sense Section

Gain

Notes 5 & 6.

2.85

3.00

3.15

2.85

3.00

3.15

V/V

Maximum Input Signal

V

COMP

= 5.0 V. Note 5.

0.9

1.0

1.1

0.9

1.0

1.1

V

PSRR

12

V

CC

25 V. Note 5.

70

70

dB

Input Bias Current

V

SENSE

= 0

2.0

10

2.0

10

µ

A

Delay to Output

T

J

= 25

°

C. Note 4.

150

300

150

300

ns

Output Section

Output Low Level

I

SINK

= 20 mA

I

SINK

= 200 mA

0.1

1.5

0.4

2.2

0.1

1.5

0.4

2.2

V

V

Output High Level

I

SOURCE

= 20 mA

I

SOURCE

= 200 mA

13

12

13.5

13.5

13

12

13.5

13.5

V

V

Rise Time

T

J

= 25

°

C, C

L

= 1.0 nF. Note 4.

50

150

50

150

ns

Fall Time

T

J

= 25

°

C, C

L

= 1.0 nF. Note 4.

50

150

50

150

ns

Total Standby Current

Startup Current

0.5

1.0

0.5

1.0

mA

Operating Supply Current

V

FB

= V

SENSE

= 0 V,

R

T

= 10 k

, C

T

= 3.3 nF

11

17

11

17

mA

V

CC

Zener Voltage

I

CC

= 25 mA

34

34

V

PWM Section

Maximum Duty Cycle

46

48

50

46

48

50

%

Minimum Duty Cycle

0

0

%

4. These parameters, although guaranteed, are not 100% tested in production.

5. Parameters measured at trip point of latch with V

FB

= 0.

6. Gain defined as: A =

V

COMP

/

V

SENSE

; 0

V

SENSE

0.8 V.

*Adjust V

CC

above the start threshold before setting at 15 V.

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

5

ELECTRICAL CHARACTERISTICS (continued)

(25

°

T

A

85

°

for CS2844/2845, 0

°

T

A

70

°

for CS3844/CS3845.

V

CC

= 15 V*; R

T

= 10 k

, C

T

= 3.3 nF for sawtooth mode; unless otherwise stated.)

CS2844

CS3844

CS2845/CS3845

Characteristic

Test Conditions

Min

Typ

Max

Min

Typ

Max

Min

Typ

Max

Unit

Undervoltage Lockout Section

Start Threshold

15

16

17

14.5

16

17.5

7.8

8.4

9.0

V

Min. Operating Voltage

After Turn On

9.0

10

11

8.5

10

11.5

7.0

7.6

8.2

V

*Adjust V

CC

above the start threshold before setting at 15 V.

PACKAGE PIN DESCRIPTION

Package Pin Number

DIP8 & SO8

SO14

Symbol

Symbol

Description

1

1

3

COMP

Error amp output, used to compensate error amplifier.

2

3

4

V

FB

Error amp inverting input.

3

5

5

Sense

Noninverting input to Current Sense Comparator.

4

7

6

OSC

Oscillator timing network with capacitor to ground, resistor to V

REF.

5

9

11

GND

Ground.

8

10

Pwr GND

Output driver ground.

6

10

12

V

OUT

Output drive pin.

11

13

V

CC

Pwr

Output driver positive supply.

7

12

14

V

CC

Positive power supply.

8

14

15

V

REF

Output of 5.0 V internal reference.

2, 4, 6, 13

1, 2, 7, 8,

9, 16

NC

No connection.

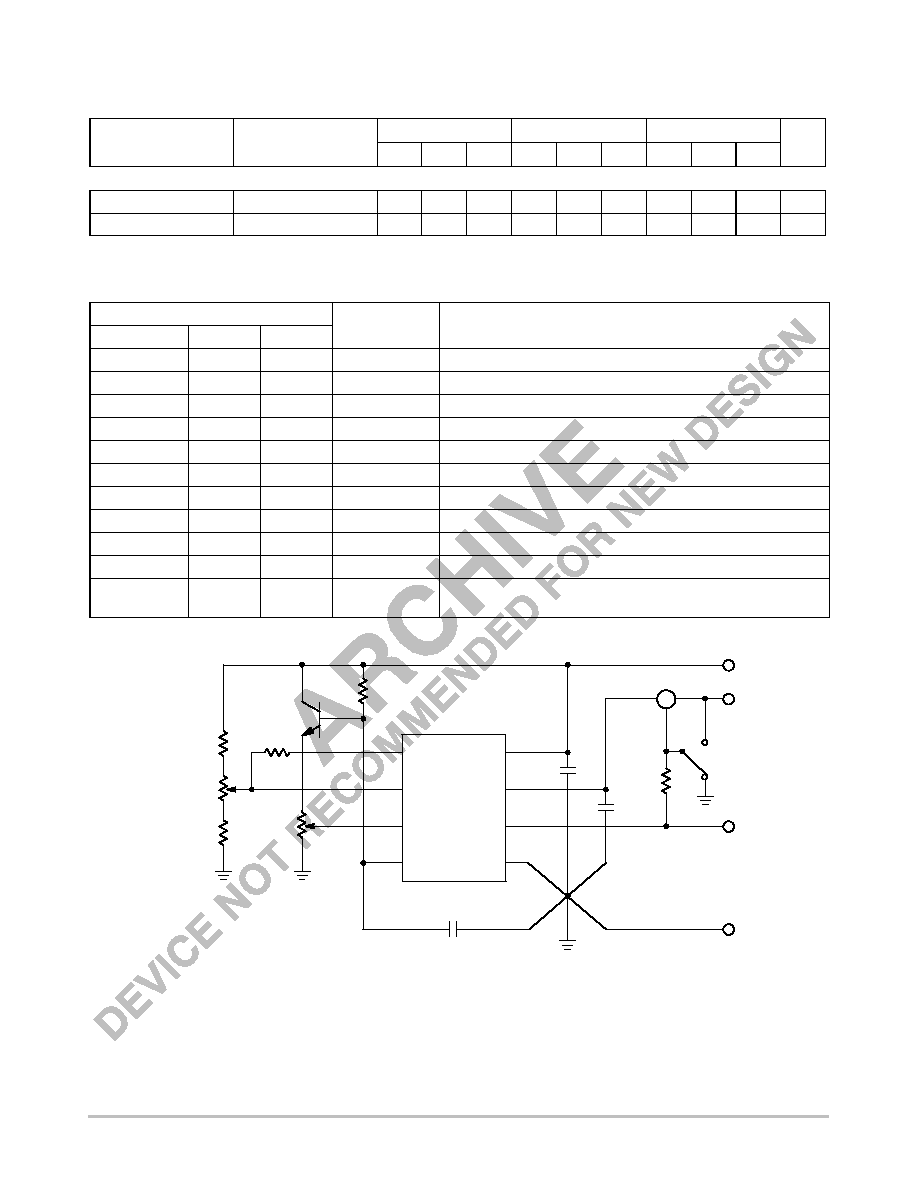

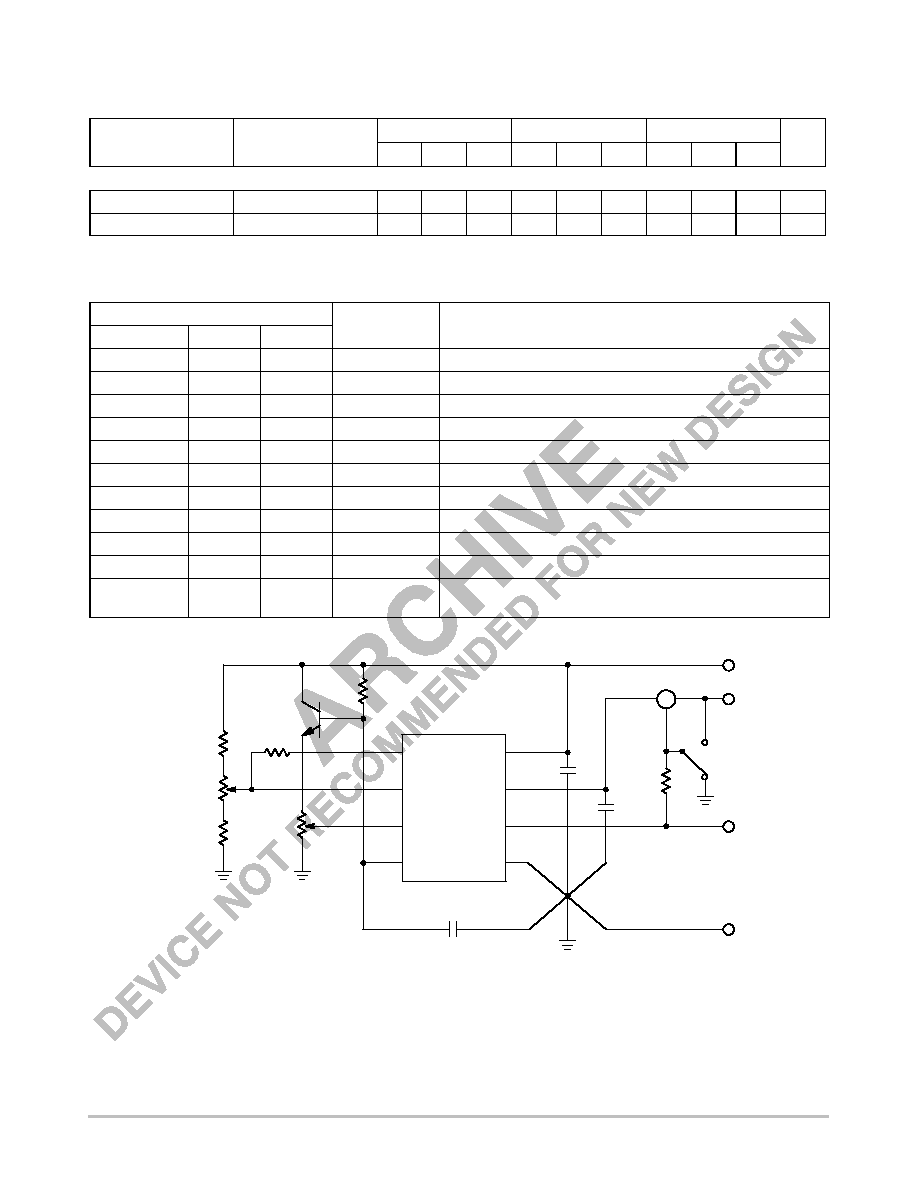

Figure 2. Test Circuit Open Loop Laboratory Test Fixture

V

REF

V

CC

V

OUT

GND

COMP

V

FB

Sense

OSC

0.1

µ

F

0.1

µ

F

R

T

1.0 k

1.0 W

2N2222

100 k

V

CC

V

REF

V

OUT

GND

A

5.0 k

Sense

ADJUST

C

T

4.7 k

4.7 k

1.0 k

ERROR AMP

ADJUST

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

6

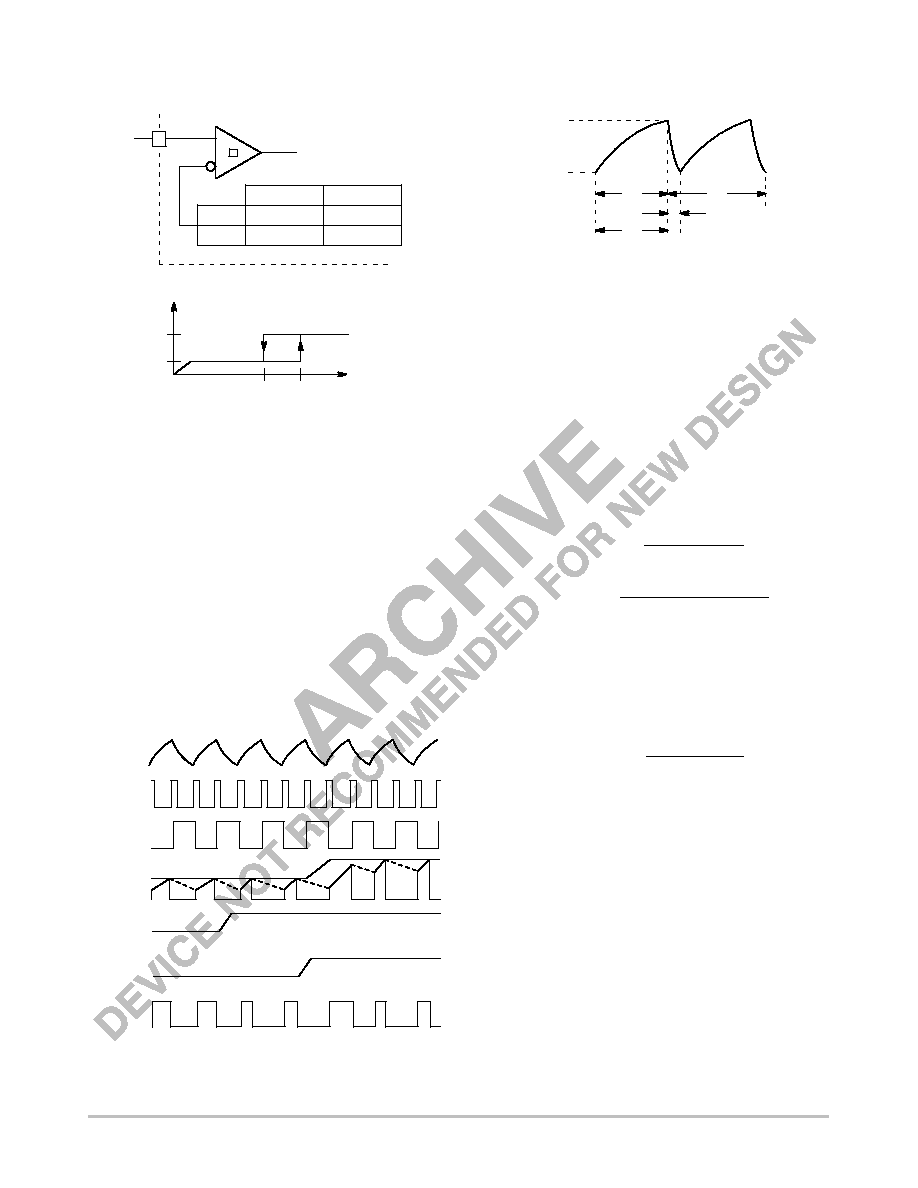

CIRCUIT DESCRIPTION

CSX845

8.4 V

7.6 V

CSX844

16 V

10 V

V

ON

V

OFF

ON/OFF Command

to reset of IC

V

CC

< 1.0 mA

< 15 mA

V

ON

V

OFF

V

CC

I

CC

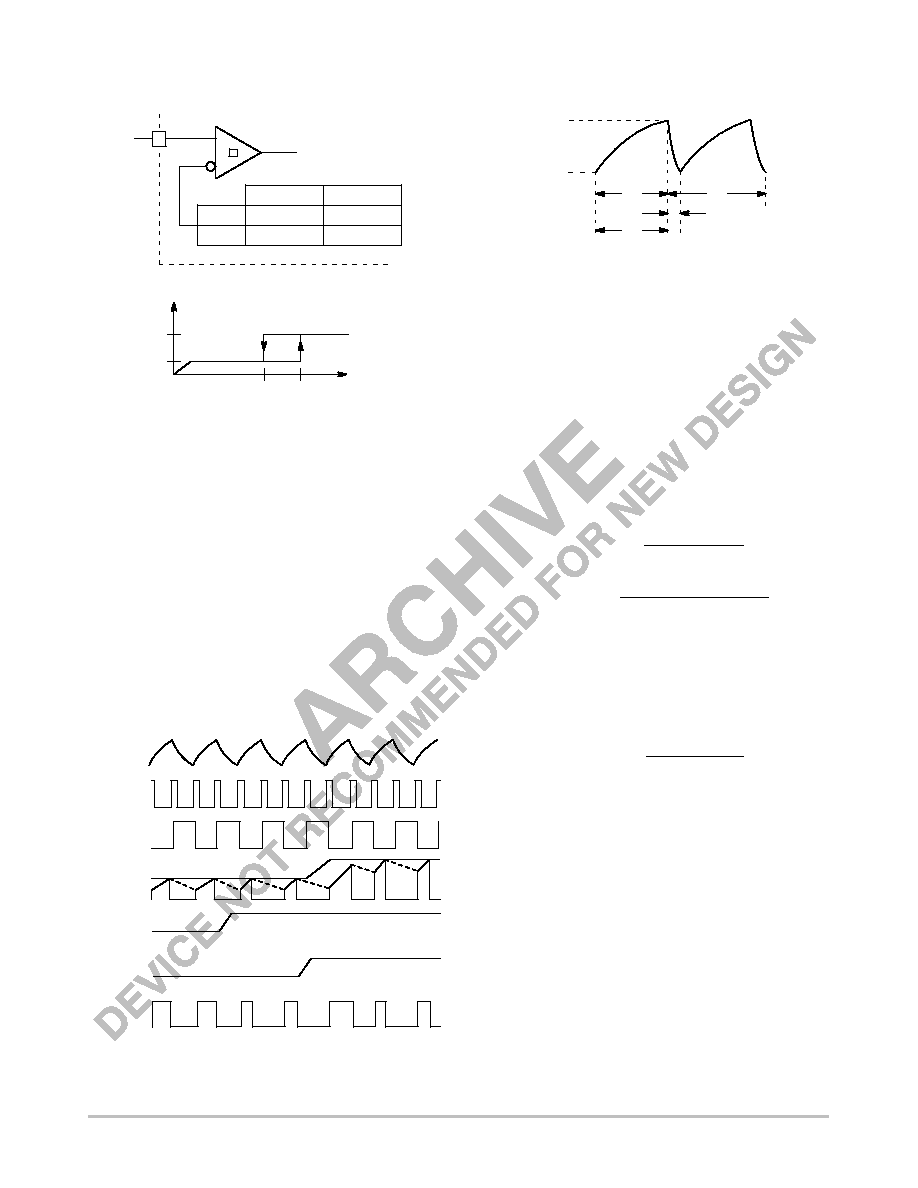

Figure 3. Startup Voltage for CSX844 and CSX845

Undervoltage Lockout

During Undervoltage Lockout (Figure 3), the output

driver is biased to sink minor amounts of current. The output

should be shunted to ground with a resistor to prevent

activating the power switch with extraneous leakage

currents.

PWM Waveform

To generate the PWM waveform, the control voltage from

the error amplifier is compared to a current sense signal

which represents the peak output inductor current (Figure

4). An increase in V

CC

causes the inductor current slope to

increase, thus reducing the duty cycle. This is an inherent

feedforward characteristic of current mode control, since

the control voltage does not have to change during changes

of input supply voltage.

Figure 4. Timing Diagram

V

OSC

OSC

RESET

Toggle

F/F Output

EA Output

Switch

Current

V

CC

I

O

V

O

Figure 5. Duty Cycle Parameters

V

upper

V

lower

t

on

t

c

t

off

t

d

t

on

= t

c

t

off

= t

c

+ 2t

d

When the power supply sees a sudden large output current

increase, the control voltage will increase allowing the duty

cycle to momentarily increase. Since the duty cycle tends to

exceed the maximum allowed to prevent transformer

saturation in some power supplies, the internal oscillator

waveform provides the maximum duty cycle clamp as

programmed by the selection of OSC components.

Setting the Oscillator

The times t

c

and t

d

can be determined as follows:

tc

+

RTCT ln

VREF

*

Vlower

VREF

*

Vupper

td

+

RTCT ln

VREF

*

IdRT

*

Vlower

VREF

*

IdRT

*

Vupper

Substituting in typical values for the parameters in the

above formulas:

V

REF

= 5.0 V, V

upper

= 2.7 V, V

lower

= 1.0 V, I

d

= 8.3 mA

then:

tc

[

0.5534RTCT

td

+

RTCT ln

2.3

*

0.0083RT

4.0

*

0.0083RT

For better accuracy R

T

should be

10 k

.

Grounding

High peak currents associated with capacitive loads

necessitate careful grounding techniques. Timing and

bypass capacitors should be connected close to Gnd in a

single point ground.

The transistor and 5.0 k

potentiometer are used to

sample the oscillator waveform and apply an adjustable

ramp to Sense.

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

7

ORDERING INFORMATION

Device

Temperature Range

Package

Shipping

CS2844LN8

DIP8

50 Units/Rail

CS2844LD14

SO14

55 Units/Rail

CS2844LDR14

SO14

2500 Tape & Reel

CS2844LDW16

25

°

C to 85

°

C

SO16L

48 Units/Rail

CS2844LDWR16

25

°

C to 85

°

C

SO16L

2500 Tape & Reel

CS2845LN8

DIP8

50 Units/Rail

CS2845LDW16

SO16L

48 Units/Rail

CS2845LDWR16

SO16L

2500 Tape & Reel

CS3844GN8

DIP8

50 Units/Rail

CS3844GD8

SO8

98 Units/Rail

CS3844GDR8

SO8

2500 Tape & Reel

CS3844GD14

SO14

55 Units/Rail

CS3844GDR14

SO14

2500 Tape & Reel

CS3844GDW16

SO16

48 Units/Rail

CS3844GDWR16

0

°

C to 70

°

C

SO16

2500 Tape & Reel

CS3845GN8

0

°

C to 70

°

C

DIP8

50 Units/Rail

CS3845GD8

SO8

98 Units/Rail

CS3845GDR8

SO8

2500 Tape & Reel

CS3845GD14

SO14

55 Units/Rail

CS3845GDR14

SO14

2500 Tape & Reel

CS3845GDW16

SO16L

48 Units/Rail

CS3845GDWR16

SO16L

2500 Tape & Reel

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

8

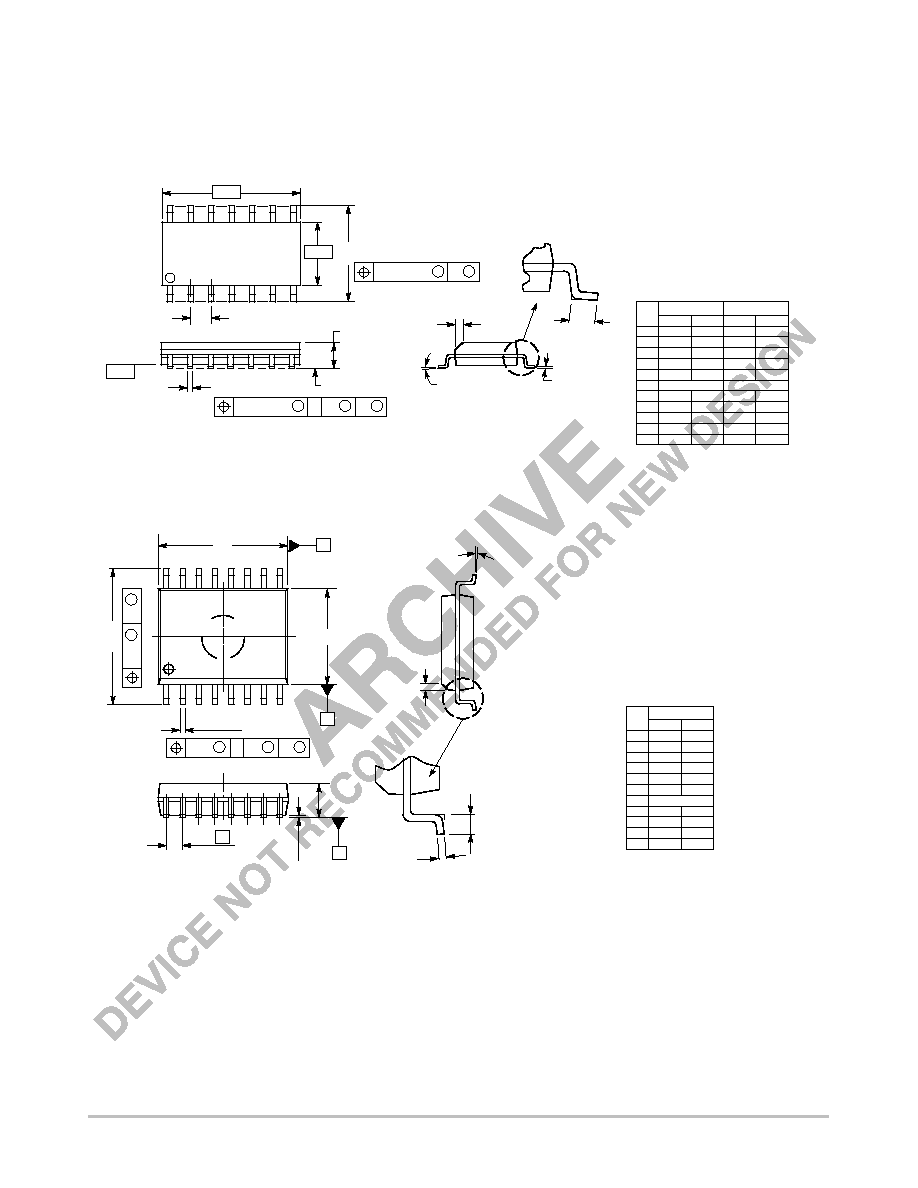

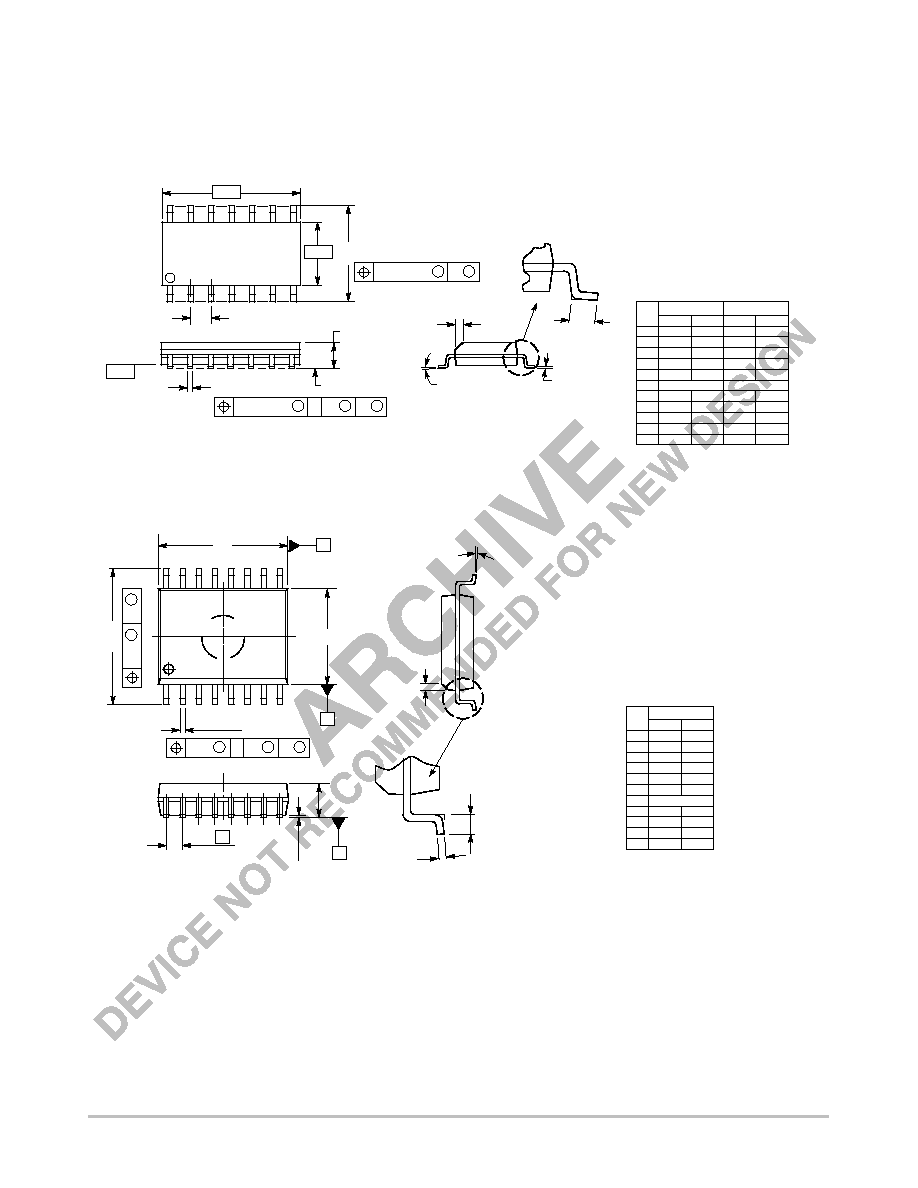

PACKAGE DIMENSIONS

DIP8

N SUFFIX

CASE 62605

ISSUE L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

1

4

5

8

F

NOTE 2

A

B

T

SEATING

PLANE

H

J

G

D

K

N

C

L

M

M

A

M

0.13 (0.005)

B

M

T

DIM

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

A

9.40

10.16

0.370

0.400

B

6.10

6.60

0.240

0.260

C

3.94

4.45

0.155

0.175

D

0.38

0.51

0.015

0.020

F

1.02

1.78

0.040

0.070

G

2.54 BSC

0.100 BSC

H

0.76

1.27

0.030

0.050

J

0.20

0.30

0.008

0.012

K

2.92

3.43

0.115

0.135

L

7.62 BSC

0.300 BSC

M

---

10

---

10

N

0.76

1.01

0.030

0.040

_

_

SO8

D SUFFIX

CASE 75107

ISSUE W

SEATING

PLANE

1

4

5

8

N

J

X 45

_

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

A

B

S

D

H

C

0.10 (0.004)

DIM

A

MIN

MAX

MIN

MAX

INCHES

4.80

5.00

0.189

0.197

MILLIMETERS

B

3.80

4.00

0.150

0.157

C

1.35

1.75

0.053

0.069

D

0.33

0.51

0.013

0.020

G

1.27 BSC

0.050 BSC

H

0.10

0.25

0.004

0.010

J

0.19

0.25

0.007

0.010

K

0.40

1.27

0.016

0.050

M

0

8

0

8

N

0.25

0.50

0.010

0.020

S

5.80

6.20

0.228

0.244

X

Y

G

M

Y

M

0.25 (0.010)

Z

Y

M

0.25 (0.010)

Z

S

X

S

M

_

_

_

_

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

9

PACKAGE DIMENSIONS

SO14

D SUFFIX

CASE 751A03

ISSUE F

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

A

B

G

P

7 PL

14

8

7

1

M

0.25 (0.010)

B

M

S

B

M

0.25 (0.010)

A

S

T

T

F

R

X 45

SEATING

PLANE

D

14 PL

K

C

J

M

_

DIM

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

A

8.55

8.75

0.337

0.344

B

3.80

4.00

0.150

0.157

C

1.35

1.75

0.054

0.068

D

0.35

0.49

0.014

0.019

F

0.40

1.25

0.016

0.049

G

1.27 BSC

0.050 BSC

J

0.19

0.25

0.008

0.009

K

0.10

0.25

0.004

0.009

M

0

7

0

7

P

5.80

6.20

0.228

0.244

R

0.25

0.50

0.010

0.019

_

_

_

_

SO16L

DW SUFFIX

CASE 751G03

ISSUE B

D

14X

B

16X

SEATING

PLANE

S

A

M

0.25

B

S

T

16

9

8

1

h

X 45

_

M

B

M

0.25

H

8X

E

B

A

e

T

A1

A

L

C

q

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

3. DIMENSIONS D AND E DO NOT INLCUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

DIM

MIN

MAX

MILLIMETERS

A

2.35

2.65

A1

0.10

0.25

B

0.35

0.49

C

0.23

0.32

D

10.15

10.45

E

7.40

7.60

e

1.27 BSC

H

10.05

10.55

h

0.25

0.75

L

0.50

0.90

q

0

7

_

_

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

10

Notes

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

11

Notes

CS2844, CS3844, CS2845, CS3845

http://onsemi.com

12

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. "Typical" parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including "Typicals" must be

validated for each customer application by customer's technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

JAPAN: ON Semiconductor, Japan Customer Focus Center

4321 NishiGotanda, Shinagawaku, Tokyo, Japan 1410031

Phone: 81357402700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

CS2844/D

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 3036752175 or 8003443860 Toll Free USA/Canada

Fax: 3036752176 or 8003443867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 8002829855 Toll Free USA/Canada