General Description

The MAX9987/MAX9988 evaluation kits (EV kits) simpli-

fy the evaluation of the MAX9987/MAX9988 LO

buffers/splitters. They are fully assembled and tested at

the factory. Standard 50

SMA connectors are includ-

ed on the EV kits for the input and all three outputs to

allow quick and easy evaluation on the test bench.

This document provides a list of equipment required to

evaluate the device, a straight-forward test procedure

to verify functionality, a circuit schematic for the EV kits,

a bill of materials (BOM) for the EV kits, and artwork for

each layer of the PC boards.

Features

o Fully Assembled and Tested

o Two-Way Power Splitting

o +14dBm to +20dBm Output Power

o ±1dB Output Power Variation

o Isolated PLL Output (+3dBm)

o Low Output Noise

-170dBc/Hz at +17dBm

o 40dB Reverse Isolation

o More than 30dB Output-to-Output Isolation

o 160mA Supply Current at +17dBm

o ESD Protection

Evaluate: MAX9987/MAX9988

MAX9987/MAX9988 Evaluation Kits

________________________________________________________________ Maxim Integrated Products

1

19-2592; Rev 0; 9/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim's website at www.maxim-ic.com.

Ordering Information

Component Suppliers

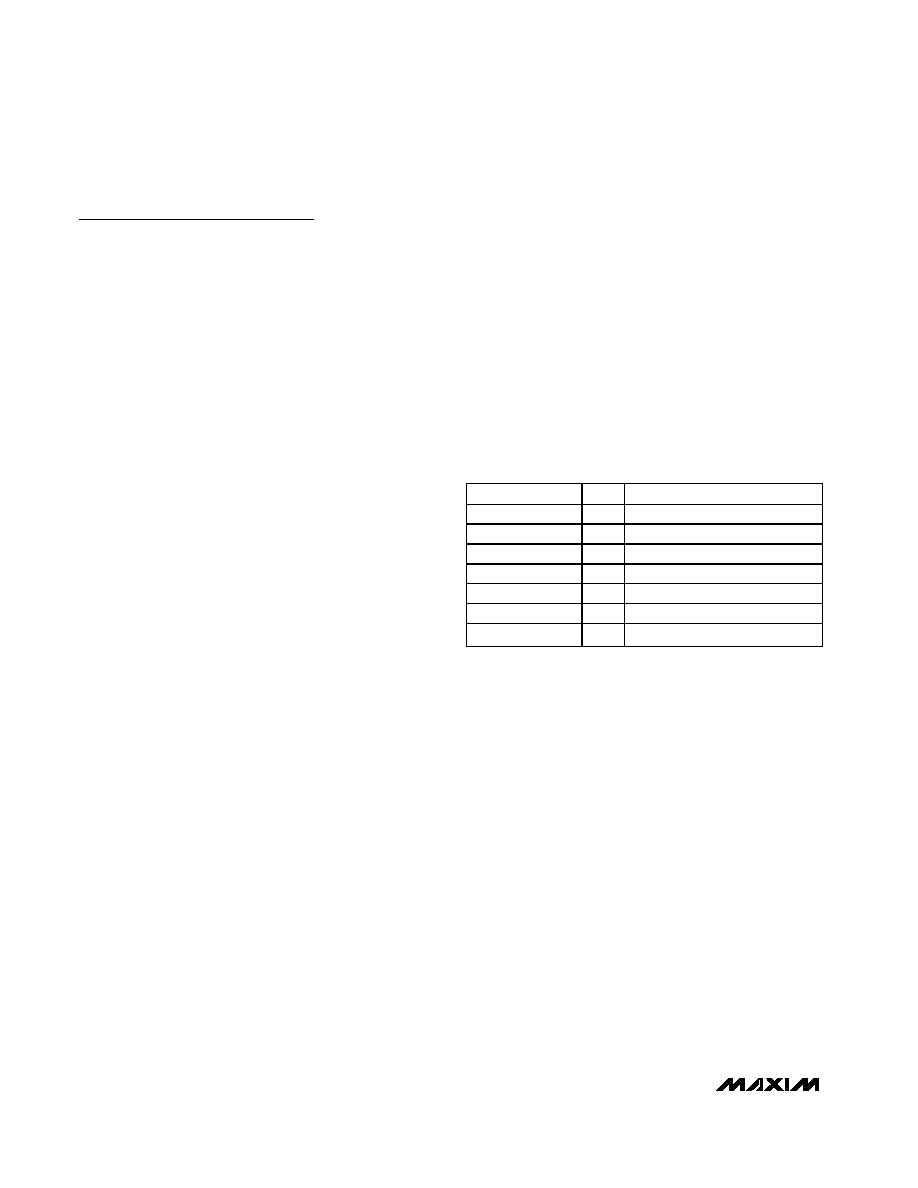

MAX9987 Component List

MAX9988 Component List

DESIGNATION

QTY

DESCRIPTION

C1, C6

2

0.1µF ±5% capacitors (0603)

Murata GRM188R71C104K

C2, C4, C5, C7,

C8, C9, C12C15

10

47pF ±5% capacitors (0603)

Murata GRM1885C1H470J

C3

1

100pF ±5% capacitors (0603)

Murata GRM1885C1H101J

C10, C11

2

5pF ±0.25pF capacitors (0603)

Murata GRM1885C11H5R0C

J1J4

4

PC board edge-mount SMA

connectors (Flat tab launch)

Johnson 142-0741-856

R1, R2, R4, R5

4

Not installed

R3

1

100

±5% resistor (0603)

TP1

1

Large test point for 0.062in PC

board (red) Mouser 151-107

TP2

1

Large test point for 0.062in PC

board (black) Mouser 151-103

U1

1

MAX9987EGP-T

DESIGNATION

QTY

DESCRIPTION

C1, C3, C6

3

0.1µF ±5% capacitors (0603)

Murata GRM188R71C104K

C2, C4, C5, C7,

C8, C9, C12C15

10

22pF ±5% capacitors (0603)

Murata GRM1885C1H220J

C10, C11

2

10pF ±5% capacitors (0603)

Murata GRM1885C1H100J

J1J4

4

PC board edge-mount SMA

connectors (Flat tab launch)

Johnson 142-0741-856

R1, R2, R4, R5

4

Not installed

R3

1

100

±5% resistor (0603)

TP1

1

Large test point for 0.062in PC

board (red) Mouser 151-107

TP2

1

Large test point for 0.062in PC

board (black) Mouser 151-103

U1

1

MAX9988EGP-T

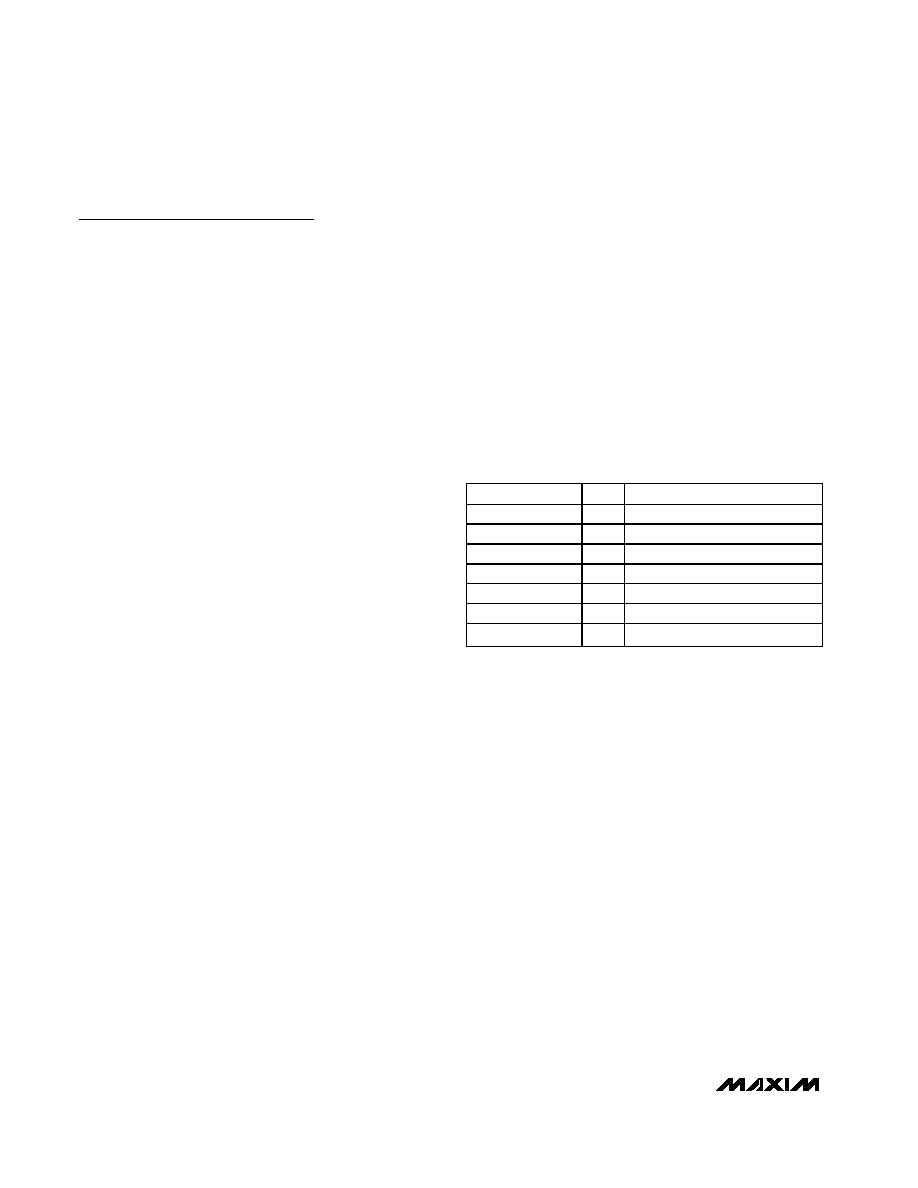

SUPPLIER

PHONE

WEBSITE

Johnson

507-833-8822

www.johnsoncomponents.com

Murata

770-436-1300

www.murata.com

PA R T

T EM P

R A N G E

I C

PA C K A G E

F R EQ U EN C Y

R A N G E ( M H z )

MAX9987EVKIT -40

°C to +85°C 20 QFN

700 to1100

MAX9988EVKIT -40

°C to +85°C 20 QFN

1500 to 2200

Evaluate: MAX9987/MAX9988

MAX9987/MAX9988 Evaluation Kits

2

_______________________________________________________________________________________

Quick Start

The MAX9987/MAX9988 EV kits are fully assembled and

factory tested. Follow the instructions in the Connections

and Setup section for proper device evaluation.

Test Equipment Required

Table 1 lists the equipment required to verify the opera-

tion of the MAX9987/MAX9988 EV kits. It is intended as

a guide only, and some substitutions are possible.

Connections and Setup

This section provides a step-by-step guide to testing

the basic functionality of the EV kits. As a general pre-

caution to prevent damaging the outputs by driving

high-VSWR loads, do not turn on DC power or RF

signal generators until all connections are made.

1) Calibrate the power meter at 900MHz for the

MAX9987, or at 1800MHz for the MAX9988. Import-

ant: Use a power sensor rated to at least 0dBm.

Measure the loss in the 20dB attenuator (pad) that

will be connected to OUT1; account for this loss as

an offset in the power meter.

2) Connect the 20dB pad to OUT1. The 20dB pad

maintains a reasonable load VSWR for the output

driver and protects the RF equipment from acci-

dental overload.

3) Connect a 50

termination to OUT2.

4) For the MAX9987, set the RF signal generator for

900MHz CW (i.e., unmodulated) at +10dBm

(accounts for 3dB loss of input pad); for the MAX9988,

set the generator for 1800MHz at +12dBm. Connect

generator to EV kit input through a 3dB pad. Disable

the RF output until all connections are made.

5) Connect the power sensor to OUT1's 20dB pad.

6) Set DC supply to +5.0V (set current limit around

250mA, if possible), and connect supplies to the EV

kit through the ammeter.

7) Enable the RF signal generator's output.

Testing the Buffers/Splitters

1) From the procedure above, the power meter should

be reading a power of about +17dBm.

2) Ensure that the supply current is not more than

175mA at VCC = 5.25V and PIN = +10dBm.

3) Disable the RF generator, turn off the DC supply

and swap the power detector/power pad to OUT2

(moving the 50

termination to OUT1), and re-

check output power level and stability over supply,

input power, and frequency, if desired.

4) Leaving the 20dB pad and 50

termination con-

nected to OUT2 and OUT1, move the power detec-

tor to OUTPLL and verify an output level of around

+3dBm.

Layout Considerations

A properly designed PC board is an essential part of

any RF/microwave circuit. Keep RF signal lines as short

as possible to reduce losses, radiation, and induc-

tance. For best performance, route the ground pin

traces directly to the exposed paddle underneath the

package. This paddle should be connected to the

ground plane of the board by using multiple vias under

the device to provide the best RF/thermal conduction

path. Solder the exposed paddle, on the bottom of the

device package, to a PC board exposed pad.

EQUIPMENT

QTY

DESCRIPTION

HP E3631A

1

Power supply

Fluke 75 series II

1

Digital MultiMeter

HP/Agilent 8648B

1

RF signal generator

HP 437B

1

RF power meter

HP 8482A

1

High-power sensor (power head)

20dB pad

1

20dB (1W) attenuators

50

termination

1

50

(1W) termination

Table 1. List of Required Equipment

Evaluate: MAX9987/MAX9988

MAX9987/MAX9988 Evaluation Kits

_______________________________________________________________________________________

5

Figure 3a. MAX9987 EV Kit PC Board Layout--Top Silkscreen

Figure 3b. MAX9988 EV Kit PC Board Layout--Top Silkscreen

1.0"

1.0"

Figure 4. MAX9987/MAX9988 EV Kit PC Board Layout--Top

Soldermask

Figure 5. MAX9987/MAX9988 EV Kit PC Board Layout--Top

Layer

1.0"

1.0"