1

LT1508

Power Factor and PWM

Controller (Voltage Mode)

, LTC and LT are registered trademarks of Linear Technology Corporation.

s

PFC and PWM Single Chip Solution

s

Synchronized Operation up to 300kHz

s

99% Power Factor Over 20:1 Load Current Range

s

Voltage Mode PWM

s

Instantaneous Overvoltage Protection

s

Dedicated Overvoltage Protection (OVP Pin)

s

Minimal Line Current Dead Zone

s

Typical 250

µ

A Start-Up Supply Current

s

Line Switching Noise Filter

s

Low Quiescent Current: 13mA

s

Fast 1.5A Peak Current Gate Drivers

s

Separate Soft Start Control

FEATURES

DESCRIPTIO

N

U

APPLICATIO

N

S

U

s

Universal Power Factor Corrected Power Supplies

and Preregulators

The LT

®

1508 is a complete solution for universal off-line

switching power supplies utilizing active power factor

correction. The PFC section is identical to the LT1248 PFC

controller except the EN/SYNC pin is removed because

PFC and PWM are synchronized internally.

The voltage mode PWM section (LT1509 is the current

mode counterpart) contains all the primary side functions

to convert the PFC preregulated high voltage output to an

isolated low voltage output. The PWM duty cycle is

internally limited to 47% (maximum 50%) to prevent

transformer saturation. PWM soft start begins when the

PFC output reaches the preset voltage. In the event of brief

line loss, PWM will be shut off when the PFC output

voltage drops below 73% of the preset value.

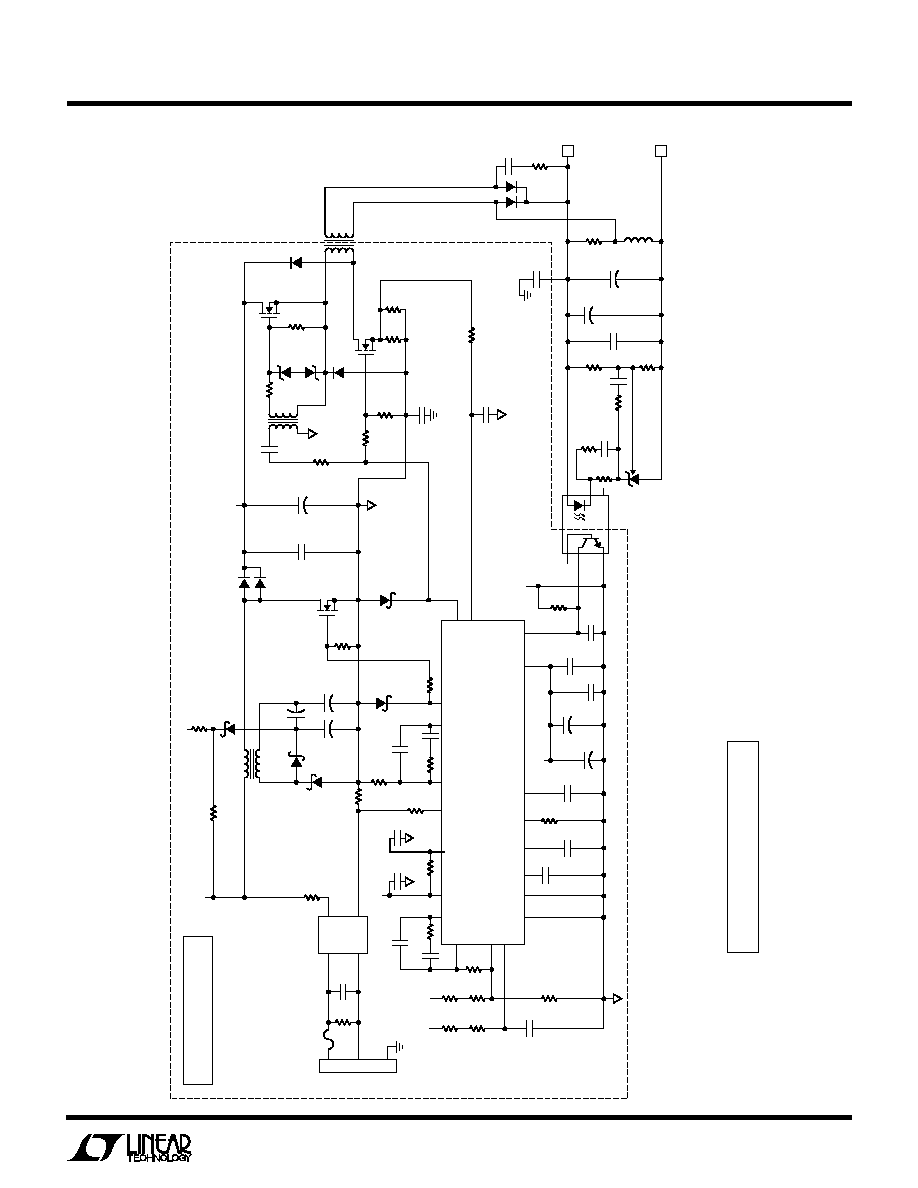

+

+

+

11

16

13

+

+

+

I

M

=

I

A

2

I

B

200

µ

A

2

4

15

19

18

1508 BD

V

SENSE

7.5V

7.9V

V

CC

16V TO 10V

14

µ

A

14

µ

A

7

µ

A

7V TO

4.7V

+

EA

CA

+

CL

2.2V

M1

I

A

I

M

I

B

25k

1V

R

2R

14

VA

OUT

10

V

REF

7.5V

V

REF

12

M

OUT

8

I

SENSE

7

CA

OUT

6

C

SET

R

SET

I

LIM

V

C

50

µ

A

RUN

RUN

R

R

Q

S

S

R

Q

R

OSC

55%

DELAY

200ns

BLANKING

PK

LIM

5

GND1

3

V

CC

17

GTDR1

16V

16V

1

GND2

2

GTDR2

20

I

AC

9

OVP

SS1

SS2

PWMOK

0.7V

+

+

NOTE: PWM PULSE IS DELAYED BY 55% DUTY CYCLE

AFTER PFC PULSE

+

+

BLOCK DIAGRA

M

W

2

LT1508

By using fixed high frequency PWM current averaging

without the need for slope compensation, the LT1508

achieves far lower line current distortion with a smaller

magnetic element than systems that use either peak

current detection, or zero current switching approach, in

both continuous and discontinuous modes of operation.

The LT1508 also provides filtering capability to reject line

DESCRIPTIO

N

U

switching noise which can cause instability when fed into

the multiplier. Line current dead zone is minimized with

low bias voltage at the current input to the multiplier. The

LT1508 provides many protection features including peak

current limiting and overvoltage protection. Implemented

with a very high speed process, the LT1508 can be

operated at frequencies as high as 300kHz.

ABSOLUTE

M

AXI

M

U

M

RATINGS

W

W

W

U

Supply Voltage ........................................................ 27V

GTDR Current Continuous ...................................... 0.5A

GTDR Output Energy ................................................ 5

µ

J

I

AC

, R

SET

, PK

LIM

Input Current .............................. 20mA

V

SENSE

, OVP Input Voltage .................................... V

MAX

I

LIM

, V

C

Input Voltage ................................................ 8V

I

SENSE

, M

OUT

Input Current ...................................

±

5mA

Operating Junction Temperature Range

LT1508C ................................................ 0

°

C to 100

°

C

LT1508I ............................................ 40

°

C to 125

°

C

Thermal Resistance (Junction-to-Ambient)

N Package ................................................... 100

°

C/W

SW Package ................................................ 120

°

C/W

PACKAGE/ORDER I

N

FOR

M

ATIO

N

W

U

U

Consult factory for Military grade parts.

1

2

3

4

5

6

7

8

9

10

TOP VIEW

SW PACKAGE

20-LEAD PLASTIC SO WIDE

N PACKAGE

20-LEAD PDIP

20

19

18

17

16

15

14

13

12

11

GTDR1

GND2

GND1

C

SET

PK

LIM

CA

OUT

I

SENSE

M

OUT

I

AC

VA

OUT

GTDR2

I

LIM

V

C

V

CC

SS1

R

SET

V

SENSE

SS2

V

REF

OVP

T

JMAX

= 125

°

C,

JA

= 100

°

C/ W (N)

T

JMAX

= 125

°

C,

JA

= 120

°

C/ W (SW)

ORDER PART

NUMBER

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Overall

Supply Current (V

CC

in Undervoltage Lockout)

V

CC

= Lockout Voltage 0.2V

q

0.25

0.45

mA

Supply Current On

11.5V

V

CC

V

MAX

q

13

19

mA

V

CC

Turn-On Threshold (Undervoltage Lockout)

q

15.5

16.5

17.5

V

V

CC

Turn-Off Threshold

q

9.5

10.5

11.5

V

Voltage Amplifier (PFC Section)

Voltage Amp Offset

VA

OUT

= 3.5V

q

10

10

mV

Input Bias Current

V

SENSE

= 0V to 7V

q

25

250

nA

Voltage Gain

70

100

dB

Voltage Amp Unity-Gain Bandwidth

3

MHz

Voltage Amp Output High (Internally Clamped)

q

11.3

13.3

V

Voltage Amp Output Low

q

1.1

2

V

Voltage Amp Short-Circuit Current

VA

OUT

= 0V

q

3

8

17

mA

ELECTRICAL CHARACTERISTICS

Maximum operating voltage (V

MAX

) = 25V, V

CC

= 18V, R

SET

= 15k to GND, C

SET

= 1nF to GND, I

AC

= 100

µ

A, I

SENSE

= 0V, CA

OUT

= 3.5V,

VA

OUT

= 5V, OVP = V

REF

. No load on any outputs unless otherwise noted.

LT1508CN

LT1508CSW

LT1508IN

LT1508ISW

3

LT1508

ELECTRICAL C

C

HARA TERISTICS

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Current Amplifier (PFC Section)

Current Amp Offset Voltage

q

±

1

±

4

mV

I

SENSE

Bias Current

q

25

250

nA

Current Amp Voltage Gain

80

110

dB

Current Amp Unity-Gain Bandwidth

3

MHz

Current Amp Output High

q

7.2

8.5

V

Current Amp Output Low

q

1.1

2

V

Current Amp Short-Circuit Current

CA

OUT

= 0V

q

3

8

17

mA

Input Range, I

SENSE

, M

OUT

(Linear Operation)

q

0.3

1

V

Reference

Reference Output Voltage

I

REF

= 0mA, T

A

= 25

°

C

7.39

7.50

7.60

V

V

REF

Load Regulation

5mA < I

REF

< 0mA

5

mV

V

REF

Line Regulation

11.5V < V

CC

< V

MAX

q

20

5

20

mV

V

REF

Short-Circuit Current

V

REF

= 0V

q

12

28

50

mA

V

REF

Worst Case

Load, Line, Temperature

q

7.32

7.5

7.68

V

Current Limit

PK

LIM

Offset Voltage

q

25

25

mV

PK

LIM

Input Current

PK

LIM

= 0.1V

q

50

100

µ

A

PK

LIM

to GTDR Propagation Delay

PK

LIM

Falling from 50mV to 50mV

400

ns

Multiplier

Multiplier Output Current

I

AC

= 100

µ

A, R

SET

= 15k

35

µ

A

Multiplier Output Current Offset

R

AC

= 1M from I

AC

to GND

q

0.05

0.5

µ

A

Multiplier Maximum Output Current

I

AC

= 450

µ

A, R

SET

= 15k, VA

OUT

= 7V, M

OUT

= 0V

q

286

260

235

µ

A

Multiplier Gain Constant (Note 1)

0.035

V

2

I

AC

Input Resistance

I

AC

from 50

µ

A to 1mA

15

25

35

k

Oscillator

Oscillator Frequency

R

SET

= 15k, C

SET

= 1000pF

q

85

100

115

kHz

R

SET

= 15k, C

SET

= 1500pF

q

58

68

78

kHz

C

SET

Ramp Peak-to-Peak Amplitude

4.35

4.7

5.0

V

C

SET

Ramp Valley Voltage

1.15

1.3

1.55

V

Overvoltage Comparator (PFC Section)

Comparator Trip Voltage Ratio (V

TRIP

/ V

REF

)

q

1.04

1.05

1.06

Hysteresis

0.35

V

OVP Bias Current

OVP = 7.5V

q

0.2

1

µ

A

OVP Propagation Delay

100

ns

Gate Drivers (GTDR1 and GTDR2)

Max Output Voltage

0mA Load, 18V < V

CC

q

12

15

17.5

V

Output High

200mA Load, 11.5V

V

CC

15V

q

V

CC

3.0

V

Output Low (Device Unpowered)

V

CC

= 0V, 50mA Load (Sinking)

q

0.9

1.5

V

Output Low (Device Active)

200mA Load (Sinking)

q

0.5

1

V

10mA Load

q

0.2

0.4

V

Peak Output Current

10nF from GTDR to GND

2

A

Rise and Fall Time

1nF from GTDR to GND

25

ns

Max Duty Cycle (PFC)

90

96

%

Max Duty Cycle (PWM) (Note 2)

44

50

%

Maximum operating voltage (V

MAX

) = 25V, V

CC

= 18V, R

SET

= 15k to GND, C

SET

= 1nF to GND, I

AC

= 100

µ

A, I

SENSE

= 0V, CA

OUT

= 3.5V,

VA

OUT

= 5V, OVP = V

REF

. No load on any outputs unless otherwise noted.

4

LT1508

I

M

I

AC

(VA

OUT

2)

2

The

q

denotes specifications which apply over the full operating

temperature range.

Note 1: Multiplier Gain Constant: K =

Note 2: GTDR2 (PWM) pulse is delayed by 53% duty cycle after GTDR1

(PFC) is set. See PFC/PWM Synchronization graph in the Typical

Performance Characteristics section.

TYPICAL PERFOR

M

A

N

CE CHARACTERISTICS

U

W

PFC Voltage Amplifier Open-Loop

Gain and Phase

FREQUENCY (Hz)

10

GAIN (dB)

100

80

60

40

20

0

20

100

1k

10k

100k

1508 G01

1M

10M

0

20

40

60

80

100

120

PHASE (DEG)

PHASE

GAIN

FREQUENCY (Hz)

10

GAIN (dB)

100

80

60

40

20

0

20

100

1k

10k

100k

1508 G02

1M

10M

0

20

40

60

80

100

120

PHASE (DEG)

PHASE

GAIN

PFC Current Amplifier Open-Loop

Gain and Phase

TIME

1508 G03

PFC (GTDR1)

53%

PWM (GTDR2)

PFC/PWM Synchronization

ELECTRICAL C

C

HARA TERISTICS

V

CC

= 18V, R

SET

= 15k to GND, C

SET

= 1nF to GND, I

AC

= 100

µ

A, I

SENSE

= 0V, CA

OUT

= 3.5V, VA

OUT

= 5V, OVP = V

REF

. No load on any

outputs, unless otherwise noted.

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Soft Start Current

SS1 Current (PFC)

SS1 = 2.5V

q

5

12

30

µ

A

SS2 Current (PWM)

SS2 = 1V

q

5

12

30

µ

A

Comparators in PWM Section

I

LIM

Input Current

I

LIM

= 0V, V

C

= 1.6V

q

0.3

2

µ

A

Current Limit Comparator (CL) Threshold

V

C

> 2.6V

q

0.95

1.1

1.20

V

GTDR2 Switching Off Threshold at V

C

or at SS2

I

LIM

= 0V

q

1

V

V

C

Input Current

V

C

= 0V

q

20

80

µ

A

PWMOK Comparator Low Threshold (in Terms of V

REF

)

q

0.57

0.63

0.70

V

C

Pin High Voltage

1mA into V

C

Pin

q

6.2

6.9

7.5

V

GTDR2 Turn-On Blanking Time

180

ns

5

LT1508

TYPICAL PERFOR

M

A

N

CE CHARACTERISTICS

U

W

Reference Voltage

vs Temperature

Supply Current vs Supply Voltage

GTDR Rise and Fall Time

Start-Up Supply Current

vs Supply Voltage

M

OUT

Pin Characteristics

Frequency vs R

SET

and C

SET

GTDR1 Maximum Duty Cycle

vs R

SET

and C

SET

Multiplier Current

JUNCTION TEMPERATURE (

°

C)

75

REFERENCE VOLTAGE (V)

75

7.536

7.524

7.512

7.500

7.488

7.476

7.464

7.452

7.440

7.428

1508 G04

50

150

25

0

25

50

100 125

I

AC

(

µ

A)

0

I

M

(

µ

A)

300

150

0

1508 G05

250

500

VA

OUT

= 7V

VA

OUT

= 6.5V

VA

OUT

= 6V

VA

OUT

= 5.5V

VA

OUT

= 5V

VA

OUT

= 4.5V

VA

OUT

= 4V

VA

OUT

= 3.5V

VA

OUT

= 3V

VA

OUT

= 2.5V

SUPPLY VOLTAGE (V)

10

SUPPLY CURRENT (mA)

16

15

14

13

12

11

10

9

8

7

6

5

1508 G06

21

32

T

J

= 25

°

C

T

J

= 125

°

C

T

J

= 55

°

C

LOAD CAPACITANCE (nF)

0

TIME (ns)

400

300

200

100

0

10

20

30

40

1508 G07

50

RISE TIME

NOTE: GTDR SLEWS

BETWEEN 1V AND 16V

FALL TIME

SUPPLY VOLTAGE (V)

0

SUPPLY CURRENT (

µ

A)

550

500

450

400

350

300

250

200

150

100

50

0

1508 G08

20

125

°

C

55

°

C

25

°

C

4

8

12

16

2

6

10

14

18

C

SET

CAPACITANCE (pF)

200

FREQUENCY (kHz)

500

450

400

350

300

250

200

150

100

50

0

1508 G09

1400

2200

600

1000

1800

R

SET

= 10k

R

SET

= 15k

R

SET

= 20k

R

SET

= 30k

C

SET

CAPACITANCE (pF)

200

MAXIMUM DUTY CYCLE

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

1508 G10

1400

2200

600

1000

1800

R

SET

= 10k

R

SET

= 15k

R

SET

= 20k

R

SET

= 30k

M

OUT

VOLTAGE (V)

M

OUT

CURRENT (mA)

1.5

1.0

0.5

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

1508 G11

2.4

1.2

0

1.2

2.4

T

J

= 125

°

C

T

J

= 25

°

C

T

J

= 55

°

C

6

LT1508

TYPICAL PERFOR

M

A

N

CE CHARACTERISTICS

U

W

R

SET

Voltage vs Current

PK

LIM

Pin Characteristics

PFC SECTION

GTDR1 (Pin 1): The PFC MOSFET gate driver is a fast

totem pole output which is clamped at 15V. Capacitive

loads like the MOSFET gates may cause overshoot. A gate

series resistor of at least 5

will prevent the overshoot.

GND2 (Pin 2): Power Ground. High current spikes occur

in this line when either GTDR1 or GTDR2 switches low.

GND1 (Pin 3): Analog Ground.

C

SET

(Pin 4): The capacitor from this pin to GND and R

SET

determines oscillator frequency. The oscillator ramp is 5V

and the frequency = 1.5/(R

SET

C

SET

).

PK

LIM

(Pin 5): The threshold of the peak current limit

comparator is GND. To set current limit, a resistor divider

can be connected from V

REF

to the current sense resistor.

CA

OUT

(Pin 6): This is the output of the current amplifier

that senses and forces the line current to follow the

reference signal that comes from the multiplier by com-

manding the pulse width modulator. When CA

OUT

is low,

the modulator has zero duty cycle.

I

SENSE

(Pin 7): This is the inverting input of the current

amplifier. This pin is clamped at 0.6V by an ESD protec-

tion diode.

M

OUT

(Pin 8): This is the multiplier high impedance

current output and the noninverting input of the current

amplifier. This pin is clamped at 0.6V and 3V.

I

AC

(Pin 9): This is the AC line voltage sensing input to the

multiplier. It is a current input that is biased at 2V to

minimize the crossover dead zone caused by low line

voltage. At the pin, a 25k resistor is in series with the

current input, so that a lowpass RC can be used to filter out

the switching noise coming down from the line with a high

line impedance environment.

VA

OUT

(Pin 10): This is the output of the voltage error

amplifier. The output is clamped at 13.5V. When the

output goes below 2.5V, the multiplier output current is

zero.

OVP (Pin 11): This is the input to the overvoltage com-

parator. The threshold is 1.05 times the reference voltage.

When the comparator trips, the multiplier, which is quickly

inhibited, blanks PFC switching to prevent further over-

shoot. This pin is also the input to the PWMOK comparator

that releases the PWM soft start (SS2) after the PFC output

gets close to the final voltage and has a hysteresis of

approximately 150V for 382V PFC output.

V

REF

(Pin 12): This is the 7.5V reference. When V

CC

goes

low, V

REF

will stay at 0V. V

REF

biases most of the internal

circuitry and can source up to 5mA externally.

V

SENSE

(Pin 14): This is the inverting input to the voltage

amplifier.

(For application help with the PFC portion of this chip, see the LT1248 data sheet)

PI

N

FU

N

CTIO

N

S

U

U

U

R

SET

CURRENT (mA)

VR

SET

V

REF

(mV)

120

100

80

60

40

20

0

20

40

60

80

100

1508 G12

1.0

0.8

0.6

0.4

0.2

0

T

J

= 125

°

C

T

J

= 25

°

C

T

J

= 55

°

C

PK

LIM

VOLTAGE (V)

PK

LIM

CURRENT (

µ

A)

360

300

240

180

120

60

0

60

120

180

240

300

1508 G13

0.8

0.4

0

0.4

0.8

T

J

= 125

°

C

T

J

= 25

°

C

T

J

= 55

°

C

7

LT1508

R

SET

(Pin 15): A resistor from R

SET

to GND sets the

oscillator charging current and the maximum multiplier

output current which is used to limit the maximum line

current.

I

M(MAX)

= 3.75V/R

SET

SS1 (Pin 16): Soft Start. SS1 is reset to zero for low V

CC

.

When V

CC

rises above the lockout threshold, SS1 is

released to ramp up at a rate set by the internal 12

µ

A

current source and an external capacitor. During this ramp

up, PFC reference voltage is equal to SS1 voltage. After

SS1 rises past 7.5V, reference voltage remains at 7.5V.

V

CC

(Pin 17): This is the supply for the chip. The LT1508

has two fast gate drivers required to fast charge high

power MOSFET gate capacitances. Good supply bypass-

ing is required consisting of a 0.1

µ

F ceramic capacitor in

parallel with a low ESR electrolytic capacitor (56

µ

F or

higher) in close proximity to IC GND.

PWM SECTION

SS2 (Pin 13): PWM Soft Start. The comparator PWMOK

monitors the OVP pin and releases the SS2 after the PFC

output gets close to the final voltage.

V

C

(Pin 18): PWM voltage mode control voltage. Normally

connects to the optocoupler amplifier output. A pull-up

current of 50

µ

A flows out of the pin.

I

LIM

(Pin 19): PWM current sense input with limit set to

1.1V.

GTDR2 (Pin 20): The PWM MOSFET gate driver is a 1.5A

fast totem pole output. It is clamped at 15V. Capacitive

loads like the MOSFET gates may cause overshoot. A gate

series resistor of at least 5

will prevent the overshoot.

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

Voltage Error Amplifier (PFC Section)

The voltage error amplifier has a 100dB DC gain and 3MHz

unity-gain frequency. The output is internally clamped at

13.3V with V

CC

= 18V. Maximum error amp output voltage

decreases to V

CC

1.5V for V

CC

less than 12V. The

noninverting input is tied to the 7.5V

REF

through a diode

and can be pulled down with the SS1 pin. Referring to

Figure 1, V

OUT

= V

REF

[(R1 + R2)/R2]. With R1 = 1M and

R2 = 20k, V

OUT

= 382V. R1 through R4, C1 and C2 form the

compensation for the voltage loop. Gain of the voltage

error amp with the values shown is given by:

VA

OUT

V

OUT

=

1 + j

(j)(f)(6.6)

f

1

f

11

1 + j

)

)

The small-signal gain for the remaining portion of the

voltage loop for frequencies below the current loop band-

width is (see Figure 2):

V

OUT

VA

OUT

V

IN

(5

)(

j)(f)(C

OUT

)(V

OUT

)

(R

REF

)(P

IN

)

R

S

(R

IAC

+ 25k)

=

C1

0.47

µ

F

7.5V

REF

1.05V

REF

OVERVOLTAGE

COMPARATOR

LT1508

R3

20k

R4

330k

C2

0.047

µ

F

REGULATOR OUTPUT

V

OUT

= 382V

1508 · F01

V

SENSE

OVP

VA

OUT

ERROR AMP

R1

1M

R2

20k

+

+

Figure 1

(For application help with the PFC portion of this chip, see the LT1248 data sheet)

PI

N

FU

N

CTIO

N

S

U

U

U

With V

IN

= 120VAC, P

IN

= 150W, R

S

= 0.15

, R

REF

= 4k,

R

IAC

= 1M, V

OUT

= 382V and C

OUT

= 470

µ

F, V

OUT

/VA

OUT

=

85/(j)(f). At very low frequencies, the loop has a 40dB/

decade slope. Additional zero-pole compensation is added

at 1Hz and 11Hz. The resulting loop gain and phase margin

is shown in Figure 3. The unity-gain bandwidth is low

compared to 120Hz, which results in low distortion and a

high power factor.

8

LT1508

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

To avoid subharmonic oscillations, the amplified downslope

of the inductor current must be less than the slope of the

oscillator ramp.

V

CA(OUT)

V

RS

(V

OSC

)(L)(f

SW

)

(V

OUT

)(R

S

)

(5V)(500

µ

H)(100k)

(382V)(0.15

)

=

= 4.4

If the current amplifier gain at 100kHz is less than 4.4,

there will be no subharmonic oscillation. The open-loop

gain of the current loop is given by:

V

RS

V

CA(OUT)

(V

OUT

)(R

S

)

(j)(2

f)(L)(V

OSC

)

3648

(j)(f)

(382V)(0.15

)

(j)(2

f)(500

µ

H)(5V)

=

=

=

The current error amp, with R5 = 4k, R6 = 20k, C3 =

0.001

µ

F and C4 = 300pF, provides zero pole compensa-

tion resulting in 16kHz loop crossover frequency. The

current amp gain at 100kHz is 1.7. The resulting current

loop gain and phase margin is shown in Figure 4.

V

IN

R

S

0.15

L

V

IN

I

IN

I

M

R

REF

4k

R5

4k

V

OUT

D1

C

OUT

470

µ

F

C4

300pF

C3

0.001

µ

F

R6

20k

I

SENSE

M

OUT

CA

OUT

+

CA

V

IN

R

IAC

1M

I

AC

1508 · F02

LT1508

+

Figure 2

FREQUENCY (kHz)

0.1

40

CURRENT LOOP GAIN (dB)

PHASE MARGIN (DEG)

40

60

80

1

10

100

1000

1508 · F04

20

0

20

30

30

45

60

15

0

15

Figure 4

FREQUENCY (Hz)

0.1

40

LOOP GAIN (dB)

PHASE MARGIN (DEG)

40

60

80

1

10

100

1000

1508 · F03

20

0

20

30

30

45

60

15

0

15

Figure 3

Current Amplifier (PFC Section)

The current amplifier has a 110dB DC gain, 3MHz unity-

gain frequency and a 2V/

µ

s slew rate. It is internally

clamped at 8.5V. Note that in the current averaging opera-

tion, high gain at twice the line frequency is necessary to

minimize line current distortion. Because CA

OUT

may need

to swing 5V over one line cycle at high line condition,

20mV AC will be needed at the inputs of the current

amplifier for a gain of 260 at 120Hz. Especially at light load

when the current loop reference signal is small, lower gain

will distort the reference signal and line current. But, if

signal gain at switching frequency is too high, the system

behaves more like a current mode system and can cause

subharmonic oscillation.

Multiplier

The multiplier has high noise immunity and superior

linearity over its full operating range. The current gain is

I

M

= (I

AC

I

EA

2

)/(200

µ

A

2

) with I

EA

= (VA

OUT

2V)/ 25k. The

error amplifier output voltage required at the input to the

multiplier is:

9

LT1508

(P

IN

)(R

S

)(25)(R

IAC

+ 25k)

(V

IN

2

)(R

REF

)

VA

OUT

= 2 +

See Figure 2 for R

REF

.

VA

OUT

is squared in the multiplier, resulting in excellent

performance over a wide range of output power and input

voltage without the addition of feedforward line frequency

ripple. Care must be taken to avoid feeding switching

frequency noise into the multiplier from the I

AC

pin. An

internal 25k is provided in series with the low impedance

multiplier input so that only a capacitor from the I

AC

pin to

GND1 is required to filter noise. The maximum multiplier

output current, which ultimately limits the input line cur-

rent, is set by a resistor from the R

SET

pin to GND1

according to the formula: I

M(MAX)

= 3.75V/R

SET

. Figure 5

shows I

M

versus I

AC

for various values of VA

OUT.

Note that

Figure 5 data was taken with R

SET

= 15k.

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

The multiplier output acts as the command signal to the

current loop error amplifier. During steady-state operation

the voltage across R

REF

= (I

M

)(R

REF

) = (I

IN

)(R

S

). Based on

this the value for R

S

is determined by:

(I

M(MAX)

)(R

REF

)(V

IN

)(eff)

P

OUT

2

R

S

with R

SET

= 15k, I

M(MAX)

= 3.75/15k = 250

µ

A. For a 300W

converter with an efficiency (eff) of 0.8 at low line (90V

RMS

)

and R

REF

set to 4k, R

S

should be less than:

(250

µ

A)(4k)(90VAC)(0.8)

300W 2

= 0.169

A 0.15

resistor will yield a maximum peak input current

of (I

M(MAX)

)(R

REF

/R

S

) = (250

µ

A)(4k)/0.15

= 6.67A. For

a 100kHz switching frequency with R

SET

= 15k, C

SET

= 1.5/

(100kHz)(15k) = 1nF. For added protection the LT1508

provides a second independent current limit comparator.

When the input voltage to the comparator (PK

LIM

pin) dips

below 0V, GTDR1 pin quickly goes low turning off the PFC

power switch. A resistor divider from V

REF

to R

S

(Figure 6)

senses the voltage across the line current sense resistor

(R

S

) and limits the peak input line current to [(7.5V/R1) +

50

µ

A] (R2/R

S

). The 50

µ

A represents the PK

LIM

input

current which flows out of the PK

LIM

pin. With R1 = 10k

and R2 = 1.8k, I

IN

= 9.6A peak above the 6.67A peak

average plus the input inductor peak ripple current.

Always use R

SET

to set the primary line current limit. The

PK

LIM

comparator is only for secondary protection. When

the line current reaches the primary limit, V

OUT

can no

longer be supported with the given input current and

begins to fall. System stability is maintained by the current

loop which is controlled by the current amplifier. When the

Oscillator Frequency and Maximum

Line Current Setting

The oscillator frequency is set by R

SET

and C

SET

. R

SET

is

the resistor from the R

SET

pin to GND1 and C

SET

is the

capacitor from the C

SET

pin to GND1. R

SET

should be

determined first. The oscillator frequency, which is equal

to the switching frequency for both the PFC and PWM

section, is determined by:

1.5

(R

SET

)(C

SET

)

f

OSC

=

I

AC

(

µ

A)

0

I

M

(

µ

A)

300

150

0

1508 · F05

250

500

VA

OUT

= 7V

VA

OUT

= 6.5V

VA

OUT

= 6V

VA

OUT

= 5.5V

VA

OUT

= 5V

VA

OUT

= 4.5V

VA

OUT

= 4V

VA

OUT

= 3.5V

VA

OUT

= 3V

VA

OUT

= 2.5V

Figure 5. Multiplier Current I

M

vs I

AC

and VA

OUT

+

I

LINE

R

S

0.15

I

PKLIM

C1

1nF

7.5V

V

REF

PK

LIM

C1 IS TO REJECT NOISE, CURRENT

LIMIT DELAY IS ABOUT 2

µ

s

R2

1.8k

R1

10k

+

1508 · F06

LT1508

Figure 6

10

LT1508

line current reaches the secondary limit, the comparator

takes over control and hysteresis may occur causing

audible noise.

Overvoltage Protection (PFC Section)

Because of the slow loop response necessary for power

factor correction, output overshoot can occur following a

sudden load reduction or removal. To protect downstream

components, the LT1508 provides an overvoltage com-

parator which senses the output voltage and quickly

reduces the line current demand. Referring back to Figure

1, V

OUT

is 382V and during normal operation, since no

current flows in R3, 7.5V appears at both the V

SENSE

and

OVP pins. When V

OUT

overshoots its preset value, the

overcurrent from R1 will flow through R2 as well as R3.

The voltage amplifier feedback will keep V

SENSE

at 7.5V.

Therefore, the equivalent AC resistance seen by the OVP

pin is R2 in parallel with R3 or 10k. With these values and

the overvoltage comparator trip level internally set at

1.05V

REF

, the comparator trips when V

OUT

overshoots

10%. Overvoltage trip level is given by:

R2 + R3

R3

(%)V

OUT

= 5%

( )

For additional protection, the OVP pin can be connected

to V

OUT

through an independent resistor divider (see

Figure 7). This ensures overvoltage protection during

safety agency abnormal testing conditions, such as

opening R1 or shorting R2.

The output of the multiplier looks like a high impedance

current source. In the current loop, offset line current is

determined by multiplier offset current and input offset

voltage of the current error amplifier. A 4mV current

amplifier V

OS

translates to 27mA line current and 6.7W

input power for 250VAC

line if a 0.15

sense resistor is

used. Under a no-load condition or when the load power

is less than the offset output power, the offset line current

could slowly charge the output to an overvoltage level.

This is because the best the overvoltage comparator can

do is to reduce the multiplier output current to zero.

Unfortunately, this does not guarantee zero output current

if the current amplifier has offset. To regulate V

OUT

under

+

R4

1.05M

R5

20k

R1

1M

R2

20k

V

SENSE

OVP

ERROR

AMP

+

OVERVOLTAGE

COMPARATOR

0.047

µ

F

V

OUT

0.47

µ

F

330k

VA

OUT

1.05V

REF

V

OUT

= 382V

OVERVOLTAGE = 420V

1508 · F07

LT1508

Figure 7

this condition, the amplifier M1 (see Block Diagram)

becomes active. When VA

OUT

reduces to 2.2V, M1 sup-

plies up to 7

µ

A of current to the resistor at the I

SENSE

pin

in order to cancel a negative V

OS

and keep V

OUT

error to

within 2V.

Undervoltage Lockouts and Soft Start

The LT1508 turns on when V

CC

reaches 16V and remains

on until V

CC

falls below 10V, whereupon the chip enters the

lockout state. In the lockout state, the oscillator is off and

the V

REF

and gate driver pins remain low. A capacitor from

SS1 to GND1 determines the ramp-up time of the PFC

section. SS1 is released from a zero when V

CC

rises above

the lockout threshold. Once released, an internal 14

µ

A

current source ramps the voltage error amplifier's refer-

ence voltage to 7.5V. SS1 voltage then continues beyond

7.5V. A second capacitor from SS2 to GND1 determines

the start-up time from the PWM section. A PWMOK

comparator (see Block Diagram) holds SS2 low until the

OVP pin reaches 7V. This corresponds to the PFC output

voltage reaching approximately 93% of its preset voltage.

SS2 is diode coupled to the PMW comparator which is

connected to the V

C

pin by a second diode. Holding SS2

low at any time will disable PWM output. Once released,

the 14

µ

A current source ramps the PWM comparator

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

11

LT1508

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

input up to V

C

and then the SS2 voltage continues beyond

V

C

. The PWMOK comparator contains hysteresis and will

pull SS2 low disabling the PWM section if the PFC output

voltage falls below approximately 62% of its preset value

(240V with nominal 382V output).

Start-Up and Supply Voltage

The LT1508 draws only 250

µ

A before the chip starts at

16V on V

CC

. To trickle start, a 91k resistor from the power

line to V

CC

supplies trickle current, and C4 holds V

CC

up

while switching starts (see Figure 8); then the auxiliary

winding takes over and supplies the operating current.

Note that D3 and the larger values of C3 are only necessary

for systems that have sudden large load variations down

to minimum load and/or very light load conditions. Under

these conditions the loop may exhibit a start/restart mode

because switching remains off long enough for C4 to

discharge below 10V. Large values for C3 will hold V

CC

up

until switching resumes. For less severe load variations D3

is replaced with a short and C3 is omitted. The turns ratio

between the primary winding determines V

CC

according to :

N

P

N

S

V

OUT

V

CC

2V

=

for 382V V

OUT

and 18V V

CC

, Np/Ns

19.

Figure 8

V

CC

N

P

N

S

R1

91k

1W

C1

2

µ

F

1508 · F08

+

+

C2

2

µ

F

C3

390

µ

F

+

C4

100

µ

F

+

LINE

MAIN INDUCTOR

D2

D3

D1

Output Capacitor (PFC Section)

GTDR2 (PWM) pulse is synchronized to GTDR1 (PFC) pulse

with 53% duty cycle delay to reduce RMS ripple current in the

output capacitor. See PFC/PWM Synchronization graph in

the Typical Performance Characteristics section.

The peak-to-peak 120Hz PFC output ripple is determined by:

V

P-P

= 2I

LOAD(DC)

(Z)

where I

LOAD(DC)

is the DC load current of the PWM stage

and Z is the capacitor impedance at 120Hz.

For 470

µ

F, impedance is 2.8

at 120Hz. At 335W load,

I

LOAD(DC)

= 335V/382V = 0.88A, V

P-P

= (2)(0.88)(2.8

) =

5V. If less ripple is desired higher capacitance should be

used. The selection of the output capacitor is based on

voltage ripple, hold-up time and ripple current. Assuming

the DC converter (PWM section) is designed to operate

with 240V to 382V

IN

, the minimum hold-up time is a

function of the energy storage capacity of the capacitor:

(0.5)C

OUT

P

OUT

t

HOLD

=

(382V 0.5V

PP

)

2

240V

2

with C

OUT

= 470

µ

F, V

P-P

= 11.5V, and P

OUT

= 335W,

t

HOLD

= 60ms which is 3.6 line cycles at 60Hz. The ripple

current can be divided into two major components. The

first is the 120Hz component which is related to the DC

load current as follows:

I

120HZ

I

LOAD(DC)

2

The second component is made up of switching frequency

components due to the PFC stage charging the capacitor

and the PWM stage discharging the capacitor. For a 300W

output PFC forward converter running from an input

voltage of 100V

RMS

, the total high frequency ripple current

was measured to be 1.79A

RMS

.

For the United Chemicon KMH 450V capacitor series,

ripple current at 100kHz is specified 1.43 times higher

than the 120Hz limit.

12

LT1508

The total equivalent 120Hz ripple in the output capacitor

can be calculated by:

I

HF

1.43

I

RMS

=

I

120HZ

2

+

( )

2

I

HF

= 100kHz Ripple Current.

For I

LOAD(DC)

= 0.88A, 1

120Hz

= 0.62A and the equivalent

120Hz ripple current is:

1.79

1.43

I

RMS

=

= 1.4A

RMS

0.62

2

+

( )

2

Table 1 lists the ripple current components from lab

measurements for various output powers and line volt-

ages. The 120Hz ripple current rating at 105

°

C ambient is

1.72A for the 470

µ

F KMH 35mm

×

50mm capacitor. The

expected life of the output capacitor may be calculated

from thermal stress analysis:

(105

°

C +

T

K

) (T

A

+

T

O

)

10

L = (L

O

)2

where

L = Expected life time

L

O

= Hours of load life at rated ripple current and rated

ambient temperature

T

K

= Capacitor internal temperature rise at rated

condition.

T

K

= (I

2

R)/(KA), where I is the rated cur-

rent, R is capacitor ESR and KA is a volume constant.

T

A

= Operating ambient temperature

T

O

= Capacitor internal temperature rise at operating

condition

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

Table 1. PFC Capacitor RMS Ripple Current

100W

200W

300W

V

INRMS

I

120HZ

I

HF

I

120HZ

I

HF

I

120HZ

I

HF

100

0.2

0.6

0.41

1.18

0.62

1.79

120

0.2

0.5

0.41

0.97

0.62

1.45

230

0.2

0.53

0.41

0.87

0.62

1.26

In our example, L

O

= 2000 hours assuming

T

K

= 5

°

C at

rated 1.72A.

T

O

can then be calculated from:

I

RMS

1.72A

T

O

=

T

K

= 5

°

C

( )

2

1.4A

= 3.3

°

C

1.72A

( )

2

Assuming the operating ambient temperature is 60

°

C, the

approximate lifetime is:

(105

°

C + 5

°

C) (60 + 3.3

°

C)

10

L = (2000)(2)

= 50,870 Hours

For longer life a capacitor with a higher ripple current rating

or parallel capacitors should be used.

PWM Comparators

The LT1508 includes two comparators in the PWM section

which implement voltage mode PWM control. The V

C

or

control voltage pin sets duty factor. An additional current

limit comparator turns GTDR2 off in the event the I

LIM

pin

voltage exceeds 1.1V. On-chip blanking avoids reset due

to leading edge noise.

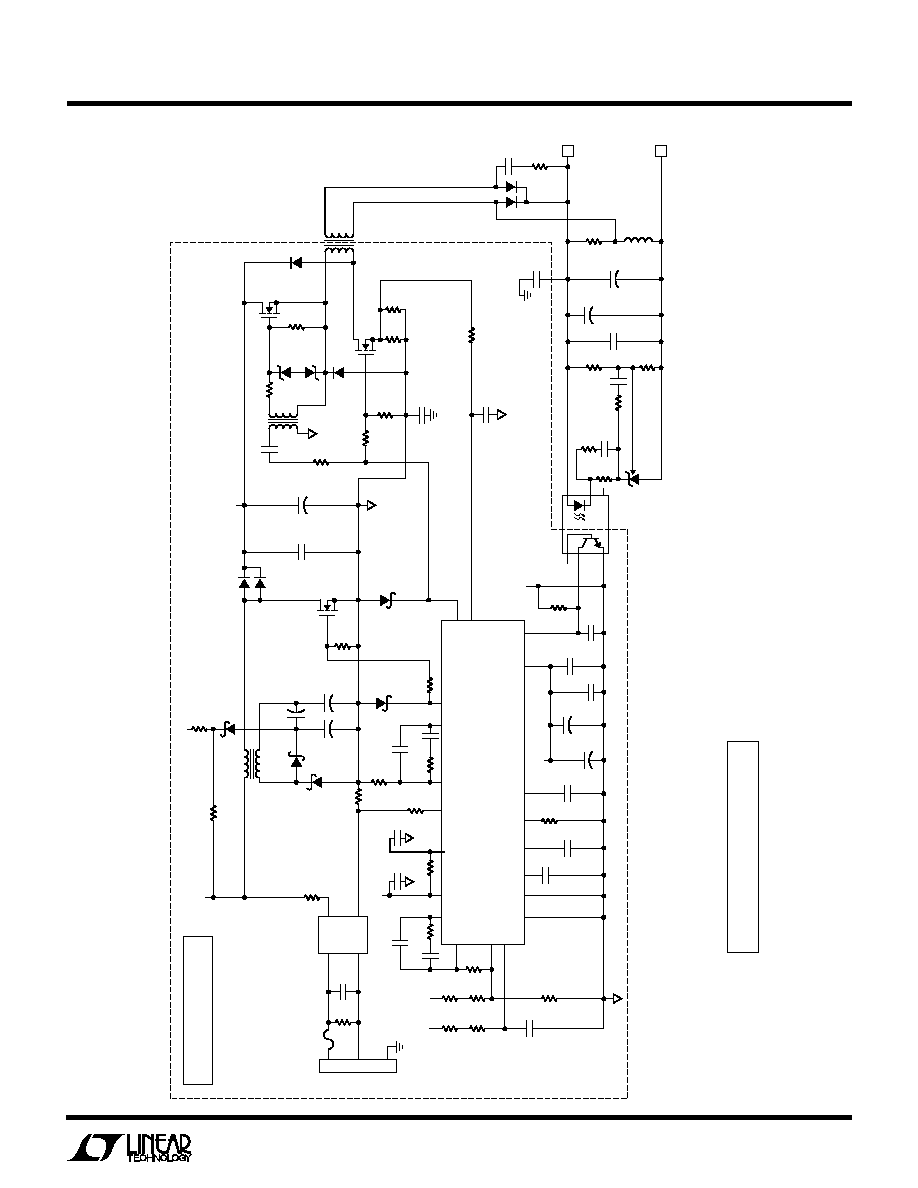

Typical Application

Figure 9 shows a 24VDC, 300W power factor corrected,

universal input supply. The 2-transistor forward converter

offers many benefits including low peak currents,

nondissipative snubber, 500VDC switches and automatic

core reset guaranteed by the LT1508's 50% maximum

duty cycle.

13

LT1508

Figure 9. 24V, 300W Off-Line PFC Supply

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

Danger!! Lethal Voltages Present

V

SENSE

OVP

I

AC

R27

20k

1%

R35

499k

1%

R22

330k

R24

10k

R1

0.15

5W

V

IN

R3

91k

1W

R33

499k

1%

R32

499k

1%

R34

499k

1%

382VBUS

14

11

9

V

CC

V

REF

V

C

17

18

6

5

4

1

2

3

I

LIM

GTDR2

LT1508

VA

OUT

V

REF

PK

LIM

GTDR1

M

OUT

I

SENSE

CA

OUT

C2

0.47

µ

F

C30

120

µ

F

35V

C26

120

µ

F

35V

R25

20k

R11

20

C24

1nF

C29

300pF

C6

2.2

µ

F

50V

C8

330

µ

F

35V

C7

2.2

µ

F

50V

D9

1N5818

D10

1N5818

Q1

IRFP450

D3

ERA82-004

D2

ERA82-004

D4

MURH860CT

V

OUT

382VBUS

D1

ERA82-004

T1

C3

0.1

µ

F

C23

47nF

C9

1

µ

F

"X"

R2

1M

1/2W

1

2

3

LINE

LINE

GND

12

10

1

3

2

4

58

7

6

1

V

IN

V

REF

R36

4.02k

1%

RT1

SG57

R16

15k

1%

R26

20k

1%

NOTE: UNLESS OTHERWISE SPECIFIED

1. ALL RESISTORS 1/4W, 5%

2. ALL CAPACITANCE VALUES IN MICROFARADS

T1: COILTRONICS CTX02-13141-X2 (407) 241-7876

T2: COILTRONICS CTX02-13063-X3

T3: BI TECHNOLOGY HM41-11510 (714) 447-2345

F1

6.3F

E1

90VAC TO

264VAC

19

20

Danger!! Lethal Voltages Present

In This Section

C25

1nF

C21

1nF

C22

4.7nF

C20

47nF

C32

1

µ

F

C31

1

µ

F

C19

10nF

C11

1

µ

F

63V

E3

COM

C4

4.7nF

"Y"

C18

0.1

µ

F

0.068

µ

F

C33

1

µ

F

R37

4.02k

1%

R39

20k

R14

3.3

15V

GND2

GND1

C

SET

SS2

R

SET

SS1

23

4

1

3

1

5

1

6

15V

+

+

R21

2K

U4

LT1431

1508 F09

U3

CNY17-3

R20

2.2k

R19

1k

33

R31

30.1k

1%

R6

10

2W

D11

MUR3020PT

R7

10

1W

R30

3.4k

1%

C12

1000

µ

F

35V

+

C13

1000

µ

F

35V

L1

67

µ

F

+

E2

24V

C16

1nF

R9

10

D8

MUR160

D5

1N965B

15V

D6

1N965B

15V

R41

20k

C28

100pF

R40

470

R8

10

+

~

~

U1

KPBC606

+

+

+

+

D7

MUR160

Q1

IRF840

T2

Q3

IRF840

C1

1

µ

F

400V

C14

330

µ

F

450V

C10

1

µ

F

63V

T3

R5

0.51

R4

0.51

R13

20k

R10

20

C5

4.7nF

"Y"

C1: ELECTRONIC CONCEPTS 5MP12J105K

L1: COILTRONICS CTX02-13140-X3

R

1: JW MILLER/FUKUSHIMA MPC71

RT1: KETEMA SG57 SURGE GARD

·

·

·

·

·

·

14

LT1508

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

An LT1431 reference/amplifier coupled to a low cost

optoisolator closes the loop from secondary side to pri-

mary side. Efficiency versus power and line voltage is

shown in Figure 10. The PFC preregulator alone has

efficiency numbers between 90% and 97% over line and

load.

A 3-turn secondary added to the 70-turn primary of T1

bootstraps V

CC

to about 15V supplying the chip's 13mA

requirement as well as about 39mA to cover the gate

current of the three FETs and high side transformer. A

0.15

sense resistor is used to sense input current and

servo to the command created by the outer voltage and

multiplier. Thus the input current follows the input line

voltage, and changes as necessary, in order to maintain

constant bank voltage. The forward converter sees a

voltage input of 382VDC unless the line voltage drops out,

in which case the 330

µ

F main capacitor discharges to

240VDC before the PWM stage is shut down. Compared to

a typical off-line converter, the effective input voltage

range of the forward converter is much smaller, simplify-

ing the design. Additionally, the higher bus voltage pro-

vides greater hold-up times for given capacitor size.

V

RMS

90

EFFICIENCY (%)

80

85

250

1508 · F1O

75

70

132

180

90

200W/300W

100W

30W

Figure 10

15

LT1508

Dimensions in inches (millimeters) unless otherwise noted.

PACKAGE DESCRIPTIO

N

U

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

N Package

20-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

N20 0695

0.015

(0.381)

MIN

0.125

(3.175)

MIN

0.130

±

0.005

(3.302

±

0.127)

0.065

(1.651)

TYP

0.045 0.065

(1.143 1.651)

0.018

±

0.003

(0.457

±

0.076)

0.005

(0.127)

MIN

0.100

±

0.010

(2.540

±

0.254)

0.255

±

0.015*

(6.477

±

0.381)

1.040*

(26.416)

MAX

1

2

3

4

5

6

7

8

9

10

19

11

12

13

14

16

15

17

18

20

0.009 0.015

(0.229 0.381)

0.300 0.325

(7.620 8.255)

0.325

+0.025

0.015

+0.635

0.381

8.255

(

)

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

16

LT1508

©

LINEAR TECHNOLOGY CORPORATION 1995

1508f LT/TP 0697 7K · PRINTED IN USA

Dimensions in inches (millimeters) unless otherwise noted.

PACKAGE DESCRIPTIO

N

U

SW Package

20-Lead Plastic Small Outline (Wide 0.300)

(LTC DWG # 05-08-1620)

S20 (WIDE) 0396

NOTE 1

0.496 0.512*

(12.598 13.005)

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

0.394 0.419

(10.007 10.643)

9

10

11

12

0.037 0.045

(0.940 1.143)

0.004 0.012

(0.102 0.305)

0.093 0.104

(2.362 2.642)

0.050

(1.270)

TYP

0.014 0.019

(0.356 0.482)

TYP

0

°

8

°

TYP

NOTE 1

0.009 0.013

(0.229 0.330)

0.016 0.050

(0.406 1.270)

0.291 0.299**

(7.391 7.595)

×

45

°

0.010 0.029

(0.254 0.737)

NOTE:

1. PIN 1 IDENT, NOTCH ON TOP AND CAVITIES ON THE BOTTOM OF PACKAGES ARE THE MANUFACTURING OPTIONS.

THE PART MAY BE SUPPLIED WITH OR WITHOUT ANY OF THE OPTIONS

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

*

**

PART NUMBER

DESCRIPTION

COMMENTS

LT1084

5A Low Dropout Linear Regulator

Good for Post Regulation of Switching Power Supplies

LT1105

Simplified Off-Line Controller

Solution for Universal Off-Line Inputs with Output to 100W

LT1241-5

High Frequency Current Mode PWM Controller

Operates at Oscillator Frequencies up to 500kHz

LT1247

High Frequency Current Mode PWM Controller

Operates at Oscillator Frequencies up to 1MHz

LT1248

Full-Feature Average Current Mode Power Factor Controller

Provides All Features in 16-Lead Package

LT1249

Minimal Parts Count Power Factor Controller

Simplified PFC Design

LT1509

Power Factor and PWM Controller

Current Mode PWM

RELATED PARTS

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

q

(408) 432-1900

FAX: (408) 434-0507

q

TELEX: 499-3977

q

www.linear-tech.com