Copyright

© Cirrus Logic, Inc. 2005

(All Rights Reserved)

http://www.cirrus.com

CS5461A

Single Phase, Bi-directional Power/Energy IC

Features

· Energy Data Linearity: ±0.1% of Reading over

1000:1 Dynamic Range

· On-chip Functions:

- Instantaneous Voltage, Current, and Power

- I

RMS

and V

RMS

, Apparent and Active (Real) Power

- Energy-to-pulse Conversion for Mechanical

Counter/Stepper Motor Drive

- System Calibrations and Phase Compensation

- Temperature Sensor

- Voltage Sag Detect

· Meets Accuracy Spec for IEC, ANSI, & JIS.

· Low Power Consumption

· Current Input Optimized for Sense Resistor.

· GND-referenced Signals with Single Supply

· On-chip 2.5 V Reference (25 ppm/°C typ)

· Power Supply Monitor

· Simple Three-wire Digital Serial Interface

· "Auto-boot" Mode from Serial E

2

PROM.

· Power Supply Configurations:

VA+ = +5 V; AGND = 0 V; VD+ = +3.3 V to +5 V

Description

The CS5461A is an integrated power measure-

ment device which combines two

analog-to-digital converters, power calculation

engine, energy-to-frequency converter, and a

serial interface on a single chip. It is designed to

accurately measure instantaneous current and

voltage, and calculate V

RMS

, I

RMS

, instanta-

neous power, apparent power, and active power

for single-phase, 2- or 3-wire power metering

applications.

The CS5461A is optimized to interface to shunt

resistors or current transformers for current mea-

surement, and to resistive dividers or potential

transformers for voltage measurement.

The CS5461A features a bi-directional serial in-

terface for communication with a processor, and

a programmable energy-to-pulse output func-

tion. Additional features include on-chip

functionality to facilitate system-level calibration,

temperature sensor, voltage sag detection, and

phase compensation.

ORDERING INFORMATION:

See

Page 41.

VA+

VD+

IIN+

IIN-

VIN+

VIN-

VREFIN

VREFOUT

AGND

XIN

XOUT CPUCLK

DGND

CS

SDO

SDI

SCLK

INT

Voltage

Reference

System

Clock

/K

Clock

Generator

Serial

Interface

E-to-F

Power

Monitor

PFMON

x1

RESET

Digital

Filter

Calibration

MODE

Power

Calculation

Engine

4th Order

Modulator

2nd Order

Modulator

Temperature

Sensor

Digital

Filter

PGA

HPF

Option

HPF

Option

E1

E2

E3

x10

AUG `05

DS661F1

CS5461A

2

DS661F1

TABLE OF CONTENTS

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Characteristics & Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Digital Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Switching Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Digital Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Voltage and Current Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Power Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Linearity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Voltage Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Current Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 High-pass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Performing Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Energy Pulse Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4.1 Normal Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4.2 Alternate Pulse Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.3 Mechanical Counter Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.4 Stepper Motor Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.5 Pulse Output E3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4.6 Anti-creep for the Pulse Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4.7 Design Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Voltage Sag-detect Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 On-chip Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.7 Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.8 System Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.9 Power-down States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.10 Oscillator Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.11 Event Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.11.1 Typical Interrupt Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.12 Serial Port Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.12.1 Serial Port Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.13 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CS5461A

DS661F1

3

6. Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Configuration Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Current and Voltage DC Offset Register ( I

DCoff

,V

DCoff

) . . . . . . . . . . . . . . 26

6.3 Current and Voltage Gain Register ( I

gn

,V

gn

) . . . . . . . . . . . . . . . . . . . . . . 26

6.4 Cycle Count Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 PulseRateE

1,2

Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6 Instantaneous Current, Voltage and Power Registers ( I , V , P ) . . . . . . . . 27

6.7 Active (Real) Power Registers ( P

Active

) . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.8 I

RMS

and V

RMS

Registers ( I

RMS

, V

RMS

) . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.9 Power Offset Register ( P

off

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.10 Status Register and Mask Register ( Status , Mask ) . . . . . . . . . . . . . . . . 28

6.11 Current and Voltage AC Offset Register ( V

ACoff

, I

ACoff

) . . . . . . . . . . . . . 29

6.12 PulseRateE

3

Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.13 Temperature Register ( T ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.14 System Gain Register ( SYS

Gain

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.15 Pulsewidth Register ( PW ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.16 Voltage Sag Duration Register ( VSAG

Duration

) . . . . . . . . . . . . . . . . . . . . 30

6.17 Voltage Sag Level Register ( VSAG

Level

) . . . . . . . . . . . . . . . . . . . . . . . . 30

6.18 Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.19 Temperature Gain Register ( T

Gain

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.20 Temperature Offset Register ( T

off

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.21 Apparent Power Register ( S ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7. System Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Channel Offset and Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.1 Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.1.1 Duration of Calibration Sequence . . . . . . . . . . . . . . . . . . . . . 33

7.1.2 Offset Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.2.1 DC Offset Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . 33

7.1.2.2 AC Offset Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . 34

7.1.3 Gain Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.3.1 AC Gain Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.3.2 DC Gain Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . 35

7.1.4 Order of Calibration Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 Phase Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.3 Active Power Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8. Auto-boot Mode Using E

2

PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1 Auto-Boot Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2 Auto-Boot Data for E

2

PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 Suggested E

2

PROM Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9. Basic Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10. Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11. Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12. Environmental, Manufacturing, & Handling Information . . . . . . . . . . . . . . . . . 41

13. Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CS5461A

4

DS661F1

LIST OF FIGURES

Figure 1. CS5461A Read and Write Timing Diagrams ............................................................... 11

Figure 2. Data Flow..................................................................................................................... 13

Figure 3. Normal Format on pulse outputs

E1

and

E2

................................................................ 16

Figure 4. Alternate Pulse Format on

E1

and

E2

.......................................................................... 17

Figure 5. Mechanical Counter Format on

E1

and

E2

.................................................................. 17

Figure 6. Stepper Motor Format on

E1

and

E2

............................................................................ 18

Figure 7. Voltage Sag Detect...................................................................................................... 19

Figure 8. Oscillator Connection................................................................................................... 20

Figure 9. Calibration Data Flow .................................................................................................. 33

Figure 10. System Calibration of Offset. ..................................................................................... 33

Figure 11. System Calibration of Gain ........................................................................................ 34

Figure 12. Example of AC Gain Calibration ................................................................................ 34

Figure 13. Another Example of AC Gain Calibration .................................................................. 34

Figure 14. Typical Interface of E

2

PROM to CS5461A ................................................................ 36

Figure 15. Typical Connection Diagram (Single-phase, 2-wire Direct Connect to Power Line)37

Figure 16. Typical Connection Diagram (Single-phase, 2-wire Isolated from Power Line)...... 38

Figure 17. Typical Connection Diagram (Single-phase, 3-wire).................................................. 38

Figure 18. Typical Connection Diagram (Single-phase, 3-wire No Neutral Available)............. 39

LIST OF TABLES

Table 1. Current Channel PGA Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. E1 and E2 Pulse Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3. Interrupt Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CS5461A

DS661F1

5

1. OVERVIEW

The CS5461A is a CMOS monolithic power measurement device with a computation engine and an en-

ergy-to-frequency pulse output. The CS5461A combines a programmable-gain amplifier, two

ana-

log-to-digital converters (ADCs), system calibration and a computation engine on a single chip.

The CS5461A is designed for power measurement applications and is optimized to interface to a cur-

rent-sense resistor or transformer for current measurement, and to a resistive divider or potential trans-

former for voltage measurement. The voltage and current channels provide programmable gains to

accommodate various input levels from a wide variety of sensing elements. With single +5 V supply on

VA+/AGND, both of the CS5461A's input channels can accommodate common mode as well as signal

levels between (AGND - 0.25 V) and VA+.

Additionally, the CS5461A is equipped with a computation engine that calculates I

RMS

, V

RMS

, apparent

power and active (real) power. To facilitate communication to a microprocessor, the CS5461A includes a

simple three-wire serial interface which is SPITM and MicrowireTM compatible. The CS5461A provides

three outputs for energy registration. E1 and E2 are designed to directly drive a mechanical counter or

stepper motor, or interface to a microprocessor. The pulse output E3 is designed to assist with meter cal-

ibration.

CS5461A

6

DS661F1

2. PIN DESCRIPTION

Clock Generator

Crystal Out

Crystal In

1,24

XOUT, XIN - The output and input of an inverting amplifier. Oscillation occurs when connected to

a crystal, providing an on-chip system clock. Alternatively, an external clock can be supplied to

the XIN pin to provide the system clock for the device.

CPU Clock Output

2

CPUCLK - Output of on-chip oscillator which can drive one standard CMOS load.

Control Pins and Serial Data I/O

Serial Clock Input

5

SCLK - A Schmitt Trigger input pin. Clocks data from the SDI pin into the receive buffer and out of

the transmit buffer onto the SDO pin when CS is low.

Serial Data Output

6

SDO -Serial port data output pin.SDO is forced into a high impedance state when CS is high.

Chip Select

7

CS - Low, activates the serial port interface.

Mode Select

8

MODE - High, enables the "auto-boot" mode. The mode pin is pulled low by an internal resistor.

High Frequency Energy

Output

18

E3 - Active low pulses with an output frequency proportional to the active power. Used to assist in

system calibration.

Reset

19

RESET - A Schmitt Trigger input pin. Low activates Reset, all internal registers (some of which

drive output pins) are set to their default states.

Interrupt

20

INT - Low, indicates that an enabled event has occurred.

Energy Output

21,22

E1, E2 - Active low pulses with an output frequency proportional to the active power. Indicates if

the measured energy is negative.

Serial Data Input

23

SDI - Serial port data input pin. Data will be input at a rate determined by SCLK.

Analog Inputs/Outputs

Differential Voltage Inputs

9,10

VIN+, VIN- - Differential analog input pins for the voltage channel.

Differential Current Inputs

15,16

IIN+, IIN- - Differential analog input pins for the current channel.

Voltage Reference Output

11

VREFOUT - The on-chip voltage reference output. The voltage reference has a nominal magni-

tude of 2.5 V and is referenced to the AGND pin on the converter.

Voltage Reference Input

12

VREFIN - The input to this pin establishes the voltage reference for the on-chip modulator.

Power Supply Connections

Positive Digital Supply

3

VD+ - The positive digital supply.

Digital Ground

4

DGND - Digital Ground.

Positive Analog Supply

14

VA+ - The positive analog supply.

Analog Ground

13

AGND - Analog ground.

Power Fail Monitor

1

7

PFMON - The power fail monitor pin monitors the analog supply. If PFMON's voltage threshold is

not met, a Low-Supply Detect (LSD) bit is set in the status register.

VREFIN

12

Voltage Reference Input

VREFOUT

11

Voltage Reference Output

VIN-

10

Differential Voltage Input

VIN+

9

Differential Voltage Input

MODE

8

Mode Select

CS

7

Chip Select

SDO

6

Serial Data Ouput

SCLK

5

Serial Clock

DGND

4

Digital Ground

VD+

3

Positive Digital Supply

CPUCLK

2

CPU Clock Output

XOUT

1

Crystal Out

AGND

13

Analog Ground

VA+

14

Positive Analog Supply

IIN-

15

Differential Current Input

IIN+

16

Differential Current Input

PFMON

17

Power Fail Monitor

E3

18

High Frequency Energy Output

RESET

19

Reset

INT

20

Interrupt

E1

21

Energy Output 1

22

SDI

23

Serial Data Input

XIN

24

Crystal In

E2

Energy Output 2

CS5461A

DS661F1

7

3. CHARACTERISTICS & SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS

ANALOG CHARACTERISTICS

·

Min / Max characteristics and specifications are guaranteed over all

Recommended Operating Conditions

.

·

Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

·

VA+ = VD+ = 5 V ±5%; AGND = DGND = 0 V; VREFIN = +2.5 V. All voltages with respect to 0 V.

·

MCLK = 4.096 MHz.

Parameter

Symbol Min Typ

Max

Unit

Positive Digital Power Supply

VD+

3.135

5.0

5.25

V

Positive Analog Power Supply

VA+

4.75

5.0

5.25

V

Voltage Reference

VREFIN

-

2.5

-

V

Specified Temperature Range

T

A

-40

-

+85

°C

Parameter

Symbol Min Typ

Max

Unit

Linearity Performance

Active Power Accuracy

All Gain Ranges

(Note 1)

Input Range 0.1% - 100%

P

Active

-

±0.1

-

%

Current RMS Accuracy

All Gain Ranges

(Note 1)

Input Range 1.0% - 100%

Input Range 0.3% - 1.0%

Input Range 0.1% - 0.3%

I

RMS

-

-

-

±0.1

±0.2

±3.0

-

-

-

%

%

%

%

Voltage RMS Accuracy

All Gain Ranges

(Note 1)

Input Range 5% - 100%

V

RMS

-

±0.1

-

%

Analog Inputs (Both Channels)

Common Mode Rejection

(DC, 50, 60 Hz)

CMRR

80

-

-

dB

Common Mode + Signal

All Gain Ranges

-0.25

-

VA+

V

Analog Inputs (Current Channel)

Differential Input Range

(Gain = 10)

[(IIN+) - (IIN-)]

(Gain = 50)

IIN

-

-

500

100

-

-

mV

P-P

mV

P-P

Total Harmonic Distortion

(Gain = 50)

THD

80

94

-

dB

Crosstalk with Voltage Channel at Full Scale

(50, 60 Hz)

-

-115

-

dB

Input Capacitance

(Gain = 10)

(Gain = 50)

IC

-

-

32

52

-

-

pF

pF

Effective Input Impedance

EII

30

-

-

k

Noise (Referred to Input)

(Gain = 10)

(Gain = 50)

N

I

-

-

-

-

22.5

4.5

µV

rms

µV

rms

Offset Drift (Without the high-pass filter)

OD

-

4.0

-

µV/°C

Gain Error

(Note 2)

GE

-

±0.4

%

Analog Inputs (Voltage Channel)

Differential Input Range

{(VIN+) - (VIN-)}

VIN

-

500

-

mV

P-P

Total Harmonic Distortion

THD

65

75

-

dB

Crosstalk with Current Channel at Full Scale

(50, 60 Hz)

-

-70

-

dB

Input Capacitance

All Gain Ranges

IC

-

0.2

-

pF

Effective Input Impedance

EII

2

-

-

M

Noise (Referred to Input)

N

V

-

-

140

µV

rms

Offset Drift (Without the high-pass Filter)

OD

-

16.0

-

µV/°C

Gain Error

(Note 2)

GE

-

±3.0

%

CS5461A

8

DS661F1

ANALOG CHARACTERISTICS

(Continued)

1. Applies when the HPF option is enabled.

2. Applies before system calibration.

3. All outputs unloaded. All inputs CMOS level.

4. Measurement method for PSRR: VREFIN tied to VREFOUT, VA+ = VD+ = 5 V, a 150 mV (zero-to-peak) (60 Hz)

sinewave is imposed onto the +5 V DC supply voltage at VA+ and VD+ pins. The "+" and "-" input pins of both input

channels are shorted to AGND. Then the CS5461A is commanded to continuous conversion acquisition mode, and

digital output data is collected for the channel under test. The (zero-to-peak) value of the digital sinusoidal output

signal is determined, and this value is converted into the (zero-to-peak) value of the sinusoidal voltage (measured

in mV) that would need to be applied at the channel's inputs, in order to cause the same digital sinusoidal output.

This voltage is then defined as Veq. PSRR is then (in dB)

:

5. When voltage level on PFMON is sagging, and LSD bit is at 0, the voltage at which LSD bit is set to 1.

6. If the LSD bit has been set to 1 (because PFMON voltage fell below PMLO), this is the voltage level on PFMON at

which the LSD bit can be permanently reset back to 0.

VOLTAGE REFERENCE

Notes:

7. The voltage at VREFOUT is measured across the temperature range. From these measurements the following

formula is used to calculate the VREFOUT Temperature Coefficient:.

8. Specified at maximum recommended output of 1 µA, source or sink.

Parameter

Symbol Min

Typ

Max

Unit

Temperature Channel

Temperature Accuracy

T

-

±5

-

°C

Power Supplies

Power Supply Currents (Active State)

I

A+

I

D+

(VA+ = VD+ = 5 V)

I

D+

(VA+ = 5 V, VD+ = 3.3 V)

PSCA

PSCD

PSCD

-

-

-

1.3

2.9

1.7

-

-

-

mA

mA

mA

Power Consumption

Active State (VA+ = VD+ = 5 V)

(Note 3)

Active State (VA+ = 5 V, VD+ = 3.3 V)

Stand-By State

Sleep State

PC

-

-

-

-

21

12

8

10

28

16.5

-

-

mW

mW

mW

µW

Power Supply Rejection Ratio

(DC, 50 and 60 Hz)

(Note 4)

Voltage Channel

Current Channel

PSRR

45

70

65

75

-

-

dB

dB

PFMON Low-voltage Trigger Threshold

(Note 5)

PMLO

2.3

2.45

-

V

PFMON High-voltage Power-On Trip Point

(Note 6)

PMHI

-

2.55

2.7

V

Parameter

Symbol Min Typ

Max

Unit

Reference Output

Output Voltage

VREFOUT

+2.4

+2.5

+2.6

V

Temperature Coefficient

(Note 7)

TC

VREF

-

25

60

ppm/°C

Load Regulation

(Note 8)

V

R

-

6

10

mV

Reference Input

Input Voltage Range

VREFIN

+2.4

+2.5

+2.6

V

Input Capacitance

-

4

-

pF

Input CVF Current

-

25

-

nA

PSRR

20

150

V

eq

----------

log

=

( V R E F O U T

M A X

- V R E F O U T

M IN

)

V R E F O U T

A V G

(

(

1

T

A M A X

- T

A M I N

(

(

1 . 0 x 1 0

(

(

6

T C

V R E F

=

CS5461A

DS661F1

9

DIGITAL CHARACTERISTICS

·

Min / Max characteristics and specifications are guaranteed over all

Recommended Operating Conditions

.

·

Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

·

VA+ = VD+ = 5V ±5%; AGND = DGND = 0 V. All voltages with respect to 0 V.

·

MCLK = 4.096 MHz.

Notes:

9. All measurements performed under static conditions.

10. If a crystal is used, then XIN frequency must remain between 2.5 MHz - 5.0 MHz. If an external oscillator is used,

XIN frequency range is 2.5 MHz - 20 MHz, but K must be set so that MCLK is between 2.5 MHz - 5.0 MHz.

11. If external MCLK is used, then the duty cycle must be between 45% and 55% to maintain this specification.

12. The frequency of CPUCLK is equal to MCLK.

13. The minimum FSCR is limited by the maximum allowed gain register value. The maximum FSCR is limited by the

full-scale signal applied to the channel input.

14. Configuration Register bits PC[6:0] are set to "0000000".

15. The MODE pin is pulled low by an internal resistor.

Parameter

Symbol Min

Typ

Max

Unit

Master Clock Characteristics

Master Clock Frequency

Internal Gate Oscillator (Note 10) MCLK

2.5

4.096

20

MHz

Master Clock Duty Cycle

40

-

60

%

CPUCLK Duty Cycle

(Note 11 and 12)

40

60

%

Filter Characteristics

Phase Compensation Range

(Voltage Channel, 60 Hz)

-2.8

-

+2.8

°

Input Sampling Rate

DCLK = MCLK/K

-

DCLK/8

-

Hz

Digital Filter Output Word Rate

(Both Channels) OWR

-

DCLK/1024

-

Hz

High-pass Filter Corner Frequency

-3 dB

-

0.5

-

Hz

Full Scale Calibration Range (

Referred to Input

)

(Note 13) FSCR

25

-

100

%F.S.

Channel-to-channel Time-shift Error

(Note 14)

1.0

µs

Input/Output Characteristics

High-level Input Voltage

All Pins Except XIN and SCLK and RESET

XIN

SCLK and RESET

V

IH

0.6 VD+

(VD+) - 0.5

0.8

VD+

-

-

-

-

-

-

V

V

V

Low-level Input Voltage (VD = 5 V)

All Pins Except XIN and SCLK and RESET

XIN

SCLK and RESET

V

IL

-

-

-

-

-

-

0.8

1.5

0.2

VD+

V

V

V

Low-level Input Voltage (VD = 3.3 V)

All Pins Except XIN and SCLK and RESET

XIN

SCLK and RESET

V

IL

-

-

-

-

-

-

0.48

0.3

0.2

VD+

V

V

V

High-level Output Voltage

I

out

= +5 mA

V

OH

(VD+) - 1.0

-

-

V

Low-level Output Voltage

I

out

= -5 mA

V

OL

-

-

0.4

V

Input Leakage Current

(Note 15)

I

in

-

±1

±10

µA

3-state Leakage Current

I

OZ

-

-

±10

µA

Digital Output Pin Capacitance

C

out

-

5

-

pF

CS5461A

10

DS661F1

SWITCHING CHARACTERISTICS

·

Min / Max characteristics and specifications are guaranteed over all

Recommended Operating Conditions

.

·

Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

·

VA+ = 5 V ±5% VD+ = 3.3 V ±5% or 5 V ±5%; AGND = DGND = 0 V. All voltages with respect to 0 V.

·

Logic Levels: Logic 0 = 0 V, Logic 1 = VD+.

Notes:

16. Specified using 10% and 90% points on wave-form of interest. Output loaded with 50 pF.

17. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an external

clock source.

Parameter

Symbol Min Typ

Max

Unit

Rise Times

Any Digital Input Except SCLK

(Note 16)

SCLK

Any Digital Output

t

rise

-

-

-

-

-

50

1.0

100

-

µs

µs

ns

Fall Times

Any Digital Input Except SCLK

(Note 16)

SCLK

Any Digital Output

t

fall

-

-

-

-

-

50

1.0

100

-

µs

µs

ns

Start-up

Oscillator Start-Up Time

XTAL = 4.096 MHz (Note 17)

t

ost

-

60

-

ms

Serial Port Timing

Serial Clock Frequency

SCLK

-

-

2

MHz

Serial Clock

Pulse Width High

Pulse Width Low

t

1

t

2

200

200

-

-

-

-

ns

ns

SDI Timing

CS Falling to SCLK Rising

t

3

50

-

-

ns

Data Set-up Time Prior to SCLK Rising

t

4

50

-

-

ns

Data Hold Time After SCLK Rising

t

5

100

-

-

ns

SDO Timing

CS Falling to SDO Driving

t

6

-

20

50

ns

SCLK Falling to New Data Bit (hold time)

t

7

-

20

50

ns

CS Rising to SDO Hi-Z

t

8

-

20

50

ns

Auto-Boot Timing

Serial Clock

Pulse Width Low

Pulse Width High

t

9

t

10

8

8

MCLK

MCLK

MODE setup time to RESET Rising

t

11

50

ns

RESET rising to CS falling

t

12

48

MCLK

CS falling to SCLK rising

t

13

100

8

MCLK

SCLK falling to CS rising

t

14

16

MCLK

CS rising to driving MODE low (to end auto-boot sequence).

t

15

50

ns

SDO guaranteed setup time to SCLK rising

t

16

100

ns

CS5461A

DS661F1

11

t

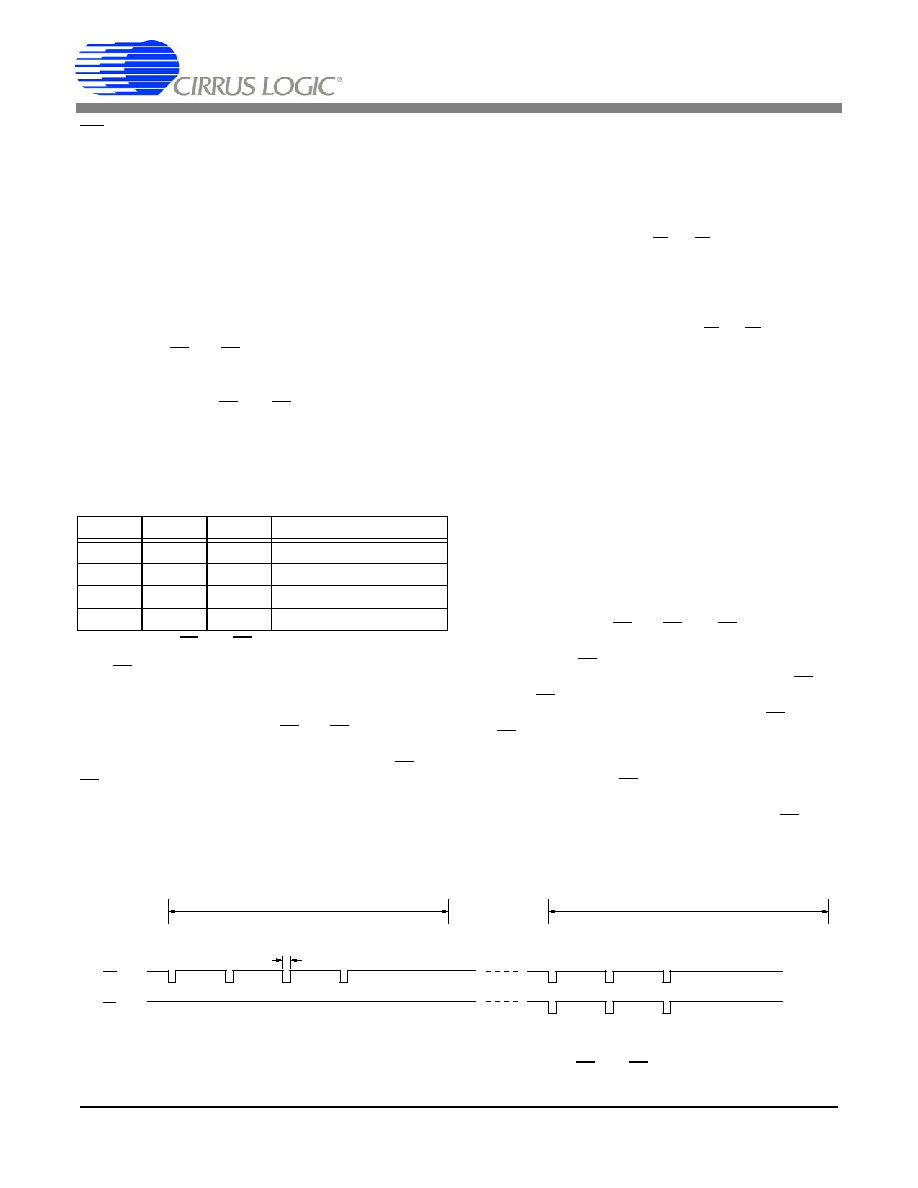

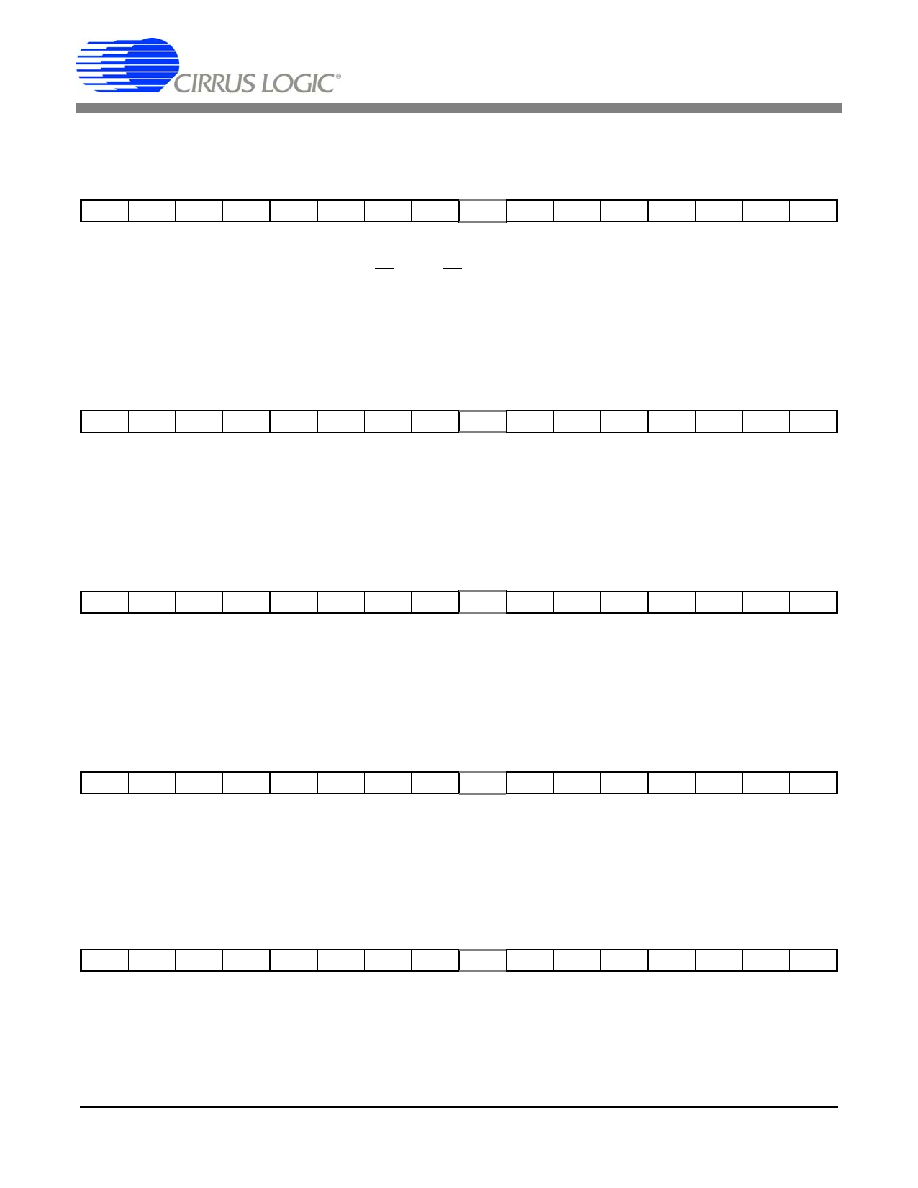

1

t

2

t

3

t

4

t

5

MSB

MS

B-1

LS

B

MSB

MS

B-1

LS

B

MSB

MS

B-1

LS

B

MSB

MS

B-1

LS

B

C o m m a n d T im e 8 S C L K s

H ig h B yte

M id B y te

L o w B yte

C S

S C L K

S D I

t

1 0

t

9

R E S E T

S D O

S C L K

C S

L a s t 8

B its

S D I

M O D E

ST

OP bit

D a t a f r o m E E P R O M

t

1 6

t

4

t

5

t

1 4

t

1 5

t

7

t

1 3

t

1 2

t

1 1

( IN P U T )

( IN P U T )

( O U T P U T )

( O U T P U T )

( O U T P U T )

( IN P U T )

SDI Write Timing (Not to Scale)

SDO Read Timing (Not to Scale)

Figure 1. CS5461A Read and Write Timing Diagrams

Auto-Boot Sequence Timing (Not to Scale)

t

1

t

2

MS

B

MSB-

1

LS

B

C o m m a n d T im e 8 S C L K s

S Y N C 0 o r S Y N C 1

C o m m a n d

S Y N C 0 o r S Y N C 1

C o m m a n d

MSB

MSB-

1

LS

B

MSB

MSB-

1

LS

B

MSB

MSB-

1

LS

B

H ig h B y t e

M id B y t e

L o w B y t e

C S

S D O

S C L K

S D I

t

6

t

7

t

8

S Y N C 0 o r S Y N C 1

C o m m a n d

U N K N O W N

CS5461A

12

DS661F1

ABSOLUTE MAXIMUM RATINGS

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes

.

Notes:

18. VA+ and AGND must satisfy {(VA+) - (AGND)}

+ 6.0 V.

19. VD+ and AGND must satisfy {(VD+) - (AGND)}

+ 6.0 V.

20. Applies to all pins including continuous over-voltage conditions at the analog input pins.

21. Transient current of up to 100 mA will not cause SCR latch-up.

22. Maximum DC input current for a power supply pin is ±50 mA.

23. Total power dissipation, including all input currents and output currents.

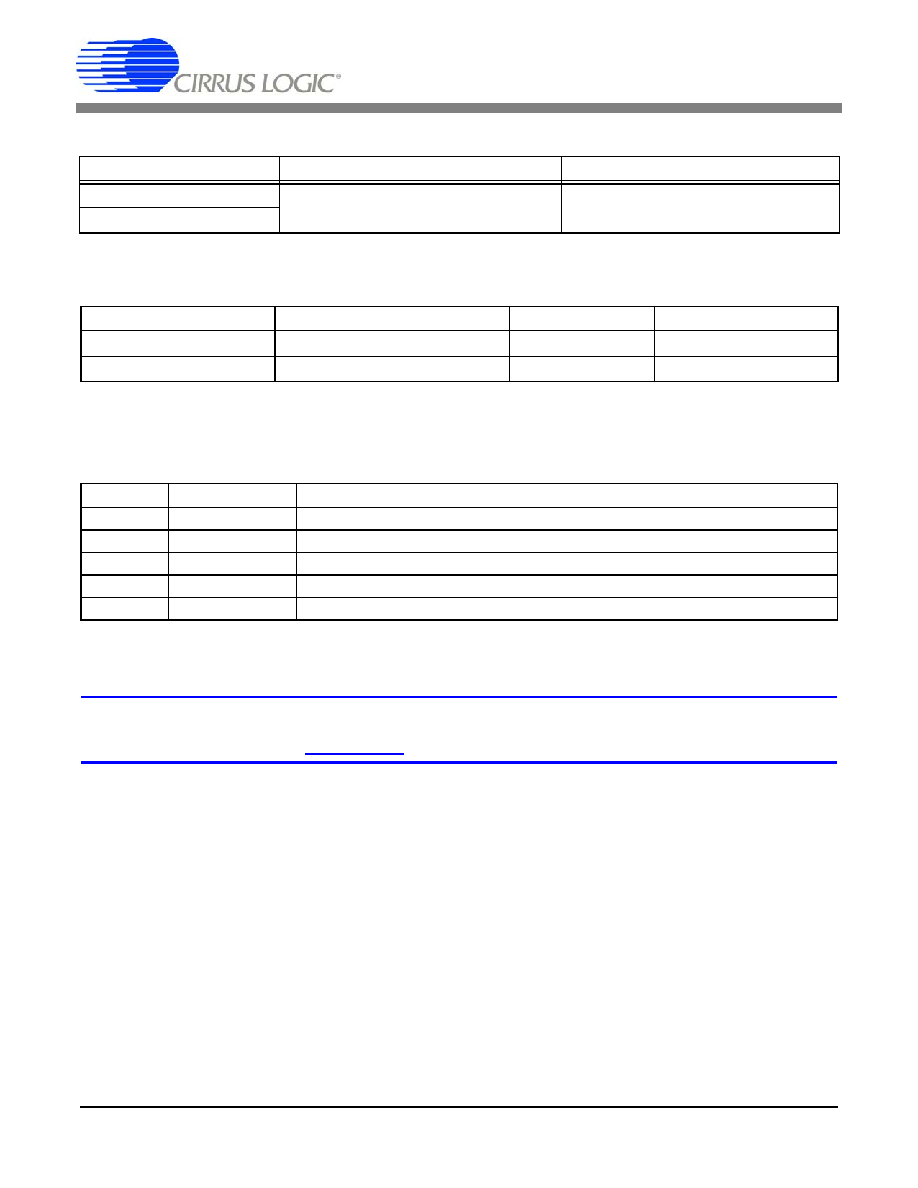

Parameter

Symbol Min Typ

Max

Unit

DC Power Supplies

(Notes 18 and 19)

Positive Digital

Positive Analog

VD+

VA+

-0.3

-0.3

-

-

+6.0

+6.0

V

V

Input Current, Any Pin Except Supplies

(Notes 20, 21, 22)

I

IN

-

-

±10

mA

Output Current, Any Pin Except VREFOUT

I

OUT

-

-

100

mA

Power Dissipation

(Note 23)

P

D

-

-

500

mW

Analog Input Voltage

All Analog Pins

V

INA

- 0.3

-

(VA+) + 0.3

V

Digital Input Voltage

All Digital Pins

V

IND

-0.3

-

(VD+) + 0.3

V

Ambient Operating Temperature

T

A

-40

-

85

°C

Storage Temperature

T

stg

-65

-

150

°C

CS5461A

DS661F1

13

4. THEORY OF OPERATION

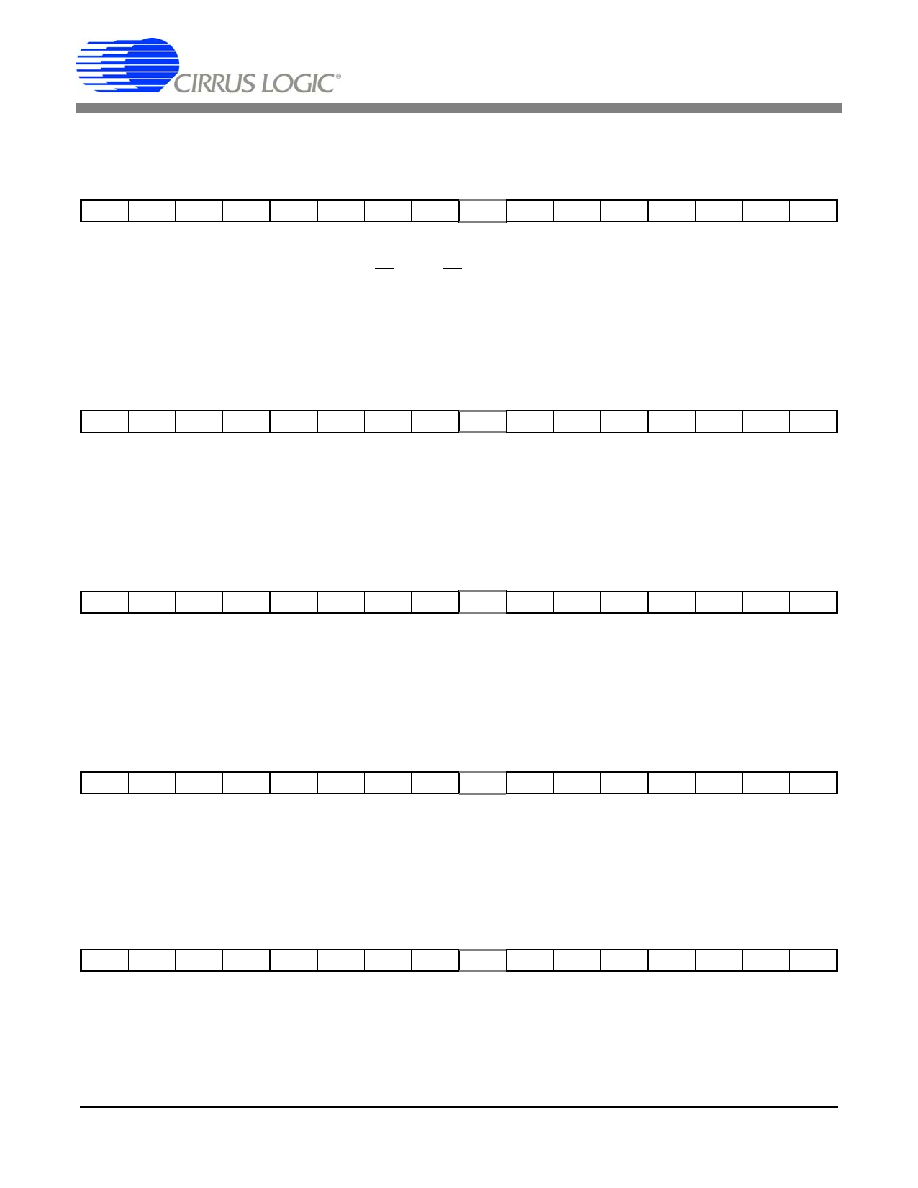

The CS5461A is a dual-channel analog-to-digital con-

verter (ADC) followed by a computation engine that per-

forms power calculations and energy-to-pulse

conversion. The flow diagram for the two data paths is

depicted in

Figure 2

. The analog inputs are structured

with two dedicated channels, voltage and current, then

optimized to simplify interfacing to sensing elements.

The voltage-sensing element introduces a voltage

waveform on the voltage channel input VIN± and is sub-

ject to a gain of 10x. A second-order, delta-sigma mod-

ulator samples the amplified signal for digitization.

Simultaneously, the current-sensing element introduces

a voltage waveform on the current channel input IIN±

and is subject to the two selectable gains of the pro-

grammable gain amplifier (PGA). The amplified signal is

sampled by a fourth-order, delta-sigma modulator for

digitization. Both converters sample at a rate of

MCLK/8, the over-sampling provides a wide dynamic

range and simplified anti-alias filter design.

4.1 Digital Filters

The decimating digital filters on both channels are Sinc

3

filters followed by 4th-order, IIR filters. The single-bit

data is passed to the low-pass decimation filter and out-

put at a fixed word rate. The output word is passed to

the IIR filter to compensate for the magnitude roll-off of

the low-pass filtering operation.

An optional digital High-pass Filter (HPF in

Figure 2

) re-

moves any DC component from the selected signal

path. By removing the DC component from the voltage

and/or the current channel, any DC content will also be

removed from the calculated active power as well. With

both HPFs enabled, the DC component will be removed

from the calculated V

RMS

and I

RMS

as well as the appar-

ent power.

4.2 Voltage and Current Measurements

The digital filter output word is then subject to a DC off-

set adjustment and a gain calibration (See

Section 7.

System Calibration

on page 33). The calibrated mea-

surement is available to the user by reading the instan-

taneous voltage and current registers.

The Root Mean Square (RMS) calculations are per-

formed on N instantaneous voltage and current sam-

ples, V

n

and I

n

respectively (where N is the cycle count),

using the formula:

and likewise for V

RMS

, using V

n

. I

RMS

and V

RMS

are ac-

cessible by register reads, which are updated once ev-

ery cycle count (referred to as a computational cycle).

4.3 Power Measurements

The instantaneous voltage and current samples are

multiplied to obtain the instantaneous power (see

Fig-

ure 2

). The product is then averaged over N conver-

sions to compute active power and used to drive energy

pulse outputs E1, E2 and E3. Output E3 provides a uni-

form pulse stream that is proportional to the active pow-

er and is designed for system calibration.

To generate a value for the accumulated active energy

over the last computation cycle, the active power can be

multiplied by the time duration of the computation cycle.

VOLTAGE

SINC3

+

X

V

*

gn

X

V *

CURRENT

SINC3

+

X

I

*

gn

DELAY

REG

DELAY

REG

HPF

Option

X

I

*

RMS

V

*

RMS

E1

IIR

I *

I

DCoff

*

V

DCoff

*

PGA

IIR

X

+

+

Energy-to-pulse

X

E3

+

X

+

Configuration Register *

Digital Filter

Digital Filter

HPF

Option

X

S *

2nd Order

Modulator

4th Order

Modulator

x10

+

I

ACoff

*

+

+

V

ACoff

*

+

E2

N

÷

N

N

÷

N

P

*

Active

N

÷

N

Poff*

P*

X

X

SYS

Gain

*

PC6 PC5 PC4 PC3 PC2 PC1 PC0

6

PulseRateE

1,2

*

PulseRateE

3

*

Energy-to-pulse

*DENOTES REGISTER NAME.

Figure 2. Data Flow.

I

RMS

In

n

0

=

N 1

N

--------------------

=

CS5461A

14

DS661F1

The apparent power is the combination of the active

power and reactive power, without reference to an im-

pedance phase angle, and is calculated by the

CS5461A using the following formula:

The apparent power is registered once every computa-

tion cycle.

4.4 Linearity Performance

The linearity of the V

RMS

, I

RMS

, and active power mea-

surements (before calibration) will be within ±0.1% of

reading over the ranges specified, with respect to the in-

put voltage levels required to cause full-scale readings

in the I

RMS

and V

RMS

registers. Refer to

Linearity Per-

formance Specifications

on page 7.

Until the CS5461A is calibrated, the accuracy of the

CS5461A (with respect to a reference line-voltage and

line-current level on the power mains) is not guaranteed

to within ±0.1%. See

Section 7. System Calibration

on

page 33. The accuracy of the internal calculations can

often be improved by selecting a value for the Cycle

Count Register that will cause the time duration of one

computation cycle to be equal to (or very close to) a

whole-number of power-line cycles (and N must be

greater than or equal to 4000).

S

V

RMS

I

RMS

×

=

CS5461A

DS661F1

15

5. FUNCTIONAL DESCRIPTION

5.1 Analog Inputs

The CS5461A is equipped with two fully differential in-

put channels. The inputs VIN

± and IIN± are designated

as the voltage and current channel inputs, respectively.

The full-scale differential input voltage for the current

and voltage channel is

±250 mV

P

.

5.1.1 Voltage Channel

The output of the line-voltage resistive divider or trans-

former is connected to the VIN+ and VIN- input pins of

the CS5461A. The voltage channel is equipped with a

10x, fixed-gain amplifier. The full-scale signal level that

can be applied to the voltage channel is

±250 mV. If the

input signal is a sine wave the maximum RMS voltage

at a gain 10x is:

which is approximately 70.7% of maximum peak volt-

age. The voltage channel is also equipped with a Volt-

age Gain Register, allowing for an additional

programmable gain of up to 4x.

5.1.2 Current Channel

The output of the current-sense resistor or transformer

is connected to the IIN+ and IIN- input pins of the

CS5461A. To accommodate different current-sensing

elements, the current channel incorporates a Program-

mable Gain Amplifier (PGA) with two programmable in-

put gains. Configuration Register bit Igain (See Table 1)

defines the two gain selections and corresponding max-

imum input-signal level.

For example, if Igain=0, the current channel's PGA gain

is set to 10x. If the input signals are pure sinusoids with

zero phase shift, the maximum peak differential signal

on the current or voltage channel is

±250 mV

P

. The in-

put-signal levels are approximately 70.7% of maximum

peak voltage producing a full-scale energy pulse regis-

tration equal to 50% of absolute maximum energy pulse

registration. This will be discussed further in

Section 5.4

Energy Pulse Output

on page 16.

The Current Gain Register also allows for an additional

programmable gain of up to 4x. If an additional gain is

applied to the voltage and/or current channel, the maxi-

mum input range should be adjusted accordingly.

5.2 High-pass Filters

By removing the offset from either channel, no error

component will be generated at DC when computing the

active power. By removing the offset from both chan-

nels, no error component will be generated at DC when

computing V

RMS

, I

RMS

, and apparent power. Configura-

tion Register bits VHPF and IHPF activate the HPF in

the voltage and current channel respectively.

5.3 Performing Measurements

The CS5461A performs measurements of instanta-

neous voltage (V

n

) and current (I

n

), and calculates in-

stantaneous power (P

n

) at an Output Word Rate (OWR)

of

where K is the clock divider setting in the Configuration

Register.

The RMS voltage (V

RMS

), RMS current (I

RMS

), and ac-

tive power (P

Active

) are computed using N instanta-

neous samples of V

n

, I

n

and P

n

respectively, where N is

the value in the Cycle Count Register (N) and is referred

to as a "computation cycle". The apparent power (S) is

the product of V

RMS

and I

RMS

. A computation cycle is

derived from the master clock (MCLK), with frequency:

Under default conditions & with K = 1, N = 4000, and

MCLK = 4.096 MHz the OWR = 4000 Hz and the

Computation Cycle = 1 Hz.

All measurements are available as a percentage of full

scale. The format for signed registers is a two's comple-

ment, normalized value between -1 and +1. The format

for unsigned registers is a normalized value between 0

and 1. A register value of

represents the maximum possible value.

At each instantaneous measurement, the CRDY bit will

be set (logic 1) in the Status Register, and the INT pin

will become active if the CRDY bit is unmasked in the

Mask Register. At the end of each computation cycle,

the DRDY bit will be set in the Status Register, and the

Igain

Maximum Input Range

0

±250 mV

10x

1

±50 mV

50x

Table 1. Current Channel PGA Configuration

250mVP

2

---------------------

176.78mVRMS

OWR

MCLK K

/

(

)

1024

-----------------------------

=

Computation Cycle

OWR

N

---------------

=

2

23

1

(

)

2

23

------------------------

0.99999988

=

CS5461A

16

DS661F1

INT pin will become active if the DRDY bit is unmasked

in the Mask Register. When these bits are set, they

must be cleared (logic 0) by the user before they can be

asserted again.

If the Cycle Count Register (N) is set to 1, all output cal-

culations are instantaneous, and DRDY, like CRDY, will

indicate when instantaneous measurements are fin-

ished. Some calculations are inhibited when the cycle

count is less than 2.

5.4 Energy Pulse Output

The CS5461A provides three output pins for energy reg-

istration. The E1 and E2 pins provide a simple interface

which energy can be registered. These pins are de-

signed to directly connect to a stepper motor or electro-

mechanical counter. E1 and E2 pins can be set to one

of four pulse output formats, Normal, Alternate, Stepper

Motor, or Mechanical Counter. Table 2 defines the

pulse output format, which is controlled by bits ALT in

the Configuration Register, and MECH and STEP in the

Control Register.

The E3 pin is designated for system calibration, the

pulse rate can be selected to reach a frequency of

512 kHz.

The pulse output frequency of E1 and E2 is directly pro-

portional to the active power calculated from the input

signals. To calculate the output frequency on E1 and

E2, the following transfer function can be utilized:

With MCLK = 4.096 MHz, PF = 1, and default settings,

the pulses will have an average frequency equal to the

frequency setting in the PulseRateE

1,2

Register when

the input signals applied to the voltage and current

channels cause full-scale readings in the instantaneous

voltage and current registers. When MCLK/K is not

equal to 4.096 MHz, the user should scale the

PulseRateE

1,2

Register by a factor of

4.096 MHz/(MCLK/K) to get the actual pulse rate out-

put.

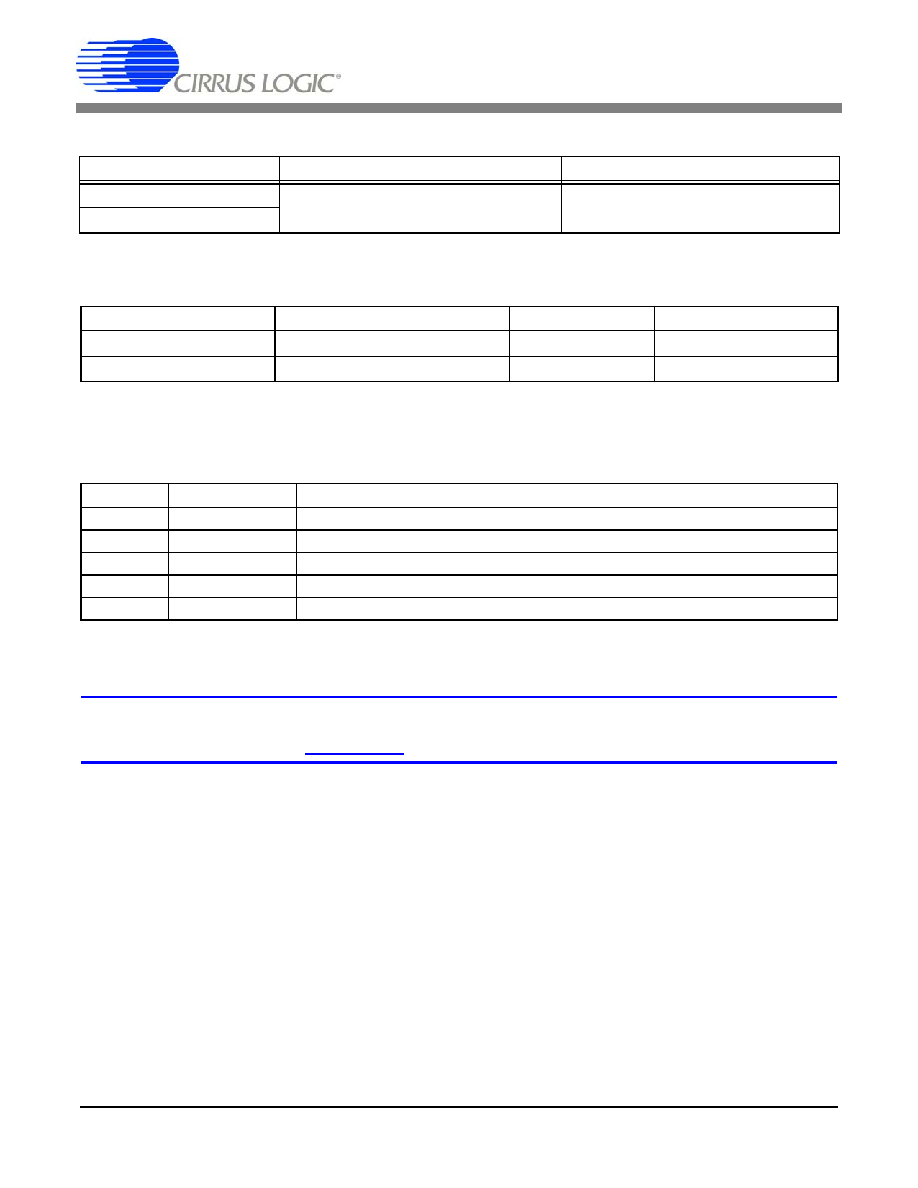

5.4.1 Normal Format

The Normal format is the default.

Figure 3

illustrates the

output format on pins E1 and E2. The E1 pin outputs ac-

tive-low pulses with a frequency proportional to the ac-

tive power. The E2 pin is the energy direction indicator.

Positive energy is represented by a pulse on the E1 pin

while the E2 pin remains high. Negative energy is rep-

resented by synchronous pulses on both the E1 pin and

the E2 pin.

The PulseRateE

1,2

Register defines the average fre-

quency on output pin E1, when full-scale input signals

are applied to the voltage and current channels. The

maximum pulse frequency from the E1 pin

ALT

STEP

MECH

FORMAT

0

0

0

Normal

0

X

1

Mechanical Counter

0

1

0

Stepper Motor

1

X

1

Alternate Pulse

Table 2. E1 and E2 Pulse Output Format

FREQ

E

= Average frequency of E1 and E2 pulses [Hz]

VIN = rms voltage across VIN+ and VIN- [V]

VGAIN = Voltage channel gain

IIN = rms voltage across IIN+ and IIN- [V]

IGAIN = Current channel gain

PF = Power Factor

PulseRateE1,2 = Maximum frequency on E1 and E2 [Hz]

VREFIN = Voltage at VREFIN pin [V]

FREQ

E

VIN VGAIN

×

IIN

×

IGAIN

PF

×

PulseRateE1 2

,

×

×

VREFIN

2

------------------------------------------------------------------------------------------------------------------------------------------------

=

E 1

P o s itiv e E n e rg y B u rs t

N e g a tiv e E n e rg y B u rs t

. . .

. . .

. . .

. . .

E 2

t

d u r

Figure 3. Normal Format on pulse outputs E1 and E2

CS5461A

DS661F1

17

is (MCLK/K)/16. The pulse duration (t

dur

) is an integer

multiple of MCLK cycles, approximately equal to:

The maximum pulse duration (t

dur

) is determined by the

sampling rate and the minimum is defined by the maxi-

mum pulse frequency. The t

dur

limits are:

The Pulse Width Register (PW) does not affect the nor-

mal format.

5.4.2 Alternate Pulse Format

Setting bits MECH = 1 and STEP = 0 in the Control

Register and ALT = 1 in the Configuration Register con-

figures the E1 and E2 pins for alternating pulse format

output (see

Figure 4

). Each pin produces alternating ac-

tive-low pulses with a pulse duration (t

PW

) defined by

the Pulse Width Register (PW):

If MCLK = 4.096 MHz, K = 1, and PW = 1 then

t

PW

= 0.25 ms. To ensure that pulses occur on the E1

and E2 output pins when full-scale input signals are ap-

plied to the voltage and current channels, then:

The pulse frequency (FREQ

E

) is determined by the

PulseRateE

1,2

Register and can be calculated using the

transfer function. The energy direction is not defined in

the alternate pulse format.

5.4.3 Mechanical Counter Format

Setting bits MECH = 1 and STEP = 0 in the Control

Register and bit ALT = 0 in the Configuration Register

enables E1 and E2 for mechanical counters and similar

discrete counting instruments. When energy is nega-

tive, pulses appear on E2 (see Figure 5). When energy

is positive, the pulses appear on E1. The pulse width is

defined by the Pulsewidth Register and will limit the out-

put pulse frequency (FREQ

E

). By default, PW = 512

samples, if MCLK = 4.096 MHz and K = 1 then

t

PW

= 128 ms. To ensure that pulses will occur, the

PulseRateE

1,2

Register must be set to an appropriate

value.

5.4.4 Stepper Motor Format

Setting bits STEP = 1 and MECH = 0 in the Control

Register and bit ALT = 0 in the Configuration Register

configures the E1 and E2 pins for stepper motor format.

When the accumulated active power equals the defined

tdur sec

(

)

1

PulseRateE1 2

,

8

×

--------------------------------------------

1

(MCLK/K)/16

8

×

-----------------------------------

tdur sec

(

)

1

(MCLK/K)/1024

8

×

-----------------------------------------

<

<

Figure 4. Alternate Pulse Format on E1 and E2

E1

...

...

E2

...

...

...

t

PW

FREQ

E

tPW ms

(

)

PW

(MCLK/K)/1024

-----------------------------------------

=

PulseRateE1 2

,

1

tPW

------------

<

t

PW

E1

Positive Energy

Negative Energy

...

...

...

...

E2

FREQ

E

Figure 5. Mechanical Counter Format on E1 and E2

CS5461A

18

DS661F1

energy level, the energy output pins (E1 and E2) alter-

nate changing states (see Figure 6). The duration

(t

edge

) between the alternating states is defined by the

transfer function:

The direction the motor will rotate is determined by the

order of the state changes. When energy is positive, E1

will lead E2. When energy is negative, E2 will lead E1.

The Pulse Width Register (PW) does not affect the step-

per motor format.

5.4.5 Pulse Output E3

The pulse output E3 is designed to assist with meter cal-

ibration. The pulse-output frequency of E3 is directly

proportional to the active power calculated from the in-

put signals. E3 pulse frequency is derived using a sim-

ular transfer function as E1, but is set by the value in the

PulseRateE

3

Register.

The E3 pin outputs negative and positive energy, but

has no energy direction indicator.

5.4.6 Anti-creep for the Pulse Outputs

Anti-creep allows the measurement element to maintain

an energy level, such that when the magnitude of the

accumulated active power is below this level, no energy

pulses are output. Anti-creep is enabled by setting bit

FAC in the Control Register for E3 and bit EAC in the

Control Register for E1 and E2.

For low-frequency pulse output formats (i.e. mechanical

counter and stepper motor formats), the active power is

accumulated over time. When a designated energy lev-

el is reached (determined by the transfer function) a

pulse is generated on E1 and/or E2. If active power with

alternating polarity occurs during the accumulation peri-

od (e.g. random noise at zero power levels), the accura-

cy of the registered energy will be maintained.

For high-frequency pulse output formats (i.e. normal

and alternate pulse formats), the active power is accu-

mulated over time until a

±8x buffer is defined. Then,

when the designated energy level is reached, a pulse is

generated on E1 and/or E2. For pulse outputs with high

frequencies and power levels close to zero, the extend-

ed buffer prevents random noise from being registered

as active energy.

5.4.7 Design Examples

EXAMPLE #1:

The maximum rated levels for a power line meter are

250 V rms and 20 A rms. The required number of puls-

es per second on E1 is 100 pulses per second (100 Hz),

when the levels on the power line are 220 V rms and

15 A rms.

With a 10x gain on the voltage and current channel the

maximum input signal is 250 mV

P

(see

Section 5.1 An-

alog Inputs

on page 15). To prevent over-driving the

channel inputs, the maximum rated rms input levels will

register 0.6 in V

RMS

and I

RMS

by design. Therefore the

voltage level at the channel inputs will be 150 mV rms

when the maximum rated levels on the power lines are

250 V rms and 20 A rms.

Solving for PulseRateE

1,2

using the transfer function:

Therefore with PF = 1 and

the PulseRateE

1,2

Register is set to:

EXAMPLE #2:

The required number of pulses per unit energy present

on E1 is specified to be 500 pulses per kWhr, given that

the line voltage is 250 Vrms and the line current is

20 Arms. In such a situation, the stated line voltage and

current do not determine the appropriate PulseRateE

1,2

setting. To achieve full-scale readings in the instanta-

E 1

E 2

P o s it iv e E n e r g y

N e g a t iv e E n e r g y

. . .

. . .

. . .

. . .

t

e d g e

Figure 6. Stepper Motor Format on E1 and E2

tedge sec

(

)

1

FREQE

----------------------

=

PulseRateE1 2

,

FREQE VREFIN

2

×

VIN VGAIN

×

IIN

×

PF

×

-------------------------------------------------------------------

=

VIN

220V

150mV

(

) 250V

(

)

/

(

)

×

132mV

=

=

IIN

15A

150mV

(

) 20A

(

)

/

(

)

×

112.5mV

=

=

PulseRateE

100 2.5

2

×

0.132 10

×

0.1125

×

10

×

-----------------------------------------------------------------

420.8754Hz

=

=

CS5461A

DS661F1

19

neous voltage and current registers, a 250 mV, DC-lev-

el signal is applied to the channel inputs.

As in example #1, the voltage and current channel gains

are 10x, and the voltage level at the channel inputs will

be 150 mV rms when the levels on the power lines are

250 V rms and 20 A rms. In order to achieve

500 pulse-per-kW Hr per unit-energy, the

PulseRateE

1,2

Register setting is determined using the

following equation:

Therefor, the PulseRateE

1,2

Register is approximately

1.929 Hz. The PulseRateE

1,2

Register cannot be set to

a frequency of exactly 1.929 Hz. The closest setting is

0x00003E = 1.9375 Hz.

To improve the accuracy, either gain register can be

programmed to correct for the round-off error. This val-

ue would be calculated as

If (MCLK/K) is not equal to 4.096 MHz, the

PulseRateE

1,2

Register must be scaled by a correction

factor of:

Therefore if (MCLK/K) = 3.05856 MHz the value of

PulseRateE

1,2

Register is

5.5 Voltage Sag-detect Feature

Status bit VSAG in the Status Register, indicates a volt-

age sag occurred in the power line voltage. For a volt-

age sag condition to be identified, the absolute value of

the instantaneous voltage must be less than the voltage

sag level for more than half of the voltage sag duration

(see

Figure 7

).

To activate Voltage Sag detect, a voltage sag level must

be specified in the Voltage Sag Level Register

(VSAG

Level

), and a voltage sag duration must be spec-

ified in the Voltage Sag Duration Register

(VSAG

Duration

). The voltage sag level is specified as the

average of the absolute instantaneous voltage. Voltage

sag duration is specified in terms of ADC cycles.

5.6 On-chip Temperature Sensor

The on-chip temperature sensor is designed to assist in

characterizing the measurement element over a desired

temperature range. Once a temperature characteriza-

tion is performed, the temperature sensor can then be

utilized to assist in compensating for temperature drift.

Temperature measurements are performed during con-

tinuous conversions and stored in the Temperature

Register. The Temperature Register (T) default is Cel-

sius scale (

o

C). The Temperature Gain Register (T

gain

)

and Temperature Offset Register (T

off

) are constant val-

ues allowing for temperature scale conversions.

The temperature update rate is a function of the number

of ADC samples. With MCLK = 4.096 MHz and K = 1

the update rate is:

The Cycle Count Register (N) must be set to a value

greater than one. Status bit TUP in the Status Register,

indicates when the Temperature Register is updated.

The Temperature Offset Register sets the zero-degree

measurement. To improve temperature measurement

accuracy, the zero-degree offset should be adjusted af-

ter the CS5461A is initialized. Temperature offset cali-

bration is achieved by adjusting the Temperature Offset

Register (T

off

) by the differential temperature (

T) mea-

sured from a calibrated digital thermometer and the

CS5461A temperature sensor. A one-degree adjust-

ment to the Temperature Register (T) is achieved by

PulseRateE1 2

,

500pulses

kWHr

------------------------------

1Hr

3600s

----------------

×

1kW

1000W

-------------------

250mV

150mV

250V

-------------------

-------------------------

×

×

250mV

150mV

20A

-------------------

-------------------------

×

=

Vgn or Ign

PulseRateE

1.929

-----------------------------------

1.00441

0x404830

=

=

4.096MHz

(MCLK/K)

----------------------------

PulseRateE1 2

,

×

PulseRateE1 2

,

4.096

3.05856

---------------------

1.929Hz

×

2.583Hz

=

Level

Duration

Figure 7. Voltage Sag Detect

2240 samples

(MCLK/K)/1024

-----------------------------------------

0.56 sec

=

CS5461A

20

DS661F1

adding 2.737649x10

-4

to the Temperature Offset Regis-

ter (T

off

). Therefore,

if T

off

= -0.09104831 and

T = -7.0 (

o

C), then

or 0xF419BC (2's compliment notation) is stored in the

Temperature Offset Register (T

off

).

To convert the Temperature Register (T) from a Celsius

scale (

o

C) to a Fahrenheit scale (

o

F) utilize the formula

Applying the above relationship to the CS5461A tem-

perature measurement algorithm

If T

off

= -0.09296466 and T

gain

= 23.799 for a Celsius

scale, then the modified values are T

off

= -0.08809772

(0xF4B937) and T

gain

= 42.8382 (0x55AD29) for a

Fahrenheit scale.

5.7 Voltage Reference

The CS5461A is specified for operation with a +2.5 V

reference between the VREFIN and AGND pins. To uti-

lize the on-chip 2.5 V reference, connect the VREFOUT

pin to the VREFIN pin of the device. The VREFIN pin

can be used to connect external filtering and/or refer-

ences.

5.8 System Initialization

Upon powering up, the digital circuitry is held in reset

until the analog voltage reaches 4.0 V. At that time, an

eight-XIN-clock-period delay is enabled to allow the os-

cillator to stabilize. The CS5461A will then initialize.

A hardware reset is initiated when the RESET pin is as-

serted with a minimum pulse width of 50 ns. The

RESET signal is asynchronous, with a Schmitt-trigger

input. Once the RESET pin is de-asserted, an

eight-XIN-clock-period delay is enabled.

A software reset is initiated by writing the command of

0x80. After a hardware or software reset, the internal

registers (some of which drive output pins) will be reset

to their default values. Status bit DRDY in the Status

Register, indicates the CS5461A is in its active state

and ready to receive commands.

5.9 Power-down States

The CS5461A has two power-down states, stand-by

and sleep. In the stand-by state all circuitry except the

voltage reference and crystal oscillator is turned off. To

return the device to the active state a power-up com-

mand is sent to the device.

In sleep state all circuitry except the instruction decoder

is turned off. When the power-up command is sent to

the device, a system initialization is performed (see

Section 5.8 System Initialization

on page 20).

5.10 Oscillator Characteristics

The XIN and XOUT pins are the input and output of an

inverting amplifier configured as an on-chip oscillator,

as shown in Figure 8. The oscillator circuit is designed

to work with a quartz crystal. To reduce circuit cost, two

load capacitors C1 and C2 are integrated in the device,

from XIN to DGND, and XOUT to DGND. PCB trace

lengths should be minimized to reduce stray capaci-

tance. To drive the device from an external clock

source, XOUT should be left unconnected while XIN is

driven by the external circuitry. There is an amplifier be-

tween XIN and the digital section which provides

CMOS-level signals. This amplifier works with sinusoi-

dal inputs so there are no problems with slow edge

times.

The CS5461A can be driven by an external oscillator

ranging from 2.5 to 20 MHz, but the K divider value must

be set such that the internal MCLK will run somewhere

between 2.5 MHz and 5 MHz. The K divider value is set

with the K[3:0] bits in the Configuration Register. As an

example, if XIN = MCLK = 15 MHz, and K is set to 5,

then DCLK is 3 MHz, which is a valid value for DCLK.

Toff Toff

T

(

+

2.737649 10

4

)

×

=

Toff

0.09104831

7.0

(

+

2.737649 10

4

)

×

0.09296466

=

=

F

o

9

5

--- C

o

17.7778

+

(

)

=

T

F

o

9

5

---

T

×

gain

(

)

T

C

o

Toff

17.7778

2.737649 10

4

×

(

)

+

(

)

+

[

]

=

Oscillator

Circuit

DGND

XIN

XOUT

C1

C1 =

22 pF

C2

C2 =

Figure 8. Oscillator Connection

CS5461A

DS661F1

21

5.11 Event Handler

The INT pin is used to indicate that an internal error or

event has taken place in the CS5461A. Writing a logic 1

to any bit in the Mask Register allows the corresponding

bit in the Status Register to activate the INT pin. The in-

terrupt condition is cleared by writing a logic 1 to the bit

that has been set in the Status Register.

The behavior of the INT pin is controlled by the IMODE

and IINV bits of the Configuration Register.

If the interrupt output signal format is set for either falling

or rising edge, the duration of the INT pulse will be at

least one DCLK cycle (DCLK = MCLK/K).

5.11.1 Typical Interrupt Handler

The steps below show how interrupts can be handled.

INITIALIZATION:

1) All Status bits are cleared by writing 0xFFFFFF to

the Status Register.

2) The condition bits which will be used to generate

interrupts are then set to logic 1 in the Mask Reg-

ister.

3) Enable interrupts.

INTERRUPT HANDLER ROUTINE:

4) Read the Status Register.

5) Disable all interrupts.

6) Branch to the proper interrupt service routine.

7) Clear the Status Register by writing back the read

value in step 4.

8) Re-enable interrupts.

9) Return from interrupt service routine.

This handshaking procedure ensures that any new in-

terrupts activated between steps 4 and 7 are not lost

(cleared) by step 7.

5.12 Serial Port Overview

The CS5461A incorporates a serial port transmit and re-

ceive buffer with a command decoder that interprets

one-byte (8 bits) commands as they are received. There

are four types of commands; instructions, synchroniz-

ing, register writes and register reads (See

Section 5.13

Commands

on page 22).

Instructions are one byte in length and will interrupt any

instruction currently executing. Instructions do not affect

register reads currently being transmitted.

Synchronizing commands are one byte in length and

only affect the serial interface. Synchronizing com-

mands do not affect operations currently in progress.

Register writes must be followed by three bytes of data.

register reads can return up to four bytes of data.

Commands and data are transferred most-significant bit

(MSB) first.

Figure 1

on page 11, defines the serial port

timing and required sequence necessary to write to and

read from the serial port receive and transmit buffer, re-

spectively. While reading data from the serial port, com-

mands and data can be simultaneously written. Starting

a new register read command while data is being read

will terminate the current read in progress. This is ac-

ceptable if the remainder of the current read data is not

needed. During data reads, the serial port requires input

data. If a new command and data is not sent, SYNC0 or

SYNC1 must be sent.

5.12.1 Serial Port Interface

The serial port interface is a "4-wire" synchronous serial

communications interface. The interface is enabled to

start excepting SCLKs when CS (Chip Select) is assert-

ed. SCLK (Serial bit-clock) is a Schmitt-trigger input that

is used to strobe the data on SDI (Serial Data In) into the

receive buffer and out of the transmit buffer onto SDO

(Serial Data Out).

If the serial port interface becomes unsynchronized with

respect to the SCLK input, any attempt to clock valid

commands into the serial interface may result in unex-

pected operation. The serial port interface must then be

re-initialized by one of the following actions:

-

Drive the CS pin high, then low.

-

Hardware Reset (drive RESET pin low, for at

least 10 µs).

-

Issue the Serial Port Initialization Sequence,

which is 3 (or more) SYNC1 command bytes

(0xFF) followed by one SYNC0 command byte

(0xFE).

If a resynchronization is necessary, it is best to re-initial-

ize the part either by hardware or software reset (0x80),

as the state of the part may be unknown.

IMODE

IINV

INT Pin

0

0

Active-low Level

0

1

Active-high Level

1

0

Low Pulse

1

1

High Pulse

Table 3. Interrupt Configuration

CS5461A

22

DS661F1

5.13 Commands

All commands are 8-bits in length. Any byte that is not listed in this section is invalid. Commands that write to regis-

ters must be followed by 3 bytes of data. Commands that read data can be chained with other commands (e.g., while

reading data, a new command can be sent which can execute during the original read). All commands except reg-

ister reads, register writes, and SYNC0 & SYNC1 will abort any currently executing commands.

5.13.1 Start Conversions

Initiates acquiring measurements and calculating results. The device has two modes of acquisition.

C3

Modes of acquisition/measurement

0 = Perform a single computation cycle

1 = Perform continuous computation cycles

5.13.2 SYNC0 and SYNC1

The serial port can be initialized by asserting CS or by sending three or more consecutive SYNC1 commands fol-

lowed by a SYNC0 command. The SYNC0 or SYNC1 can also be sent while sending data out.

SYNC

0 = Last byte of a serial port re-initialization sequence.

1 = Used during reads and serial port initialization.

5.13.3 Power-Up/Halt

If the device is powered-down, Power-Up/Halt will initiate a power on reset. If the part is already powered-on, all

computations will be halted.

5.13.4 Power-down and Software Reset

To conserve power the CS5461A has two power-down states. In stand-by state all circuitry, except the analog/digital

clock generators, is turned off. In the sleep state all circuitry, except the instruction decoder, is turned off. Bringing

the CS5461A out of sleep state requires more time than out of stand-by state, because of the extra time needed to

re-start and re-stabilize the analog oscillator.

S[1:0]

Power-down state

00 = Software Reset

01 = Halt and enter stand-by power saving state. This state allows quick power-on

10 = Halt and enter sleep power saving state.

11 = Reserved

B7

B6

B5

B4

B3

B2

B1

B0

1

1

1

0

C3

0

0

0

B7

B6

B5

B4

B3

B2

B1

B0

1

1

1

1

1

1

1

SYNC

B7

B6

B5

B4

B3

B2

B1

B0

1

0

1

0

0

0

0

0

B7

B6

B5

B4

B3

B2

B1

B0

1

0

0

S1

S0

0

0

0

CS5461A

DS661F1

23

5.13.5 Register Read/Write

The Read/Write informs the command decoder that a register access is required. During a read operation, the ad-

dressed register is loaded into an output buffer and clocked out by SCLK. During a write operation, the data is

clocked into an input buffer and transferred to the addressed register upon completion of the 24

th

SCLK.

W/R

Write/Read control

0 = Read

1 = Write

RA[4:0]

Register address bits (bits 5 through 1) of the read/write command.

Address

RA[4:0]

Name

Description

0

00000

Config

Configuration

1

00001

I

DCoff

Current DC Offset

2

00010

I

gn

Current Gain

3

00011

V

DCoff

Voltage DC Offset

4

00100

V

gn

Voltage Gain

5

00101

Cycle Count

Number of A/D conversions used in one computation cycle (N)).

6

00110

PulseRateE

1,2