DSP101

DSP102

FEATURES

q

ZERO-CHIP INTERFACE TO STANDARD

DSP ICs: AD, AT&T, MOTOROLA, TI

q

SINGLE CHANNEL: DSP101

q

DUAL CHANNEL: DSP102

Two Serial Outputs or Cascade to Single

32-Bit Word

q

SAMPLING RATE TO 200kHz

q

DYNAMIC SPECIFICATIONS:

Signal/(Noise + Distortion) = 88dB;

Spurious-Free Dynamic Range = 94dB;

THD = 91dB

q

SERIAL OUTPUT DATA COMPATIBLE

WITH 16-, 24-, AND 32-BIT DSP IC

FORMATS

DESCRIPTION

The DSP101 and DSP102 are high performance sam-

pling analog-to-digital converters designed for sim-

plicity of use with modern digital signal processing

ICs. Both are complete with all interface logic for use

directly with DSP ICs, and provide full sampling and

conversion at rates up to 200kHz.

The DSP101 offers a single conversion channel, with

18 bits of serial data output, allowing the user to drive

16-bit, 24-bit, or 32-bit DSP ports. The DSP102 offers

two complete conversion channels, with either two

full 18-bit output ports, or a mode to cascade two

16-bit conversions into a 32-bit port as one word.

Both the DSP101 and DSP102 are packaged in stan-

dard, low-cost 28-pin plastic DIP packages. Each is

offered in two performance grades to match applica-

tion requirements.

18-Bit Sampling ADC

18-Bit Sampling ADC

Reference

Convert

Command

Analog

Input

Channel A

Analog

Input

Channel B

Channel B on DSP102 Only

Control

Logic

Select Sync Format

Channel A User Tag In

Sync

Bit Clock

Channel A Data/

Cascaded Data

Channel B Data

Channel B User Tag In

Cascade

International Airport Industrial Park · Mailing Address: PO Box 11400 · Tucson, AZ 85734 · Street Address: 6730 S. Tucson Blvd. · Tucson, AZ 85706

Tel: (520) 746-1111 · Twx: 910-952-1111 · Cable: BBRCORP · Telex: 066-6491 · FAX: (520) 889-1510 · Immediate Product Info: (800) 548-6132

®

DSP-Compatible Sampling Single/Dual

ANALOG-TO-DIGITAL CONVERTERS

©

1990 Burr-Brown Corporation

PDS-1068C

Printed in U.S.A. October. 1993

®

DSP101/102

2

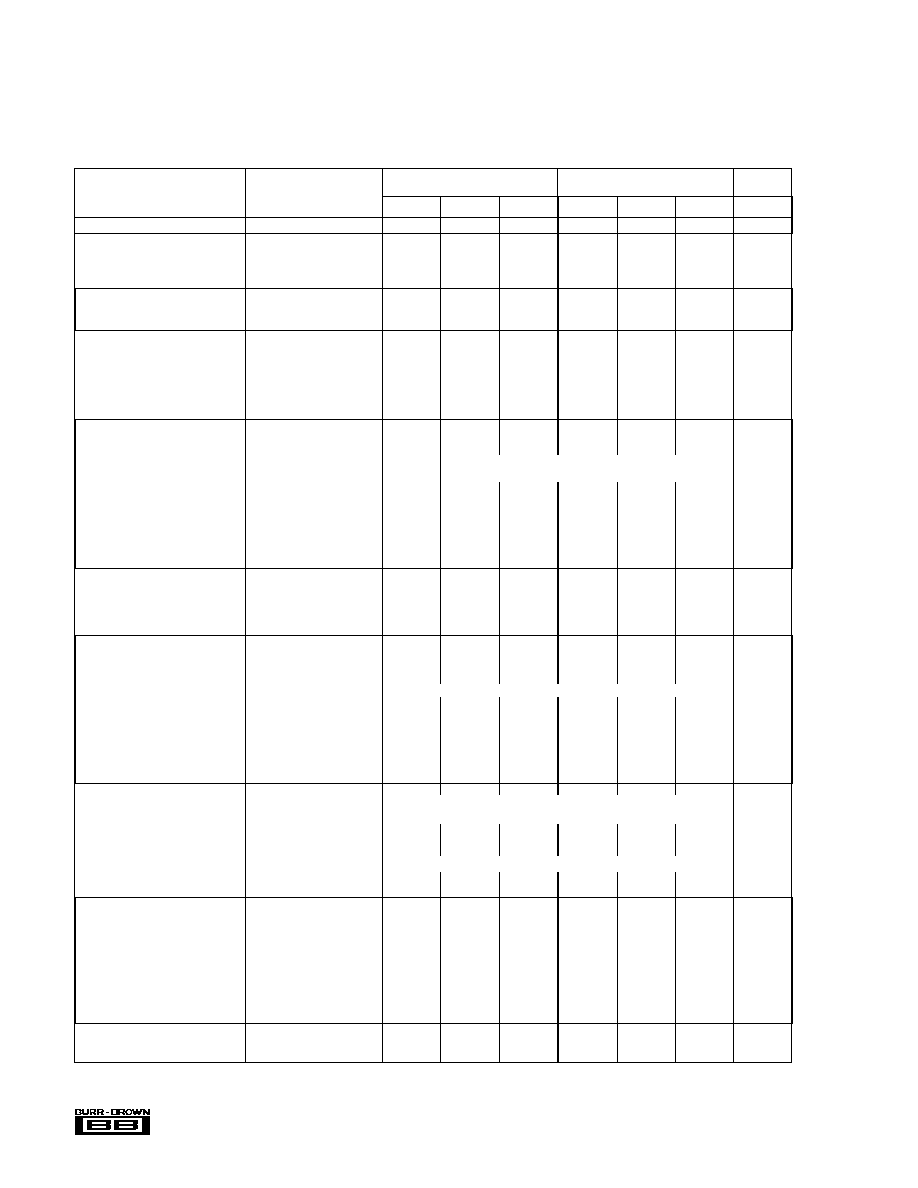

SPECIFICATIONS

ELECTRICAL

At T

A

= 0

°

C to 70

°

C,

±

2.75V input signal, sampling frequency (f

S

) = 200kHz, V

A

+ = V

D

= +5V, V

A

= 5V, 16MHz external clock on OSC1, CLKOUT tied to CLKIN,

8MHzdata transfer clock on XCLK, data analysis band-limited to 20kHz, unless otherwise specified.

Sufficient to meet AC Accuracy Specifications

Sufficient to meet AC Accuracy Specifications

DSP101JP

DSP101KP

DSP102JP

DSP102KP

PARAMETER

CONDITIONS

MIN

TYP

MAX

MIN

TYP

MAX

UNITS

RESOLUTION

18

*

Bits

ANALOG INPUT

Voltage Range

±

2.75V

*

V

Impedance

1

*

k

Capacitance

20

*

pF

THROUGHPUT SPEED

Complete Cycle

Acquisition + Conversion

5

*

µ

s

Throughput Rate

200

*

kHz

AC ACCURACY

(1)

Signal-to-(Noise + Distortion) Ratio

f

IN

= 1kHz

83

86

86

88

dB

(2)

f

IN

= 1kHz (60dB)

32

*

dB

f

IN

= 25kHz

82

*

dB

Total Harmonic Distortion

f

IN

= 1kHz

90

86

91

89

dB

Spurious-Free Dynamic Range

f

IN

= 1kHz

89

92

92

94

dB

Signal-to-Noise Ratio (SNR)

f

IN

= 1kHz

84

88

87

89

dB

DC ACCURACY

Gain Error

±

5

*

%

Gain Error Mismatch

DSP102 Channels

±

2

*

%

Integral Linearity

±

2.75V Input Range

Differential Linearity

±

2.75V Input Range

Integral Linearity Error

±

0.7V Input Range

±

0.003

*

%

Differential Linearity Error

±

0.7V Input Range

±

0.002

*

%

No Missing Codes

±

0.7V Input Range

14

*

Bits

Bipolar Zero Error

(3)

±

2

mV

Bipolar Zero Mismatch

(3)

DSP102 Channels

±

2

mV

Power Supply Sensitivity

5.25V < V

A

< 4.75V

60

*

dB

+4.75V < V

A

+, V

D

+ < +5.25V

60

*

dB

SAMPLING DYNAMICS

Aperture Delay

30

*

ns

Aperture Jitter

100

*

ps, rms

Transient Response

1

*

µ

s

Overvoltage Recovery

5

*

µ

s

DIGITAL INPUTS

Logic Levels (Except OSC1)

V

IL

I

L

=

±

10

µ

A

0

+0.8

*

*

V

V

IH

I

H

=

±

10

µ

A

+2.4

+5

*

*

V

OSC1 Clock

74HC Compatible

Frequency

16

MHz

Data Transfer Clock (XCLK)

Frequency

0.1

12

*

*

MHz

Duty Cycle

40

50

60

*

*

%

Conversion Clock (CLKIN)

Frequency

0.5

5.33

*

*

MHz

Duty Cycle

25

33

55

*

*

*

%

DIGITAL OUTPUTS

Format

Serial; MSB first; 16/18-bit and Cascaded 32-bit Mode

Coding

Binary Two's Complement

Logic Levels (Except OSC2)

V

OL

I

SINK

= 4mA

0

+0.4

*

*

V

V

OH

I

SOURCE

= 4mA

+2.4

+5

*

*

V

OSC2

Can only be used to drive crystal oscillator.

Conversion Clock (CLKOUT)

Drive Capability

±

2mA

*

mA

POWER SUPPLIES

Rated Voltage

V

A

+

+4.75

+5

+5.25

*

*

*

V

V

A

5.25

5

4.75

*

*

*

V

V

D

+4.75

+5

+5.25

*

*

*

V

Power Consumption

XCLK = OSC1 = 12MHz

250

425

*

*

mW

Supply Current

XCLK = OSC1 = 12MHz

I

A

+

30

45

*

*

mA

I

A

18

25

*

*

mA

I

D

5

15

*

*

mA

TEMPERATURE RANGE

Specification

0

+70

*

*

o

C

Storage

65

+125

*

*

o

C

NOTES: (1) All dynamic specifications are based on 2048-point FFTs, using four-term Blackman-Harris window. (2) All specifications in dB are referred to a full-

scale input,

±

2.75Vp-p. (3) Adjustable to zero with external potentiometer.

®

DSP101/102

3

DSP102 CHANNEL SEPARATION ON CHANNEL B WITH

±2.75V, 1kHz INPUT ON CHANNEL A

Frequency (kHz)

0

0

Magnitude (dB)

20

40

60

80

100

120

25

50

75

100

FREQUENCY SPECTRUM of ±2.75V, 451kHz INPUT

(Using Four-Term Blackman-Harris Window)

Frequency (kHz)

0

0

Magnitude (dB)

20

40

60

80

100

120

25

50

75

100

Undersampling

SINAD means Signal-to-(Noise + Distortion) Ratio.

THD means Total Harmonic Distortion thru 8th harmonic.

SNR means Signal-to-Noise Ratio excluding harmonics

SFDR means Spurious Free Dynamic Range, including

thru the 8th.

harmonics.

TYPICAL PERFORMANCE CURVES

At T

A

= +25

°

C, V

A

+ = V

D

+ = +5V, V

A

= V

D

= 5V, Sampling Frequency f

S

= 200kHz; External Clock Input at OSC1 = 80f

S

= 16MHz, XCLK = 40f

S

= 8MHz; Using

2048 Point FFT; Data analysis limited to 0 to 20kHz band; Unless otherwise specified.

55 40 25

0

25

70

85

125

Ambient Temperature (°C)

DYNAMIC PERFORMANCE vs TEMPERATURE

SINAD, SNR and SFDR (dB)

THD (dB)

80

85

90

95

80

85

90

95

100

100

f

IN

= 1kHz, ±2.75V

SINAD

THD

SNR

SFDR

FREQUENCY SPECTRUM of ±2.75V, 1kHz INPUT

(Average of 12 FFTs, No Window Used)

Frequency (kHz)

0

0

25

50

75

100

Magnitude (dB)

30

60

90

120

FREQUENCY SPECTRUM of ±2.75V, 20kHz INPUT

(Using Four-Term Blackman-Harris Window)

Frequency (kHz)

0

0

Magnitude (dB)

20

40

60

80

100

120

25

50

75

100

INTERMODULATION DISTORTION WITH 1kHz AND 3kHz INPUTS

(Using Four-Term Blackman-Harris Window)

Frequency (kHz)

0

0

Magnitude (dB)

20

40

60

80

100

120

25

50

75

100

®

DSP101/102

4

55 40 25

0

25

70

85

125

Ambient Temperature (°C)

DYNAMIC PERFORMANCE vs TEMPERATURE

(Data Analysis Over Full 0 to 100kHz Band)

SINAD, SNR and SFDR (dB)

THD (dB)

75

80

85

90

95

75

80

85

90

95

100

100

f

IN

= 1kHz, ±2.75V

SINAD

THD

SFDR

SNR

TYPICAL PERFORMANCE CURVES

(CONT)

At T

A

= +25

°

C, V

A

+ = V

D

+ = +5V, V

A

= V

D

= 5V, Sampling Frequency f

S

= 200kHz; External Clock Input at OSC1 = 80f

S

= 16MHz, XCLK = 40f

S

= 8MHz; Using

2048 Point FFT; Data analysis limited to 0 to 20kHz band; Unless otherwise specified.

000E

Output Code and Equivalent Voltage

(Binned at 16-bit level)

HISTOGRAM OF 5k CONVERSION RESULTS ON DSP102

(Both Inputs Grounded)

Number of Conversions Yielding This Code

2500

2000

1500

1000

500

0

Channel A

Channel B

1.17mV

0000

0V

FFF7

FFF1

1.26mV

Code

Voltage

70

75

80

85

90

95

70

75

80

85

90

95

100

100

30

0

60

90

120

150

180

Conversion Rate (kHz)

SINAD, SNR and SFDR (dB)

THD (dB)

DYNAMIC PERFORMANCE vs CONVERSION RATE

(Data Analysis over Full 0 to f

S

/2 Band,

OSC1 = 12.288MHz, XCLK = 3.072MHz)

SINAD

SNR

THD

SFDR

f

IN

= 1kHz, ±2.75V (0dB)

60

70

80

90

1

10

100

1000

Input Frequency (kHz)

Total Harmonic Distortion (dB)

TOTAL HARMONIC DISTORTION

vs INPUT FREQUENCY

100

±2.75V Input (0dB)

55 40 25

0

25

70

85

125

Ambient Temperature (°C)

DYNAMIC PERFORMANCE vs TEMPERATURE

(f

S

= 180kHz Asychronous to 12.288MHz

Crystal Between OSC1 and OSC2)

SINAD, SNR and SFDR (dB)

THD (dB)

70

75

80

85

90

95

70

75

80

85

90

95

100

100

Ambient Temperature (°C)

f

IN

= 1kHz, ±2.75V

THD

SFDR

SNR

SINAD

100

90

80

70

60

50

40

30

20

10

0.1

1

10

100

Input Frequency (kHz)

SINAD (dB)

SINAD vs INPUT FREQUENCY

(Data Analysis over Full 0 to 100kHz Band)

0

±2.75V Input (0dB)

±0.275V Input (20dB)

±2.75mV Input (60dB)

®

DSP101/102

5

TYPICAL DSP102 FFT SETUP

REF

VINB

VPOTB

Burr-Brown

ZPB34

DSP

Processor

CASC

SSF

OSC1

CLKOUT

CLKIN

CONV

XCLK

SYNC

SOUTA

DSP102

22

12

11

15

20

200kHz

150

16MHz TTL Oscillator

FFT

Software

÷80

÷2

+5V

10

13

21

16

8MHz

27

26

25

0.1µF

1

10µF

+

10µF

+

220pF

150

220pF

Brüel & Kjaer

Model 1049

Digital Signal

Generator

6 Pole,

150kHz

Low-Pass

Filter

1kHz

1/2

OPA2604

1/2

OPA2604

2

VPOTA

±2.75V

VINA

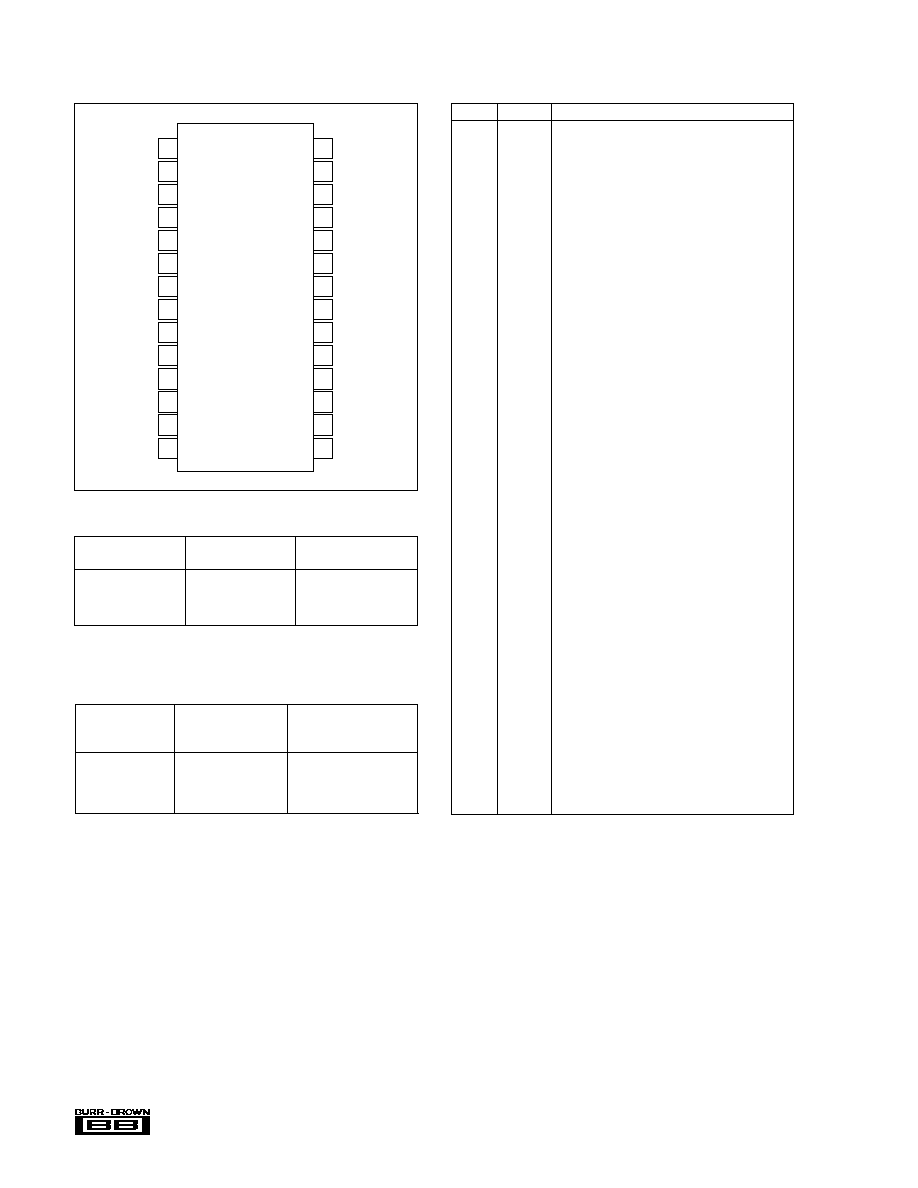

DSP101 PIN ASSIGNMENTS

PIN #

NAME

DESCRIPTION

1

VPOT

Trim Reference Out. 10

µ

F Tantalum to AGND.

Voltage on this pin is approximately 2.75V.

2

VIN

Analog In.

3

MSB

MSB Adjust In.

4

VOS

VOS Adjust In.

5

V

A

5V Analog Power.

6

V

A

+

+5V Analog Power.

7

DGND

Digital Ground.

8

DGND

Digital Ground.

9

V

D

+5V Digital Power.

10

CLKIN

Conversion Clock In.

11

CLKOUT

Conversion Clock Out. Can drive multiple

DSP101/DSP102s to synchronize conversion.

12

SSF

Select Synch Format In. If HIGH, SYNC will be

active High. If LOW, SYNC will be active Low.

See timing diagram (Figure 1).

13

OSC1

Oscillator Point 1 Input/External Clock In. If using

external clock, drive with 74HC logic levels.

Connect to DGND if not used.

14

OSC2

Oscillator Point 2 Output. Provides drive for

crystal oscillator. Make no electrical connection if

using external clock.

15

SYNC

Data Synchronization Out. Active High when SSF

is HIGH; active Low when SSF is LOW.

16

XCLK

Data Transfer Clock In.

17

No Internal Connection.

18

TAG

User Tag In. Data clocked into this pin is

appended to the conversion results on SOUT.

See timing diagram (Figure 1).

19

No Internal Connection.

20

SOUT

Serial Data Out. MSB first, Binary Two's

Complement format.

21

CONV

Convert Command In. Falling edge puts converter

into hold state, initiates conversion, and transmits

previous conversion results to DSP IC with

appropriate SYNC pulse.

22

DGND

Digital Ground.

23

No Internal Connection.

24

No Internal Connection.

25

No Internal Connection.

26

CAP

Bypass Capacitor. 10

µ

F Tantalum to AGND.

Voltage on this pin is approximately 2.7V.

27

REF

Reference Bypass. 0.1

µ

F Ceramic to AGND.

Voltage on this pin is approximately 3.8V.

28

AGND

Analog Ground.

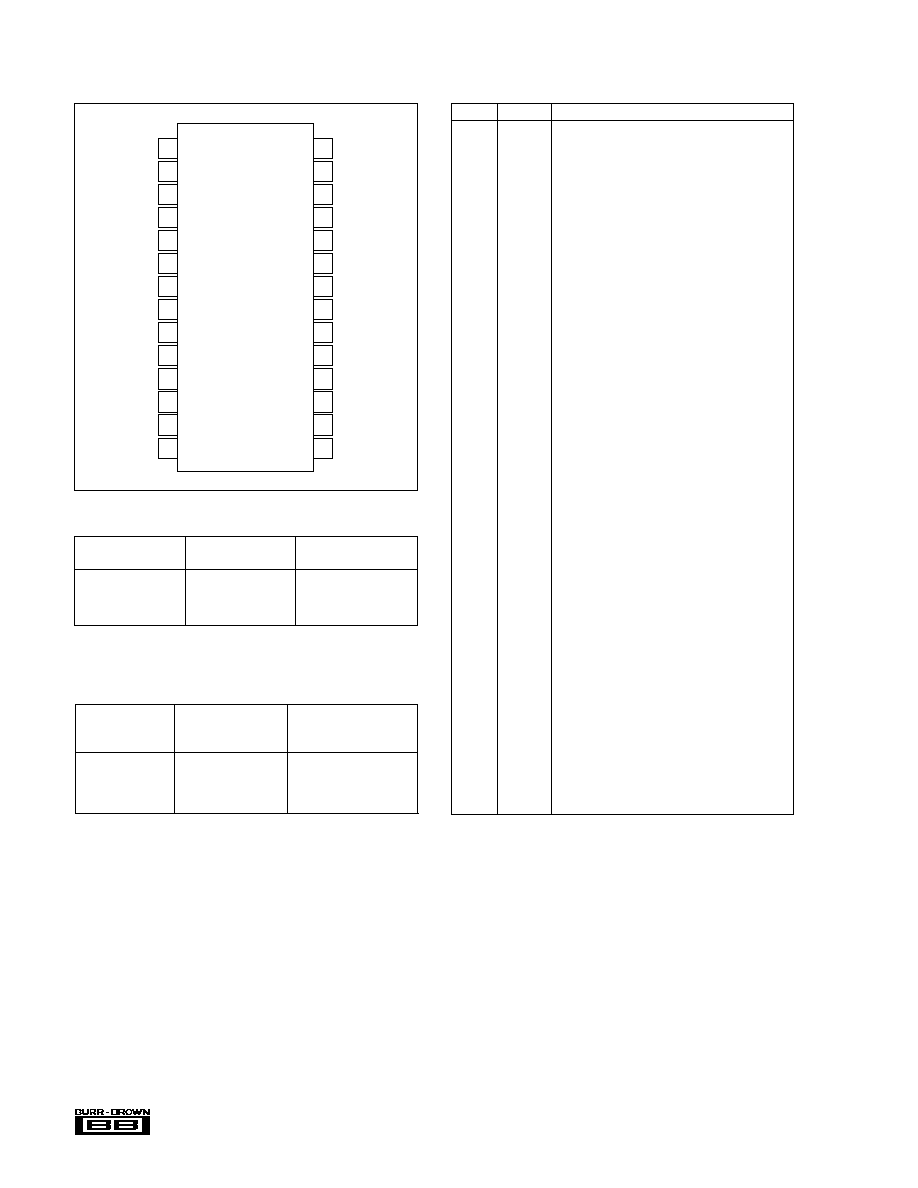

DSP101 PIN CONFIGURATION

ABSOLUTE MAXIMUM RATINGS

V

A

+ to Analog Common .................................................................... +7V

V

A

to Analog Common .................................................................... 7V

V

D

to Digital Common ........................................................................ +7V

Analog Common to Digital Common ...................................................

±

1V

Control Inputs to Digital Common ............................... 0.5 to V

D

+ 0.5V

Analog Input Voltage ..........................................................................

±

5V

Maximum Junction Temperature .................................................... 150

o

C

Internal Power Dissipation ............................................................. 825mW

Lead Temperature (soldering, 10s) ............................................... +300

o

C

Thermal Resistance,

JA

, Plastic DIP ............................................ 50

o

C/W

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VPOT

VIN

MSB

VOS

V

V +

DGND

DGND

V

D

CLKIN

CLKOUT

SSF

OSC1

OSC2

A

A

AGND

REF

CAP

DGND

CONV

SOUT

TAG

XCLK

SYNC

DSP101

Top View

DIP

®

DSP101/102

6

DSP102 PIN ASSIGNMENTS

PIN #

NAME

DESCRIPTION

1

VPOTA

Channel A Trim Reference Out. 10

µ

F Tantalum to

AGND. Voltage on this pin is approximately 2.75V.

2

VINA

Channel A Analog In.

3

MSBA

Channel A MSB Adjust In.

4

VOSA

Channel A VOS Adjust In.

5

V

A

5V Analog Power.

6

V

A

+

+5V Analog Power.

7

DGND

Digital Ground.

8

DGND

Digital Ground.

9

V

D

+5V Digital Power.

10

CLKIN

Conversion Clock In.

11

CLKOUT

Conversion Clock Out. Can drive multiple DSP101/

DSP102s to synchronize conversion.

12

SSF

Select Synch Format In. If HIGH, SYNC will be

active High. If LOW, SYNC will be active Low. See

timing diagram (Figure 1).

13

OSC1

Oscillator Point 1 Input / External Clock In. If using

external clock, drive with 74HC logic levels.

Connect to DGND if not used.

14

OSC2

Oscillator Point 2 Output. Provides drive for crystal

oscillator. Make no electrical connection if using

external clock.

15

SYNC

Data Synchronization Out. Active High when SSF

is HIGH; active Low when SSF is LOW.

16

XCLK

Data Transfer Clock In.

17

SOUTB

Channel B Serial Data Out. MSB first, Binary

Two's Complement format.

18

TAGA

Channel A User Tag In. Data clocked into this pin

is appended to the conversion results of SOUTA.

See timing diagram (Figure 1).

19

TAGB

Channel B User Tag In. Data clocked into this pin

is appended to the conversion results of SOUTB.

See timing diagram (Figure 1).

20

SOUTA

Channel A Serial Data Out. MSB first, Binary

Two's Complement format. If CASC is HIGH, 32

bits of data output, with first 16 bits being Channel

A data.

21

CONV

Convert Command In. Falling edge puts converter

into hold state, initiates conversion, and transmits

previous conversion results to DSP IC with

appropriate SYNC pulse.

22

CASC

Select Cascade Mode In. If HIGH, DSP102

transmits a 32-bit word on SOUTA, with the first 16

bits being data on Channel A. If LOW, DSP102

transmits data for both channels simultaneously.

23

VOSB

Channel B VOS Adjust In.

24

MSBB

Channel B MSB Adjust In.

25

VINB

Channel B Analog In.

26

VPOTB

Channel B Trim Reference Out. 10

µ

F Tantalum to

AGND. Voltage on this pin is approximately 2.75V.

27

REF

Reference Bypass. 0.1

µ

F Ceramic to AGND.

Voltage on this pin is approximately 3.8V.

28

AGND

Analog Ground.

DSP102 PIN CONFIGURATION

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

Top View

DIP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VPOTA

VINA

MSBA

VOSA

V

A

V

A

+

DGND

DGND

V

D

CLKIN

CLKOUT

SSF

OSC1

OSC2

AGND

REF

VPOTB

VINB

MSBB

VOSB

CASC

CONV

SOUTA

TAGB

TAGA

SOUTB

XCLK

SYNC

DSP102

ORDERING INFORMATION

NUMBER

SIGNAL-TO-

OF

(NOISE + DIST.) RATIO

MODEL

CHANNELS

dB min

DSP101JP

1

83

DSP101KP

1

86

DSP102JP

2

83

DSP102KP

2

86

PACKAGE INFORMATION

PACKAGE DRAWING

MODEL

PACKAGE

NUMBER

(1)

DSP101JP

28-Pin Plastic DIP

215

DSP101KP

28-Pin Plastic DIP

215

DSP102JP

28-Pin Plastic DIP

215

DSP102KP

28-Pin Plastic DIP

215

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix D of Burr-Brown IC Data Book.

®

DSP101/102

7

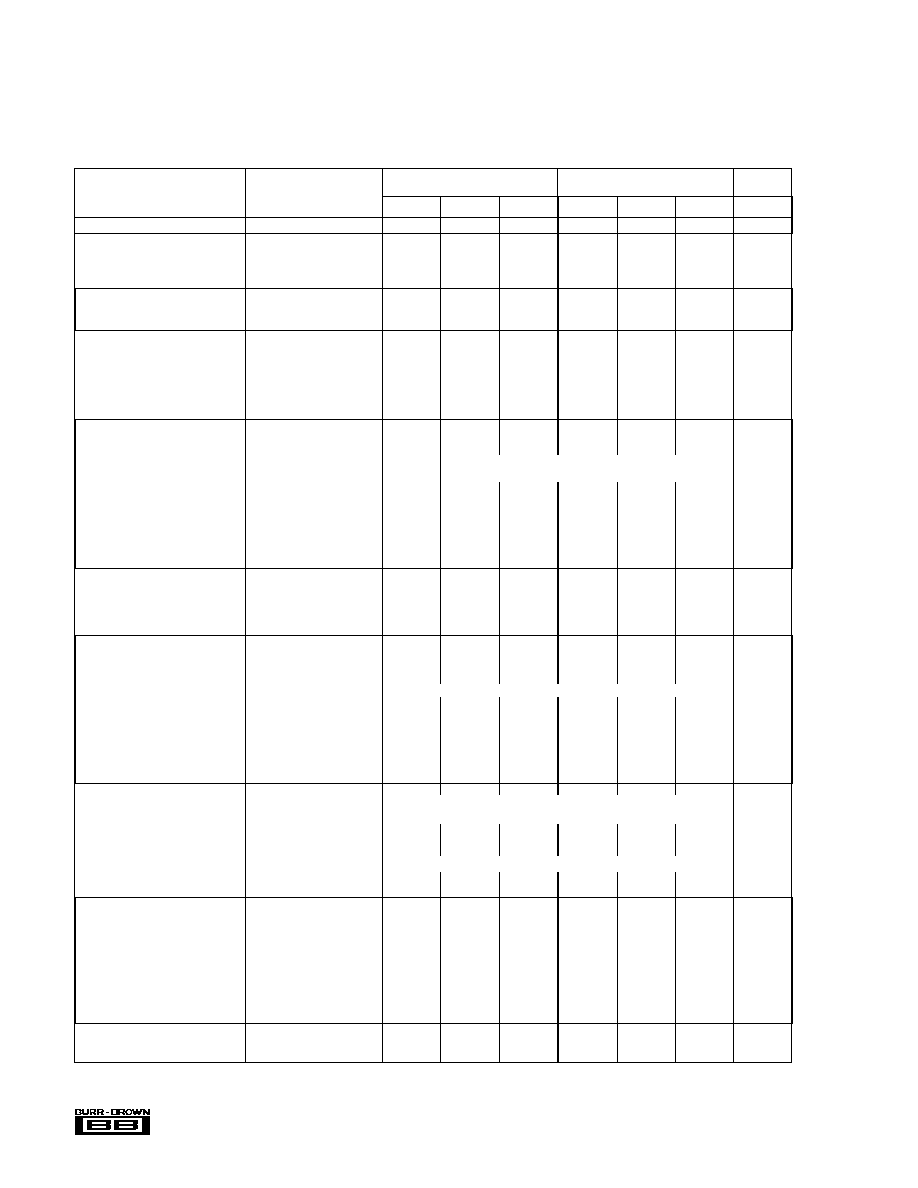

FIGURE 1. DSP101 and DSP102 Timing.

NOTES: (1) When using a DSP IC in a 16-bit mode, these data bits will be ignored by the processor. (2) f

OSC1

must be at least 72 times faster than the conversion rate. (t

3

, t

4

72 t

12

)

SYMBOL

DESCRIPTION (C

L

= 50pF)

MIN

MAX

UNITS

t

1

XCLK period. Duty Cycle 50%

±

10%

83

ns

t

2

Convert Command LOW Time

50

ns

t

3

Convert Period (CASC = LOW on DSP102)

24

t

1

t

4

Convert Period (CASC = HIGH on DSP102)

40

t

1

t

5

SYNC Active Delay after Convert Falling Edge

t

1

+40

2 t

1

ns

t

6

SYNC LOW to HIGH Delay from XCLK Rising

15

ns

t

7

SYNC HIGH to LOW Delay from XCLK Rising

15

ns

t

8

SOUTA/B Data Valid Delay from XCLK Rising

15

ns

t

9

SOUTA/B Data Valid After from XCLK Rising

10

ns

t

10

TAGA/B Data Setup before XCLK Rising

20

ns

t

11

TAGA/B Data Hold after XCLK Rising

0

n

s

t

12

OSC1 Period.

(2)

Duty Cycle 50%

±

10%

62

667

ns

t

13

CLKOUT Period. Duty Cycle 33%

±

1

0

%

3

t

12

ns

t

14

CLKIN Period. Duty Cycle 33%

±

20%

186

2000

ns

t

15

CLKIN HIGH

62

1050

t

16

CLKIN LOW

84

1340

t

12

t

13

t

14

OSC1

CLKOUT

CLKIN

Conversion Clock Timing

(2)

t

15

t

16

XCLK

CONV

SYNC (SSF = HIGH)

SYNC (SSF = LOW)

XCLK

CONV

SOUTA (CASC = HIGH)

Bit 1 (MSB)

t

2

t

5

t

3

t

2

t

6

t

7

t

6

t

7

t

4

t

9

Bit 1 (MSB)

Bit 2

Bit 16 (LSB)

t

2

t

1

t

1

t

2

Bit 16

DSP102 Cascade Mode (CASC = HIGH)

Channel A Data

Channel B Data

SOUTA/B (CASC = LOW on DSP102)

t

9

Bit 1 (MSB)

Bit 2

Bit 16

Bit 17

Bit 18 (LSB)

(1)

(2)

t

8

TAG Bit 1

TAG Bit 2

TAGA/B

t

11

TAG Bit 1

TAG Bit 2

t

10

t

8

®

DSP101/102

8

THEORY OF OPERATION

The DSP101 and DSP102 are sampling analog-to-digital

converters optimized for handling dynamic signals. They

have complete logic interface circuitry for ease of use with

standard digital signal processing ICs, and transmit data

words in a serial stream. The successive approximation

conversion architecture is combined with an inherently sam-

pling switched capacitor array to provide maximum user

flexibility over sampling and conversion timing.

The DSP101 and DSP102 are pipelined internally. When the

user gives a convert command at time (t), two actions are

initiated. First, the internal sample/holds are switched to the

hold state, and a conversion cycle is initiated. At the same

time, the DSP101 or DSP102 transmits a synchronization

pulse and starts shifting out the conversion results from the

previous convert command at (t-1) using the system bit

clock. The data from the conversion at time (t) is shifted out

of the converter after the next convert command is received.

Both the DSP101 and the DSP102 are 18-bit A/Ds inter-

nally. When the DSP IC is programmed to accept 16-bit

word lengths, the processor will ignore the last two data bits

transmitted from the DSP101 or DSP102. A Cascade Mode

on the DSP102 can be invoked to transmit data for both

conversion channels over a single serial line as a 32-bit

word. In this mode, the first 16 bits of data transmitted after

the Sync pulse contain data from channel A, followed by 16

bits of information from channel B, allowing a single 32-bit

word to contain data for both channels.

A unique Tag feature allows additional digital data to be

appended to the conversion results, so that a single data

word contains conversion results plus other signal informa-

tion, such as gain settings or multiplexer channel settings in

front of the converter.

The DSP101 and DSP102 are high-resolution A/D convert-

ers complete with sampling capability and on-board refer-

ences. They can acquire and convert analog signals at up to

a 200kHz sampling rate. Both operate from

±

5V supplies,

and have full-scale analog input ranges of

±

2.75V.

BASIC OPERATION

Figure 2 shows the minimum connections required to oper-

ate the DSP101. The falling edge of a convert command on

pin 21 puts the internal sampling capacitor array into the

hold state. The falling edge on pin 21 also starts the process

to initiate a conversion and transmit data from the previous

conversion, synchronizing both appropriately to the 10MHz

clock input on pin 13. Figure 1 shows the timing relationship

between the convert command, the output data, and the

synchronization pulse.

In this basic system, the 10MHz clock is used both to

generate a 3.33MHz conversion clock and as the data trans-

fer bit clock for outputting data. Per Figure 1, there must be

at least 72 clock pulses on pin 13 between convert com-

mands, so that this circuit can sample and convert at up to

138kHz.

FIGURE 2. DSP101 Basic Operation.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

10µF

10µF

0.1µF

AGND

REF

CAP

NC

NC

NC

DGND

CONV

SOUT

NC

TAG

NC

XCLK

SYNC

DSP101

+

+

10µF

5V

+5V

NOTES: (1) Leave Unconnected.

(2) Protection from power supply momentary overrange.

VPOT

VIN

MSB

VOS

VA

VA+

DGND

DGND

VD

CLKIN

CLKOUT

SSF

OSC1

OSC2

(1)

(1)

(1)

(1)

(1)

= Analog Ground

= Digital Ground

Convert Command

Serial Data Output

Synch

Pulse

Bit Clock

10µF

+5V

10MHz, 50%

(±10%) 74HC

Logic Level Clock Input

±2.75 Analog Input

10µF

+

+

5V

+

(1)

(1)

(1)

10

(

2)

®

DSP101/102

9

The convert command at pin 21 causes a Sync pulse to be

output on pin 15, followed by the data from the previous

conversion output on pin 20. The Sync pulse will be HIGH

for one bit clock cycle, since pin 12 is tied HIGH. (A LOW

Sync pulse will be output on pin 15 if pin 12 is tied LOW.)

Data is serially transmitted in an MSB-first data stream, in

Binary Two's Complement format. Both the Sync pulse (pin

15) and the data stream (pin 20) are synchronized to the bit

clock (at pins 13 and 16), with the timing relationships

shown in Figure 1.

After the 18 bits of data from the previous conversion have

been transmitted, pin 20 will continue to clock out LOWs

until a new convert command restarts the process, since pin

18 (the Tag input) is grounded. If pin 18 is tied HIGH, pin

20 will clock out HIGHs between conversion cycles.

CONVERSION

A falling edge on pin 21 (CONV) puts the internal sampling

capacitors in the hold state with minimum aperture jitter,

initiates a conversion synchronized to the conversion clock,

and outputs the data from the previous conversion with an

appropriate Sync pulse. On the DSP102, a single convert

command simultaneously samples both channels. The tim-

ing relationship between the convert command, Sync and

the output data is shown in Figure 1. Both Sync and the

output data are synchronized to XCLK, the system bit clock.

Following a convert command falling edge, pin 21 must be

held LOW at least 50ns.

Convert commands can be sent to the DSP101 and DSP102

completely asynchronous to other clocks in the system. This

allows external events to be used to trigger conversions.

From Figure 1, it can be seen that two different clocking

conditions must be considered in determining the minimum

acceptable time between convert commands. First, there

need to be a minimum of 24 XCLK periods between convert

commands, to allow internal synchronization and transmis-

sion of Sync and the data. (In the Cascade Mode on the

DSP102, there need to be at least 40 XCLK periods between

convert commands, to allow transmission of the 32-bit data

words.) When used with DSP processors programmed for

data words longer than 16 bits, the transmission time to the

processor may determine the minimum time between con-

vert commands.

The second limitation on convert commands is the require-

ment that the internal analog-to-digital converter be given

enough time to complete a conversion, shift the data to the

output register, and acquire a new sample. This condition is

met by having a minimum of 24 CLKIN periods between

convert commands, or a minimum of 72 clock cycles on

OSC1, if it is used to generate the conversion clock (CLKOUT

driving CLKIN).

SIGNAL ACQUISITION

After a conversion is completed, the DSP101 or DSP102

will switch back to the sampling mode. With at least 24

CLKIN periods between convert commands, the A/D will

have had sufficient time to acquire a new input sample to full

rated accuracy.

DATA FORMAT AND INPUT LEVELS

The DSP101 and DSP102 output serial data, MSB first, in

Binary Two's Complement format. In the Cascade Mode on

the DSP102, the serial data will first contain 16 bits of data

for channel A, MSB-first, followed by channel B data, again

MSB-first. The analog input levels that generate specific

output codes are shown in Table I.

As with all standard A/Ds, the first output transition will

occur at an analog input voltage 1/2 LSB above negative full

scale (2.75V + 1/2 LSB) and the last transition will occur

3/2 LSB below positive full scale (+2.75V 3/2 LSB.) See

Figure 3.

1FFFF

H

1FFFE

H

00001

00000

H

3FFFF

H

20001

H

20000

H

Digital Output (18-bit Words)

0.00V

+2.749979V

20.98µV

2.75V

H

FIGURE 3. Analog Input to Digital Output Diagram.

DIGITAL OUTPUT

(BINARY TWO'S COMPLEMENT)

16-BIT

18-BIT

ANALOG

WORDS

WORDS

DESCRIPTION

INPUT

BINARY CODE

(HEX)

(HEX)

Least Significant Bit

(LSB = )

16-bit Words

84

µ

V

18-bit Words

21

µ

V

Input Range

±

2.75V

+ Full Scale

+2.749916V

7FFF

(2.75V1LSB)

+2.749979V

1FFFF

Bipolar Zero

(Midscale)

One LSB below

84

µ

V

FFFF

Bipolar Zero

21

µ

V

3FFFF

Full Scale

2.75V

100...000

8000

20000

5.5V

2

n

TABLE I. Ideal Input Voltage vs Output Code.

0V

000...000

0000

00000

011...111

111...111

®

DSP101/102

10

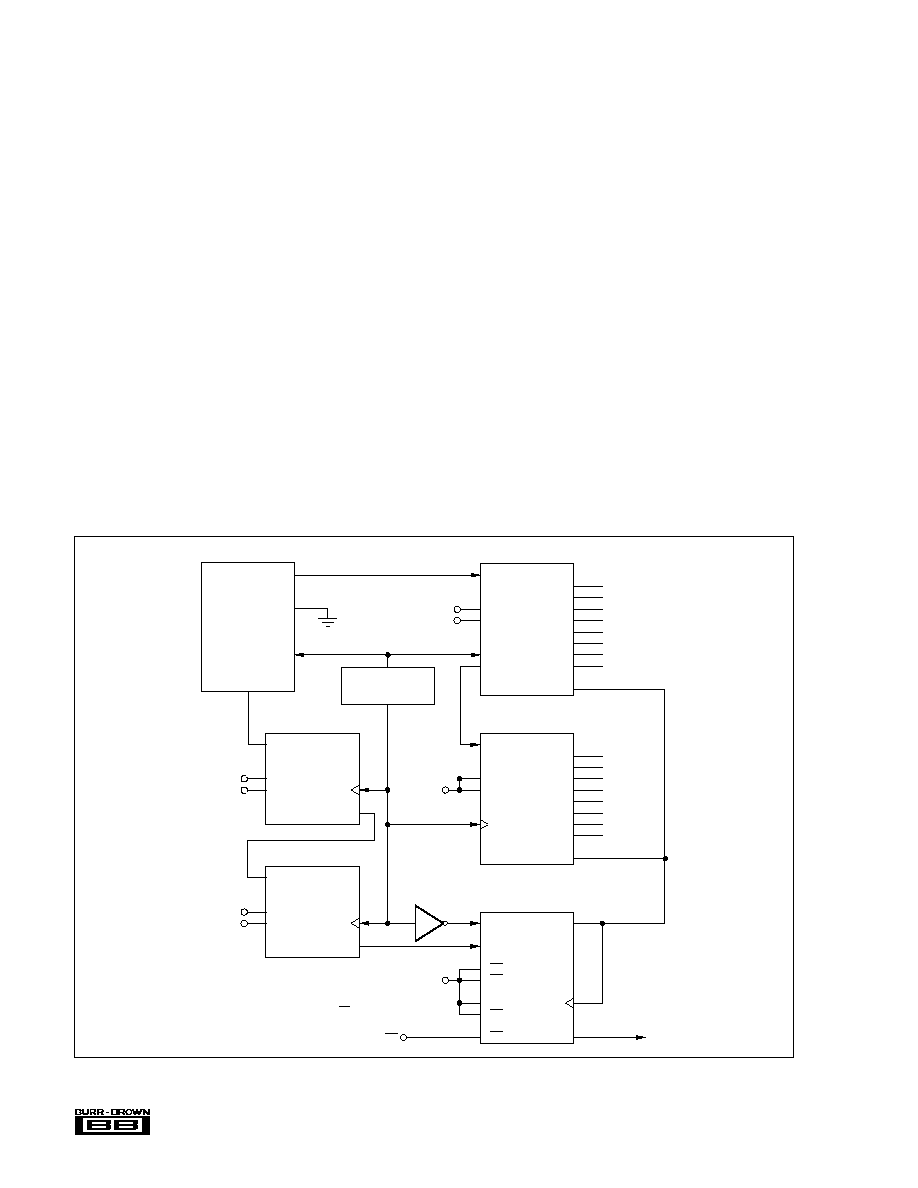

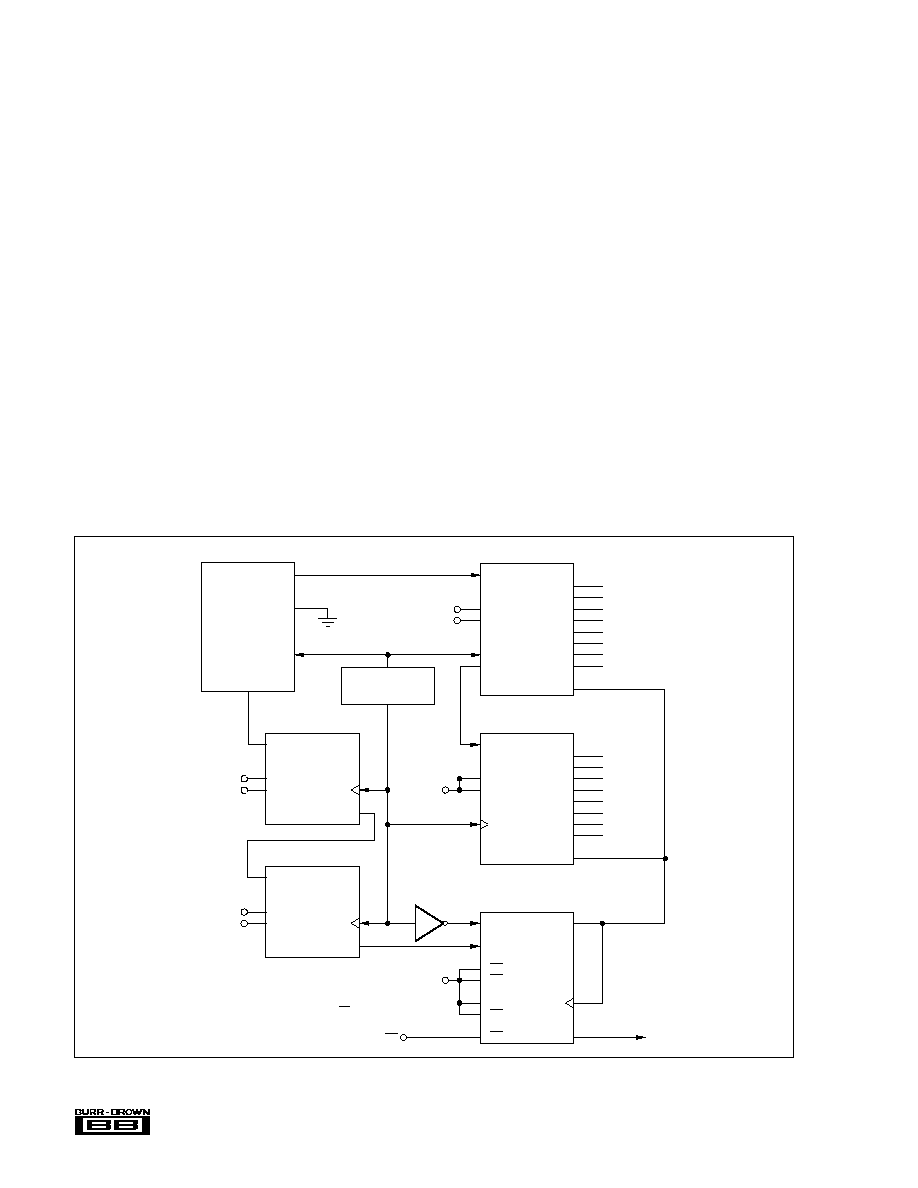

FIGURE 4. Output Structure of DSP102.

DATA TRANSFER

The internal A/Ds generate 18 bits of data, transmitting the

data MSB first. When read by a DSP IC programmed to

accept 16 bits of data, the first 16 MSB bits of data from the

DSP101, or each channel of the DSP102, will be shifted into

the processor's input shift register, and the last two least

significant bits of data from the A/D will be ignored,

although they will still be present on the serial data line.

When the DSP processor is programmed to accept words of

more than 16-bit length (typically 24-bit or 32-bit), the

DSP101 and DSP102 will transmit the full 18-bit conversion

results, after which the information input on the TAG input

(or TAGA and TAGB on the DSP102) will be appended to

the output word. (See Tag Feature below.)

In the Cascade Mode, the DSP102 will first transmit the 16

MSBs from channel A, followed by the full 18 bits from

channel B, although DSP processors programmed to accept

32 bits of data will ignore the final two bits of information

on Channel B. See the DSP102 Cascade Mode section below

for details of the Cascade mode.

DATA SYNCHRONIZATION

A convert command both initiates a conversion and starts

the process for transmitting data from the previous conver-

sion. Convert commands can come at any time, completely

asynchronous to the conversion clock or the bit clock, and

the conversion clock may also be independent of the bit

clock. The DSP101 and DSP102 internally synchronize the

output data, Sync pulse, and Tag inputs to the bit clock.

While the convert command, conversion clock and bit clock

can be asynchronous, system performance is usually en-

hanced by synchronizing all of them to a system master

clock, whenever the application permits. This minimizes

changes in digital loads and currents when the critical S/H

transition and A/D bit decisions are occurring. Within the

DSP101 and DSP102 themselves, running asynchronous

convert commands, conversion clocks and bit clocks typi-

cally degrades performance only several dB, as shown in the

various typical performance curves, but the system board

design can easily have more effect.

When a convert command is received, the internal logic

generates an appropriate Sync pulse, synchronized to XCLK,

as shown in Figure 1. The output Sync pulse will be active

High or active Low depending on whether a HIGH or a

LOW, respectively, is input at SSF (pin 12).

The convert command also causes the conversion results

from the previous conversion to be loaded into the output

shift register, synchronous to XCLK. Figure 4 shows the

operation of the internal data shift registers on the DSP102.

The DSP101 is basically similar, but includes only the top of

the figure, showing the SOUTA path.

(LSB)

18

16

14

12

10

8

6

4

2

(MSB)

1

18-bit Register

Channel B Conversion Results from SAR

Shift/Load

(1)

CONV

CLKIN

XCLK

TAGB

18

(LSB)

D

1

16

14

12

10

8

6

4

2

1

(MSB)

18-bit Register

Channel A Conversion Results from SAR

CONV

CLKIN

XCLK

Shift/Load

(1)

TAGA

18-bit Shift Register

18-bit Shift Register

18-bit Shift Register

18-bit Shift Register

SOUTA

SOUTB

D

2

E

CASC

NOTE: (1) Signal internal to DSP101/DSP102 which also generates SYNC pulse.

RCK

D1

D1

D

RCK

D

®

DSP101/102

11

During the internal successive approximation conversion

process, the conversion results are shifted into the input shift

registers of the output stage on the DSP102. A new convert

command latches that data into the 18-bit parallel latches

shown. The internal signal that also generates the Sync

pulse, labeled "Shift/Load" in Figure 4, synchronously loads

the conversion data into the output shift register on the rising

edge of XCLK. The conversion results are then clocked out

of the shift register on subsequent rising edges of XCLK.

DATA TRANSFER CLOCK

XCLK is the data transfer clock, or bit clock, for the system,

and is an input for the DSP101 or DSP102. This input is

TTL- and 74HC-level compatible. The serial data and SYNC

outputs are synchronized internally to this clock, with data

valid on the rising edge of XCLK, per the timing shown in

Figure 1. Data input on pin 18 (TAG) on the DSP101, or on

pins 18 and 19 on the DSP102 (TAGA and TAGB), will be

clocked into the output shift register on the rising edge of

XCLK, as discussed in the Tag Feature section.

CONVERSION CLOCK

The analog-to-digital converter sections in the DSP101 and

DSP102 were designed to provide accurate conversions

under worst case conditions of supplies, temperatures, etc.

In order to achieve a full 200kHz sampling capability, they

were designed to use a 33% duty cycle conversion clock

(CLKIN on pin 10) as shown in Figure 1. The clock is LOW

FIGURE 6. DSP101 or DSP102 Power Supply Connections.

FIGURE 5. DSP101 or DSP102 Conversion Clock Circuit.

To other

DSP102's CLKIN for

synchronous operation

1M

Crystal is CTS Knight MP122 12.288MHz,

20pF load, series resonant mode.

12.288MHz

÷3

SAR Clock

Control

10pF

10

11

DSP101 or DSP102

CLKOUT

OSC2

OSC1

13

14

10pF

CLKIN

long enough for internal analog circuitry to settle suffi-

ciently between bit decisions to insure rated accuracy. Bit

decisions in the A/D are then made on the rising edge of

CLKIN.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

10µF

10µF

0.1µF

VPOTA

AGND

REF

VPOTB

10µF

DSP101 or DSP102

+

+

+

+

10µF

0.01µF

5V Analog

+5V Analog

+5V Digital

V

V +

DGND

DGND

V

A

A

D

= Analog Ground

= Digital Ground

(1)

(1)

NOTES: (1) Pin 1 and pin 26 must be bypassed with 10µF tantalum capacitors, on both the DSP101 and DSP102.

(2) Protection from power supply momentary overrange.

10

(2)

®

DSP101/102

12

When a convert command is received, the DSP101 or

DSP102 immediately switches the sampling capacitors to

the hold state, and then internally gates the conversion clock

to the A/D appropriately. Allowing a minimum of 24 CLKIN

pulses between conversions insures that there is sufficient

time for complete, accurate conversions, and allows the

input sampling capacitor to fully acquire the next sample,

regardless of the timing between the convert command and

CLKIN.

In most applications, CLKIN (pin 10) can be driven from a

50% duty cycle clock without performance degradation.

During characterization of the DSP101 and DSP102, the

performance of a number of parts was measured under

various conditions with a 4.8MHz, 50% duty cycle input to

CLKIN at a full 200kHz conversion rate without noticeable

degradation.

OSCILLATOR INPUTS AND CLKOUT

The DSP101 or DSP102 can generate a 33% duty cycle

conversion clock output on CLKOUT (pin 11). This is

accomplished by dividing by three a clock from either an

external 74HC-level clock or from a crystal oscillator.

CLKOUT can deliver

±

2mA, and can be used to drive

multiple DSP101 or DSP102 CLKINs. See Figure 1 for the

timing relationship between OSC1 and CLKOUT.

To use an external 74HC-level clock, drive the clock into

OSC1 (pin 13), and leave OSC2 (pin 14) unconnected.

To use a crystal oscillator to generate the conversion clock,

refer to Figure 5. Connect the oscillator between OSC1 and

OSC2. OSC2 provides the drive for the crystal oscillator.

This pin cannot be used elsewhere in the system.

FIGURE 7. DSP101 or DSP102 Input Buffering.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

10µF

10µF

0.1µF

VPOTA

VINA

REF

VPOTB

VINB

150

220pF

+

7

5

6

1/2

OPA2604

Analog

Input B

150

+

1/2

OPA2604

Analog

Input A

2.2µF

2.2µF

5V

+5V

3

2

4

8

220pF

DSP101 or DSP102

(1)

+

+

+

+

1

Leave out on DSP101

(1)

NOTE: (1) On DSP101, pin 25 is not internally

connected. Pin 26 must still be bypassed with

the 10µF Tantalum capacitor.

If CLKOUT is not used, both it and OSC2 should be left

unconnected, and OSC1 should be grounded.

TAG FEATURE

Figure 4 shows the implementation of the TAG feature on

the DSP101 and DSP102. When a convert command is

received, the internal Shift/Load signal loads conversion

result data into the output shift register synchronous to

XCLK. Between convert commands, the information input

on TAG (on the DSP101) or on TAGA and TAGB (on the

DSP102) will be clocked into the output shift register on the

rising edges of XCLK. Since this is an 18-bit shift register,

the data input on the Tag lines will be output on SOUT

(DSP101) or SOUTA and SOUTB (DSP102) delayed by 18

bit clocks.

The Tag Feature can be used in various ways. The Tag

inputs can be tied HIGH or LOW to differentiate between

two converters in a system. As discussed in the Applications

section below, the Tag feature can be used to append to the

serial output data word information on multiplexer channel

address, or other digital data related to the input signal (such

as the setting on a programmable gain amplifier.) Another

option would be to daisy-chain multiple DSP101 or DSP102

converters, linking the serial output of one to the Tag input

of the next. This can simplify the transmission of data from

multiple A/Ds over a single optical isolation channel.

DSP102 CASCADE MODE

If pin 22 (CASC) is tied HIGH, the DSP102 will be in the

Cascade Mode. In this mode, when a convert command is

received, the DSP102 will transmit a 32-bit data word on pin

®

DSP101/102

13

20 (SOUTA) containing data for both input channels in two

16-bit words. Referring to Figure 1, the first 16 bits of data

will be the results for channel A, followed by 16 bits of

information for channel B. The data will be transferred MSB

first. A convert command at time (t) will initiate the trans-

mission of the results of the conversion initiated at time

(t 1).

From the descriptions above of the internal shift registers

shown in Figure 4, it can be seen that the DSP102 in the

Cascade Mode actually continues to shift out data after the

32nd bit of the data word. The next two bits clocked out will

be the last two data bits from the full 18-bit conversion on

channel B, after which the information output on SOUTA

will be the information clocked into TAGB 35 bit clock

cycles earlier.

In the Cascade mode on the DSP102, SOUTB will still

output channel B conversion data and tag data as usual.

ANALOG PERFORMANCE

LINEARITY

The DSP101 and DSP102 are optimized for signal process-

ing applications with wide dynamic range requirements.

Linearity is trimmed for best performance in the range

around 0V, which is critical for handling low amplitude

signals. The DSP101 and DSP102 typically have integral

and differential non-linearity below

±

0.003% in the input

range of

±

0.7V, with there being no missing codes at the

14-bit level in this range. Over the full

±

2.75V input range,

the largest non-linearities are centered around the bit #2

transition points at +1.375V and 1.375V levels.

NOISE AND BIPOLAR ZERO ERROR

The equivalent input noise and bipolar zero error of the

DSP101 and DSP102 is shown in the typical performance

section for both channels on a DSP102. The inputs to both

channels were grounded, and the results of 5,000 conver-

sions was recorded. The data shown is binned at the 16-bit

level. The noise results from all sources in the circuit,

including clocks, reference noise, etc.

In a theoretically ideal converter with no offset and no noise,

the results of all 5,000 conversion for each channel would lie

in the bin corresponding to bipolar zero, code 0000. The

typical DSP101 or DSP102 will have offset errors in the

range of 1 to 2mV, and the two channels on the DSP102 will

be matched closer than 2mV. The DSP102 shown in the

typical performance section has the worst offset, 0.8mV,

on channel A, with channel B being less than 1mV different,

and the three sigma noise on either channel being less than

250

µ

V.

INPUT BANDWIDTH

From the typical performance curves, it can be seen that

there is very little degradation in Signal-to-(Noise + Distor-

tion) for input signals up to 100kHz. The wideband sampling

input typically maintains a 60dB Signal-to-(Noise + Distor-

tion) Ratio undersampling 500kHz input signals.

LAYOUT CONSIDERATIONS

Because of the high resolution, linearity and speed of the

DSP101 and DSP102, system design problems such as

ground path resistance, contact resistance and power supply

quality become very important.

FIGURE 8. DSP101 or DSP102 Optional MSB and Offset Adjust.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

0.1µF

VPOTA

MSBA

VOSA

REF

VPOTB

MSBB

VOSB

150k

25k

10µF

47k

25k

+

47k

25k

10µF

150k

25k

+

DSP101 or DSP102

(1)

47k

0.01µF

0.01µF

0.01µF

47k

0.01µF

Leave out on DSP101

(1)

NOTE: (1) On DSP101, pins 23 and 24 are

not internally connected. Pin 26 must still be

bypassed with the 10µF Tantalum capacitor.

®

DSP101/102

14

Optimal dynamic performance is achieved by soldering the

parts directly into boards, to keep the A/Ds as close as

possible to ground. The use of sockets will often degrade AC

performance. Zero-Insertion-Force sockets are particularly

poor because longer lead lengths create inductance.

Short traces on the board, and bypass capacitors as close as

possible to the A/D, will further improve dynamic perfor-

mance.

GROUNDS

To achieve the maximum performance from the DSP101 or

DSP102, care should be taken to minimize the effect of

changes in current flowing in the system grounds, particu-

larly while bit decisions are being made in the successive

approximation converter's comparator. Pin 28 (AGND) on

both the DSP101 and the DSP102 is the most critical, and

care should be taken to make this pin as close as possible to

the same potential as the system analog ground.

Whenever possible, it is strongly recommended that separate

analog and digital ground planes be used. With an LSB level

of 84

µ

V at the 16-bit level, and one-quarter of that at the

18-bit level, the currents switched in a typical DSP system

can easily corrupt the accuracy of the A/Ds unless great care

is taken to analyze and design for current flows.

FIGURE 9. Driving a 16-bit Parallel Port from the DSP101.

TTL Bit

Clock

20

12

Serial Data

74HC594

(1)

DSP101

SOUT

SSF

XCLK

SR CLK

QH

SR CLR

R CLR

10

13

15

1

2

3

4

5

6

7

12

SYNC

D15 (LSB)

D14

D13

D12

D11

D10

D9

D8

QH

RCK

QA

D1

74HC164

D2

CLR

Serial Data

74HC594

(1)

SR CLK

SR CLR

R CLR

10

13

11

15

1

2

3

4

5

6

7

12

D7

D6

D5

D4

D3

D2

D1

D0 (MSB)

QH

RCK

QA

+5V

8

13

+5V

1

2

9

CLK

Q7

15

D1

74HC164

D2

CLR

CLK1

74HC74

5

11

9

CLK2

Q2

Q1

+5V

8

13

+5V

1

2

9

CLK

Q7

4

1

12

10

13

D1

S1

R1

D2

S2

R2

+5V

RD

Data Valid Signal

NOTE: (1) Substituting

74HC595s provides three

state outputs, with pin 13 (OE)

used to enable the parallel

data lines.

+5V

+5V

2

3

14

11

9

14

16

+5V

HC04

POWER SUPPLY DECOUPLING

All of the supplies should be decoupled to the appropriate

grounds using tantalum capacitors in parallel with ceramic

capacitors, as shown in Figure 6. For optimum performance

of any high resolution A/D, all of the supplies should be as

clean as possible. If separate digital and analog supplies are

available in a system, care should be taken to insure that the

difference between the analog and the digital supplies is not

more than 0.5V for more than a few hundred milliseconds,

as may occur at power-on.

INPUT SIGNAL CONDITIONING

To avoid introducing distortion, the DSP101 and DSP102

analog inputs must be driven by a source with low imped-

ance over the input bandwidth needed in the application. Op

amps such as the NE5532 or Burr-Brown's OPA2604 work

well over audio bandwidths. Figure 7 shows an appropriate

input driver circuit. The 150

and 220pF shown on the input

help reduce the dynamic load on the input signal condition-

ing amp in front of the A/D, since all switched capacitor

array architectures exhibit fast changes in input current load

as the input sampling switch is opened and closed. These

dynamic changes in the load can affect any signal condition-

ing circuit at the input. Other R and C combinations can be

®

DSP101/102

15

used, but the resistor should not exceed 200

, or the output

settling time of the signal conditioning amplifier may be too

long.

EXTERNAL ADJUSTMENTS

All of the specifications for the DSP101 and DSP102, plus

the typical performance curves, are based on the perfor-

mance of these A/Ds without external trims. In most appli-

cations, external trims are not required.

OFFSET ADJUST

Where required by specific applications, offsets can be ad-

justed using the circuit of Figure 8. When not adjusted, VOS

(pin 4) on the DSP101, and VOSA (pin 4) and VOSB (pin 23)

on the DSP102, should be left open. If these pins are con-

nected to traces on the board, they should be bypassed to

ground with 0.01

µ

F capacitors, as close as possible to the A/D.

To trim offset, one alternative is to ground the analog input

while converting continually. Then adjust the trimpot (on

VOS for the DSP101, on VOSA and VOSB for the DSP102)

until the output code is toggling between the codes FFFF and

0000 (Hex) at the 16-bit level (3FFFF and 00000 at the

18-bit level.) This will center the offset at 1/2 LSB below

0V, which is respectively 42

µ

V or 10

µ

V at the 16- and

18-bit levels.

The offset can also be adjusted by providing a sine wave to

the A/D input. Using FFT, or even simple averaging of

several thousand conversion results at a time, the trimpots

can be adjusted until there is no DC offset of the signal.

Grounding the input, or providing the sine wave, as far in

front of the A/D as possible allows offset from intervening

signal conditioning components to be also corrected by this

procedure.

MSB ADJUST

In most applications, adjustment of the Most Significant Bit

weight will not be required. When not adjusted, MSB (pin 3)

on the DSP101, and MSBA (pin 3) and MSBB (pin 24) on

the DSP102, should be left open. If these pins are connected

to traces on the board, they should be bypassed to ground

with 0.01

µ

F capacitors, as close as possible to the A/D.

MSB (pin 3) on the DSP101, and MSBA (pin 3) and MSBB

(pin 24) on the DSP102, are internally connected to a

resistor divider network that is used to laser-trim the weight

FIGURE 10. A Complete Eight-Channel Analog Input System Using the DSP202 and the HI-508A.

CI

OPA627

Out

EN

A

0

A

1

A

2

In

1

In

2

In

3

In

4

In

5

In

6

In

7

In

8

D

C

B

A

LD

CLK

8D

7D

6D

5D

4D

3D

2D

1D

H

G

F

E

D

C

B

A

SOUT

VIN

SSF

QD

QC

QB

QA

CL

CO

EP

ET

6

11

5

12

4

13

3

14

9

1

8Q

7Q

6Q

5Q

4Q

3Q

2Q

1Q

CLK

74HC574

15

74HC163

74HC166

SI

S/L

CLK

CL

QH

9

8

7

6

5

12

13

14

15

16

14

12

11

10

5

4

3

2

1

15

17

18

19

4

3

2

SYNC

XCLK

TAG

CONV

2

12

15

16

18

20

21

DSP101

9

6

7

7

10

2

1

11

150

C

1

220pF

HI-508A

8

2

1

16

15

9

10

11

12

7

6

5

4

+5V

+5V

+5V

5

4

74HC221

3

+5V

B

A

CL

2

1

R/C

CE

Q

Q

13

4

14

15

1000pF

C

4

+5V

R

2

4.7k

13

R

1

NOTE: (1) Must be low source impedance

with unused inputs tied to ground.

Analog Inputs

(1)

Convert Command

(Positive Edge Triggered)

6

2

3

OE

Serial Data Out

®

DSP101/102

16

of the MSB capacitor in the CDAC. These pins are nomi-

nally at +100mV after laser-trimming during manufacturing.

They can handle external inputs up to about one diode drop

below ground (0.6V) before internal clamping circuitry is

triggered.

Figure 8 shows an appropriate circuit for adjusting the

weight of the most significant bit to minimize differential

non-linearity at the critical major-carry transition. To adjust,

provide a small amplitude sine wave to the selected A/D

input pin while converting continually, and adjust for maxi-

mum Signal-to-(Noise + Distortion) ratio, using appropriate

signal analysis software.

GAIN ADJUST

If circuit gain needs to be adjusted in hardware, rather than

in system software, appropriate trimpots should be included

in the analog signal conditioning section in front of the

DSP101 or DSP102. No specific gain adjust circuitry is

included in the parts.

APPLICATIONS

INTERFACING DSP101 TO PARALLEL PORTS

Figure 9 shows a circuit for converting the serial output data

from the DSP101 into 16 bits of parallel data, within the

timing constraints of the serial bit-stream from the DSP101.

In many applications, this circuit can be easily incorporated

into gate arrays or other programmed logic circuits already

used in the system, since the extra gate count is not high.

This circuit adds an additional pipeline delay to the conver-

sion data, so that the parallel data from a conversion at time

(t) is valid one conversion cycle plus 17 XCLK clocks later

(at t+1 plus 17 times XCLK). A convert command at time

(t+1) generates a Sync and begins transmitting serial data

from SOUT. The serial data is shifted into the 74HC594

shift registers, and Sync is shifted through the 74HC164

shift registers. The Q1 output of the 74HC74 dual D-type

flip-flops clocks the conversion data into the output register

of the 74HC594s, and triggers a data valid signal on its Q2

output. The user can then read the data at any time before the

next conversion is started, and the Read signal will reset the

data valid output from Q2.

In many systems, galvanic isolation of signals is required.

Using opto-couplers on the serial data lines in Figure 9

allows a fully isolated system to be built using a DSP101 and

only three couplers across the barrier (for serial data, XCLK

and SYNC.)

MULTIPLEXING INPUTS TO THE DSP101

Figure 10 shows a complete circuit for sequentially scanning

eight analog input channels with a single DSP101, and using

the Tag feature on the DSP101 to append the multiplexer

channel address to the serial output conversion results.

The circuit in Figure 10 includes the required digital logic

and timing logic. The 74HC163 counter provides the scan

sequence to the Burr-Brown HI-508A analog multiplexer. In

order to allow the HI-508A enough time to switch to the next

channel and settle before the DSP101 begins a conversion,

a 74HC221 one-shot introduces a 3

µ

s delay for the DSP101

convert command input.

The Burr-Brown OPA627 provides a low impedance source

for the DSP101, buffering it from the output impedance of

FIGURE 11. Analog Input and Analog Output System.

TTL Bit

Clock

12

13

11

9

10

15

XCLK

SIN

SYNC

SSF

SWL

CONV

±3V Analog Output

21

VOUT

DSP201

Conversion Rate

Generator

XCLK

SOUT

SYNC

SSF

DSP101

SSF

SWL

16

20

15

12

2

±2.75V

Analog Input

CLKR

DATA IN

SYNC

XCLK

DATA OUT

SYNC

SSF

(2)

VIN

Digital Signal

Processor IC

21

CONV

(1)

(2)

(3)

DSP PROCESSOR

SYNC FORMAT

SERIAL I/O WORD

SSF

(2)

SWL

(3)

DSP32C, DSP16

Active Low

16 Bits

LOW

HIGH

DSP56001

Active High

24 Bits

HIGH

LOW

DSP56001

Active High

16 Bits

HIGH

HIGH

TMS320C25/C30

Active High

16 Bits

HIGH

HIGH

ADSP2101/2105

Active High

16 Bits

HIGH

HIGH

(1) See Burr-Brown

DSP201/DSP202

product data sheet

for full description of

this DAC.

®

DSP101/102

17

the multiplexer. This unity-gain buffer minimizes distortion,

taking full advantage of the resolution and bandwidth of the

DSP101.

The 74HC574D register delays the multiplexer address data

by one conversion before appending the channel data to the

serial conversion results from the DSP101. This attaches the

channel address to the correct conversion results. Since the

channel scanning shown in Figure 10 is sequential, this

delay latch could be left out and software could recognize

that the time (t) conversion results have the MUX address

from the time (t-1) conversion appended. However, for

systems using non-sequential scan lists, this delay latch is

essential to maintain the conversion data and channel ad-

dress integrity.

The 74HC166 synchronous loading shift register loads the

channel address tag data into the shift register on the rising

edge of the bit clock, in conjunction with the Sync output of

the DSP101. The channel address tag data is then clocked

into the DSP101 Tag input (pin 18) by the bit clock, while

the conversion data is clocked out the other end of the

DSP101 shift register (discussed in another section of this

data sheet.)

Figure 10 was developed and tested using a Burr-Brown

ZPB34 DSP board, which contains an AT&T DSP32C, so

that the SYNC output is programmed to be active LOW. The

circuit needs to be modified for DSP processors from ADI,

TI, and Motorola, which use active HIGH Sync pulses. For

these processors, tie SSF (pin 12) on the DSP101 HIGH, and

use a 74HC04 hex inverter to invert the Sync signal to the

74HC574 and 74HC166.

The same basic circuit can be duplicated to drive two

channels in a DSP102, or can be easily modified for more or

less than eight channels of analog input.

USING DSP101 AND DSP102 WITH

TEXAS INSTRUMENTS DSP ICS

Figures 11 thru 17 show various ways to use the DSP101

and DSP102 with DSP ICs from the Texas Instruments

TMS320Cxx series. For simplicity, all of these circuits are

FIGURE 13. Using DSP102 with TMS320C30 in Cascade Mode.

16

15

20

17

22

12

21

CLKR -0

FSR-0

DR-0

±2.75V Analog Input

Channel A

2

25

VINA

VINB

TMS320C30

Conversion Rate

Generator

DSP102

XCLK

SYNC

SOUTA

SOUTB

CASC

SSF

CONV

±2.75V Analog Input

Channel B

+5V

+5V

NOTE: Serial port 0 programmed

for 32-bit data.

TTL Bit

Clock

NC

FIGURE 12. Using DSP102 with TMS320C30.

TTL Bit

Clock

16

15

20

17

22

12

21

CLKR

±2.75V Analog Input

Channel A

2

VINA

VINB

TMS320C30

Conversion Rate

Generator

DSP102

25

XCLK

SYNC

SOUTA

SOUTB

CASC

SSF

CONV

±2.75V Analog Input

Channel B

DR-0

DR-1

FSR-0

FSR-1

+5V

®

DSP101/102

18

based on using the TME320Cxx in the mode where SSF

(Select Synch Format, pin 12) is tied HIGH, so that there is

an active High synchronization pulse generated by the

DSP101 or DSP102 after receiving a convert command. The

synchronization pulse can be changed to active Low simply

by making SSF LOW, where appropriate, without changing

the basic operation of the A/Ds.

In all cases, the DSP101 and DSP102 will transmit data

MSB-first, and the TMS320Cxx needs to be programmed

for this.

Figure 11 shows a circuit for using the TMS320C25 or

TMS320C30 in a complete analog input and analog output

system using the DSP101 along with the Burr-Brown DSP201

D/A.

FIGURE 14. Two-Channel Analog Input and Output System with TMS320C30.

TTL Bit

Clock

12

11

9

10

16

15

XCLK

SYNC

SSF

SWL

CASC

CONV

±3V Analog Output

Channel A

21

5

VOUTA

VOUTB

DSP202

Conversion Rate

Generator

XCLK

SYNC

SSF

CASC

CONV

DSP102

+5V

+5V

16

15

12

22

21

±2.75V Analog Input

Channel A

DR-0

DR-1

CLKX-0

CLKX-1

±3V Analog Output

Channel B

DX-0

DX-1

FSX-0

FSX-1

CLKR-0

CLKR-1

FSR-0

FSR-1

+5V

TMS320C30

VINA

VINB

±2.75V Analog Input

Channel B

2

25

NOTES: (1) Sample rate on DSP102 and DSP202 may differ. (2) Analog Devices ADSP2101 may be used. SPORT1 and SPORT2

are used for serial MSB first communication. (3) See Burr-Brown DSP201/DSP202 product data sheet for full description of this DAC.

(1)

(3)

SOUTA

SOUTB

20

17

SINA

SINB

13

14

FIGURE 15. Two-Channel Analog Input and Output System with TMS320C30 in Cascade Mode.

TTL Bit

Clock

12

13

14

11

9

10

16

15

XCLK

SINA

SINB

SYNC

SSF

SWL

CASC

CONV

±3V Analog Output

Channel A

21

5

VOUTA

VOUTB

DSP202

Conversion Rate

Generator

XCLK

SOUTA

SOUTB

SYNC

SSF

CASC

CONV

DSP102

+5V

+5V

+5V

16

20

17

15

12

22

21

±2.75V Analog Input

Channel A

CLKR-0

DR-0

±3V Analog Output

Channel B

CLKX-0

DX-0

FSR-0

+5V

+5V

TMS320C30

VINA

VINB

±2.75V Analog Input

Channel B

2

25

NOTES: (1) Program TMS320C30 for 32-bit mode. (2) Sample rate on DSP102 and DSP202 may differ. (3) DSP32C may be used in this mode.

(4) See Burr-Brown DSP201/202 product data sheet for full description of this DAC.

FSX-0

NC

(2)

(4)

®

DSP101/102

19

SERIAL PORT

Port Global Control Register

0x0EBC040

FSX/DX/CLKX Port Control Register

0x00000111

FSR/DR/CLKR Port Control Register

0x00000111

Receive/Transmit Timer Control Register

0x0000000F

TIMER

Timer Global Control Register

0x000002C1

Timer Period Register

0x000000B5

NOTE: Assumes TMS320C31 has 32MHz Master Clock.

USING TMS320C31 TO GENERATE

ALL CONTROL SIGNALS

Figure 17 shows a circuit for using the TMS320C31 with a

DSP102 and a Burr-Brown DSP202 D/A to provide a two

channel analog I/O system. The flexibility of the TMS320C31

allows it to generate the data transfer clock (XCLK) and the

Convert Command, minimizing additional circuitry and syn-

chronizing the timing signals to the processor's master

clock. In this circuit, the DSP102 and DSP202 are used in

their Cascade modes, transmitting and receiving two chan-

nels of data in a single 32-bit word. (See the Cascade Mode

section above.)

Table II shows how to set up the circuit in Figure 17 for a

44.1kHz conversion rate for both channels of the DSP102

A/D and both channels of the DSP202 D/A. Both inputs and

outputs will be simultaneously converted.

XCLK

SYNC

SOUT

SSF

CONV

VIN

DSP101

TTL Bit

Clock

Conversion Rate

Generator

XCLK

FSX

TXD

±2.75V Analog Input

16

15

20

12

21

+5V

NOTES: (1) TMS320C25 FSR external, 16-bit data.

2

TMS320C25

FIGURE 16. Using DSP101 with TMS320C25.

FIGURE 17. Two Channel Analog I/O Using TMS320C31.

1M

XCLK

SYNC

SSF

SWL

CASC

CONV

±3V Analog Output

VOUTA

DSP202

XCLK

SYNC

CASC

DSP102

±2.75V Analog Input

DR0

FSR0

DX0

FSX0

+5V

VINA

TMS3200C31

CONV

VINB

OSC2

OSC1

TCLK0

+5V

Channel A

±3V Analog Output

VOUTB

+5V

+5V

+5V

10pF

10pF

12.288MHz

±2.75V Analog Input

Channel B

Channel A

Channel B

SINA

SINB

SOUTA

SOUTB

SSF

NC

CLKR0

CLKX0

TABLE II. TMS320C31 Register Settings for 44.1kHz Con-

version Rate in Figure 17.

®

DSP101/102

20

USING DSP101 AND DSP102

WITH MOTOROLA DSP ICS

Figure 18 shows how to use the DSP101 with a Motorola

DSP56001. Using the DSP102 requires using two

DSP56001s. The DSP56001 needs to be programmed to

receive data MSB-first with SYNC in the Bit Mode.

SSF (pin 12) needs to be tied HIGH for using either the

DSP101 or the DSP102 with DSP56001s. This will cause

the DSP101 or DSP102 to transmit an appropriate active

High synchronization pulse on SYNC (pin 15) after a con-

vert command is received by the A/D. Timing is shown in

Figure 1.

USING DSP101 AND DSP102 WITH AT&T DSP ICS

Figures 11, 19, 20, and 21 show how to use the DSP101 and

DSP102 with the DSP16 and DSP32C in different modes.

The AT&T processors need to be programmed to accept

data MSB-first, and the DSP101 or DSP102 needs to have

SSF (pin 12) tied LOW, so that an appropriate active Low

synchronization pulse will be transmitted by the A/D after a

convert command is received.

Figures 19 and 20 show the DSP32C and DSP16 respec-

tively used with the DSP101 to handle a single analog input

channel.

Figure 21 shows how to transmit to a single DSP32C

conversion results from both DSP102 channels in a single

32-bit word, using the Cascade mode on the A/D.

Figure 11 indicates how to build a complete analog input and

analog output system using a DSP32C or DSP16 with a

DSP101 and a Burr-Brown DSP201 D/A.

XCLK

SYNC

SOUT

SSF

CONV

VIN

DSP101

TTL Bit

Clock

Conversion Rate

Generator

SCK

FSR (SC2)

SRD

DSP56001

±2.75V Analog Input

16

15

20

12

21

+5V

NOTES: (1) DSP56001 programmed for MSB bit first data. (2) DSP56001 data may be either 16-bit or 24-bit.

2

FIGURE 18. Using DSP101 with DSP56001.

XCLK

SYNC

SOUT

VIN

DSP101

TTL Bit

Clock

Conversion Rate

Generator

ICK

ILD

DATA IN

±2.75V Analog Input

16

15

20

NOTE: (1) DSP32C programmed for MSB bit first 16-bit data.

2

DSP32C

SSF

CONV

12

21

FIGURE 19. Using DSP101 with DSP32C.

®

DSP101/102

21

USING DSP101 AND DSP102 WITH ADI DSP ICS

When using the DSP101 or DSP102 with the fixed-point

ADSP21xx series, the processors need to be programmed to

receive data MSB-first.

Figure 22 shows how to use the DSP102 with an ADSP2101

to provide a two-channel simultaneous sampling system.

Figure 23 shows the connections required to generate an

analog input channel using an ADSP2105 with the DSP101.

The same basic circuit can be used to connect a DSP101 to

the ADSP2101.

Figure 11 indicates how to build a complete analog I/O

system using either the ADSP2101 or the ADSP2105 with a

DSP101 and a Burr-Brown DSP201 D/A.

The two serial ports on the ADSP2101 can also be used with

the DSP102 and the Burr-Brown DSP202 D/A to make two

complete analog I/O channels, as indicated in footnote 2 of

Figure 14.

TTL Bit

Clock

16

20

15

12

ICK

DATA IN

ILD

±2.75V Analog Input

2

VIN

DSP16

Conversion Rate

Generator

DSP101

XCLK

SOUT

SYNC

SSF

NOTE: DSP16 programmed for MSB bit first, 16-bit data.

21

CONV

FIGURE 20. Using DSP101 with DSP16.

FIGURE 21. Using DSP102 with DSP32C in Cascade Mode.

XCLK

SYNC

SOUTA

SOUTB

CASC

SSF

CONV

VINA

VINB

DSP102

TTL Bit

Clock

Conversion Rate

Generator

ICK

ILD

DATA IN

±2.75V Analog Input

Channel A

16

15

20

17

22

12

21

NOTES: (1) DSP32C programmed 32-bit data MSB bit first. (2) Data format is Channel A, 16 bits, MSB first, then Channel B.

2

DSP32C

±2.75V Analog Input

Channel B

25

NC

+5V

®

DSP101/102

22

TTL Bit

Clock

16

15

20

17

DR-0

DR-1

±2.75V Analog Input

Channel A

2

25

VINA

VINB

ADSP-2101

Conversion Rate

Generator

DSP102

XCLK

SYNC

SOUTA

SOUTB

±2.75V Analog Input

Channel B

+5V

SCLK-0

SCLK-1

RFS-0

RFS-1

12

21

SSF

CONV

22

CASC

FIGURE 22. Using DSP102 with ADSP-2101.

FIGURE 23. Using DSP101 with ADSP-2105.

TTL Bit

Clock

16

20

15

12

21

±2.75V Analog Input

2

VIN

ADSP-2105

Conversion Rate

Generator

DSP101

XCLK

SOUT

SYNC

SSF

CONV

+5V

SCLK

DR

RFS

DEM-DSP102/202 EVALUATION BOARD

An evaluation fixture, the DEM-DSP102/202, is available to

simplify evaluation of the DSP101 and DSP102, and the

companion digital-to-analog converters, the single DSP201