Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

Small Form Factor MT-RJ

Fiber Optic Transceivers

for Gigabit Ethernet

Technical Data

HFBR-5912E,

850 nm VCSEL

HFCT-5912E,

1300 nm FP Laser

Features

· Compliant with

Specifications for

IEEE 802.3z/ Gigabit

Ethernet

· Multisourced 2 x 5 Package

Style with Integral MT-RJ

Connector

· Performance

HFBR-5912E (1000 Base-SX)

220 m Links in 62.5/125

µm MMF 160 MHz*km

Cables

275 m Links in 62.5/125

µm MMF 200 MHz*km

Cables

500 m Links in 50/125 µm

MMF 400 MHz*km Cables

550 m Links in 50/125 µm

MMF 500 MHz*km Cables

HFCT-5912E (1000 Base-LX)

550 m Links in 62.5/125

µm MMF Cables

10 km Links in 8/125 µm

SMF Cables

· IEC 60825-1 Class 1/CDRH

Class 1 Laser Eye Safe

· Single +3.3 V Power Supply

Operation with PECL Logic

I/O Interfaces, TTL Signal

Detect and Transmit Disable

· Wave Solder and Aqueous

Wash Process Compatible

Applications

· Switch to Switch Interface

· Switched Backbone

Applications

· High Speed Interface for

File Servers

· High Performance Desktops

Related Products

· Physical Layer ICs Available

for Optical or Copper

Interface (HDMP-1636A/

1646A)

· Quad SERDES IC Available

for High Density Interfaces

(HDMP-1680)

· 1x9 Fiber Optic Transceivers

for Gigabit Ethernet

(HFBR/HFCT-53D5)

· Gigabit Interface Converters

(GBIC) for Gigabit Ethernet

SX HFBR-5601

LX HFCT-5611

Description

The HFBR/HFCT-5912E

transceiver from Agilent allows

the system designer to implement

a range of solutions for multimode

and single mode Gigabit Ethernet

applications.

The transceivers are configured

in the new multisourced industry

standard 2 x 5 dual-in-line package

with an integral MT-RJ fiber

connector.

Transmitter Section

The transmitter section of the

HFBR-5912E consists of an

850 nm Vertical Cavity Surface

Emitting Laser (VCSEL) in an

optical subassembly (OSA),

which mates to the fiber cable.

The HFCT-5912E incorporates a

1300 nm Fabry-Perot (FP) Laser

designed to meet the Gigabit

Ethernet LX specification. The

OSA is driven by a custom silicon

bipolar IC which accepts

differential PECL logic signals

(ECL referenced to a +3.3 V

supply) and provides bias and

modulation control for the laser.

Receiver Section

The receiver of the HFBR-5912E

includes a GaAs PIN photodiode

mounted together with a custom,

silicon bipolar transimpedance

preamplifier IC in an OSA. This

OSA is mated to a custom silicon

bipolar circuit that provides post-

amplification and quantization.

The HFCT-5912E utilizes an InP

PIN photodiode in a similar

configuration.

The post-amplifier also includes

a Signal Detect circuit which

provides a TTL logic-high output

upon detection of an optical signal.

2

APPLICATION SUPPORT

Package and Handling

Instructions

Flammability

The HFBR/HFCT-5912E

transceiver housing consists of

high strength, heat resistant,

chemically resistant, and UL 94 V-0

flame retardant plastic and metal

packaging.

Recommended Solder and

Wash Process

The HFBR/HFCT-5912E is

compatible with industry-

standard wave or hand solder

processes.

Process plug

This transceiver is supplied with

a process plug for protection of

the optical port within the MT-RJ

connector receptacle. This

process plug prevents

contamination during wave

solder and aqueous rinse as well

as during handling, shipping and

storage. It is made of a high-

temperature, molded sealing

material that can withstand

+80°C and a rinse pressure of

110 lbs per square inch. Due to

the differences in the multimode

and single mode connector

construction, the HFBR-5912E

and HFCT-5912E process plugs

are different and not

interchangeable. The multimode

port plug is black and the single

mode variant is a blue color.

Recommended Solder fluxes

Solder fluxes used with the

HFBR/HFCT-5912E should be

water-soluble, organic fluxes.

Recommended solder fluxes

include Lonco 3355-11 from

London Chemical West, Inc. of

Burbank, CA, and 100 Flux from

Alpha-Metals of Jersey City, NJ.

Recommended Cleaning/

Degreasing Chemicals

Alcohols:

methyl, isopropyl,

isobutyl.

Aliphatics:

hexane, heptane

Other:

naphtha.

Do not use

partially halogenated

hydrocarbons such as 1,1.1

trichloroethane, ketones such as

MEK, acetone, chloroform, ethyl

acetate, methylene dichloride,

phenol, methylene chloride, or

N-methylpyrolldone. Also,

Agilent does not recommend the

use of cleaners that use

halogenated hydrocarbons

because of their potential

environmental harm.

Regulatory Compliance

(See the Regulatory Compliance

Table for transceiver performance)

The overall equipment design will

determine the certification level.

The transceiver performance is

offered as a figure of merit to

assist the designer in considering

their use in equipment designs.

Electrostatic Discharge (ESD)

There are two design cases in

which immunity to ESD damage

is important.

The first case is during handling

of the transceiver prior to

mounting it on the circuit board.

It is important to use normal ESD

handling precautions for ESD

sensitive devices. These pre-

cautions include using grounded

wrist straps, work benches, and

floor mats in ESD controlled

areas. The transceiver perform-

ance has been shown to provide

adequate performance in typical

industry production environments.

The second case to consider is

static discharges to the exterior of

the equipment chassis containing

the transceiver parts. To the

extent that the MT-RJ connector

receptacle is exposed to the

outside of the equipment chassis

it may be subject to whatever

system-level ESD test criteria that

the equipment is intended to meet.

The transceiver performance is

more robust than typical industry

equipment requirements of today.

Electromagnetic Interference

(EMI)

Most equipment designs utilizing

these high-speed transceivers

from Agilent will be required to

meet the requirements of FCC in

the United States, CENELEC

EN55022 (CISPR 22) in Europe

and VCCI in Japan. Refer to EMI

section (page 5) for more details.

Immunity

Equipment utilizing these

transceivers will be subject to

radio-frequency electromagnetic

fields in some environments.

These transceivers have good

immunity to such fields due to

their shielded design.

Eye Safety

These laser-based transceivers

are classified as AEL Class I

(U.S. 21 CFR(J) and AEL Class 1

per EN 60825-1 (+A11). They are

eye safe when used within the

data sheet limits per CDRH. They

are also eye safe under normal

operating conditions and under

all reasonably foreseeable single

fault conditions per EN60825-1.

Agilent has tested the transceiver

design for compliance with the

requirements listed below under

normal operating conditions and

under single fault conditions

where applicable. TUV Rheinland

has granted certification to these

transceivers for laser eye safety

and use in EN 60950 and

EN 60825-2 applications. Their

performance enables the

transceivers to be used without

concern for eye safety up to 5.0 V

transmitter V

CC

.

3

CAUTION:

There are no user serviceable parts

nor any maintenance required for

the HFBR/HFCT-5912E. All

adjustments are made at the

factory before shipment to our

customers. Tampering with or

modifying the performance of the

HFBR/HFCT-5912E will result in

voided product warranty. It may

also result in improper operation

of the HFBR/HFCT-5912E

circuitry, and possible overstress

of the laser source. Device

degradation or product failure

may result.

Connection of the HFBR/HFCT-

5912E to a non-approved optical

source, operating above the

recommended absolute maximum

conditions or operating the

HFBR/HFCT-5912E in a manner

inconsistent with its design and

function may result in hazardous

radiation exposure and may be

considered an act of modifying or

manufacturing a laser product.

The person(s) performing such

an act is required by law to

recertify and reidentify the laser

product under the provisions of

U.S. 21 CFR (Subchapter J).

Optical Power Budget

and Link Penalties

The worst-case Optical Power

Budget (OPB) in dB for a fiber-

optic link is determined by the

difference between the minimum

transmitter output optical power

(dBm avg) and the minimum

receiver sensitivity (dBm avg).

This OPB provides the necessary

optical signal range to establish a

working fiber-optic link. The

OPB is allocated for the fiber-

optic cable length and the corre-

sponding link penalties. For

proper link performance, all

penalties that affect the link

performance must be accounted

for within the link optical power

budget. The Gigabit Ethernet

IEEE 802.3z standard identifies,

and has modeled, the

contributions of these OPB

penalties to establish the link

length requirements for 9/125 µm

single mode and 50/125 µm and

62.5/125 µm multimode fiber

usage. Refer to the IEEE 802.3z

standard and its supplemental

documents that develop the

model, empirical results and final

specifications.

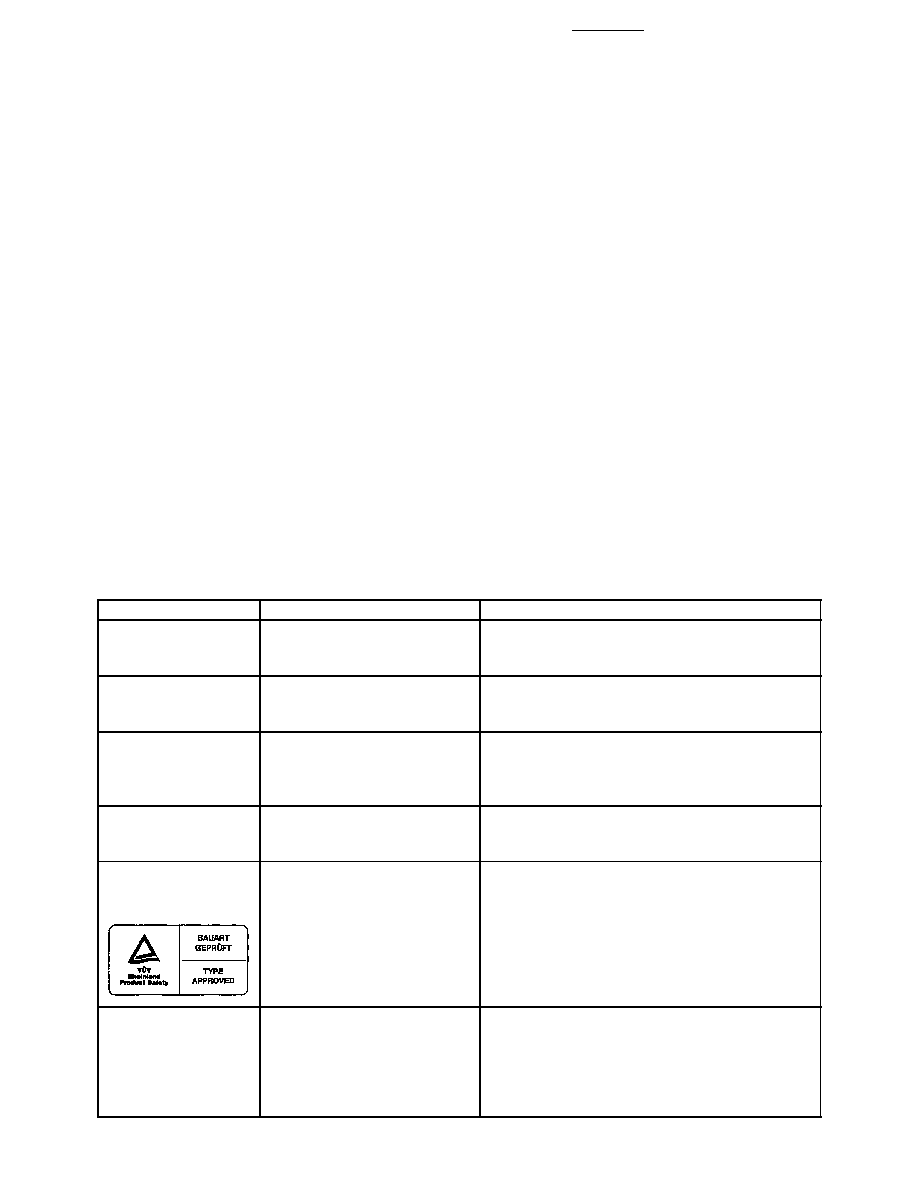

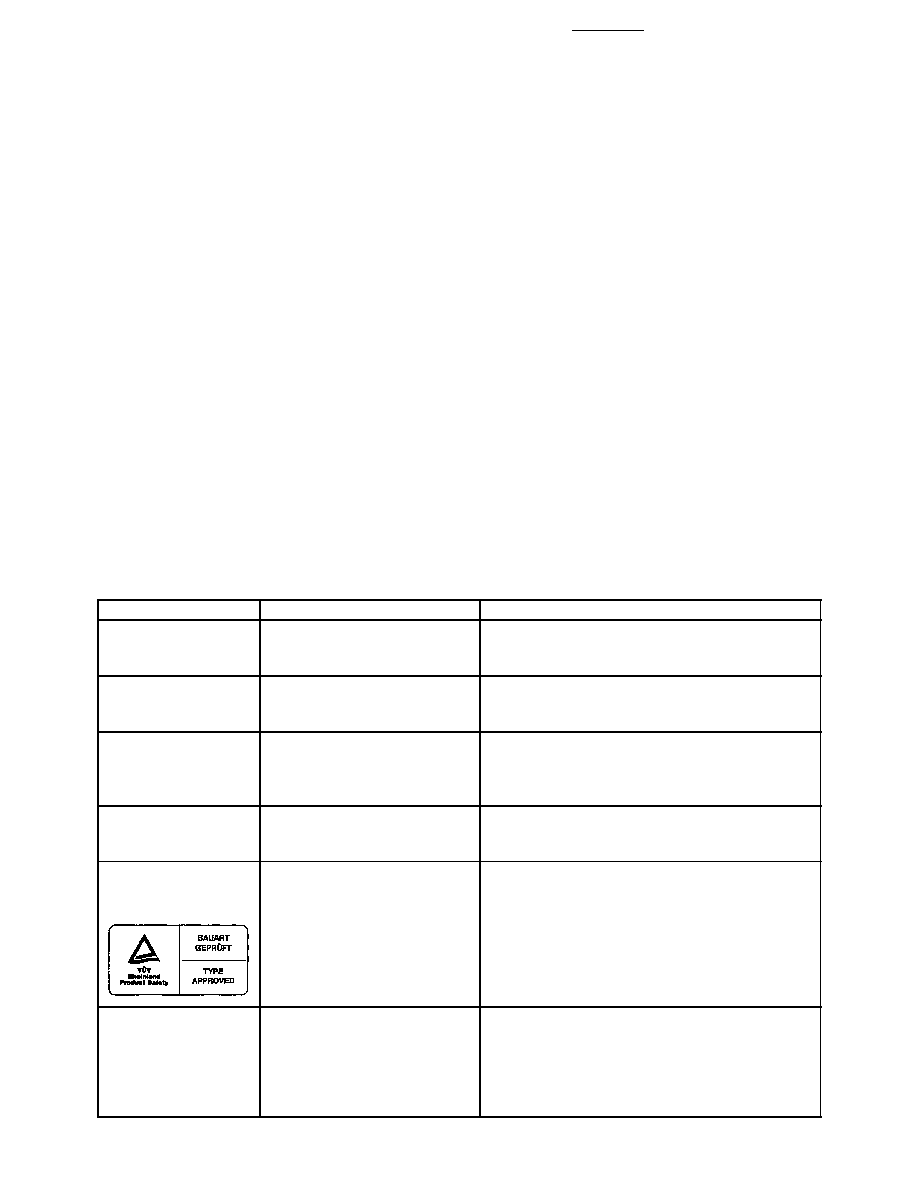

Regulatory Compliance

Feature

Test Method

Performance

Electrostatic Discharge

(ESD) to the

Electrical Pins

MIL-STD-883C

Method 3015.4

Class 1 (>1500 V).

Electrostatic Discharge

(ESD) to the MT-RJ

Receptacle

Variation of IEC 801-2

Typically withstand at least 15 kV without damage

when the MT-RJ connector receptacle is contacted

by a Human Body Model probe.

Electromagnetic

Interference (EMI)

FCC Class B

CENELEC EN55022 Class B

(CISPR 22A)

VCCI Class I

Margins are dependent on customer board and

chassis designs.

Immunity

Variation of IEC 801-3

Typically show no measurable effect from a

10 V/m field swept from 27 to 1000 MHz applied to

the transceiver without a chassis enclosure.

Laser Eye Safety

and Equipment Type

Testing

US 21 CFR, Subchapter J

per Paragraphs 1002.10

and 1002.12

EN 60825-1: 1994 +A11

EN 60825-2: 1994

EN 60950: 1992+A1+A2+A3

AEL Class I, FDA/CDRH

HFBR-5912E Accession # 9720151-09

HFCT-5912E Accession # 9521220-20

AEL Class 1, TUV Rheinland of North America

HFBR-5912E: Certificate # E9971083.01

HFCT-5912E: Certificate # 933/510817/05

Protection Class III

Component

Recognition

Underwriters Laboratories and

Canadian Standards Association

Joint Component Recognition

for Information Technology

Equipment Including Electrical

Business Equipment.

UL File # E173874

4

10 km Link Support

As well as complying with the LX

5 km standard, the HFCT-5912E

specification provides additional

margin allowing for a 10 km

Gigabit Ethernet link on single

mode fiber. This is accomplished

by limiting the spectral width and

center wavelength range of the

transmitter while increasing the

output optical power and

improving sensitivity. All other

LX cable plant recommendations

should be followed.

Data Line

Interconnections

Agilent's HFBR/HFCT-5912E

fiber-optic transceiver is designed

to couple to +3.3 V PECL signals.

In order to reduce the number of

passive components required on

the customer's board, Agilent has

included the functionality of the

external transmitter bias resistors

and coupling capacitors within

the fiber optic module. The

transceiver is compatible with a

"dc-coupled" configuration and

Figure 3 depicts the circuit

options. Additionally, there is an

internal, 50 Ohm termination

resistance within the transmitter

input section. The transmitter

driver circuit regulates the output

optical power. The regulated light

output will maintain a constant

output optical power provided

the data pattern is reasonably

balanced in duty factor. If the

data duty factor has long,

continuous state times (low or

high data duty factor), then the

output optical power will

gradually change its average

output optical power level to its

preset value.

Per the multisource agreement,

the HFBR/HFCT-5912E feature a

transmit disable function which is

a single-ended +3.3 V TTL input

signal dc-coupled to pin 8.

As for the receiver section, it is

internally ac-coupled between

the preamplifier and the post-

amplifier stages. The actual Data

and Data-bar outputs of the post-

amplifier are dc-coupled to their

respective output pins (pins 4, 5).

Signal Detect is a single-ended,

+3.3 V TTL output signal that is

dc-coupled to pin 3 of the

module. Signal Detect should not

be ac-coupled externally to the

follow-on circuits because of its

infrequent state changes.

Caution should be taken to

account for the proper intercon-

nection between the supporting

Physical Layer integrated circuits

and this HFBR/HFCT-5912E

transceiver. Figure 3 illustrates a

recommended interface circuit

for interconnecting to a +3.3 V dc

PECL fiber-optic transceiver.

Electrical and

Mechanical Interface

Recommended Circuit

Figure 3 shows the recommended

interface for deploying the Agilent

transceiver in a +3.3 V system.

Also present are power supply

filtering arrangements which

comply with the recommendations

of the small form factor

multisource agreement. This

configuration ensures noise

rejection compatibility between

transceivers from various vendors.

Power Supply Filtering and

Ground Planes

It is important to exercise care in

circuit board layout to achieve

optimum performance from these

transceivers. Figure 3 shows the

recommended power supply filter

circuit for the SFF transceiver. It

is further recommended that a

contiguous ground plane be

provided in the circuit board

directly under the transceiver to

provide a low inductance ground

for signal return current. This

recommendation is in keeping

with good high frequency board

layout practices.

The HFBR/HFCT-5912E is

designed to cope with the

electrically noisy environment

inside the chassis box of Gigabit

data communication systems. To

minimize the impact of

conducted and radiated noise

upon receiver performance the

metal cover at the rear of the

HFBR/HFCT-5912E should be

connected to the host system's

circuit common ground plane.

To maximize the shielding

effectiveness and minimize the

radiated emissions that escape

from the host system's chassis

box the metal shield that covers

the MT-RJ receptacle should

make electrical contact with the

aperture required for the optical

connector. The metal cover at

the rear of the fiber-optic module

is dielectrically isolated from the

metal shield that covers the

MT-RJ receptacle to avoid

conflicts between circuit and

chassis common.

Package footprint and front

panel considerations

The Agilent transceiver complies

with the circuit board "Common

Transceiver Footprint" hole

pattern defined in the original

multisource announcement

which defined the 2 x 5 package

style. This drawing is reproduced

in Figure 5 with the addition of

ANSI Y14.5M compliant

dimensioning to be used as a

guide in the mechanical layout of

your circuit board. Figure 6

shows the front panel dimensions

associated with such a layout.

5

Eye Safety Circuit

For an optical transmitter device

to be eye-safe in the event of a

single fault failure, the transmit-

ter must either maintain eye-safe

operation or be disabled.

In the HFBR-5912E there are

three key elements to the laser

driver safety circuitry: a monitor

diode, a window detector circuit,

and direct control of the laser

bias. The window detection

circuit monitors the average

optical power using the monitor

diode. If a fault occurs such that

the transmitter dc regulation

circuit cannot maintain the

preset bias conditions for the

laser emitter within ± 20%, the

transmitter will automatically be

disabled. Once this has occurred,

an electrical power reset or

toggling the transmit disable will

allow an attempted turn-on of the

transmitter. If fault remains the

transmitter will stay disabled.

The HFCT-5912E utilizes an

optical subassembly consisting of

a short piece of single mode fiber

along with a current limiting

circuit to guarantee eye-safety. It

is intrinsically eye safe and does

not require shut down circuitry.

Signal Detect

The Signal Detect circuit provides

a TTL low output signal when the

optical link is broken or when the

transmitter is OFF as defined by

the Gigabit Ethernet specification

IEEE 802.3z, Table 38.1. The

Signal Detect threshold is set to

transition from a high to low

state between the minimum

receiver input optional power and

-30 dBm avg. input optical power

indicating a definite optical fault

(e.g. unplugged connector for the

receiver or transmitter, broken

fiber, or failed far-end transmitter

or data source). A Signal Detect

indicating a working link is

functional when receiving

encoded 8B/10B characters. The

Signal Detect does not detect

receiver data error or error-rate.

Data errors can be determined by

signal processing offered by

upstream PHY ICs.

Electromagnetic

Interference (EMI)

One of a circuit board designer's

foremost concerns is the control

of electromagnetic emissions

from electronic equipment.

Success in controlling generated

Electromagnetic Interference

(EMI) enables the designer to

pass a governmental agency's

EMI regulatory standard and

more importantly, it reduces the

possibility of interference to

neighboring equipment. Agilent

has designed the HFBR/HFCT-

5912E to provide excellent EMI

performance. The EMI

performance of a chassis is

dependent on physical design and

features which help improve EMI

suppression. Agilent encourages

using standard RF suppression

practices and avoiding poorly

EMI-sealed enclosures.

Radiated Emissions for the

HFBR-5912E and HFCT-5912E

have been tested successfully in

several environments. While this

number is important for system

designers in terms of emissions

levels inside a system, Agilent

recognizes that the performance

of most interest to our customers

is the emissions levels, which

could be expected to radiate to

the outside world from inside a

typical system. In their

application, SFF transceivers are

intended for use inside an

enclosed system, protruding

through the specified panel

opening at the specified

protrusion depth.

Along with the system advantage

of high port density comes the

increase in the number of

apertures. Careful attention must

be paid to the locations of high-

speed clocks or gigabit circuitry

with respect to these apertures.

While experimental measurements

and experiences do not indicate

any specific transceiver emissions

issues, Agilent recognizes that

the transceiver aperture is often a

weak link in system enclosure

integrity and has designed the

modules to minimize emissions

and if necessary, contain the

internal system emissions by

shielding the aperture.

To that end, Agilent's gigabit

MT-RJ transceivers (HFCT-5912E

and HFBR-5912E) have nose

shields which provide a

convenient chassis connection to

the nose of the transceiver. This

nose shield improves system EMI

performance by closing off the

MT-RJ aperture. Localized

shielding is also improved by

tying the four metal housing

package grounding tabs to signal

ground on the PCB. Though not

obvious by inspection, the nose

shield and metal housing are

electrically separated for

customers who do not wish to

directly tie chassis and signal

grounds together. The

recommended transceiver

position, PCB layout and panel

opening for both HFBR-5912E

and HFCT-5912E are the same,

making them mechanically drop-

in compatible. Figure 6 shows

the recommended positioning of

the transceivers with respect to

the PCB and faceplate.

Document Outline