ESD WARNING: NORMAL HANDLING PRECAUTIONS SHOULD BE TAKEN TO AVOID STATIC DISCHARGE.

Agilent HEDS-9730, HEDS-9731

Small Optical Encoder Modules

480lpi Digital Output

Data Sheet

Description

The HEDS- 973X is a high

performance incremental

encoder module. When operated

in conjunction with either a

codewheel or codestrip, this

module detects rotary or linear

position. The encoder consists

of a lensed LED source and a

detector IC enclosed in a small

C- shaped plastic package. Due

to a highly collimated light

source and a unique

photodetector array, the module

is extremely tolerant to

mounting misalignment.

The two channel digital outputs

and 3.3V supply input are

accessed through four solder

plated leads located on 2.54mm

(0.1inch) centers.

The standard HEDS- 973X is

designed for use with an

appropriate optical radius

codewheel or linear codestrip.

Other options are available.

Please contact the factory for

more information.

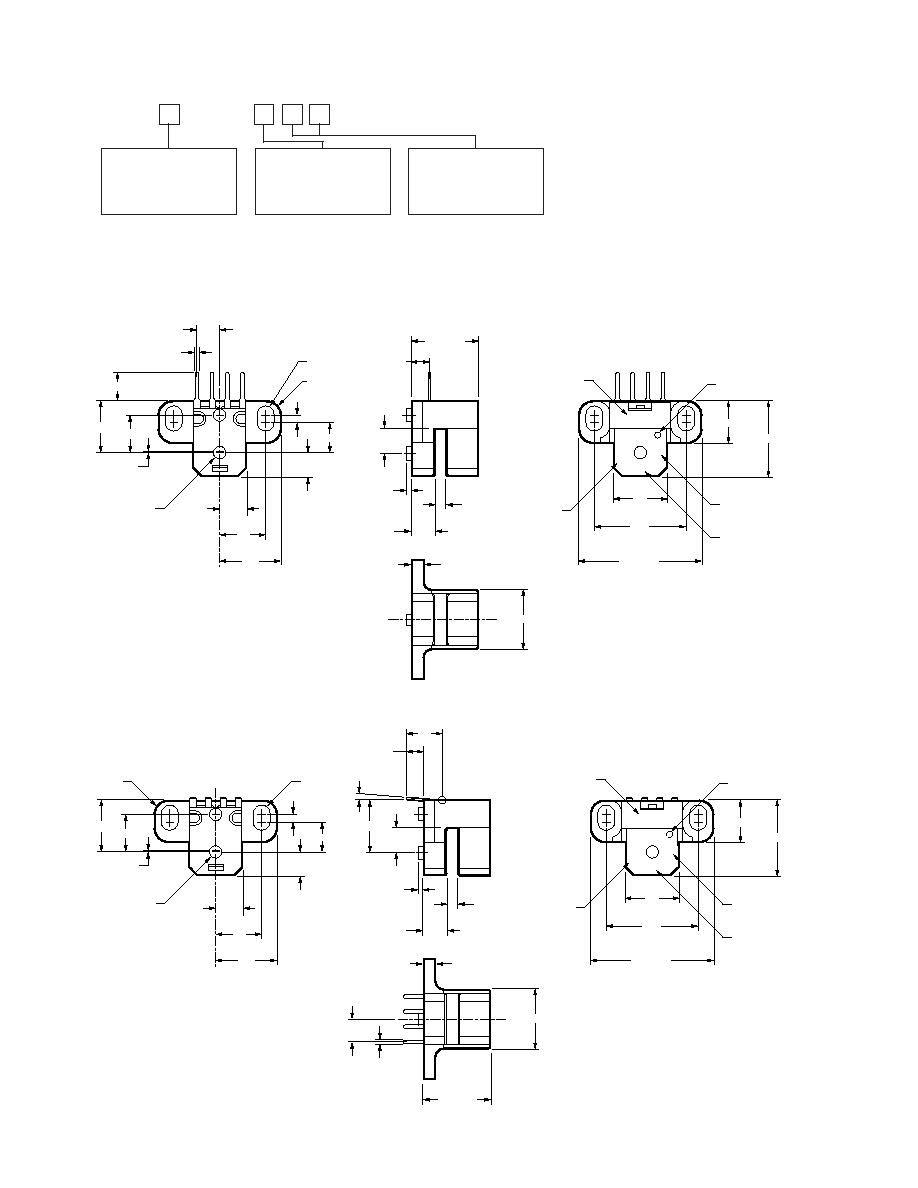

Block Diagram

Figure 1

RESISTOR

LENS

LED

COMPARATORS

PHOTO-

DIODES

SIGNAL

PROCESSING

CIRCUITRY

+

Ð

A

2

A

EMITTER SECTION

CODE

WHEEL

DETECTOR SECTION

+

Ð

B

4

GND

1

VCC

3

B

CHANNEL A

CHANNEL B

Features

· Small Size

· High Resolution

· Two Channel Quadrature Output

· Linear and Rotary Applications

· No Signal Adjustment required

· TTL or 3.3V/5V CMOS Compatible

· Wave Solderable

· Lead-free Package

· -40

o

C to 85

o

C Operating

Temperature

· Single 3.3V Supply

Applications

The HEDS- 973X provides

sophisticated motion detection,

making closed loop control very

cost competitive. Typical

applications include printers,

plotters, copiers and office

automation equipment.

Note:

Agilent Technologies' encoders are not

recommended for use in safety critical

applications, e.g., ABS braking systems and

critical-care medical equipment. Please contact a

sales representative if more clarification is

needed.

2

Theory of Operation

A HEDS- 973X is a C- shaped

emitter/detector module.

Coupled with a codewheel, it

translates rotary motion into a

two- channel digital output;

coupled with a codestrip, it

translates linear motion into

digital outputs.

As seen in Figure 1, the module

contains a single Light Emitting

Diode (LED) as its light source.

The light is collimated into

parallel beam by means of a

single lens located directly over

the LED. Opposite the emitter is

the integrated detector circuit.

This IC consists of

photodetectors and a signal

processing circuitry necessary

to produce the digital

waveforms.

The codewheel/codestrip moves

between the emitter and

detector, causing the light beam

to be interrupted by the pattern

of spaces and bars on the

codewheel/ codestrip. The

photodiodes, which detect these

interruptions, are arranged in a

pattern that corresponds to the

radius and count density of the

codewheel/ codestrip. These

photodiodes are also spaced

such that a light period on one

pair of detectors corresponds to

a dark period on the adjacent

pairs of detectors. The

photodiode outputs are fed

through the signal processing

circuitry. Two comparators

receive these signal and produce

the final outputs for Channels A

and B. Due to this integrated

phasing technique the output of

channel A is in quadrature with

Channel B (90 degrees out of

phase).

Definitions

Note: Refer to Figure 2

Count (N): The number of bar

and window pairs or counts per

revolution (CPR) of the

codewheel. Or the number of

lines per inch of the codestrip

(LPI)

1 shaft Rotation = 360 degrees

= N cycles

1 cycle (c) = 360 electrical

degree, equivalent to 1 bar and

window pair.

Pulse Width (P): The number of

electrical degrees that an output

is high during one cycle,

nominally 180

°

e or 1/2 a cycle.

Pulse Width Error (

P): The

deviation in electrical degrees of

the pulse width from its ideal

value of 180

°

e.

State Width (S): The number of

electrical degrees between a

transition in the output of

channel A and the neighboring

transition in the output of

channel B. There are 4 states

per cycle, each nominally 90

°

e.

State Width Error (

S): The

deviation in electrical degrees of

each state width from its ideal

value of 90

°

e.

Phase (

): The number of

electrical degrees between the

center of the high state on

channel A and the center of the

high state on channel B. This

value is nominally 90

°

e for

quadrature output.

Phase Error (

): The deviation

in electrical degrees of the

phase from its ideal value of

90

°

e.

Direction of Rotation: When

the codewheel rotates in the

counter- clockwise direction (as

viewed from the encoder end of

the motor), channel A will lead

channel B. If the codewheel

rotates in the clockwise

direction, channel B will lead

channel A.

Optical Radius (R

op

): The

distance from the codewheel's

center of rotation to the optical

center (O

.

C) of the encoder

module.

Angular Misalignment Error

(E

A

): Angular misalignment of

the sensor in relation to then

tangential direction. This applies

for both rotary and linear

motion.

Mounting Position (R

M

):

Distance from Motor Shaft

center of rotation to center of

Alignment Tab receiving hole.

Output Waveforms

Figure 2.

3

Absolute Maximum Ratings

Recommended Operating Conditions

Electrical Characteristics

Encoding Characteristics

Parameter

Symbol

Min.

Max.

Units

Notes

Storage Temperature

T

S

-40

85

°

C

Operating Temperature

T

A

-40

85

°

C

Supply Voltage

V

CC

-0.5

7

Volts

Output Voltage

V

O

-0.5

V

CC

Volts

Output Current per Channel

I

OUT

-1.5

19

mA

Soldering Temperature

T

SOL

20

260

°

C

t

5 sec

Parameter

Symbol

Min.

Typ.

Max.

Units

Notes

Temperature

T

A

-40

85

°

C

Supply Voltage

V

CC

2.8

3.3 or 5

5.2

Volts

Ripple < 100mVp-p

Load Capacitance

C

L

100

pF

Pull-up Resistor

R

L

none

Recommend no pullup. Device

has integrated 2.5 k

on outputs

Frequency

f

40

kHz

Velocity (rpm) x N/60

Angular Misalignment

E

A

-2.0

0.0

+2.0

Deg.

Refer to Mounting Consideration

Mounting Position

R

M

R

OP

-0.14

(R

OP

-0.006)

mm

(inch)

Refer to Mounting Consideration

Electrical Characteristics Over the Recommended Operating Conditions. Typical Values at 25

°

C.

Parameter

Symbol

Min.

Typ.

Max.

Units

Notes

Supply Current

I

CC

12

25

40

mA

Typ. 3.3V

55

85

Typ. 5V

High Level Output Voltage

V

OH

2.4

Volts

When V

OH

= 2.4V (Min)Typ.

I

OH

= -0.4 mA @ 3.3VTyp.

I

OH

= -1.0 mA @ 5V

Low Level Output Voltage

V

OL

0.4

Volts

When V

OL

= 0.4V (Max)Typ.

I

OL

= 12 mA @ 3.3VTyp.

I

OL

= 14 mA @ 5V

Rise Time

t

r

200

ns

C

L

=25 pF

Fall Time

t

f

50

ns

Encoding Characteristics Over the Recommended Operating Conditions and Mounting Conditions These characteristics do

not include codewheel/codestrip contribution. The typical values are average over the full rotation of the codewheel

Parameter

Symbol

Typical

Maximum Units

Notes

Pulse Width Error

P

5

50

°

e

State Width Error

S

3

50

°

e

Phase Error

2

15

°

e

4

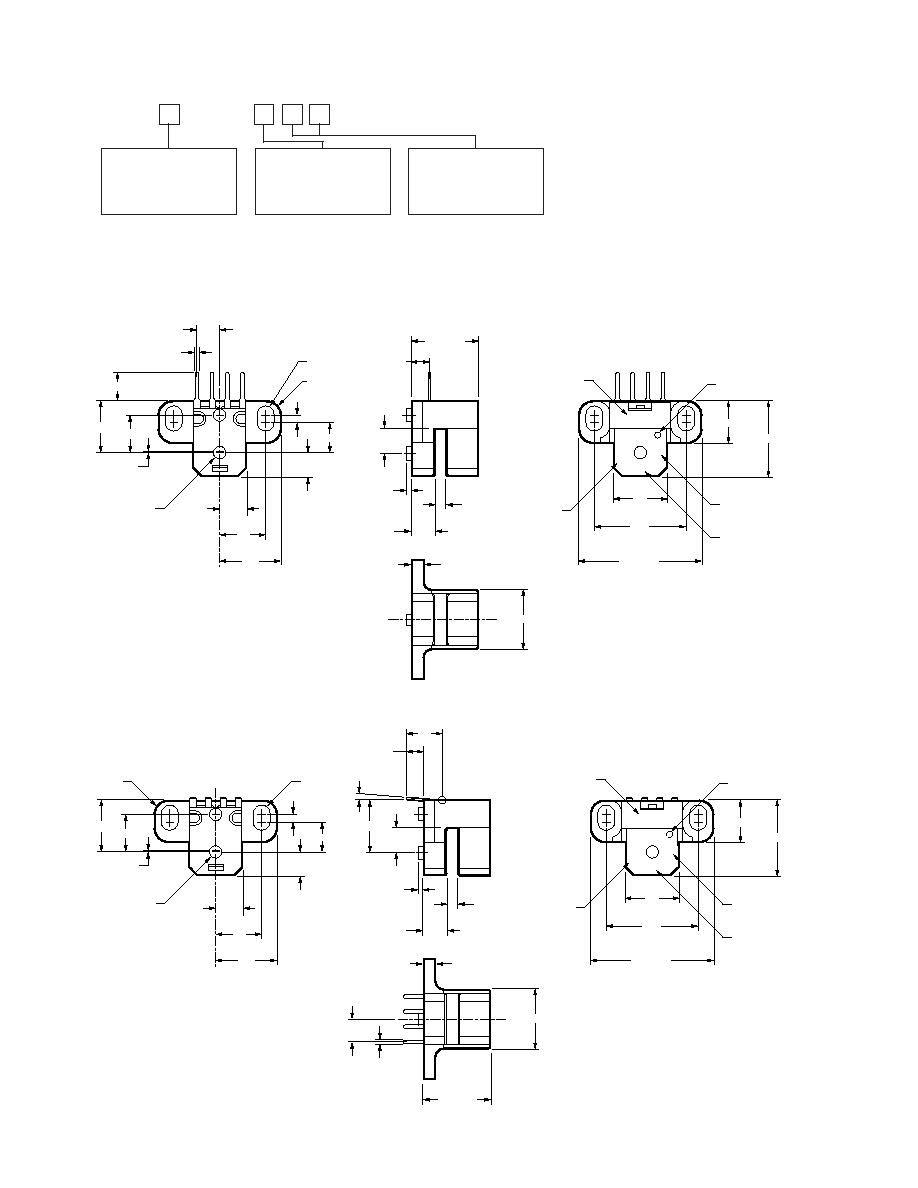

Mounting Considerations

Note: These dimensions include shaft end play and codewheel warp.

For both rotary and linear motion, angular misalignment, E

A

must be

±

1 degrees to achieve Encoding Characteristics.

All dimension for mounting the module and codewheel/codestrip should be measured with respect to two mounting posts, as shown above

Recommended Codewheel and Codestrip Characteristics

Parameter

Symbol

Min.

Max.

Unit

Notes

Window/bar Ratio

Ww/Wb

0.9

1.1

Window Length (Rotary)

L

W

1.80

(0.071)

2.31

(0.091)

mm

(inch)

Absolute Maximum Codewheel Radius

(Rotary)

R

c

Rop + 3.40

(Rop + 0.134)

mm

(inch)

Includes eccentricity errors

Center of Post to Inside Edge of Window

W1

1.04

(0.041)

mm

(inch)

Center of Post to Outside Edge of Window

W2

0.76

(0.036)

mm

(inch)

Center of Post to Inside Edge of Codestrip

L

3.60

(0.142)

mm

(inch)

E A

ALIGNMENT TAB RECEIVING HOLE

IMAGE SIDE OF

CODEWHEEL/CODESTRIP

A 0.13 mm (0.005")

CENTER OF ROTATION

MOTOR SHAFT CENTER

- A -

Rm

MAX.

Rop

Rm = Rop - 0.14 (0.006)

DIMENSIONS IN MILLIMETERS (INCHES).

L

C OF ALIGNMENT TAB

5.32

(0.209)

SEE NOTE 1

MAX.

6.30

(0.248)

MIN.

6.50

(0.256)

2X R

HOLE MIN.

2.03

(0.080)

DEEP MIN.

1.0

(0.039)

MIN.

2.03

(0.080)

DEEP MIN.

1.0

(0.039)

4.40 ± 0.13

0.17 ± 0.005

Lw

Wb

Wb

Rop

W1

W2

Rc

Ww

Ww

MAX 3.4 (0.134)

L

5

Ordering Information

Package Dimension

HEDS - 973

Lead Configurations

0 - Straight leads

1 - Bent leads

Bracket Option

50

Resolution

3 - 480 LPI

Option

Option 50

XXXXX

YYWW

C X

50

AGILENT

8.7

6.4

0.14

(OPTICAL CENTER)

2x

2.00 ± 0.02

1.4

5.0

3.9

R 1.4

10.1

7.5

4.2

3.90 ± 0.10

0.8

1.70 ± 0.15

4.2

3.0

9.8

1.8

3.8

0.5

20.2 ± 0.5

15.0

8.4

PART #

(REFER -05)

C = COUNTRY

OF ORIGIN

MARKING

(REFER -05

FOR DETAILS)

DATE CODE

12.6 ± 0.5

7.0

OPTION CODE

PIN 1 ID

CH B

V

CC

CH A

GND

LEAD THICKNESS = 0.25 mm

LEAD PITCH = 2.54 mm

10.8 ± 0.5

5.5 ± 0.3

R 2.6

Bent Version - Option 50

XXXXX

YYWW

C X

50

AGILENT

8.7

6.4

0.14

(OPTICAL CENTER)

2x

2.00 ± 0.02

R 2.6

1.4

5.0

3.9

R 1.4

10.1

7.5

4.2

3.90 ± 0.10

0.8

1.70 ± 0.15

9.2 ± 0.3

5° TYP.

4.2

3.0 ± 0.3

6.0

9.8

1.8

10.8 ± 0.5

3.8

0.5

20.2 ± 0.5

15.0

8.4

PART #

(REFER -05)

DATE CODE

12.6 ± 0.5

7.0

OPTION CODE

PIN 1 ID

CH B

V

CC

CH A

GND

LEAD THICKNESS = 0.25 mm

LEAD PITCH = 2.54 mm

C = COUNTRY

OF ORIGIN

MARKING

(REFER -05

FOR DETAILS)