HEDS-9000 (8 pg)

Two Channel Optical

Incremental Encoder Modules

Technical Data

Features

· High Performance

· High Resolution

· Low Cost

· Easy to Mount

· No Signal Adjustment

Required

· Small Size

· -40

°

C to 100

°

C Operating

Temperature

· Two Channel Quadrature

Output

· TTL Compatible

· Single 5 V Supply

Description

The HEDS-9000 and the HEDS-

9100 series are high performance,

low cost, optical incremental

encoder modules. When used with

a codewheel, these modules

detect rotary position. The

modules consist of a lensed (LED)

source and a detector IC enclosed

in a small C-shaped plastic

package. Due to a highly col-

limated light source and unique

photodetector array, these

modules are extremely tolerant to

mounting misalignment.

The two channel digital outputs

and the single 5 V supply input

are accessed through five 0.025

inch square pins located on 0.1

inch centers.

Standard resolutions for the

HEDS-9000 are 500 CPR and

1000 CPR for use with a HEDS-

6100 codewheel or equivalent.

ESD WARNING: NORMAL HANDLING PRECAUTIONS SHOULD BE TAKEN TO AVOID STATIC DISCHARGE.

HEDS-9000

HEDS-9100

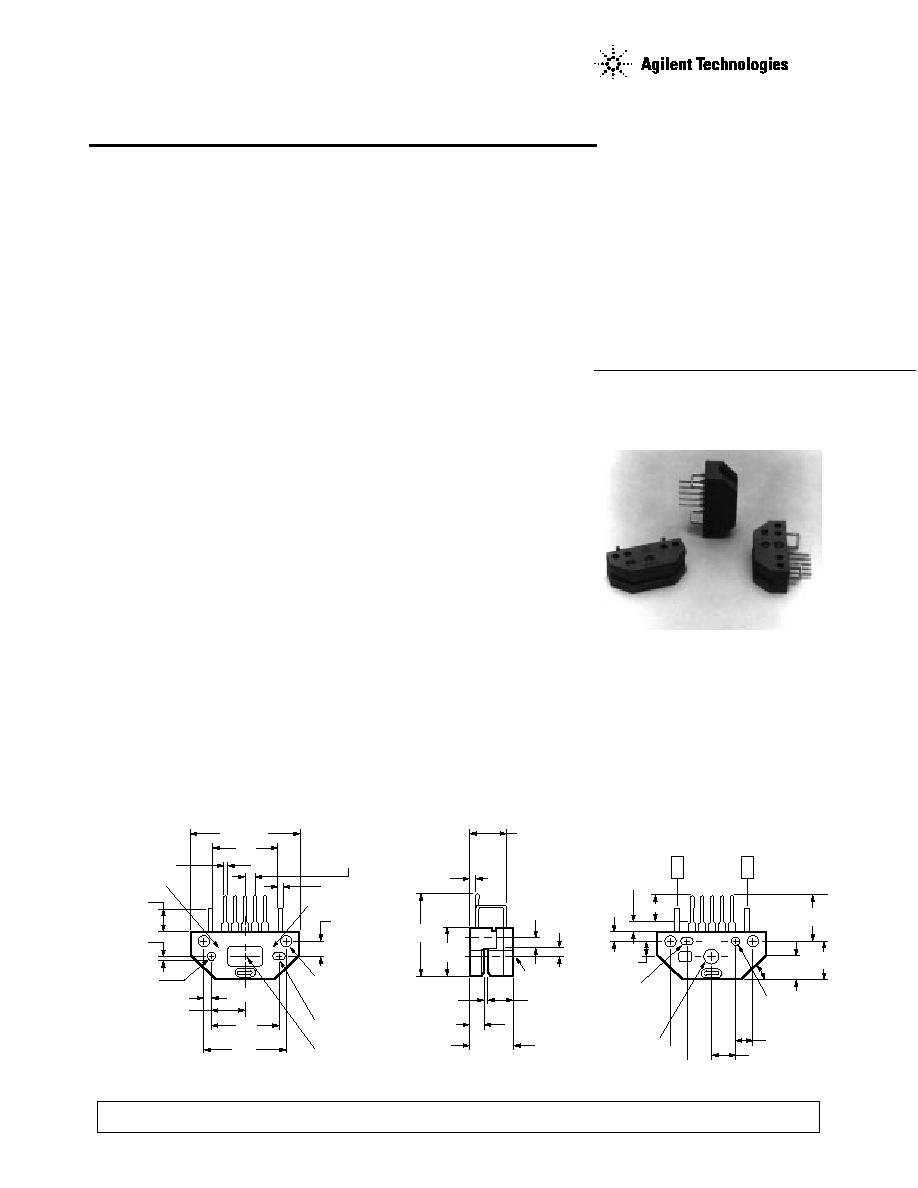

Package Dimensions

26.67 (1.05)

HEDS-9X00

15.2

(0.60)

CL

17.27

(0.680)

20.96

(0.825)

1.85 (0.073)

8.64 (0.340)

REF.

ALIGNING RECESS

2.44/2.41 DIA.

(0.096/0.095)

2.16 (0.085)

DEEP

1.02 ± 0.10

(0.040 ± 0.004)

5.1 (0.20)

X00

YYXX

OPTION CODE

0.63 (0.025)

SQR. TYP.

2.54 (0.100) TYP.

DATE CODE

1.0 (0.04)

3.73 ± 0.05

(0.147 ± 0.002)

2.67 (0.105) DIA.

MOUNTING THRU

HOLE 2 PLACES

2.44/2.41 X 2.79

(0.096/0.095 X 0.110)

2.16 (0.085) DEEP

OPTICAL CENTER

1.52 (0.060)

20.8

(0.82)

11.7

(0.46)

8.6 (0.34)

1.78 ± 0.10

(0.070 ± 0.004)

2.92 ± 0.10

(0.115 ± 0.004)

10.16

(0.400)

5.46 ± 0.10

(0.215 ± 0.004)

OPTICAL

CENTER LINE

2.54

(0.100)

2.21

(0.087)

5.8

(0.23)

6.35 (0.250) REF.

ALIGNING RECESS

2.44/2.41 X 2.79

(0.096/0.095 X 0.110)

2.16 (0.085) DEEP

4.11 (0.162)

ALIGNING RECESS

2.44/2.41 DIA.

(0.096/0.095)

2.16 (0.085) DEEP

OPTICAL

CENTER

45°

8.81

(0.347)

11.9

(0.47)

4.75 ± 0.10

(0.187 ± 0.004)

2.9

(0.11)

1.8

(0.07)

6.9 (0.27)

V

CC

GND

5 CH. B

4 V

CC

3 CH. A

2 N.C.

1 GND

SIDE A

SIDE B

TYPICAL DIMENSIONS IN

MILLIMETERS AND (INCHES)

2

For the HEDS-9100, standard

resolutions between 96 CPR and

512 CPR are available for use

with a HEDS-5120 codewheel or

equivalent.

Applications

The HEDS-9000 and 9100

provide sophisticated motion

detection at a low cost, making

them ideal for high volume

applications. Typical applications

include printers, plotters, tape

drives, and factory automation

equipment.

Note: Agilent Technologies

encoders are not recommended

for use in safety critical

applications. Eg. ABS braking

systems, power steering, life

support systems and critical care

medical equipment. Please

contact sales representative if

more clarification is needed.

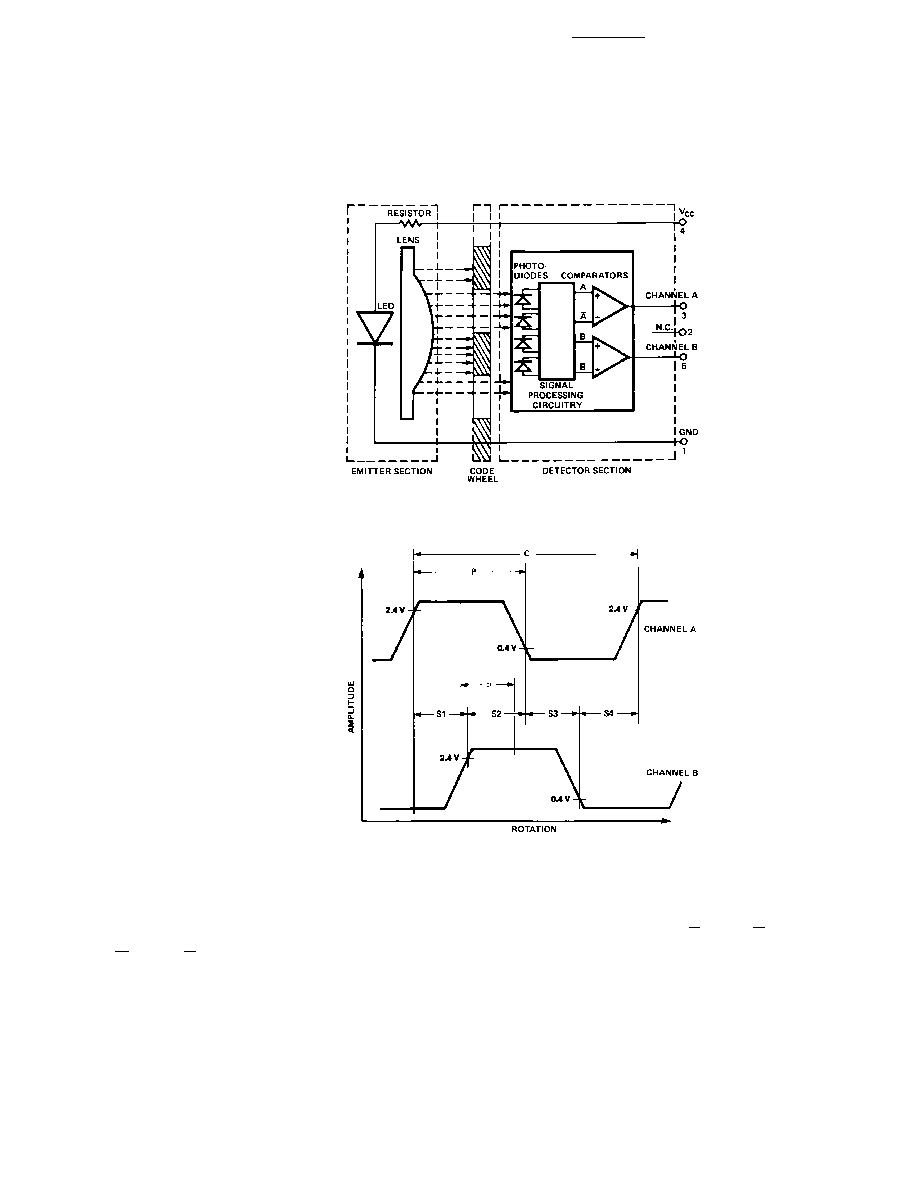

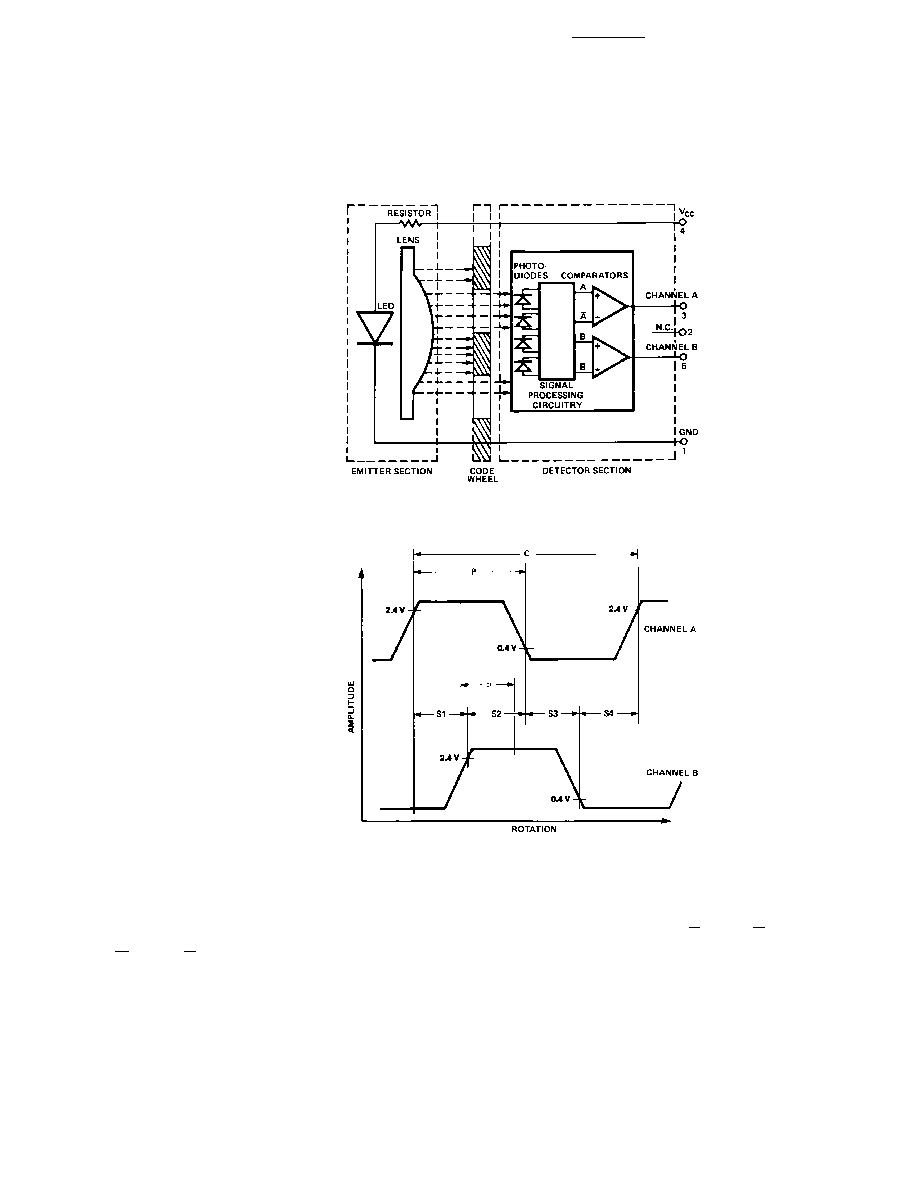

Theory of Operation

The HEDS-9000 and 9100 are C-

shaped emitter/detector modules.

Coupled with a codewheel, they

translate the rotary motion of a

shaft into a two-channel digital

output.

As seen in the block diagram,

each module contains a single

Light Emitting Diode (LED) as its

light source. The light is

collimated into a parallel beam by

means of a single polycarbonate

lens located directly over the

LED. Opposite the emitter is the

integrated detector circuit. This

IC consists of multiple sets of

photodetectors and the signal

processing circuitry necessary to

product the digital waveforms.

The codewheel rotates between

the emitter and detector, causing

the light beam to be interrupted

Block Diagram

by the pattern of spaces and bars

on the codewheel. The

photodiodes which detect these

interruptions are arranged in a

pattern that corresponds to the

radius and design of the ode-

wheel. These detectors are also

spaced such that a light period on

one pair of detectors corresponds

to a dark period on the adjacent

pair of detectors. The photodiode

outputs are then fed through the

signal processing circuitry

resulting in A, A, B, and B. Two

comparators receive these signals

and produce the final outputs for

channels A and B. Due to this

integrated phasing technique, the

digital output of channel A is in

quadrature with that of channel B

(90 degrees out of phase).

Output Waveforms

3

Absolute Maximum Ratings

Storage Temperature, T

S .....................................................................

-40

°

C to 100

°

C

Operating Temperature, T

A ................................................................

-40

°

C to 100

°

C

Supply Voltage, V

CC ......................................................................................

-0.5 V to 7 V

Output Voltage, V

O ........................................................................................

-0.5 V to V

CC

Output Current per Channel, I

out .................................................

-1.0 mA to 5 mA

Definitions

Count (N):

The number of bar

and window pairs or counts per

revolution (CPR) of the

codewheel.

1 Shaft Rotation = 360

mechanical

degrees,

= N cycles.

1 cycle (C) = 360

electrical

degrees (

°

e),

= 1 bar and

window pair.

Pulse Width (P): The number of

electrical degrees that an output

is high during 1 cycle. This value

is nominally 180

°

e or 1/2 cycle.

Pulse Width Error (

P):

The

deviation, in electrical degrees of

the pulse width from its ideal

value of 180

°

e.

State Width (S):

The number of

electrical degrees between a

transition in the output of channel

A and the neighboring transition

in the output of channel B. There

are 4 states per cycle, each

nominally 90

°

e.

State Width Error (

S):

The

deviation, in electrical degrees, of

each state width from its ideal

value of 90

°

e.

Phase (

):

The number of elec-

trical degrees between the center

of the high state of channel A and

the center of the high state of

channel B. This value is nominally

90

°

e for quadrature output.

Phase Error (

):

The deviation

of the phase from its ideal value

of 90

°

e.

Direction of Rotation:

When the

codewheel rotates in the direction

of the arrow on top of the

module, channel A will lead

channel B. If the codewheel

rotates in the opposite direction,

channel B will lead channel A.

Optical Radius (R

op

):

The dis-

tance from the codewheel's center

of rotation to the optical center

(O.C.) of the encoder module.

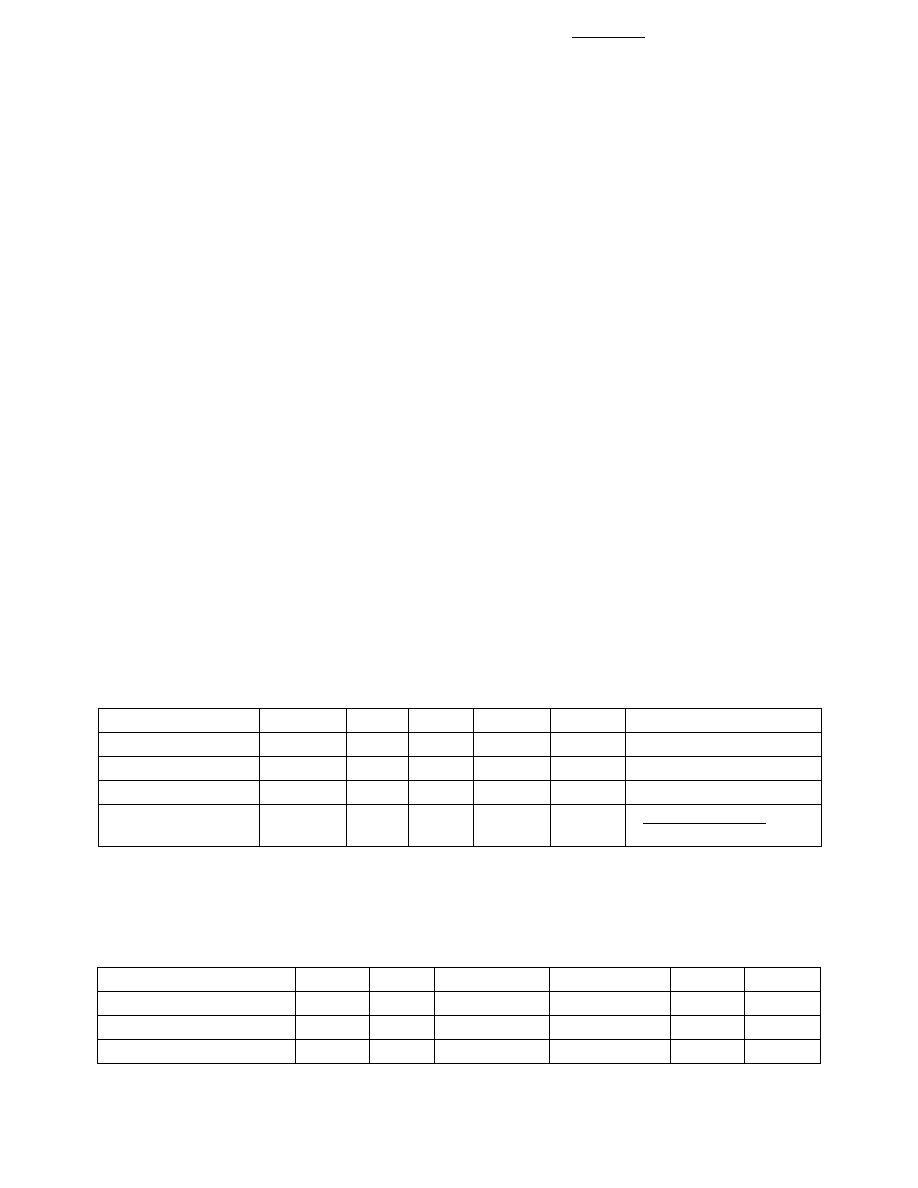

Recommended Operating Conditions

Parameter

Symbol

Min.

Typ.

Max.

Units

Notes

Temperature

T

-40

100

°

C

Supply Voltage

V

CC

4.5

5.5

Volts

Ripple < 100 mV

p-p

Load Capacitance

C

L

100

pF

3.3 k

pull-up resistor

Count Frequency

f

100

kHz

Velocity (rpm) x N

60

Note: The module performance is guaranteed to 100 kHz but can operate at higher frequencies.

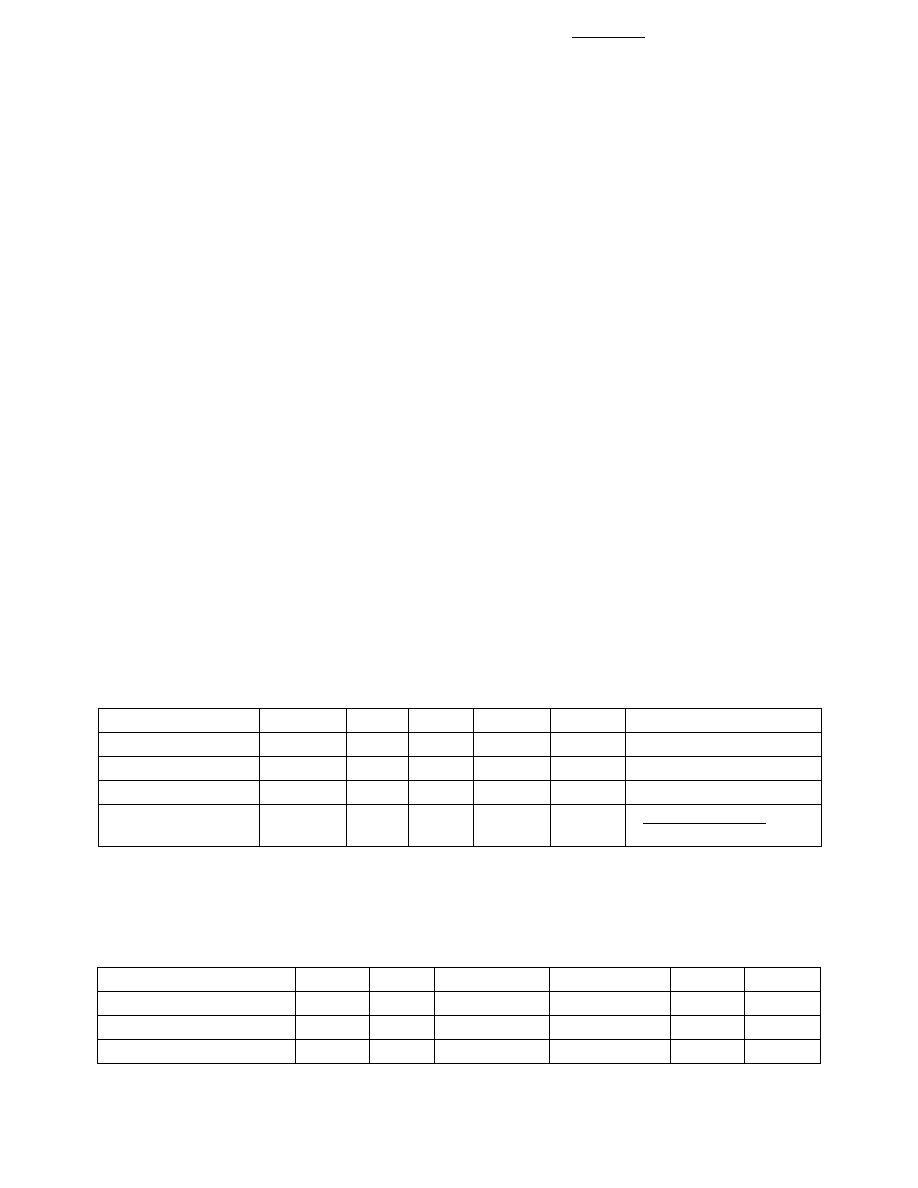

Encoding Characteristics

Encoding Characteristics over Recommended Operating Range and Recommended Mounting Tolerances.

These Characteristics do not include codewheel/codestrip contribution.

Description

Sym.

Typ.

Case 1 Max.

Case 2 Max.

Units

Notes

Pulse Width Error

P

30

40

°

e

Logic State Width Error

S

30

40

°

e

Phase Error

2

10

105

°

e

Case 1: Module mounted on tolerance circle of

±

0.13 mm (

±

0.005 in.).

Case 2: HEDS-9000 mounted on tolerances of

±

0.50 mm (0.020").

HEDS-9100 mounted ontolerances of

±

0.38 mm (0.015").

4

Electrical Characteristics

Electrical Characteristics over Recommended Operating Range, typical at 25

°

C.

Parameter

Symbol

Min.

Typical

Max.

Units

Notes

Supply Current

I

CC

17

40

mA

High Level Output Voltage

V

OH

2.4

Volts

I

OH

= -40

µ

A max.

Low Level Output Voltage

V

OL

0.4

Volts

I

OL

= 3.2 mA

Rise Time

t

r

200

ns

C

L

= 25 pF

Fall Time

t

f

50

ns

R

L

= 11 k

pull-up

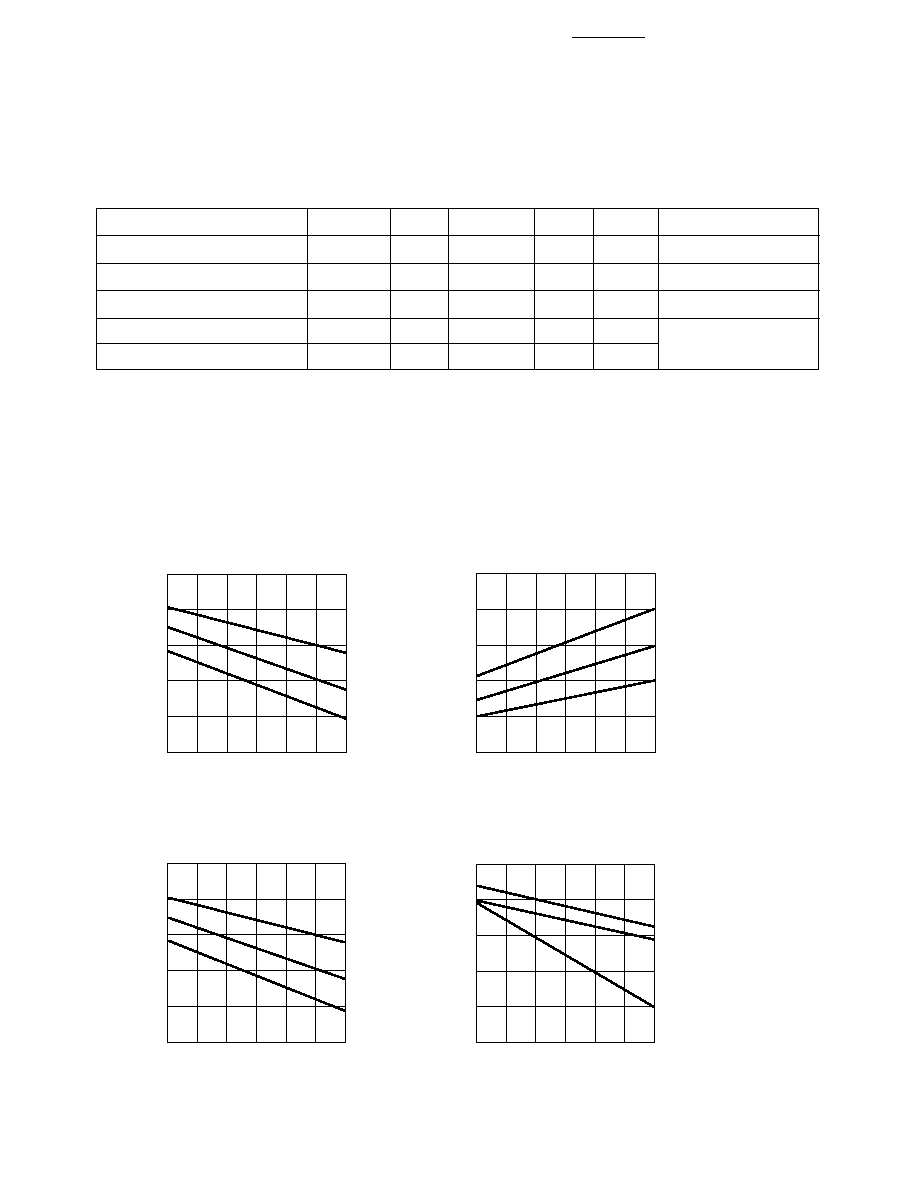

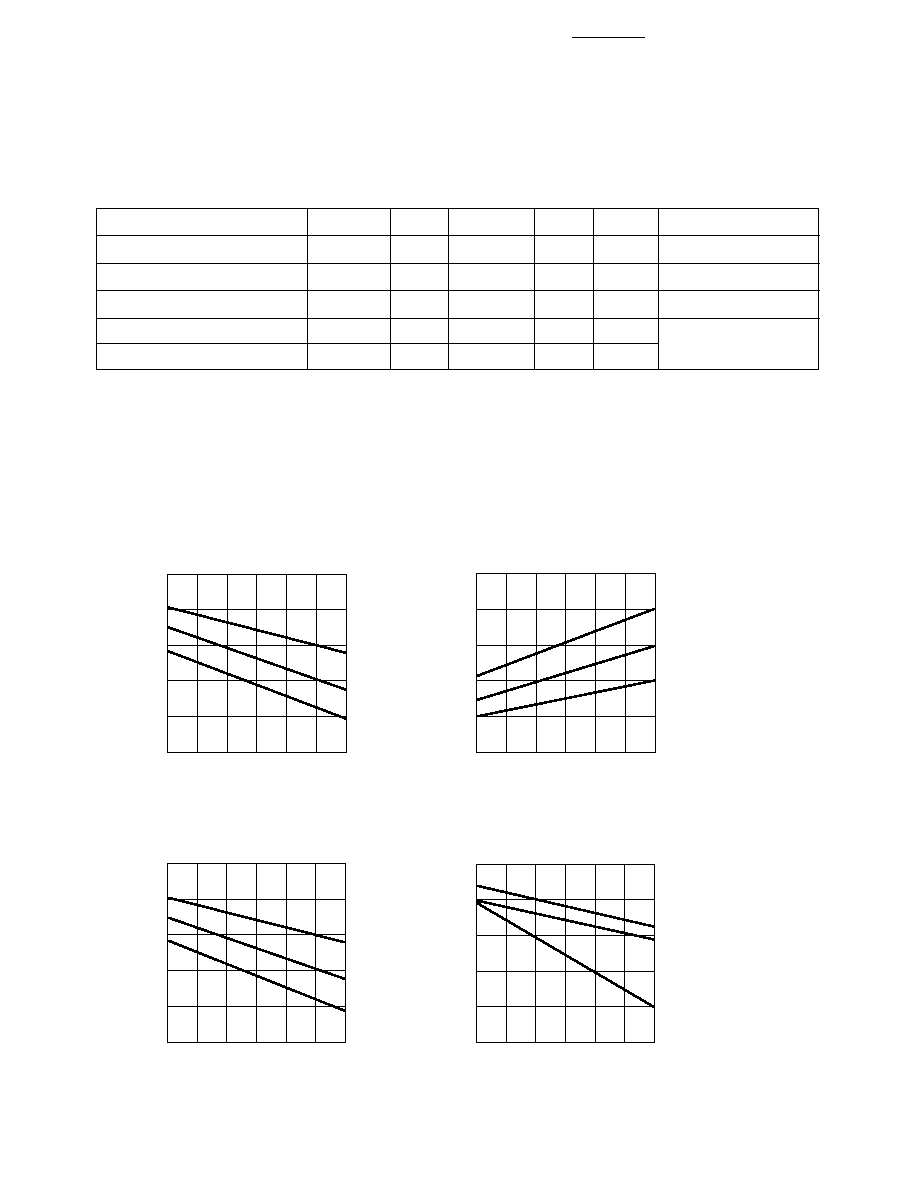

Derating Curves over Extended Operating Frequencies (HEDS-9000/9100)

Below are the derating curves for state, duty, phase and V

OH

over extended operating frequencies of up to

240 kHz (recommended maximum frequency is 100 kHz). The curves were derived using standard TTL load.

40

°

C operation is not feasible above 160 kHz because V

OH

will drop below 2.4 V (the minmum TTL for logic

state high) beyond that frequency.

120

220

FREQUENCY (kHz)

-40

0

CHANGE IN PULSE WIDTH ERROR

(ELECTRICAL DEGREE)

240

-30

-20

160

-10

140

200

180

100°C

25°C

-40°C

-50

120

220

FREQUENCY (kHz)

10

50

CHANGE IN STATE WIDTH ERROR

(ELECTRICAL DEGREE)

240

20

30

160

40

140

200

180

100°C

25°C

-40°C

0

120

220

FREQUENCY (kHz)

-10

0

CHANGE IN PHASE ERROR

(ELECTRICAL DEGREE)

240

-5

160

140

200

180

100°C

25°C

-40°C

120

220

FREQUENCY (kHz)

3

5

CHANGE IN V

OH

(VOLTS)

240

4

160

140

200

180

100°C

25°C

-40°C

2

1

0

5

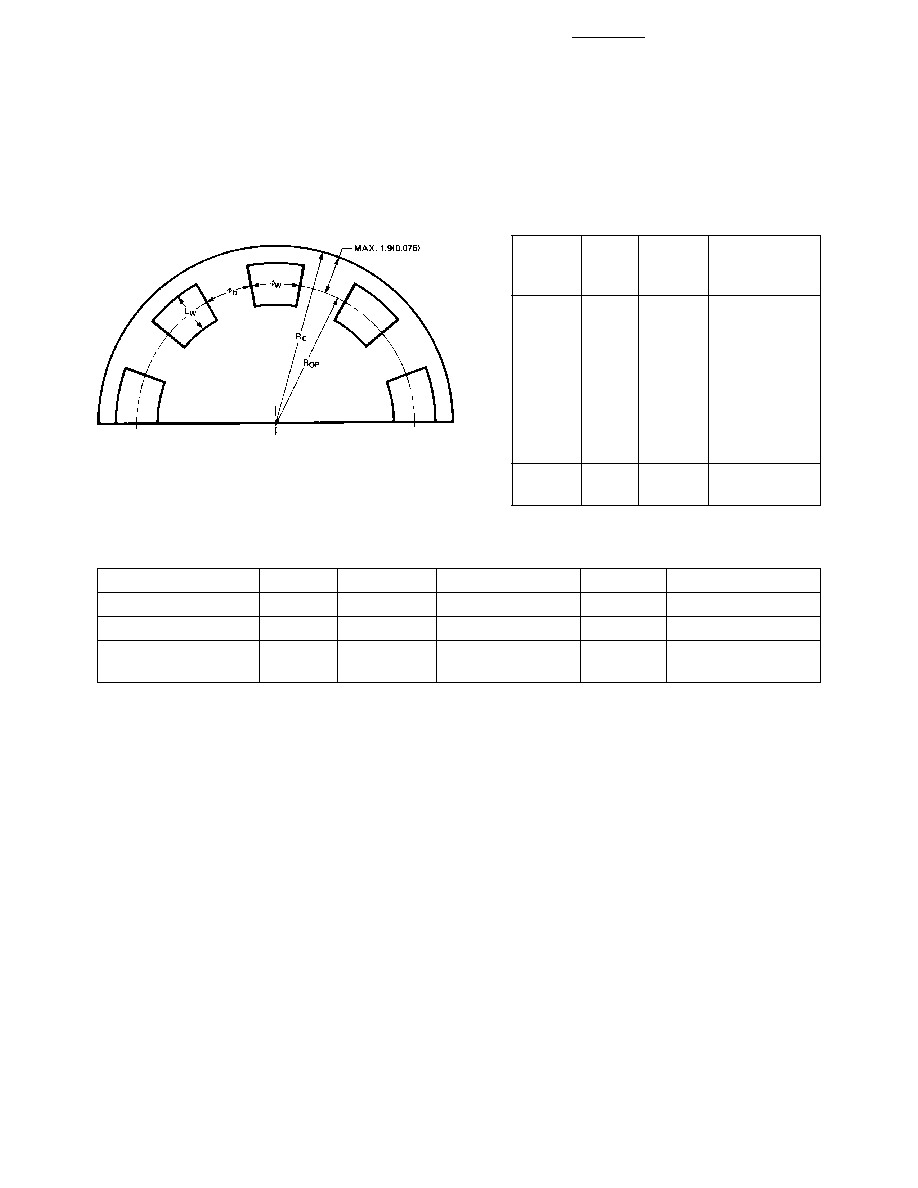

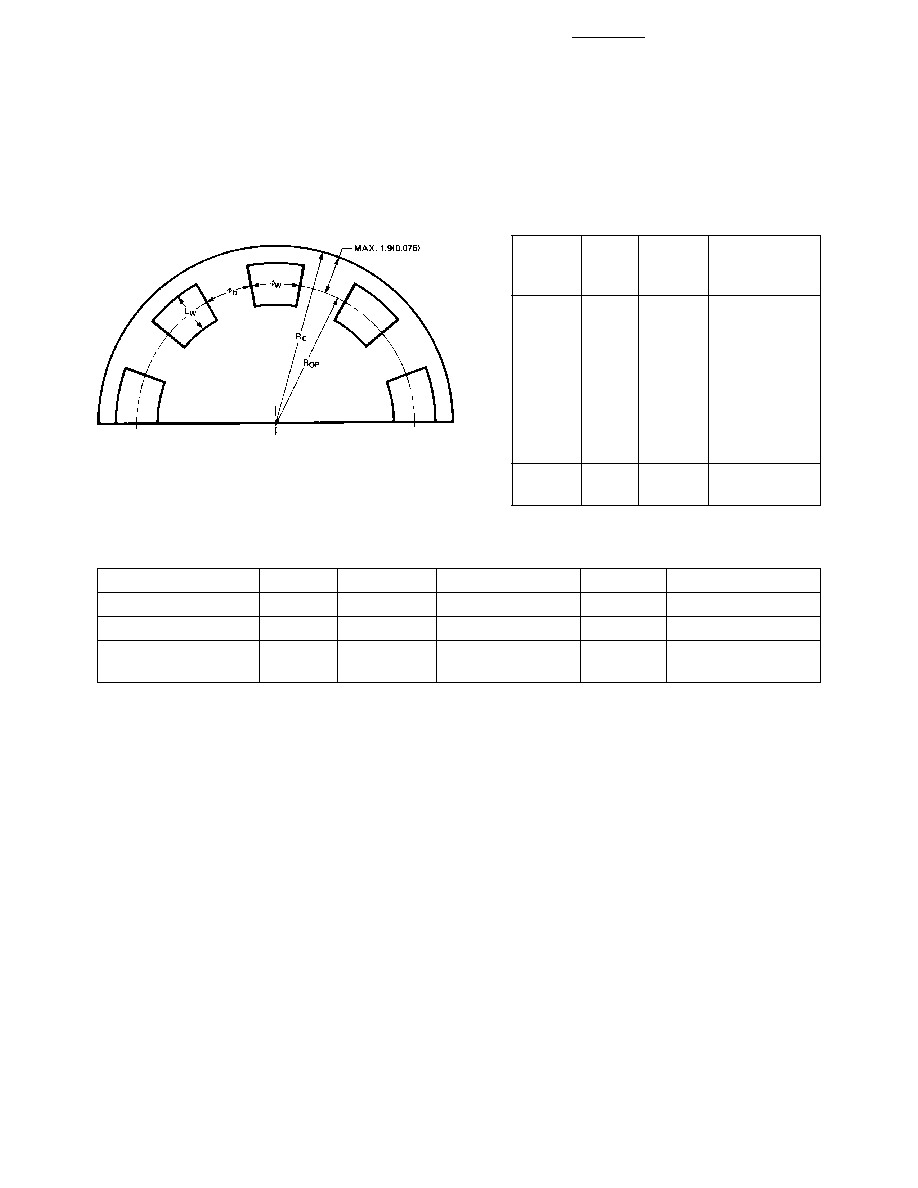

Recommended Codewheel Characteristics

Figure 1. Codestrip Design

Codewheel Options

Optical

HEDS

CPR

Radius

Series

(N)

Option

mm (in.)

5120

96

K

11.00 (0.433)

5120

100

C

11.00 (0.433)

5120

192

D

11.00 (0.433)

5120

200

E

11.00 (0.433)

5120

256

F

11.00 (0.433)

5120

360

G

11.00 (0.433)

5120

400

H

11.00 (0.433)

5120

500

A

11.00 (0.433)

5120

512

I

11.00 (0.433)

6100

500

A

23.36 (0.920)

6100

1000

B

23.36 (0.920)

Parameter

Symbol

Minimum

Maximum

Units

Notes

Window/Bar Ratio

w

/

b

0.7

1.4

Window Length

L

W

1.8 (0.071)

2.3 (0.09)

mm (inch)

Absolute Maximum

R

C

R

OP

+ 1.9 (0.0075)

mm (inch)

Includes eccentricity

Codewheel Radius

errors

Document Outline