AX07CF192

32-Bit Embedded Flash MCU

User's Manual

(Preliminary)

Aeroflex Microelectronic Solutions

4350 Centennial Blvd.

Colo. Spgs., CO 80907

www.aeroflex.com

January, 2003

AX07CF192

2

Aeroflex Microelectronic Solutions Sales Offices

Main Office

Boston Office

European Office

4350 Centennial Blvd.

6 Daniel Webster Hwy, #3

719-594-8166

Colo. Spgs., CO 80907

Nashua, NH 03602

800-645-8862

603-888-3975

Melbourne Sales Office

California Sales Office

1901 S. Harbor City Blvd., Suite 802

120 Columbia St., Suite 200

Melbourne, FL 32901

Aliso Viejo, CA 92656

321-951-4164

949-362-2260

ARM

®

is trademark of Advanced RISC Machine Ltd.

ARM7TDMI is designed by ARM Ltd.

Aeroflex Microelectronic Solutions reserves the right to make changes to any products and services herein at any

time without notice. Consult Aeroflex or an authorized sales representative to verify that the information in this

product handbook is current before using this product. Aeroflex does not assume any responsibility or liability arising

out of the application or use of any product or service described herein, except as expressly agreed to in writing by

Aeroflex ; nor does the purchase, lease, or use of a product or service from Aeroflex convey a license under any

patent rights, copyrights, trademark rights, or any other of the intellectual rights of Aeroflex or of third parties.

COPYRIGHT 2003

AX07CF192

3

Contents

Chapter 1...........................................................................................................................13

Introduction .................................................................................................................13

1.1

General Description................................................................................14

1.2

Features ................................................................................................15

1.3

Pin Descriptions .....................................................................................16

1.4

Operation Mode description ....................................................................21

1.5

Memory Map..........................................................................................25

Chapter 2...........................................................................................................................27

ARM7TDMI Core .........................................................................................................28

2.1

General Description................................................................................28

2.2

Features ................................................................................................28

2.3

Core Block Diagram................................................................................29

2.4

Instruction Set ........................................................................................30

2.4.1

ARM Instruction Set ...........................................................................30

2.4.2

THUMB Instruction Set ......................................................................33

2.4.3

The Program Status Registers ............................................................36

2.4.3.1

The condition code flags ...........................................................36

2.4.3.2

The control bits ........................................................................37

2.4.4

ARM pseudo-instructions ...................................................................39

2.4.5

THUMB pseudo-instructions ...............................................................43

Chapter 3...........................................................................................................................43

BUS Controller ............................................................................................................47

3.1

Overview ...............................................................................................48

3.1.1

Features ...........................................................................................48

3.1.2

Pin Configuration ...............................................................................49

3.2

Bus Controller Registers .........................................................................50

3.2.1

Configuration Registers......................................................................51

3.3

Operation...............................................................................................52

3.3.1

Area Division.....................................................................................52

3.3.2

Area Division.....................................................................................53

Chip Select Signals............................................................................53

3.4

Basic Bus Interface.................................................................................54

3.4.1

Overview...........................................................................................54

3.4.2

Byte Lane Write Control .....................................................................54

3.4.3

Basic Bus Control Signal Timing .........................................................56

3.4.4

Wait Control ......................................................................................63

3.4.5

Bus Arbiter ........................................................................................63

Chapter 4...........................................................................................................................65

MCU Controller............................................................................................................65

4.1

General Description................................................................................66

4.2

Pin Function Description.........................................................................66

4.3

Register Description ..............................................................................67

4.3.1

Register Memory Map........................................................................67

4.3.2

PINMUX Register ..............................................................................68

4.3.3

MCU Device Code Register

(0x0900_002C Read Only)

..........................71

Chapter 5...........................................................................................................................72

Power Management Unit..............................................................................................72

5.1

General Description................................................................................73

5.2

Operation Modes....................................................................................74

5.2.1

Introduction .......................................................................................74

5.2.2

Reset and Operation Modes ...............................................................74

5.3

Power Management Unit Register Map....................................................76

5.4

Register Description ...............................................................................77

AX07CF192

4

5.5

Signal Timing Diagram............................................................................80

5.5.1

Power on Reset .................................................................................80

5.5.2

Watchdog Timer Overflow ..................................................................80

5.5.3

Soft Reset .........................................................................................81

Chapter 6...........................................................................................................................82

The Interrupt Controller................................................................................................82

6.1

About the Interrupt controller ...................................................................83

6.1.1

Interrupt sources................................................................................84

6.1.2

Interrupt Control.................................................................................85

6.2

Interrupt Controller Registers ..................................................................86

Chapter 7...........................................................................................................................90

Watchdog Timer ..........................................................................................................90

7.1

General Description................................................................................91

7.2

Watchdog Timer Introduction...................................................................92

7.3

Watchdog Timer Operation......................................................................93

7.3.1

Overflow Flag Timing (setting and clearing).........................................94

7.4

Watchdog Timer Memory Map.................................................................95

7.5

Watchdog Timer Register Descriptions ....................................................96

7.6

Examples of Register Setting ..................................................................99

7.6.1

Interval Timer Mode ...........................................................................99

7.6.2

Watchdog Timer Mode with Internal Reset Disable...............................99

7.6.3

Watchdog Timer Mode with Power-on Reset ..................................... 100

7.6.4

Watchdog Timer Mode with Manual Reset......................................... 101

Chapter 8......................................................................................................................... 102

The General Purpose Timer ....................................................................................... 102

8.1

About the General Purpose Timer Unit................................................... 103

8.1.1

General Purpose Timer Unit Introduction........................................... 104

8.2

General Purpose Timer Unit Memory Map.............................................. 105

8.2.1

Register Assignment ........................................................................ 105

8.2.2

General Purpose Timer Unit Register Descriptions............................. 106

8.2.2.1

Timer Global Control Registers ............................................... 106

8.2.2.2

Timer Channel Control Registers............................................. 107

8.3

General Purpose Timer Unit Operation ...................................................111

8.3.1

Free Running Mode......................................................................... 112

8.3.2

Compare Match Mode...................................................................... 114

8.3.2

Input Capture Mode......................................................................... 116

8.3.4

Synchronized Clear and Write Mode ................................................. 117

8.3.5

PWM Mode ..................................................................................... 118

8.3.5.1

PWM Mode Operation ............................................................ 118

Chapter 9......................................................................................................................... 121

UART (Universal Asynchronous Receiver/Transmitter)................................................. 121

9.1

General Description.............................................................................. 122

9.2

Features .............................................................................................. 123

9.3

Signal Description ................................................................................ 123

9.4

Internal Block Diagram.......................................................................... 124

9.5

Registers Description............................................................................ 125

9.6

UART Operation................................................................................... 136

9.6.1

FIFO Interrupt Mode Operation......................................................... 136

9.6.2

FIFO Polled Mode Operation............................................................ 137

9.7

Register Summary................................................................................ 138

Chapter 10. ...................................................................................................................... 139

GPIO (General Purpose Input Output)......................................................................... 139

10.1

General Description.............................................................................. 140

10.2

GPIO Registers .................................................................................... 141

10.2.1 Register Memory Map...................................................................... 141

10.3.1 Register Description......................................................................... 142

10.3

Functional Description .......................................................................... 143

AX07CF192

5

Chapter 11 ....................................................................................................................... 144

On-Chip SRAM.......................................................................................................... 144

11.1

General Description.............................................................................. 145

11.2

Function Description............................................................................. 146

Chapter 12 ....................................................................................................................... 146

On-chip Flash Memory ............................................................................................... 147

12.1

General Description.............................................................................. 147

12.2

Features .............................................................................................. 149

12.3

Block Diagram...................................................................................... 151

12.4

Flash Memory Register Description ....................................................... 151

12.5

On-Board Programming Mode............................................................... 156

12.5.1 Boot Mode ....................................................................................... 156

12.5.2 User Program Mode......................................................................... 159

12.6

Flash Memory Programming/Erasing.................................................... 161

12.6.1 Program & Program-Verify Mode....................................................... 161

12.6.2 Pre-program & Pre-program Verify Mode........................................... 163

12.6.3 Erase & Erase Verify Mode............................................................... 165

12.6.4 Erase Algorithm................................................................................ 167

12.7

Flash Memory PROM Mode ................................................................. 168

12.7.1 PROM Mode Setting......................................................................... 168

12.7.2 Memory Map.................................................................................... 169

12.7.3 PROM Mode Operation .................................................................... 169

12.7.4 Timing Diagram and AC/DC Characteristics....................................... 171

Chapter 13 ....................................................................................................................... 175

A/D Converter ........................................................................................................... 175

13.1

Overview ............................................................................................. 176

13.1.1 Features ......................................................................................... 176

13.1.2 Pin Configuration............................................................................. 177

13.2

A/D Converter Registers ....................................................................... 178

13.2.1 Register Descriptions....................................................................... 178

13.3

Operation............................................................................................. 181

13.4

Interrupts ............................................................................................. 182

13.5

Usage Notes ........................................................................................ 182

13.6

Example .............................................................................................. 185

Chapter 14 ....................................................................................................................... 186

Electrical Characteristics............................................................................................ 186

14.1

Absolute Maximum Ratings................................................................... 187

14.2

Recommended Operating Conditions: ................................................... 187

14.3

DC Characteristics ............................................................................... 188

14.4

AC Characteristics ............................................................................... 189

14.4

AD Conversion characteristics (Preliminary)........................................... 191

14.5

Operational Timing ............................................................................... 192

14.5.1 Clock Timing ..................................................................................... 192

14.5.2 Reset Timing..................................................................................... 193

14.5.3 Bus Timing........................................................................................ 193

AX07CF192

6

Figures

Figure 1.1 Package Outline .........................................................................................14

Figure 1.2 AX07CF192 Block Diagram.........................................................................15

Figure 1.3 AX07CF192 Memory Map...........................................................................25

Figure 1.4 Memory Map of Mode 3...............................................................................25

Figure 1.5 Memory Map of when Mode 4 and Mode 5...................................................26

Figure 1.6 Memory Map of Mode 6 and Mode 7............................................................26

Figure 2.1 ARM7TDMI Core Block Diagram..................................................................29

Figure 2.2 ARM instruction set formats.........................................................................30

Figure 2.3 Register Organization in ARM state .............................................................32

Figure 2.4 THUMB instruction set formats ....................................................................33

Figure 2.5 Register Organization in THUMB state.........................................................35

Figure 2.6 Mapping of THUMB state registers onto ARM state registers.........................35

Figure 2.7 Program status register format.....................................................................36

Figure 3.1 Block Diagram of the Bus Controller.............................................................48

Figure 3.2 Access Area Map for Each Operating Mode .................................................52

Figure 3.3 Access Size and Data Alignment Control (8-Bit Access Area) ........................54

Figure 3.4 Access Size and Data Alignment Control (16-Bit Access Area) ......................55

Figure 3.5 Bus Control Signal Write Timing for 16-Bit, 1-Wait (Word Access)..................56

Figure 3.6 Bus Control Signal Read Timing for 16-Bit, 1-Wait (Word Access)..................56

Figure 3.7 Bus Control Signal Write Timing for 16-Bit, 1-Wait (Half-word Access)............57

Figure 3.8 Bus Control Signal Read Timing for 16-Bit, 1-Wait (Half-word Access) ...........57

Figure 3.9 Bus Control Signal Write Timing for 16-Bit, 1-Wait (Byte Access)...................58

Figure 3.10 Bus Control Signal Read Timing for 16-Bit, 1-Wait (Byte Access).................58

Figure 3.11 Bus Control Signal Write Timing for 16-Bit, 2-Wait (Word Access) ................59

Figure 3.12 Bus Control Signal Read Timing for 16-Bit, 2-Wait (Word Access)................59

Figure 3.13 Bus Control Signal Write Timing for 16-Bit, 2-Wait (Half-Word Access).........60

Figure 3.14 Bus Control Signal Read Timing for 16-Bit, 2-Wait (Half-Word Access).........60

Figure 3.15 Bus Control Signal Write Timing for 16-Bit, 2-Wait (Byte Access).................61

Figure 3.16 Bus Control Signal Read Timing for 16-Bit, 2-Wait (Byte Access).................61

Figure 3.17 Example of Wait State Insertion Timing.......................................................62

Figure 3.18 Example of External Bus Master Operation.................................................64

Figure 5.1 PMU Block Diagram....................................................................................74

Figure 5.2 Reset and Power Management State Machine..............................................76

Figure 5.3 Power on Reset Timing Diagram..................................................................80

Figure 5.4 Watch Dog Timer Overflow Timing Diagram..................................................81

Figure 5.5 Soft Reset (from WDT) Timing Diagram........................................................80

Figure 5.6 Soft Reset (from PMU) Timing Diagram........................................................81

Figure 6.1 Interrupt Control Flow Diagram ....................................................................83

Figure 7.1 Watchdog Timer Module Block Diagram .......................................................91

Figure 7.2 Operation in the Watchdog Timer Mode........................................................93

Figure 7.3 Operation in the Interval Timer Mode............................................................94

Figure 7.4 Interrupt Clear in the Interval Timer Mode.....................................................98

Figure 7.5 Interrupt Clear in the Watchdog Timer Mode with Reset Disable ....................99

Figure 7.6 Interrupt Clear in the Watchdog Timer Mode with Power-on Reset ............... 100

Figure 7.7 Interrupt Clear in the Watchdog Timer Mode with Manual Reset................... 101

Figure 8.1 General-purpose Timer Unit Module Block Diagram .................................... 103

Figure 8.2 Free-Running Counter Operation ............................................................... 112

Figure 8.3 Periodic Counter Operation ....................................................................... 113

Figure 8.4 Example of 0 Output/1 Output.................................................................... 114

Figure 8.5 Example of Toggle Output ......................................................................... 115

Figure 8.6 Compare Match Signal Output Timing ........................................................ 115

Figure 8.7 Input Capture Operation............................................................................ 116

Figure 8.8 Synchronized Operation Example .............................................................. 117

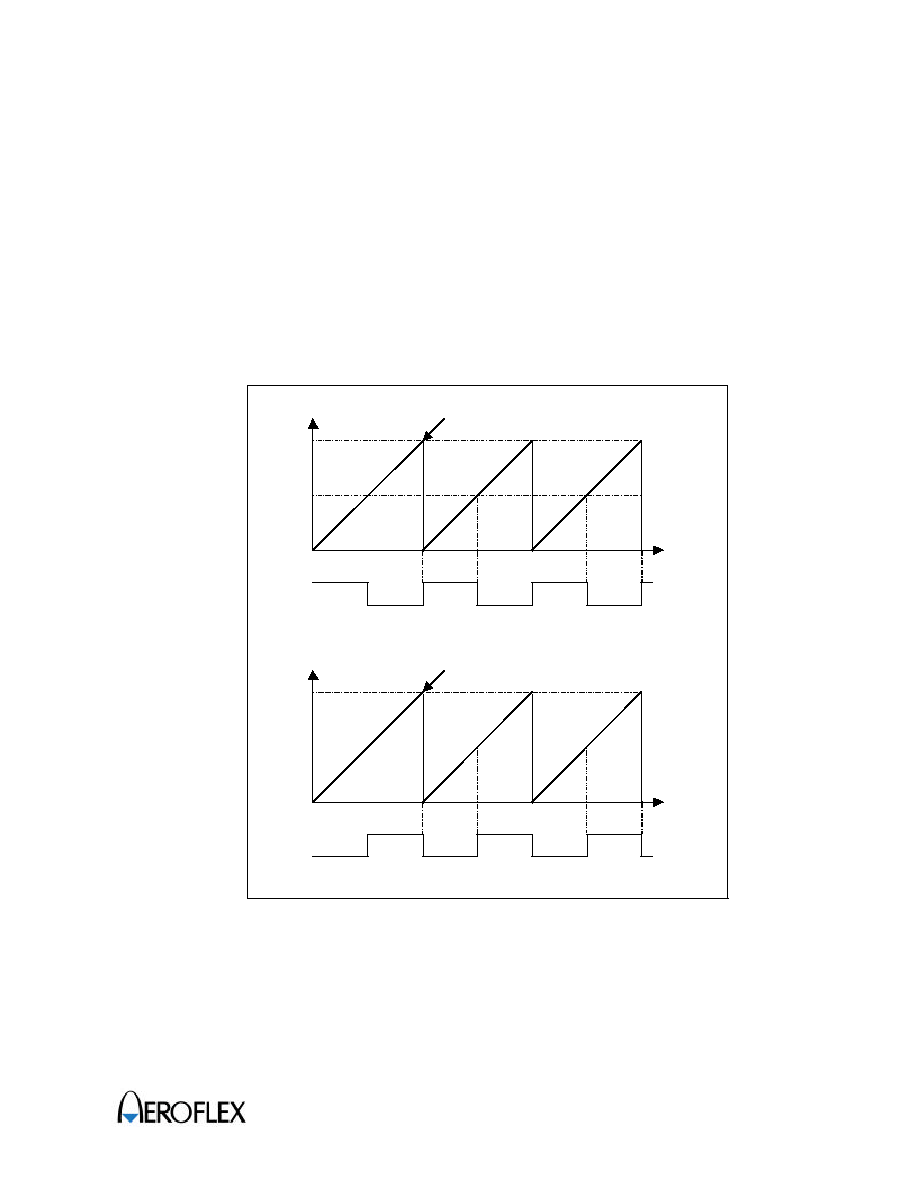

Figure 8.9 PWM Mode Operation Example 1.............................................................. 118

AX07CF192

7

Figure 8.10 PWM Mode Operation Example 2............................................................ 119

Figure 8.11 Reset-Synchronized PWM Mode Operation Example ................................ 120

Figure 9.1 TOP BLOCK Diagram ............................................................................... 122

Figure 9.2 Internal UART Diagram ............................................................................. 124

Figure 10.1 GPIO Block Diagram and PADS Connections(example for Port A and Port B)

......................................................................................................................... 140

Figure 12.1 Flash Memory Block Diagram ................................................................. 149

Figure 12.2 System Configuration When Using On-Board Boot Mode .......................... 156

Figure 12.3 Boot Mode Execution Procedure.............................................................. 157

Figure 12.4 User Mode Execution Procedure.............................................................. 159

Figure 12.5 Flash Program & Program Verify Sequence.............................................. 162

Figure 12.6 Flash Pre-program & Pre-program Verify Sequence.................................. 164

Figure 12.7 Flash Erase & Erase Verify Sequence...................................................... 166

Figure 12.8 Flash Erase Algorithm ............................................................................. 167

Figure 12.9 Read Timing Diagram.............................................................................. 171

Figure 12.10 Pre-Program/Program Timing Diagram ................................................... 172

Figure 12.11 Erase Timing Diagram ............................................................................ 173

Figure 12.12 Pre-Program/Program Verify Timing Diagram........................................... 174

Figure 12.13 Erase Verify Timing Diagram................................................................... 174

Figure 13.1 Block Diagram of A/D Converter .............................................................. 176

Figure 13.2 A/D converter Operation.......................................................................... 181

Figure 13.3 Example of Analog Input Circuit ............................................................... 183

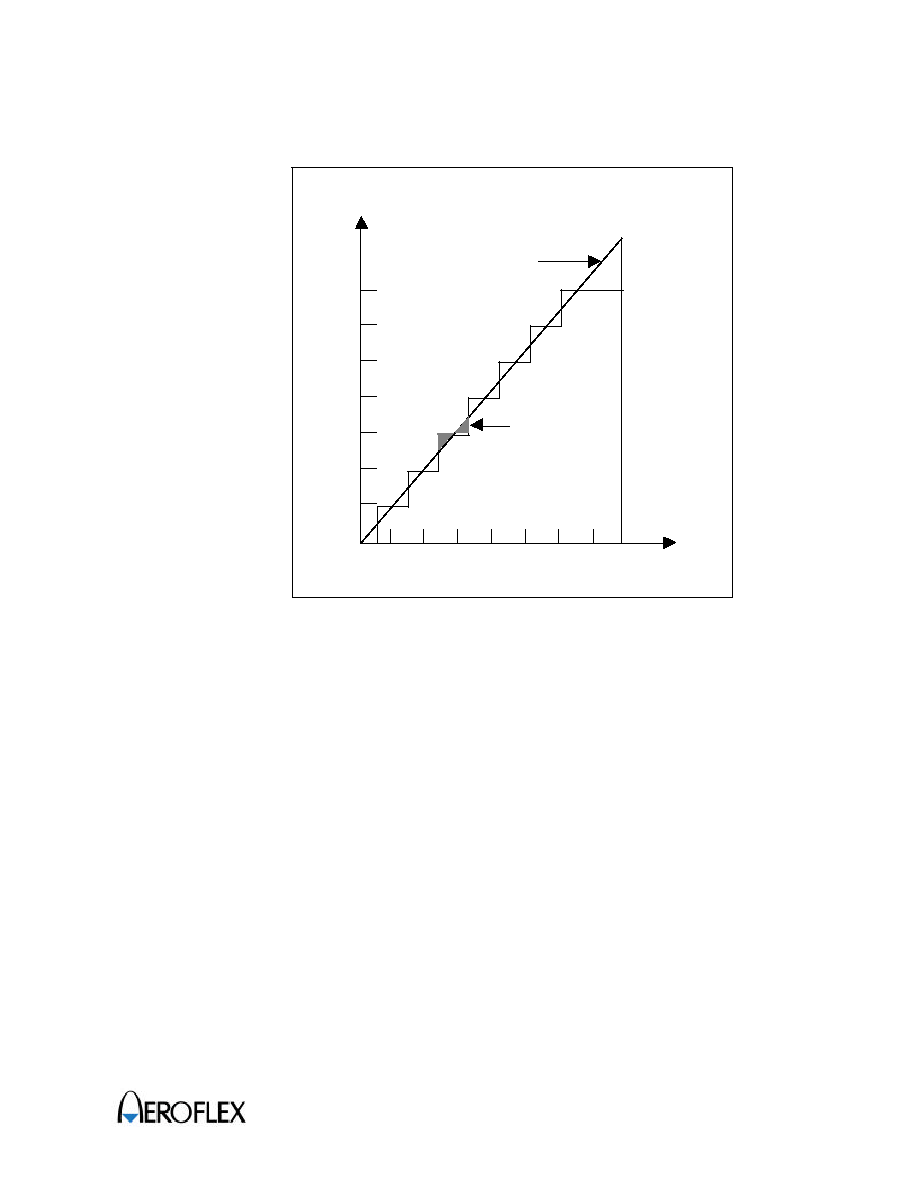

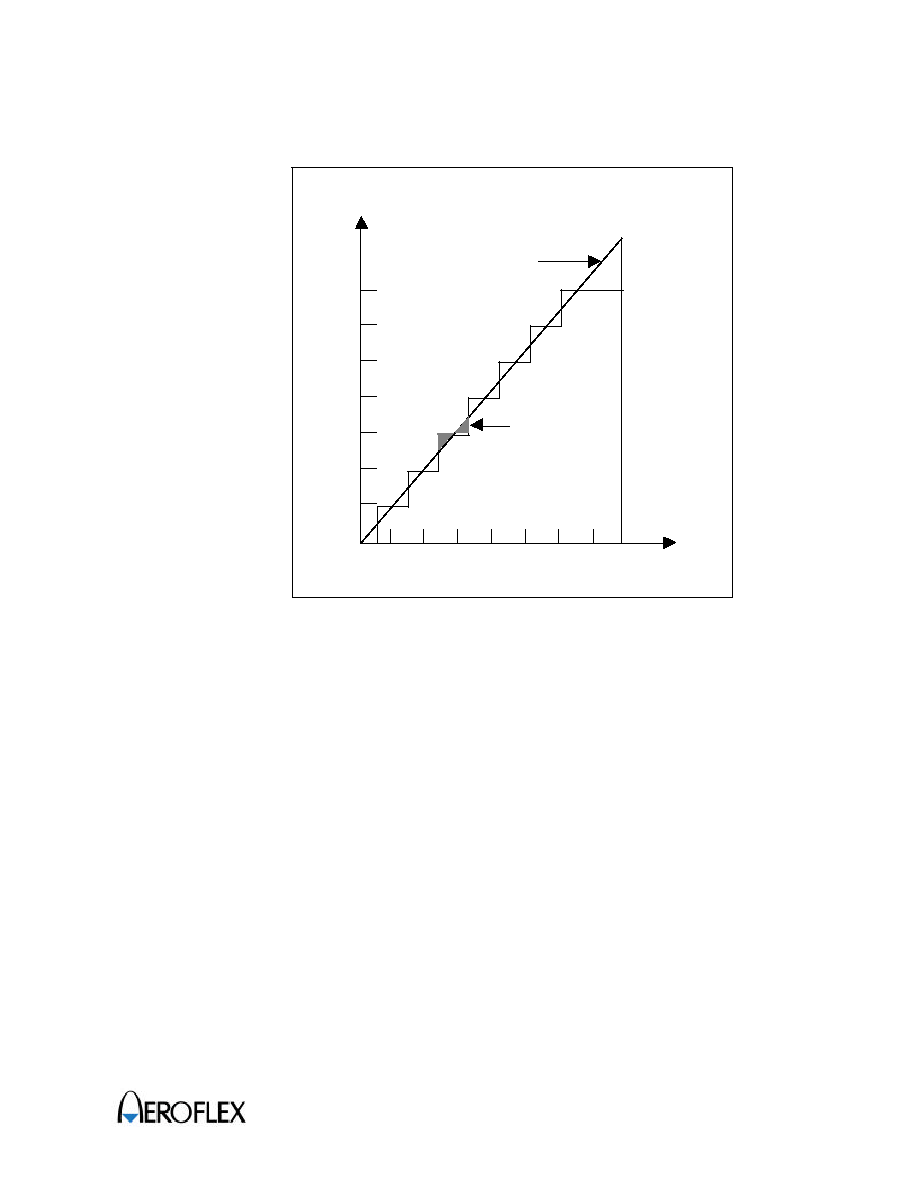

Figure 13.4 A/D Converter Accuracy Definitions (1)..................................................... 183

Figure 13.5 A/D Converter Accuracy Definitions (2)..................................................... 184

Figure 14.1 Crystal oscillator settling time................................................................... 192

Figure 14.2 Reset Input Timing .................................................................................. 192

Figure 14.3 Bus Controller Write Timing Diagram........................................................ 193

Figure 14.4 Bus Controller Read Timing Diagram........................................................ 193

Figure 14.5 Basic Bus Cycle with External Wait State.................................................. 194

Figure 14.6 Bus Release Mode Timing....................................................................... 194

AX07CF192

8

Tables

Table 1.1 Pin Descriptions ...........................................................................................16

Table 1.1 Pin Descriptions (Continued).........................................................................17

Table 1.1 Pin Descriptions (Continued).........................................................................18

Table 1.1 Pin Descriptions (Continued).........................................................................19

Table 1.1 Pin Descriptions (Continued).........................................................................20

Table 1.2 AX07CF192 Operation modes ......................................................................21

Table 1.3 Pin assignment by mode...............................................................................22

Table 1.3 Pin assignment by mode (continued) .............................................................23

Table 1.3 Pin assignment by mode (continued) .............................................................24

Table 2.1 The ARM Instruction set ...............................................................................31

Table 2.2 THUMB instruction set opcodes ....................................................................34

Table 2.3 Condition code summary ..............................................................................36

Table 2.4 PSR mode bit values ....................................................................................38

Table 3.1 Bus Controller Pins.......................................................................................49

Table 3.2 BUS Controller Register Map........................................................................50

Table 3.3 Byte Lane condition by XA[0] ........................................................................55

Table 4.1 Pin Function Descriptions .............................................................................66

Table 4.2 MCU Controller Memory map........................................................................67

Table 4.3 MCU Controller Initial values in each mode ....................................................67

Table 5.1 PMU Register Map .......................................................................................76

Table 6.1 Interrupt Controller Default Setting Value .......................................................84

Table 6.2 Interrupt Controller Memory Map ..................................................................86

Table 6.3 Interrupt Source Trigger Mode.......................................................................87

Table 7.1 Watchdog Timer APB Peripheral Memory Map...............................................95

Table 7.2 Internal Counter Clock Sources (SYSCLK = 40 MHz) .....................................97

Table 8.1 Timer Global Control Register Map.............................................................. 105

Table 8.2 Timer Channel Control Register Map ........................................................... 105

Table 8.3 Timer Channel Starting Address.................................................................. 105

Table 9.1 Signal Descriptions..................................................................................... 123

Table 9.2 UART Register Address Map (0x1500 in UART1)......................................... 125

Table 9.3 UART Register Reset Values ...................................................................... 125

Table 9.4a Divisor Values for each Baud rate (CLK=1.8432MHz) ................................. 129

Table 9.4b Divisor Values for each Baud rate (CLK=3.6864MHz) ................................. 129

Table 9.5 Interrupt Control Functions.......................................................................... 134

Table 9.6 Summary of Registers ................................................................................ 138

Table 10.1 GPIO Register Memory Map ..................................................................... 141

Table 12.1 Operating mode ....................................................................................... 148

Table 12.2 Signal description of Figure 12.1(BUS Interface)......................................... 150

Table 12.3 Flash Memory Registers ........................................................................... 151

Table 12.4 Control Register ....................................................................................... 153

Table 12.5 Erase Block Register................................................................................ 154

Table 12.6 Status & Power Register ........................................................................... 155

Table 12.7 FR_SEL Value for access to internal Register............................................. 168

Table 12.8 Setting for Register read/write ................................................................... 168

Table 12.9 Erase Block Register................................................................................ 169

Table 12.10 Setting for Flash PROM read/write........................................................... 170

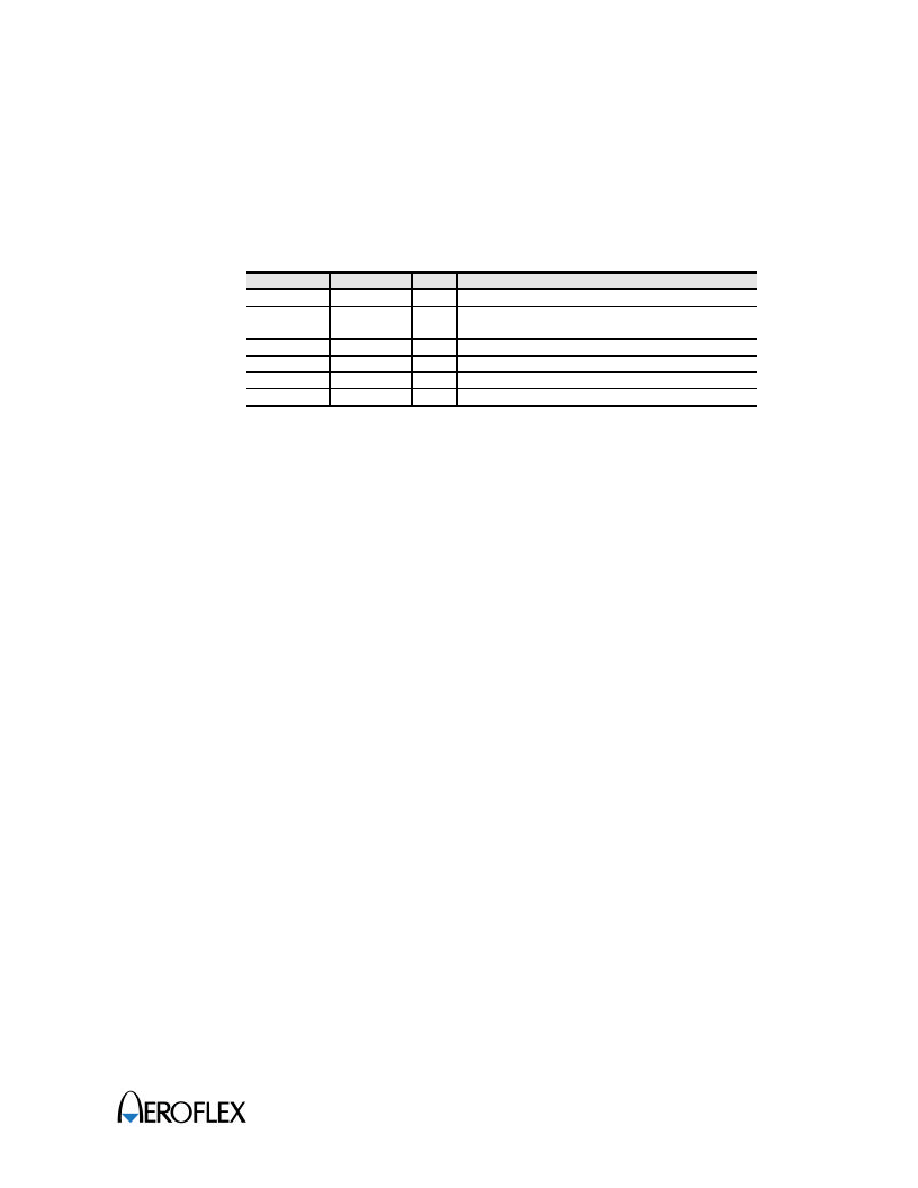

Table 12.11 DC Characteristics.................................................................................. 174

Table 12.12 AC Characteristics.................................................................................. 174

Table 13.1 A/D Converter Pins ................................................................................... 177

Table 13.2 A/D Converter Register Summary. ............................................................. 178

Table 14.1 Absolute Maximum Ratings....................................................................... 187

Table 14.2 Recommended Operating Conditions ........................................................ 187

Table 14.3 DC Characteristics ................................................................................... 188

Table 14.4 IO Circuits with pull-ups ............................................................................ 188

AX07CF192

9

Table 14.5 IO Circuits with pull-downs ........................................................................ 188

Table 14.6 Clock Timing............................................................................................ 189

Table 14.7 Control Signal Timing................................................................................ 189

Table 14.8 Bus Timing............................................................................................... 190

Table 14.9 A/D Conversion Operating Conditions........................................................ 191

Table 14.10 A/D converter Electrical Characteristics ................................................... 191

AX07CF192

10

AX07CF192

11

AX07CF192

32-Bit Embedded Flash MCU

User's Manual

(Preliminary)

AX07CF192

12

Chapter 1

AX07CF192

13

Chapter 1

Introduction

Chapter 1

AX07CF192

14

1.1

General Description

This 32-bit MCU with embedded flash memory is based on the ARM7TDMI core. The AX07CF192

contains the following functions: 192Kbytes Flash memory, 4K bytes SRAM, 6 channel 16-bit Timer,

Watch Dog Timer, 2-channel UART, Programmable Priority Interrupt Controller, 75 bits PIO, Bus Controller

including Chip select logic. These functions are implemented using the AMBA On-Chip Modular

Architecture.

Several pin count versions are offered, up to a maximum of 100 pins (AX07CF192-100, shown below).

Contact the factory for further information on reduced pin count versions.

Figure 1.1 Package Outline

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

75 74 73 72 71 70

69 68 67 66 65

64

63 62 61 60 59 58 57 56 55 54 53 52 51

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

AX07CF192

(Rev. 2)

2001.02

A

13

/P2

5

A

12

/P2

4

A

11

/P2

3

A

10

/P2

2

A

9

/P2

1

A

8

/P2

0

VSS

A

7

/P1

7

A

6

/P1

6

A

5

/P1

5

A

4

/P1

4

A

3

/P1

3

A

2

/P1

2

A

1

/P1

1

A

0

/P1

0

VDD

D

1 5

/P3

7

D

1 4

/P3

6

D

1 3

/P3

5

D

1 2

/P3

4

D

1 1

/P3

3

D

1 0

/P3

2

D

9

/P3

1

D

8

/P3

0

D

7

/P4

7

VDD

nCS

7

/TIOCA

3

/PB

0

nCS

6

/TIOCB

3

/PB

1

nCS

5

/TIOCA

4

/PB

2

nCS

4

/TIOCB

4

/PB

3

TMS/PB

4

TDO/PB

5

TDI/PB

6

TCK/PB

7

XFVPPD

/XP9

6

VSS

TxD

0

/P9

0

RxD

0

/P9

1

TxD

1

/P9

2

RxD

1

/P9

3

nIRQ

4

/P9

4

nIRQ

5

/P9

5

D

0

/P4

0

D

0

/P4

0

D

2

/P4

2

D

3

/P4

3

VSS

D

4

/P4

4

D

5

/P4

5

D

6

/P4

6

A

14

/P2

6

A

15

/P2

7

A

16

/P5

0

A

17

/P5

1

A

18

/P5

2

A

19

/P5

3

VSS

nWAIT

/P6

0

nBREQ

/P6

1

nBACK

/P6

2

CLKO/P6

7

nSTBY

nRES

nTRST

/P9

7

VSS

XTALOUT

XTALIN

VDD

nAS

/P6

3

nRD

/P6

4

nHWR

/P6

5

nLWR

/P6

6

MODE

0

MODE

1

MODE

2

AVDD

AV

REF

AN

0

/P7

0

AN

0

/P7

1

AN

0

/P7

2

AN

0

/P7

3

AN

0

/P7

4

VSS

TIOCA

5

/nIRQ

6

/P7

6

TIOCB

5

/nIRQ

7

/P7

7

P7

5

nIRQ

0

/P8

0

nCS

3

/nIRQ

1

/P8

1

nCS

2

/nIRQ

2

/P8

2

nCS

1

/nIRQ

3

/P8

3

nCS

0

/P8

4

VSS

TCLKA/PA

0

TCLKB/PA

1

TCLKC/TCIOA

0

/PA

2

TCLKD/TCIOB

0

/PA

3

A

23

/TIOCA

1

/PA

4

A

22

/TIOCB

1

/PA

5

A

21

/TIOCA

2

/PA

6

A

20

/TIOCB

2

/PA

7

Chapter 1

AX07CF192

15

1.2

Features

·

On-Chip Modular Architecture (using AMBA)

·

Utilizes the ARM7TDMI 32/16bit RISC Family

·

192Kbyte Flash memory

·

4Kbyte internal SRAM

·

8/16-bit external Data Bus

·

Eight Programmable Chip Select Outputs with external wait input

·

Low Power Consumption using Power Management Unit

·

Fully static operation : 50MHz max.

·

Programmable Priority Interrupt Controller (8 external sources)

·

Six 16-bit Multi Function Timers/Counters for General Purpose Applications

·

One 8-bit Watchdog Timer (WDT)

·

Two UARTs (Universal Asynchronous Receiver Transmitter) compatible with

16C550 UART

·

Programmable Input/Output ports (75-bits)

·

10 bit 5-channel ADC

·

100 TQFP Package

Figure 1.2 AX07CF192 Block Diagram

BUS

Controller

BUS

Controller

APB

Bridge

APB

Bridge

SRAM

4kbyte

SRAM

4kbyte

Flash Memory

192kbyte

Flash Memory

192kbyte

Arbiter

Arbiter

WDT

WDT

PIO

PIO

INTC

INTC

TIMER

TIMER

UART

UART

ADC

ADC

Multi-Function Pin MUX

Multi-Function Pin MUX

ARM7TDMI

ARM7TDMI

TIC*

TIC*

PMU

PMU

* TIC : Test Interface Controller

Max. 50MHz

ASB (Max. 50MHz)

Chapter 1

AX07CF192

16

1.3

Pin Descriptions

Table 1.1 Pin Descriptions

PIN

SYMBOL

DIR

DESCRIPTION

1

VDD

-

Power Supply 3.3V

nCS

7

O

External Chip Selection Number 7

TCIOA

3

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch3

2

PB

0

I/O

General purpose input output of port B bit0

nCS

6

O

External Chip Selection Number 6

TCIOB

3

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch3

3

PB

1

I/O

General purpose input output of port B bit 1

nCS

5

O

External Chip Selection Number 5

TIOCA

4

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch4

4

PB

2

I/O

General purpose input output of port B bit2

nCS

4

O

External Chip Selection Number 4

TIOCB

4

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch4

5

PB

3

I/O

General purpose input output of port B bit3

TMS

I

JTAG Test Mode Selection

6

PB

4

I/O

General purpose input output of port B bit4

TDO

O

JTAG Test Data Output

7

PB

5

I/O

General purpose input output of port B bit5

TDI

I

JTAG Test Data Input

8

PB

6

I/O

General purpose input output of port B bit6

TCK

I

JTAG Test Clock

9

PB

7

I/O

General purpose input output of port B bit7

10

TVPPD

I

5Vinput for the use of Programming and Erasing of the Flash Memory

11

VSS

-

Power ground

TxD

0

O

Transmit Data of UART Ch0

12

P9

0

I/O

General purpose input output of port 9 bit 0

RxD

0

O

Receive Data of UART Ch0

13

P9

1

I/O

General purpose input output of port 9 bit 1

TxD

1

O

Transmit Data of UART Ch1

14

P9

2

I/O

General purpose input output of port 9 bit 2

RxD

1

O

Receive Data of UART Ch1

15

P9

3

I/O

General purpose input output of port 9 bit 3

nIRQ

4

I

External Interrupt Request number 4

16

P9

4

I/O

General purpose input output of port 9 bit 4

nIRQ

5

I

External Interrupt Request number 5

17

P9

5

I/O

General purpose input output of port 9 bit 5

D

0

I/O

External Data Bus bit 0

18

P4

0

I/O

General purpose input output or port 4 bit 0

D

1

I/O

External Data Bus bit 1

19

P4

1

I/O

General purpose input output or port 4 bit 1

D

2

I/O

External Data Bus bit 2

20

P4

2

I/O

General purpose input output or port 4 bit 2

D

3

I/O

External Data Bus bit 3

21

P4

3

I/O

General purpose input output or port 4 bit 3

Chapter 1

AX07CF192

17

Table 1.1 Pin Descriptions (Continued)

PIN

SYMBOL

DIR

DESCRIPTION

22

VSS

-

Power ground

D

4

I/O

External Data Bus bit 4

23

P4

4

I/O

General purpose input output or port 4 bit 4

D

5

I/O

External Data Bus bit 5

24

P4

5

I/O

General purpose input output or port 4 bit 5

D

6

I/O

External Data Bus bit 6

25

P4

6

I/O

General purpose input output or port 4 bit 6

D

7

I/O

External Data Bus bit 7

26

P4

7

I/O

General purpose input output or port 4 bit 7

D

8

I/O

External Data Bus bit 8

27

P3

0

I/O

General purpose input output or port 3 bit 0

D

9

I/O

External Data Bus bit 9

28

P3

1

I/O

General purpose input output or port 3 bit 1

D

10

I/O

External Data Bus bit 10

29

P3

2

I/O

General purpose input output or port 3 bit 2

D

11

I/O

External Data Bus bit 11

30

P3

3

I/O

General purpose input output or port 3 bit 3

D

12

I/O

External Data Bus bit 12

31

P3

4

I/O

General purpose input output or port 3 bit 4

D

13

I/O

External Data Bus bit 13

32

P3

5

I/O

General purpose input output or port 3 bit 5

D

14

I/O

External Data Bus bit 14

33

P3

6

I/O

General purpose input output or port 3 bit 6

D

15

I/O

External Data Bus bit 15

34

P3

7

I/O

General purpose input output or port 3 bit 7

35

VDD

-

Power Supply 3.3V

A

0

O

External Address Bus bit 0

36

P1

0

I/O

General purpose input output or port 1 bit 0

A

1

O

External Address Bus bit 1

37

P1

1

I/O

General purpose input output or port 1 bit 1

A

2

O

External Address Bus bit 2

38

P1

2

I/O

General purpose input output or port 1 bit 2

A

3

O

External Address Bus bit 3

39

P1

3

I/O

General purpose input output or port 1 bit 3

A

4

O

External Address Bus bit 4

40

P1

4

I/O

General purpose input output or port 1 bit 4

A

5

O

External Address Bus bit 5

41

P1

5

I/O

General purpose input output or port 1 bit 5

A

6

O

External Address Bus bit 6

42

P1

6

I/O

General purpose input output or port 1 bit 6

A

7

O

External Address Bus bit 7

43

P1

7

I/O

General purpose input output or port 1 bit 7

44

VSS

-

Power ground

A

8

O

External Address Bus bit 8

45

P2

0

I/O

General purpose input output or port 2 bit 0

A

9

O

External Address Bus bit 9

46

P2

1

I/O

General purpose input output or port 2 bit 1

A

10

O

External Address Bus bit 10

47

P2

2

I/O

General purpose input output or port 2 bit 2

Chapter 1

AX07CF192

18

Table 1.1 Pin Descriptions (Continued)

PIN

SYMBOL

DIR

DESCRIPTION

A

11

O

External Address Bus bit 11

48

P2

3

I/O

General purpose input output or port 2 bit 3

A

12

O

External Address Bus bit 12

49

P2

4

I/O

General purpose input output or port 2 bit 4

A

13

O

External Address Bus bit 13

50

P2

5

I/O

General purpose input output or port 2 bit 5

A

14

O

External Address Bus bit 14

51

P2

6

I/O

General purpose input output or port 2 bit 6

A

15

O

External Address Bus bit 15

52

P2

7

I/O

General purpose input output or port 2 bit 7

A

16

O

External Address Bus bit 16

53

P5

0

I/O

General purpose input output of port 5 bit 0

A

17

O

External Address Bus bit 17

54

P5

1

I/O

General purpose input output of port 5 bit 1

A

18

I

External Address Bus bit 18

55

P5

2

I/O

General purpose input output of port 5 bit 2

A

19

O

External Address Bus bit 19

56

P5

3

I/O

General purpose input output of port 5 bit 3

57

VSS

-

Power ground

nWAIT

I

External BUS cycle wait signal

58

P6

0

I/O

General purpose input output of port 6 bit 0

nBREQ

I

External BUS Request

59

P6

1

I/O

General purpose input output of port 6 bit 1

nBACK

I

External BUS Acknowledge

60

P6

2

I/O

General purpose input output of port 6 bit 2

CLKO

O

BUS Clock Output

61

P6

7

I/O

General purpose input output of port 6 bit 7

62

nSTBY

O

Standby mode signal. Power Down mode indicating

63

nRES

I

External Reset input

nTRST

I

JTAG Test Reset input

64

P9

7

I/O

General purpose input output of port 9 bit 7

65

VSS

-

Power ground

66

XTALOUT

O

Crystal feedback output

67

XTALIN

I

Crystal or External Oscillator input

68

VDD

-

Power Supply 3.3V

nAS

O

External Address Bus strobe

69

P6

3

I/O

General purpose input output of port 6 bit 3

nRD

O

External Bus Read

70

P6

4

I/O

General purpose input output of port 6 bit 4

nHWR

O

External upper 8 bit data bus write

71

P6

5

I/O

General purpose input output of port 6 bit 5

nLWR

O

External lower 8 bit data bus write

72

P6

6

I/O

General purpose input output of port 6 bit 6

73

MODE

0

I

MODE bit 0

74

MODE

1

I

MODE bit 1

75

MODE

2

I

MODE bit 2

76

AVDD

-

Analog Power Supply 3.3V

77

AVREF

-

ADC Reference Voltage

Chapter 1

AX07CF192

19

Table 1.1 Pin Descriptions (Continued)

PIN

SYMBOL

DIR

DESCRIPTION

78

AN

0

I

ADC Channel 0 input

79

AN

1

I

ADC Channel 1 input

80

AN

2

I

ADC Channel 2 input

81

AN

3

I

ADC Channel 3 input

82

AN

4

I

ADC Channel 4 input

83

VSS

-

Power ground

TIOCA

5

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch5

nIRQ

6

I

External Interrupt Request number 6

84

P7

6

I/O

General purpose input output of port 7 bit 6

TIOCB

5

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch5

nIRQ

7

I

External Interrupt Request number 7

85

P7

7

I/O

General purpose input output of port 7 bit 7

86

P7

5

I/O

General purpose input output of port 7 bit 5

nIRQ

0

I

External Interrupt Request number 0

87

P8

0

I/O

General purpose input output of port 8 bit 0

nCS

3

O

External Chip Selection Number 3

nIRQ

1

I

External Interrupt Request number 1

88

P8

1

I/O

General purpose input output of port 8 bit 1

nCS

2

O

External Chip Selection Number 2

nIRQ

2

I

External Interrupt Request number 2

89

P8

2

I/O

General purpose input output of port 8 bit 2

nCS

1

O

External Chip Selection Number 1

nIRQ

3

I

External Interrupt Request number 3

90

P8

3

I/O

General purpose input output of port 8 bit 3

nCS

0

O

External Chip Selection Number 0

91

P8

4

I/O

General purpose input output of port 8 bit 4

92

VSS

-

Power ground

TCLKA

I

External timer input clock A

93

PA

0

I/O

General purpose input output of port A bit 0

TCLKB

I

External timer input clock B

94

PA

1

I/O

General purpose input output of port A bit 1

TCLKC

I

External timer input clock C

TIOCA

0

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch0

95

PA

2

I/O

General purpose input output of port A bit 2

TCLKD

I

External timer input clock D

TIOCB

0

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch0

96

PA

3

I/O

General purpose input output of port A bit 3

A

23

O

External Address Bus bit 23

TIOCA

1

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch1

97

PA

4

I/O

General purpose input output of port A bit 4

Chapter 1

AX07CF192

20

Table 1.1 Pin Descriptions (Continued)

PIN

SYMBOL

DIR

DESCRIPTION

A

22

O

External Address Bus bit 22

TIOCB

1

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch1

98

PA

5

I/O

General purpose input output of port A bit 5

A

21

O

External Address Bus bit 21

TIOCA

2

I/O

PWM output, Compare match output of Reg.A and signal capture input of Timer Ch2

99

PA

6

I/O

General purpose input output of port A bit 6

A

20

O

External Address Bus bit 20

TIOCB

2

I/O

PWM output, Compare match output of Reg.B and signal capture input of Timer Ch2

100

PA

7

I/O

General purpose input output of port A bit 7

Chapter 1

AX07CF192

21

1.4

Operation Mode description

AX07CF192 is Flash Memory-embedded ARM microcontroller. It has six operation modes as shown in

Table 1.2. The AX07CF192's external pin functionality can be changed by setting the external MODE pin

or by configuring the PIN MUX registers. The pin assignment by mode is shown in Table 1.3. When

changing modes the memory is remapped accordingly. Figure 1.3 shows the default memory map and

the memory maps of the alternative modes are shown in Figures 1.4, 1.5 and 1.6.

The various modes are summarized as follows:

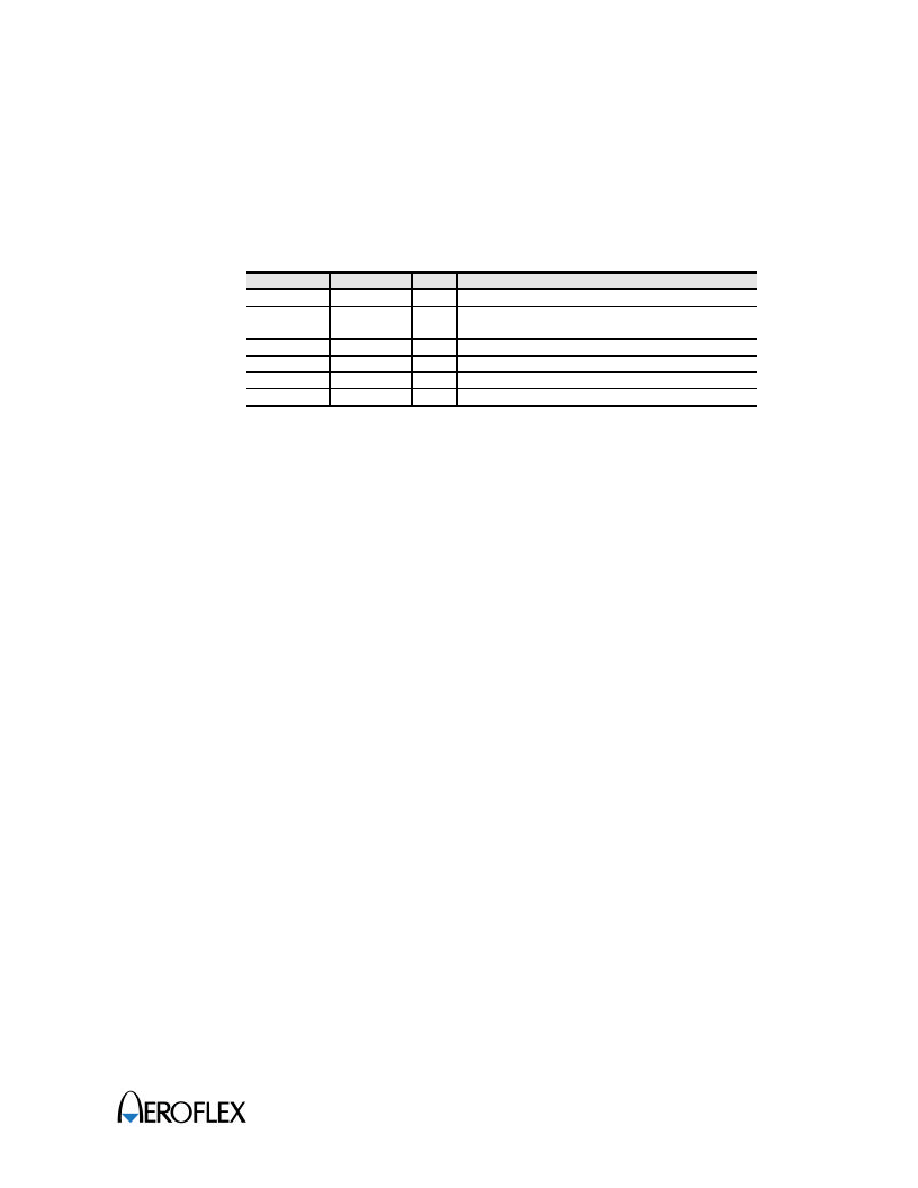

Table 1.2 AX07CF192 Operation modes

MODE

MODE DESCRIPTION

0,1

Reserved for Test

2

External 8-bit data bus with 16MBytes of Address Range

3

External 16-bit data bus with 16MBytes of Address Range

4

Flash-boot mode with 16-bit data bus

5

Flash-boot mode (micro-computer mode)

6

UART-boot mode with 16-bit data bus

7

UART-boot mode (micro-computer mode)

Chapter 1

AX07CF192

22

Table 1.3 Pin assignment by mode

MODE 2

MODE 3

MODE 4

MODE 6

MODE 5

MODE 7

PIN

External

8bit BUS

External

16bit BUS

Flash boot mode

with 16bit BUS

UART boot mode

with 16bit BUS

Flash boot mode

(Micro mode)

UART boot mode

(Micro mode)

1

VDD

ß

ß

ß

ß

ß

2

nCS7

ß

ß

ß

TIOCA3

ß

3

nCS6

ß

ß

ß

TIOCB3

ß

4

nCS5

ß

ß

ß

TIOCA4

ß

5

nCS4

ß

ß

ß

TIOCB4

ß

6

TMS

ß

ß

ß

ß

ß

7

TDO

ß

ß

ß

ß

ß

8

TDI

ß

ß

ß

ß

ß

9

TCK

ß

ß

ß

ß

ß

10

TVPPD

ß

ß

ß

ß

ß

11

VSS

ß

ß

ß

ß

ß

12

TxD0

ß

ß

ß

ß

ß

13

RxD0

ß

ß

ß

ß

ß

14

TxD1

ß

ß

ß

ß

ß

15

RxD1

ß

ß

ß

ß

ß

16

nIRQ4

ß

ß

ß

ß

ß

17

nIRQ5

ß

ß

ß

ß

ß

18

D0

ß

ß

ß

P40

ß

19

D1

ß

ß

ß

P41

ß

20

D2

ß

ß

ß

P42

ß

21

D3

ß

ß

ß

P43

ß

22

VSS

ß

ß

ß

ß

ß

23

D4

ß

ß

ß

P44

ß

24

D5

ß

ß

ß

P45

ß

25

D6

ß

ß

ß

P46

ß

26

D7

ß

ß

ß

P47

ß

27

P30

D8

ß

ß

P30

ß

28

P31

D9

ß

ß

P31

ß

29

P32

D10

ß

ß

P32

ß

30

P33

D11

ß

ß

P33

ß

31

P34

D12

ß

ß

P34

ß

32

P35

D13

ß

ß

P35

ß

33

P36

D14

ß

ß

P36

ß

34

P37

D15

ß

ß

P37

ß

35

VDD

ß

ß

ß

ß

ß

36

A0

ß

ß

ß

P10

ß

37

A1

ß

ß

ß

P11

ß

38

A2

ß

ß

ß

P12

ß

39

A3

ß

ß

ß

P13

ß

40

A4

ß

ß

ß

P14

ß

Chapter 1

AX07CF192

23

Table 1.3 Pin assignment by mode (continued)

MODE2

MODE3

MODE4

MODE6

MODE5

MODE7

PIN

No.

External

8bit BUS

External

16bit BUS

Flash boot mode

with 16bit BUS

UART boot mode

with 16bit BUS

Flash boot mode

(MICOM mode)

UART boot mode

(MICOM mode)

41

A5

ß

ß

ß

P15

ß

42

A6

ß

ß

ß

P16

ß

43

A7

ß

ß

ß

P17

ß

44

VSS

ß

ß

ß

ß

ß

45

A8

ß

ß

ß

P20

ß

46

A9

ß

ß

ß

P21

ß

47

A10

ß

ß

ß

P22

ß

48

A11

ß

ß

ß

P23

ß

49

A12

ß

ß

ß

P24

ß

50

A13

ß

ß

ß

P25

ß

51

A14

ß

ß

ß

P26

ß

52

A15

ß

ß

ß

P27

ß

53

A16

ß

ß

ß

P50

ß

54

A17

ß

ß

ß

P51

ß

55

A18

ß

ß

ß

P52

ß

56

A19

ß

ß

ß

P53

ß

57

VSS

ß

ß

ß

ß

ß

58

nWAIT

ß

ß

ß

P60

ß

59

nBREQ

ß

ß

ß

P61

ß

60

nBACK

ß

ß

ß

P62

ß

61

CLKO

ß

ß

ß

P67

ß

62

nSTBY

ß

ß

ß

nSTBY

ß

63

nRES

ß

ß

ß

nRES

ß

64

nTRST

ß

ß

ß

nTRST

ß

65

VSS

ß

ß

ß

ß

ß

66

XTALOUT

ß

ß

ß

ß

ß

67

XTALIN

ß

ß

ß

ß

ß

68

VDD

ß

ß

ß

ß

ß

69

nAS

ß

ß

ß

P63

ß

70

nRD

ß

ß

ß

P64

ß

71

nHWR

ß

ß

ß

P65

ß

72

nLWR

ß

ß

ß

P66

ß

73

MODE0

ß

ß

ß

ß

ß

73

MODE1

ß

ß

ß

ß

ß

75

MODE2

ß

ß

ß

ß

ß

76

AVDD

ß

ß

ß

ß

ß

77

AVREF

ß

ß

ß

ß

ß

78

AN0

ß

ß

ß

ß

ß

79

AN1

ß

ß

ß

ß

ß

80

AN2

ß

ß

ß

ß

ß

Chapter 1

AX07CF192

24

Table 1.3 Pin assignment by mode (continued)

MODE2

MODE3

MODE4

MODE6

MODE5

MODE7

PIN

No.

External

8bit BUS

External

16bit BUS

Flash boot mode

with 16bit BUS

UART boot mode

with 16bit BUS

Flash boot mode

(Micro mode)

UART boot mode

(Micro mode)

81

AN3

ß

ß

ß

ß

ß

82

AN4

ß

ß

ß

ß

ß

83

VSS

ß

ß

ß

ß

ß

84

TIOCA5

ß

ß

ß

ß

ß

85

TIOCB5

ß

ß

ß

ß

ß

86

P75

ß

ß

ß

ß

ß

87

nIRQ0

ß

ß

ß

ß

ß

88

nCS3

ß

ß

ß

P81

ß

89

nCS2

ß

ß

ß

P82

ß

90

nCS1

ß

ß

ß

P83

ß

91

nCS0

ß

ß

ß

P84

ß

92

VSS

ß

ß

ß

ß

ß

93

TCLKA

ß

ß

ß

ß

ß

94

TCLKB

ß

ß

ß

ß

ß

95

TCLKC

ß

ß

ß

ß

ß

96

TCLKD

ß

ß

ß

ß

ß

97

A23

ß

ß

TIOCA1

ß

ß

98

A22

ß

ß

TIOCB1

ß

ß

99

A21

ß

ß

TIOCA2

ß

ß

100

A20

ß

ß

TIOCB2

ß

ß

Chapter 1

AX07CF192

25

1.5

Memory Map

Figure 1.3 AX07CF192 Memory Map

Figure 1.4 Mode 3 Memory Map

A P B R e g i s t e r

0 x0900 1FFF

0x0900 1000

A S B R e g i s t e r

0 x0900 0FFF

0x0900 0000

Reserved

0 x0900 1FFF

0x0900 1800

O n C h i p

B O O T R O M

0 x0804 FFFF

0x0804 0000

On Chip

S R A M ( 4 K B )

0 x0803 FFFF

0x0803 0000

F L A S H

0 x0802 FFFF

0x0800 0000

nCS0 ~ nCS7

Chip Select

Area

0 x07FF FFFF

0x0000 0000

A D C

0 x0900 17FF

0x0900 1700

G P I O

0 x0900 16FF

0x0900 1600

UART1

0 x0900 15FF

0x0900 1500

UART0

0 x0900 14FF

0x0900 1400

TIMER

0 x0900 13FF

0x0900 1300

INTC

0 x0900 12FF

0x0900 1200

WDT

0 x0900 11FF

0x0900 1100

P M U

0 x0900 10FF

0x0900 1000

0 x0900 0FFF

0x0900 0400

A R M 7 T E S T

0 x0900 03FF

0x0900 0300

F M I

0 x0900 02FF

0x0900 0200

S M I

0 x0900 01FF

0x0900 0100

M C U C

0 x0900 00FF

0x0900 0000

Reserved

Reserved

Reserved

0 xFFFF F F F F

0x0900 2000

nCS0

0x000F FFFF

0x0000 0000

nCS1

0x001F FFFF

0x0010 0000

nCS2

0x002F FFFF

0x0020 0000

nCS3

0x003F FFFF

0x0030 0000

nCS4

0x004F FFFF

0x0040 0000

nCS5

0x005F FFFF

0x0050 0000

nCS6

0x006F FFFF

0x0060 0000

nCS7

0x007F FFFF

0x0070 0000

Reserved

0x07FF FFFF

0x0080 0000

Default.

SM=0 in the PMU register.

nCS0

0x00FF FFFF

0x0000 0000

nCS1

0x01FF FFFF

0x0100 0000

nCS2

0x02FF FFFF

0x0200 0000

nCS3

0x03FF FFFF

0x0300 0000

nCS4

0x04FF FFFF

0x0400 0000

nCS5

0x05FF FFFF

0x0500 0000

nCS6

0x06FF FFFF

0x0600 0000

nCS7

0x07FF FFFF

0x0700 0000

SM=1 in the PMU register.

Remap mode (R e m a p= 1 )

SM=0 in the PMU register.

nCS0

0x00FF FFFF

0x0000 1000

nCS1

0x01FF FFFF

0x0100 0000

nCS2

0x02FF FFFF

0x0200 0000

nCS3

0x03FF FFFF

0x0300 0000

nCS4

0x04FF FFFF

0x0400 0000

nCS5

0x05FF FFFF

0x0500 0000

nCS6

0x06FF FFFF

0x0600 0000

nCS7

0x07FF FFFF

0x0700 0000

nCS0

0x000F FFFF

0x0000 1000

nCS1

0x001F FFFF

0x0010 0000

nCS2

0x002F FFFF

0x0020 0000

nCS3

0x003F FFFF

0x0030 0000

nCS4

0x004F FFFF

0x0040 0000

nCS5

0x005F FFFF

0x0050 0000

nCS6

0x006F FFFF

0x0060 0000

nCS7

0x007F FFFF

0x0070 0000

Reserved

0x07FF FFFF

0x0080 0000

Remap mode ( Remap=1)

SM=1 in the PMU register.

On Chip

SRAM

0x0000 0FFF

0x0000 0000

On Chip

SRAM

0x 0 0 0 0 0 F F F

0x0000 0000

Chapter 1

AX07CF192

26

Figure 1.5 Memory Map of Modes 4 and 5

Figure 1.6 Memory Map of Modes 6 and 7

nCS0

0x000F FFFF

0x0003 0000

nCS1

0x001F FFFF

0x0010 0000

nCS2

0x002F FFFF

0x0020 0000

nCS3

0x003F FFFF

0x0030 0000

nCS4

0x004F FFFF

0x0040 0000

nCS5

0x005F FFFF

0x0050 0000

nCS6

0x006F FFFF

0x0060 0000

nCS7

0x007F FFFF

0x0070 0000

Reserved

0x07FF FFFF

0x0080 0000

Default.

SM=0 in the PMU register.

nCS0

0 x00FF FFFF

0x0003 0000

nCS1

0 x01FF FFFF

0x0100 0000

nCS2

0 x02FF FFFF

0x0200 0000

nCS3

0 x03FF FFFF

0x0300 0000

nCS4

0 x04FF FFFF

0x0400 0000

nCS5

0 x05FF FFFF

0x0500 0000

nCS6

0 x06FF FFFF

0x0600 0000

nCS7

0 x07FF FFFF

0x0700 0000

SM=1 in the PMU register.

Remap mode ( Remap=1)

SM=0 in the PMU register.

nCS0

0x00FF FFFF

0x0003 0000

nCS1

0x01FF FFFF

0x0100 0000

nCS2

0x02FF FFFF

0x0200 0000

nCS3

0x03FF FFFF

0x0300 0000

nCS4

0x04FF FFFF

0x0400 0000

nCS5

0x05FF FFFF

0x0500 0000

nCS6

0x06FF FFFF

0x0600 0000

nCS7

0x07FF FFFF

0x0700 0000

nCS0

0x000F FFFF

0x0003 0000

nCS1

0x001F FFFF

0x0010 0000

nCS2

0x002F FFFF

0x0020 0000

nCS3

0x003F FFFF

0x0030 0000

nCS4

0x004F FFFF

0x0040 0000

nCS5

0x005F FFFF

0x0050 0000

nCS6

0x006F FFFF

0x0060 0000

nCS7

0x007F FFFF

0x0070 0000

Reserved

0x07FF FFFF

0x0080 0000

Remap mode (Remap=1)

SM=1 in the PMU register.

FLASH

(192KB)

0x0002 FFFF

0x0000 1000

FLASH

(192KB)

0x0002 FFFF

0x0000 1000

FLASH

(192KB)

0 x0002 FFFF

0x0000 0000

FLASH

(192KB)

0x0002 FFFF

0x0000 0000

On Chip

SRAM(4KB)

0x0000 0FFF

0x0000 0000

On Chip

SRAM(4KB)

0x0000 0FFF

0x0000 0000

nCS0

0 x000F FFFF

0x0000 0100

nCS1

0 x001F FFFF

0x0010 0000

nCS2

0 x002F FFFF

0x0020 0000

nCS3

0 x003F FFFF

0x0030 0000

nCS4

0 x004F FFFF

0x0040 0000

nCS5

0 x005F FFFF

0x0050 0000

nCS6

0 x006F FFFF

0x0060 0000

nCS7

0 x007F FFFF

0x0070 0000

Reserved

0 x07FF FFFF

0x0080 0000

Default.

SM=0 in the PMU register.

nCS0

0x00FF FFFF

0x0000 0100

nCS1

0x01FF FFFF

0x0100 0000

nCS2

0x02FF FFFF

0x0200 0000

nCS3

0x03FF FFFF

0x0300 0000

nCS4

0x04FF FFFF

0x0400 0000

nCS5

0x05FF FFFF

0x0500 0000

nCS6

0x06FF FFFF

0x0600 0000

nCS7

0x07FF FFFF

0x0700 0000

SM=1 and OnFLASH=0

in the PMU register.

SM=0 and On FLASH=1

in the PMU register.

nCS0

0x00FF FFFF

0x0003 0000

nCS1

0x01FF FFFF

0x0100 0000

nCS2

0x02FF FFFF

0x0200 0000

nCS3

0x03FF FFFF

0x0300 0000

nCS4

0x04FF FFFF

0x0400 0000

nCS5

0x05FF FFFF

0x0500 0000

nCS6

0x06FF FFFF

0x0600 0000

nCS7

0x07FF FFFF

0x0700 0000

nCS0

0x000F FFFF

0x0003 0000

nCS1

0x001F FFFF

0x0010 0000

nCS2

0x002F FFFF

0x0020 0000

nCS3

0x003F FFFF

0x0030 0000

nCS4

0x004F FFFF

0x0040 0000

nCS5

0x005F FFFF

0x0050 0000

nCS6

0x006F FFFF

0x0060 0000

nCS7

0x007F FFFF

0x0070 0000

Reserved

0x07FF FFFF

0x0080 0000

SM=1 and OnFLASH=1

in the PMU register.

FLASH

(192KB)

0x0002 FFFF

0x0000 1000

FLASH

(192KB)

0x0002 FFFF

0x0000 1000

On Chip

Boot ROM

(256Byte)

0x0000 00FF

0x0000 0000

On Chip

Boot ROM

(256Byte)

0 x0000 00FF

0x0000 0000

0x0000 0FFF

0x0000 0000

0x0000 0FFF

0x0000 0000

Chapter 2

AX07CF192

27

Chapter 2

ARM7TDMI Core

Chapter 2

AX07CF192

28

2.1

General Description

The ARM7TDMI is a member of the ARM family of general-purpose 32-bit microprocessors, which

offer high performance and very low power consumption. This processor employs a unique

architectural strategy known as THUMB, which makes it ideally suited to high volume applications

with memory restrictions or applications where code density is an issue.

The key idea behind THUMB is a super reduced instruction set. Essentially, the ARM7TDMI has two

instruction sets, the standard 32-bit ARM set and the 16-bit THUMB set. The THUMB set's 16-bit

instruction length allows it to approach twice the density of standard ARM code while retaining most of

the ARM's performance advantage over a traditional 16-bit processor by using 16-bit registers. This is

possible because THUMB code operates on the same 32-bit register set as ARM code.

See also the ARM7TDMI Datasheet (ARM DDI 0029E) for further details.

2.2

Features

·

32bit RISC architecture

·

Low power consumption

·

ARM7TDMI core with:

- On-chip ICEbreaker debug support

- 32-bit x 8 hardware multiplier

- Thumb decompressor

·

Utilizes the ARM7TDMI embedded processor

- High performance 32-bit RISC architecture

- High density 16 bit instruction set (THUMB code)

·

Fully static operation: 0 ~ 80MHz

·

3-stage pipeline architecture (Fetch, decode, and execution stages)

·

Enhanced ARM software toolkit

THUMB code is able to provide up to 65% of the code size of ARM, and 160% of the

performance of an equivalent ARM processor connected to a 16-bit memory system.

Chapter 2

AX07CF192

29

2.3

Core Block Diagram

ICE

Breaker

Scan

Chain 0

RANGEOUT0

RANGEOUT1

ESTERN1

EXTERN0

TAP Controller

TCK

T M S

nTRST

TDI

TDO

TASPM [3:0]

IR [3:0]

SCREG [3:0]

Address Register

ALE

ABE

A

[

31:0]

Address

Incrementer

Register Bank

(31 x 32-bit registers)

(6 status registers)

P

C

b

u

s

A

L

U

b

u

s

I

n

c

r

e

m

e

n

t

e

r

b

u

s

32 x 8

Multiplier

Barrel Shifter

32-bit ALU

Write Data Register

B

b

u

s

A

b

u

s

Instruction Pipeline

& Read Data Register

& Thumb Instruction Decoder

nENOUT

nENIN

DBE

D

[

31:0]

Core

DBGRQI

BREAKPTI

DBGACK

ECLK

nEXEC

ISYNC

BL [3:0]

APE

MCLK

nWAIT

nIRQ

nFIQ

nRESET

ABORT

SEQ

LOCK

nCPI

CPA

CPB

nM [4:0]

TBE

TBIT

HIGHZ

Instruction

Decoder

&

Control

Logic

Scan

Control

D [0:31]

DIN [0:31]

DOUT [0:31]

Bus

Splitter

nRW

MAS [1:0]

nTRANS

nMREQ

nOPC

A [0:31]

Scan

Chain 1

ScanChain2

Figure 2.1 ARM7TDMI Core Block Diagram

Chapter 2

AX07CF192

30

2.4

Instruction Set

2.4.1

ARM Instructions

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Cond 0 0 I Opcode S

Rn

Rd

Operand

Data Processing / PSR Transfer

Cond 0 0 0 0 0 0 A S

Rd

Rn

Rs

1 0 0 1

Rm

Multiply

Cond 0 0 0 0 1 U A S

RdHi

RdLo

Rn

1 0 0 1

Rm

Multiply Long

Cond 0 0 0 1 0 B 0 0

Rn

Rd

0 0 0 0 1 0 0 1

Rm

Single Data Swap

Cond 0 0 0 1 0 0 1 0 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 1

Rn

Branch and Exchange

Cond 0 0 0 P U 0 W L

Rn

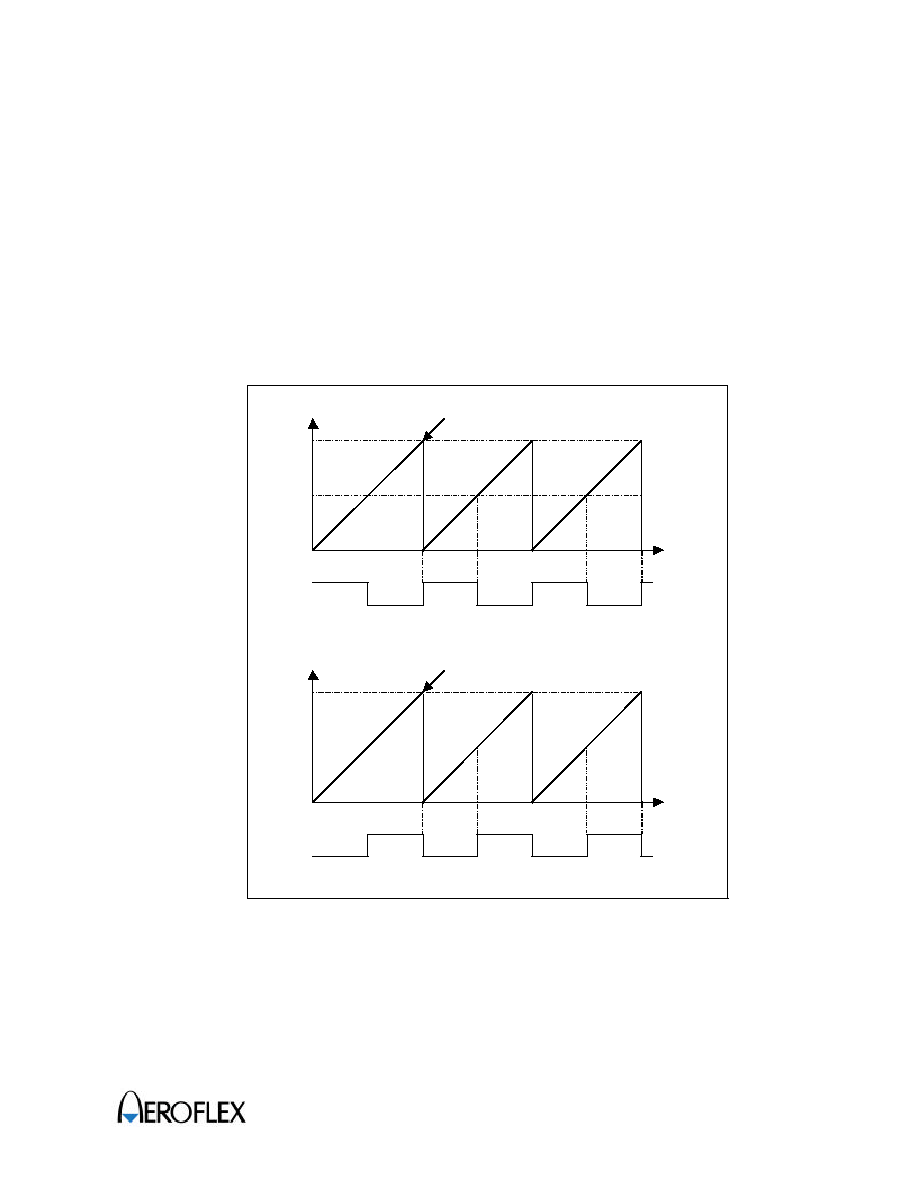

Rd