OP467 Data Sheet

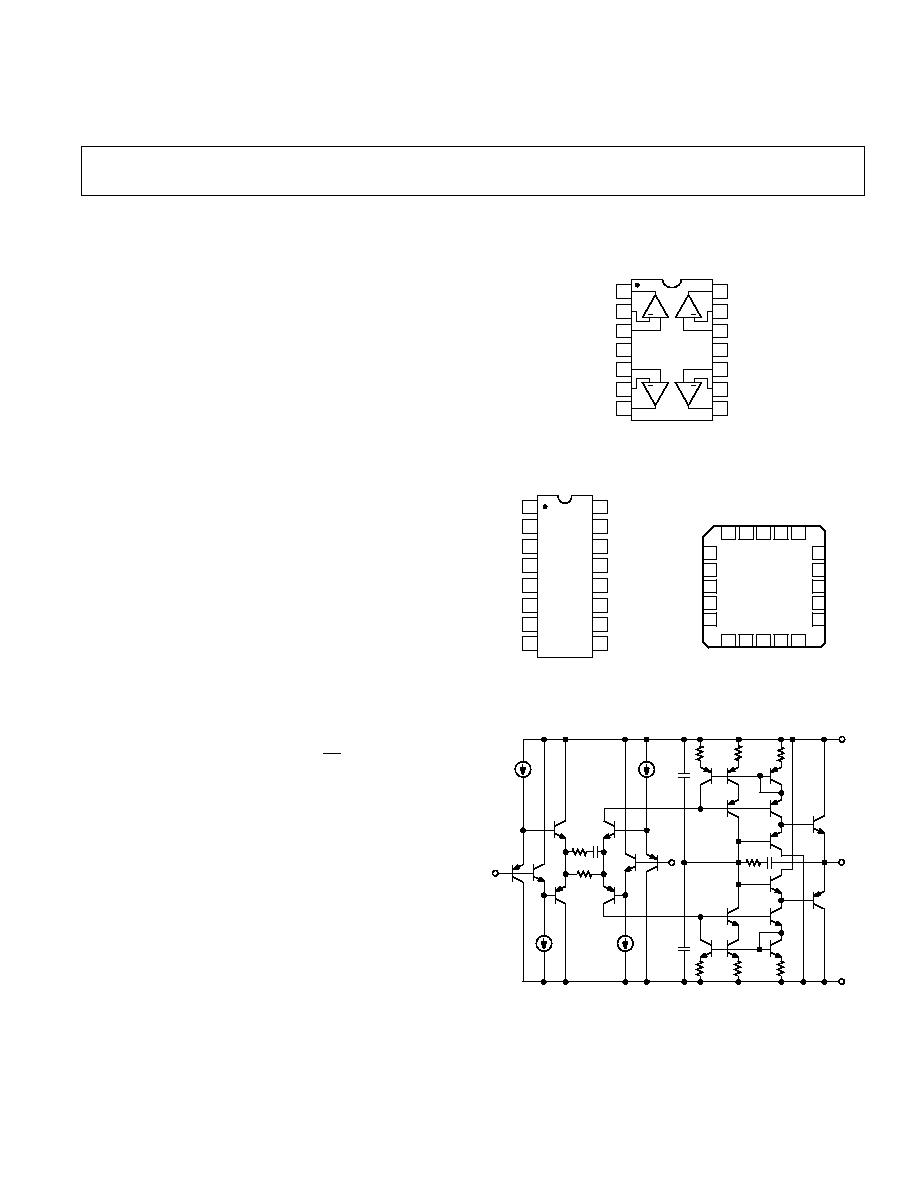

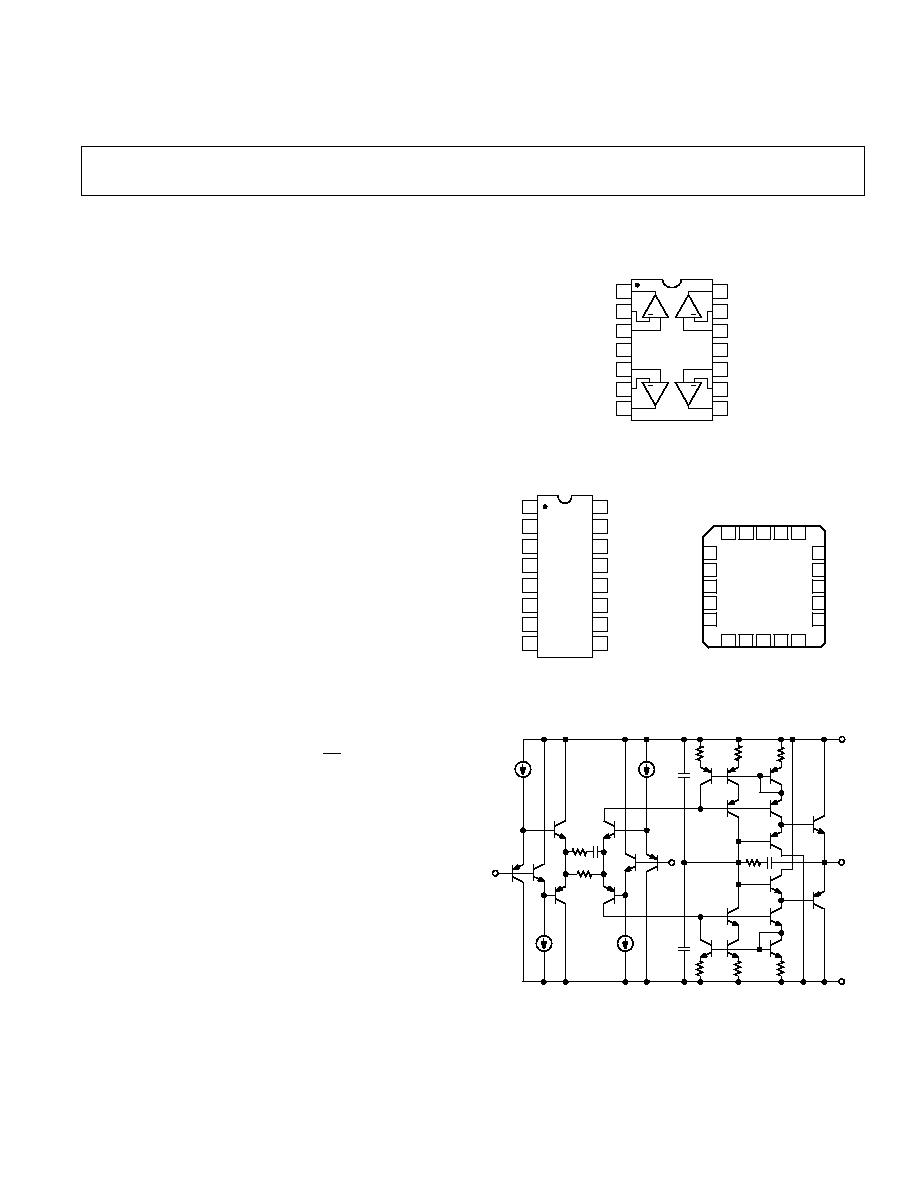

PIN CONNECTIONS

14-Lead Ceramic DIP (Y Suffix) and

14-Lead Epoxy DIP (P Suffix)

1

2

3

4

5

6

7

14

13

12

11

10

9

8

OUT A

IN A

+IN A

V+

+IN B

IN B

OUT B

OUT D

IN D

+IN D

V

+IN C

IN C

OUT C

+

+

+

+

OP467

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

Quad Precision, High Speed

Operational Amplifier

OP467

FEATURES

High Slew Rate 170 V/ s

Wide Bandwidth 28 MHz

Fast Settling Time <200 ns to 0.01%

Low Offset Voltage <500 V

Unity-Gain Stable

Low Voltage Operation 5 V to 15 V

Low Supply Current <10 mA

Drives Capacitive Loads

APPLICATIONS

High Speed Image Display Drivers

High Frequency Active Filters

Fast Instrumentation Amplifiers

High Speed Detectors

Integrators

Photo Diode Preamps

GENERAL DESCRIPTION

The OP467 is a quad, high speed, precision operational ampli-

fier. It offers the performance of a high speed op amp combined

with the advantages of a precision operational amplifier all in a

single package. The OP467 is an ideal choice for applications

where, traditionally, more than one op amp was used to achieve

this level of speed and precision.

The OP467's internal compensation ensures stable unity-gain

operation, and it can drive large capacitive loads without oscilla-

tion. With a gain bandwidth product of 28 MHz driving a 30 pF

load, output slew rate in excess of 170 V/

µ

s, and settling time to

0.01% in less than 200 ns, the OP467 provides excellent dy-

namic accuracy in high speed data-acquisition systems. The

channel-to-channel separation is typically 60 dB at 10 MHz.

The dc performance of OP467 includes less than 0.5 mV of

offset, voltage noise density below 6 nV/

Hz and total supply

current under 10 mA. Common-mode rejection and power

supply rejection ratios are typically 85 dB. PSRR is maintained

to better than 40 dB with input frequencies as high as 1 MHz.

The low offset and drift plus high speed and low noise, make the

OP467 usable in applications such as high speed detectors and

instrumentation.

The OP467 is specified for operation from

±

5 V to

±

15 V over

the extended industrial temperature range (40

°

C to +85

°

C) and

is available in 14-lead plastic and ceramic DIP, plus SOL-16

and 20-lead LCC surface mount packages.

Contact your local sales office for MIL-STD-883 data sheet and

availability.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1998

16-Lead SOL

(S Suffix)

1

2

3

4

5

6

7

8

OUT A

IN A

+IN A

V+

+IN B

IN B

OUT B

16

15

14

13

12

11

10

9

OUT D

IN D

+IN D

V

+IN C

IN C

OUT C

NC

NC

OP467

NC = NO CONNECT

+IN

IN

OUT

V+

V

Figure 1. Simplified Schematic

20-Position Chip Carrier

(RC Suffix)

+IN D

V

+IN C

NC

NC

4

5

6

7

9

19

20

1

2

3

18

17

16

15

14

8

10 11 12 13

(TOP VIEW)

+IN A

V+

+IN B

NC

NC

OUT A

IN A

OUT D

IN D

NC

IN B

OUT B

IN C

OUT C

NC

OP467

NC = NO CONNECT

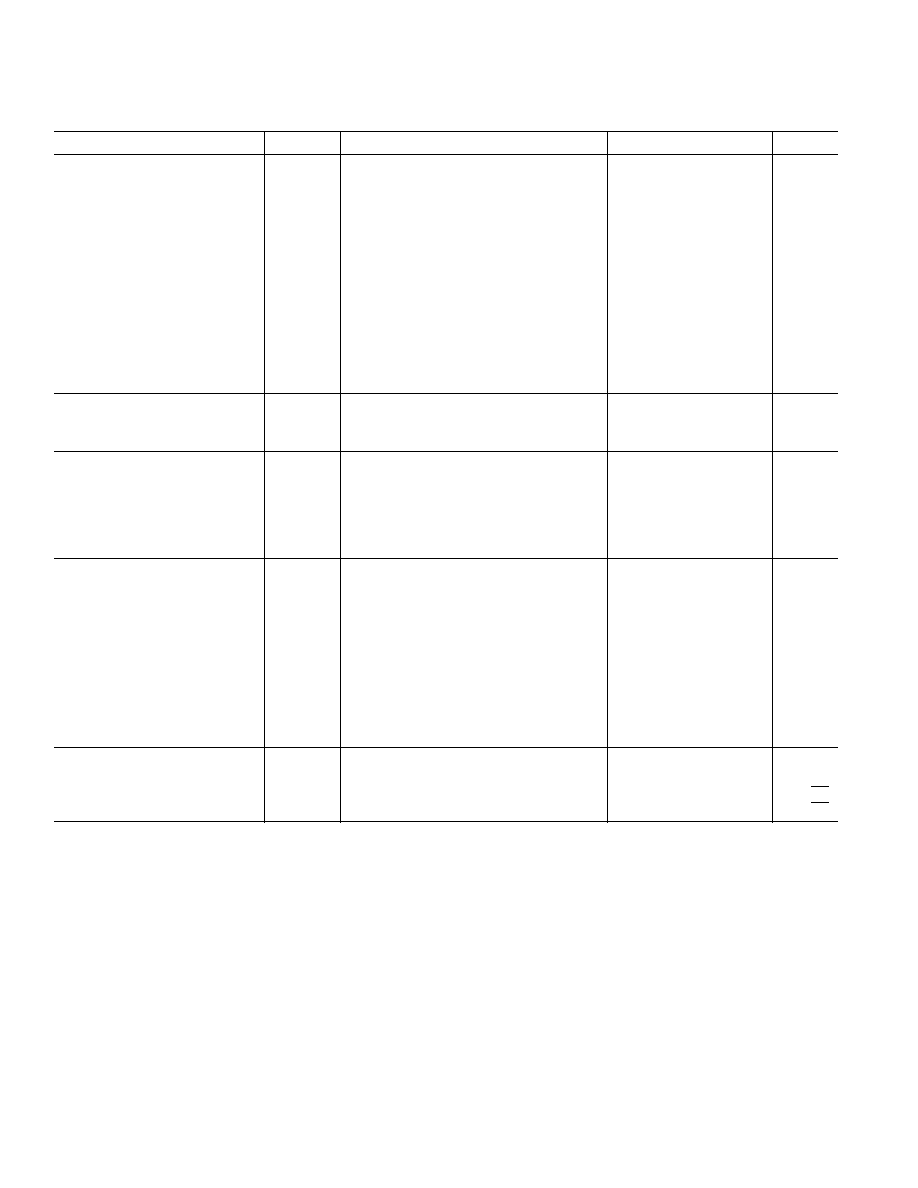

OP467SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Offset Voltage

V

OS

0.2

0.5

mV

40

°

C

T

A

+85

°

C

1

mV

Input Bias Current

I

B

V

CM

= 0 V

150

600

nA

V

CM

= 0 V, 40

°

C

T

A

+85

°

C

150

700

nA

Input Offset Current

I

OS

V

CM

= 0 V

10

100

nA

V

CM

= 0 V, 40

°

C

T

A

+85

°

C

10

150

nA

Common-Mode Rejection

CMR

V

CM

=

±

12 V

80

90

dB

CMR

V

CM

=

±

12 V, 40

°

C

T

A

+85

°

C

80

88

dB

Large Signal Voltage Gain

A

VO

R

L

= 2 k

83

86

dB

R

L

= 2 k

, 40

°

C

T

A

+85

°

C

77.5

dB

Offset Voltage Drift

V

OS

/

T

3.5

µ

V/

°

C

Bias Current Drift

I

B

/

T

0.2

pA/

°

C

Long Term Offset Voltage Drift

V

OS

/

T

Note 1

750

µ

V

OUTPUT CHARACTERISTICS

Output Voltage Swing

V

O

R

L

= 2 k

±

13.0

±

13.5

V

R

L

= 2 k

, 40

°

C

T

A

+85

°

C

±

12.9

±

13.12

V

POWER SUPPLY

Power Supply Rejection Ratio

PSRR

±

4.5 V

V

S

=

±

18 V

96

120

dB

40

°

C

T

A

+85

°

C

86

115

dB

Supply Current

I

SY

V

O

= 0 V

8

10

mA

V

O

= 0 V, 40

°

C

T

A

+85

°

C

13

mA

Supply Voltage Range

V

S

±

4.5

±

18

V

DYNAMIC PERFORMANCE

Gain Bandwidth Product

GBP

A

V

= +1, C

L

= 30 pF

28

MHz

Slew Rate

SR

V

IN

= 10 V Step, R

L

= 2 k

, C

L

= 30 pF

A

V

= +1

125

170

V/

µ

s

A

V

= 1

350

V/

µ

s

Full-Power Bandwidth

BW

V

IN

= 10 V Step

2.7

MHz

Settling Time

t

S

To 0.01%, V

IN

= 10 V Step

200

ns

Phase Margin

0

45

Degrees

Input Capacitance

Common Mode

2.0

pF

Differential

1.0

pF

NOISE PERFORMANCE

Voltage Noise

e

N

p-p

f = 0.1 Hz to 10 Hz

0.15

µ

V p-p

Voltage Noise Density

e

N

f = 1 kHz

6

nV/

Hz

Current Noise Density

i

N

f = 1 kHz

8

pA/

Hz

NOTE

1

Long Term Offset Voltage Drift is guaranteed by 1000 hrs. Life test performed on three independent wafer lots at +125

°

C, with an LTPD of 1.3.

Specifications subject to change without notice.

REV. C

2

(@ V

S

= 15.0 V, T

A

= +25 C unless otherwise noted)

OP467

REV. C

3

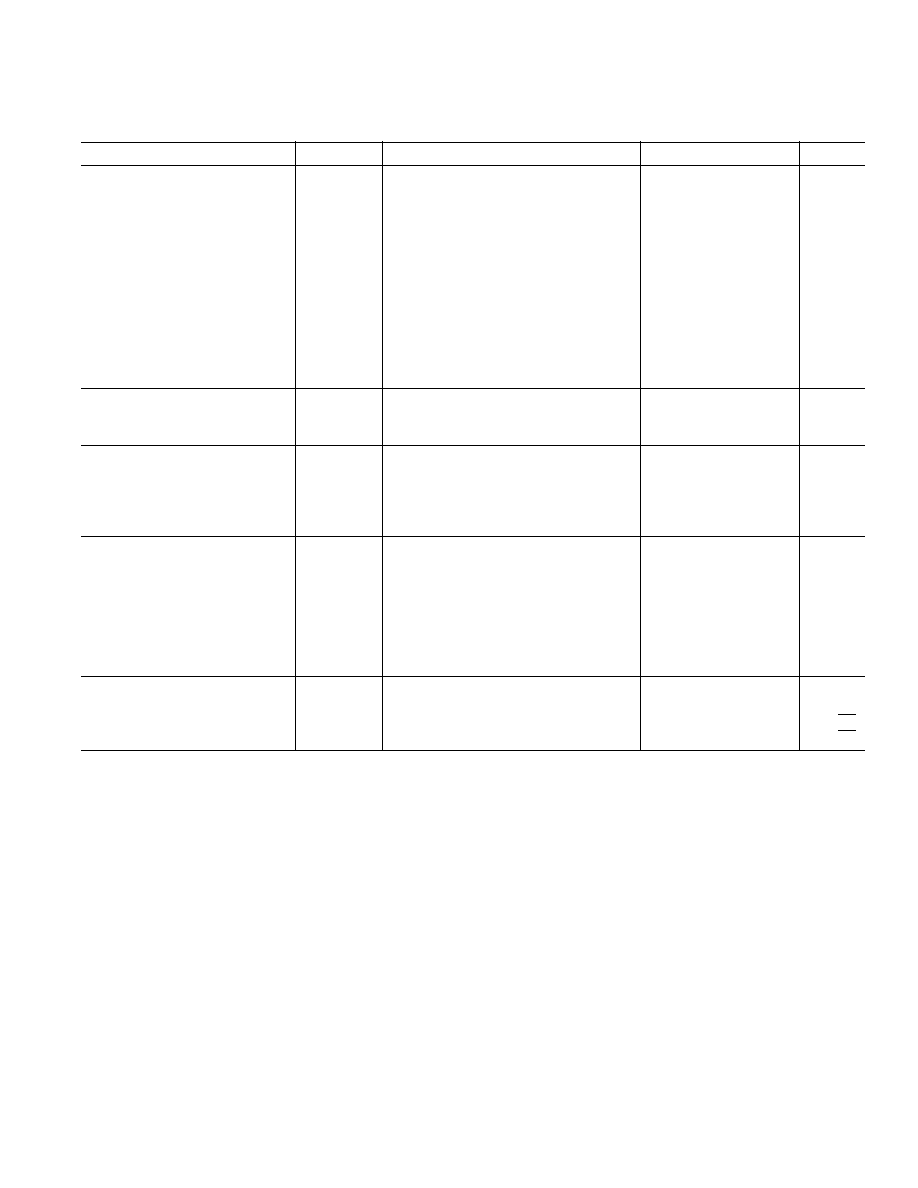

ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Offset Voltage

V

OS

0.3

0.5

mV

40

°

C

T

A

+85

°

C

1

mV

Input Bias Current

I

B

V

CM

= 0 V

125

600

nA

V

CM

= 0 V, 40

°

C

T

A

+85

°

C

150

700

nA

Input Offset Current

I

OS

V

CM

= 0 V

20

100

nA

V

CM

= 0 V, 40

°

C

T

A

+85

°

C

150

nA

Common-Mode Rejection

CMR

V

CM

=

±

2.0 V

76

85

dB

CMR

V

CM

=

±

2.0 V, 40

°

C

T

A

+85

°

C

76

80

dB

Large Signal Voltage Gain

A

VO

R

L

= 2 k

80

83

dB

R

L

= 2 k

, 40

°

C

T

A

+85

°

C

74

dB

Offset Voltage Drift

V

OS

/

T

3 5

µ

V/

°

C

Bias Current Drift

I

B

/

T

0.2

pA/

°

C

OUTPUT CHARACTERISTICS

Output Voltage Swing

V

O

R

L

= 2 k

±

3.0

±

3.5

V

R

L

= 2 k

, 40

°

C

T

A

+85

°

C

±

3.0

±

3.20

V

POWER SUPPLY

Power Supply Rejection Ratio

PSRR

±

4.5 V

V

S

=

±

5.5 V

92

107

dB

40

°

C

T

A

+85

°

C

83

105

dB

Supply Current

I

SY

V

O

= 0 V

8

10

mA

V

O

= 0 V, 40

°

C

T

A

+85

°

C

11

mA

DYNAMIC PERFORMANCE

Gain Bandwidth Product

GBP

A

V

= +1

22

MHz

Slew Rate

SR

V

IN

= 5 V Step, R

L

= 2 k

, C

L

= 39 pF

A

V

= +1

90

V/

µ

s

A

V

= 1

90

V/

µ

s

Full-Power Bandwidth

BW

V

IN

= 5 V Step

2.5

MHz

Settling Time

t

S

To 0.01%, V

IN

= 5 V Step

280

ns

Phase Margin

0

45

Degrees

NOISE PERFORMANCE

Voltage Noise

e

N

p-p

f = 0.1 Hz to 10 Hz

0.15

µ

V p-p

Voltage Noise Density

e

N

f = 1 kHz

7

nV/

Hz

Current Noise Density

i

N

f = 1 kHz

8

pA/

Hz

Specifications subject to change without notice.

(@ V

S

= 5.0 V, T

A

= +25 C unless otherwise noted)

OP467

REV. C

4

WAFER TEST LIMITS

1

Parameter

Symbol

Conditions

Limit

Units

Offset Voltage

V

OS

±

0.5

mV max

Input Bias Current

I

B

V

CM

= 0 V

600

nA max

Input Offset Current

I

OS

V

CM

= 0 V

100

nA max

Input Voltage Range

2

±

12

V min/max

Common-Mode Rejection Ratio

CMRR

V

CM

=

±

12 V

80

dB min

Power Supply Rejection Ratio

PSRR

V =

±

4.5 V to

±

18 V

96

dB min

Large Signal Voltage Gain

A

VO

R

L

= 2 k

83

dB min

Output Voltage Range

V

O

R

L

= 2 k

±

13.0

V min

Supply Current

I

SY

V

O

= 0 V, R

L

=

10

mA max

NOTES

1

Electrical tests and wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed for standard

product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

2

Guaranteed by CMR test.

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

18 V

Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

18 V

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . .

±

26 V

Output Short-Circuit Duration . . . . . . . . . . . . . . . . . . Limited

Storage Temperature Range

Y, RC Packages . . . . . . . . . . . . . . . . . . . . 65

°

C to +175

°

C

P, S Packages . . . . . . . . . . . . . . . . . . . . . . 65

°

C to +150

°

C

Operating Temperature Range

OP467A . . . . . . . . . . . . . . . . . . . . . . . . . . 55

°

C to +125

°

C

OP467G . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

°

C to +85

°

C

Junction Temperature Range

Y, RC Packages . . . . . . . . . . . . . . . . . . . . 65

°

C to +175

°

C

P, S Packages . . . . . . . . . . . . . . . . . . . . . . 65

°

C to +150

°

C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300

°

C

Package Type

A

3

JC

Units

14-Lead Cerdip (Y)

94

10

°

C/W

14-Lead Plastic DIP (P)

76

33

°

C/W

16-Lead SOL (S)

88

23

°

C/W

20-Contact LCC (RC)

78

33

°

C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

For supply voltages less than

±

18 V, the absolute maximum input voltage is equal

to the supply voltage.

3

JA

is specified for the worst case conditions, i.e.,

JA

is specified for device in socket

for cerdip, P-DIP, and LCC packages;

JA

is specified for device soldered in circuit

board for SOIC package.

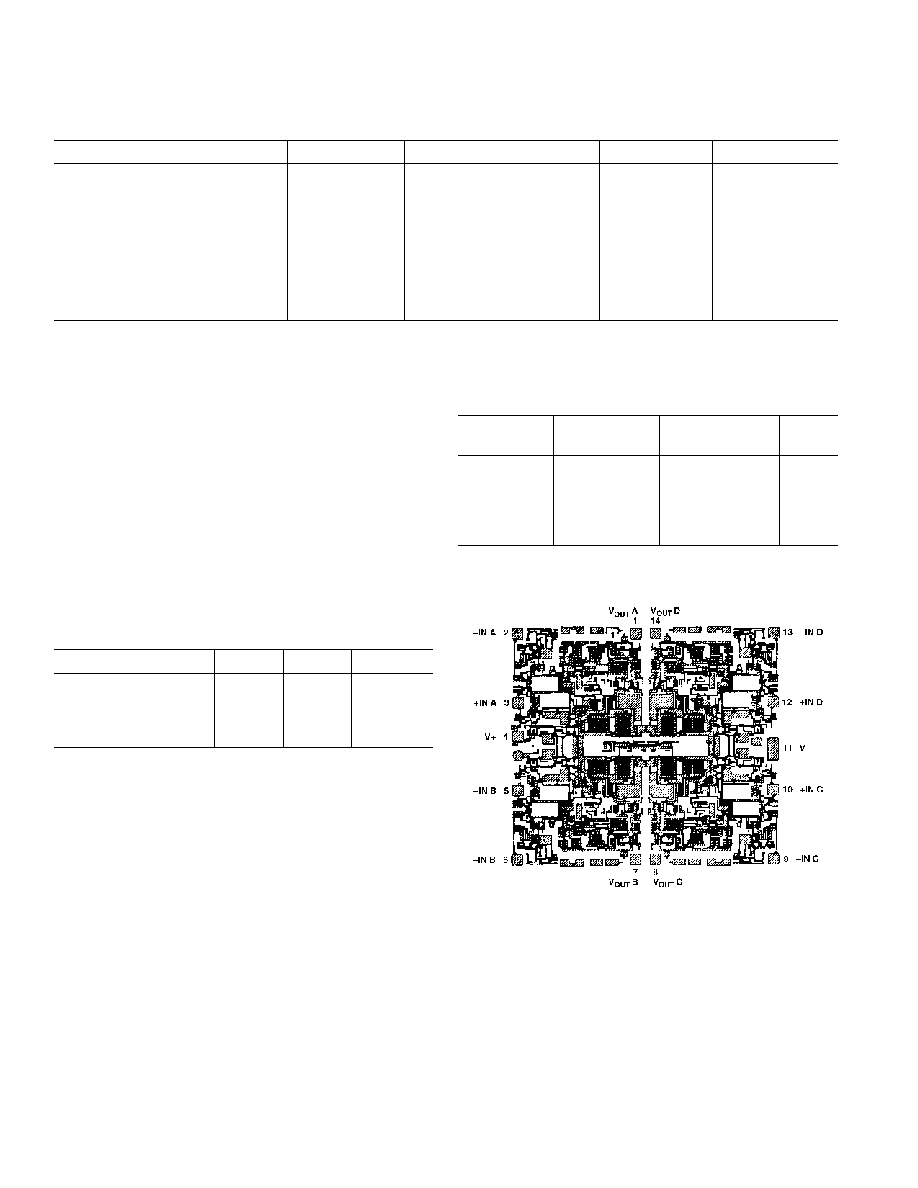

ORDERING GUIDE

Temperature

Package

Package

Model

Ranges

Descriptions

Options

OP467AY/883

55

°

C to +125

°

C 14-Lead Cerdip

Q-14

OP467ARC/883 55

°

C to +125

°

C 20-Contact LCC

E-20A

OP467GP

40

°

C to +85

°

C

14-Lead Plastic DIP N-14

OP467GS

40

°

C to +85

°

C

16-Lead SOL

R-16

OP467GBC

+25

°

C

DICE

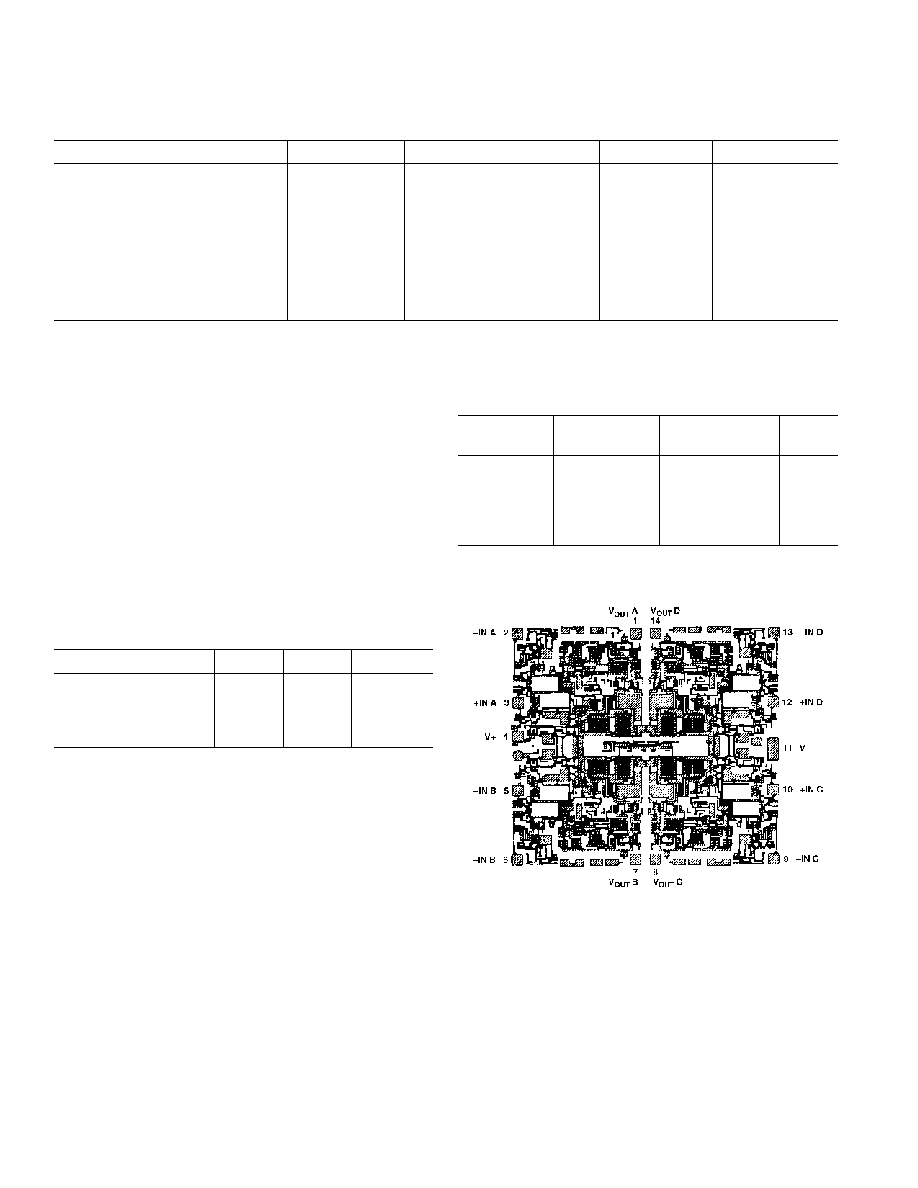

DICE CHARACTERISTICS

OP467 Die Size 0.111 0.100 inch, 11,100 sq. mils Sub-

strate is Connected to V+, Number of Transistors 165.

(

@ V

S

= 15.0 V, T

A

= +25 C unless otherwise noted.)

OP467

REV. C

5

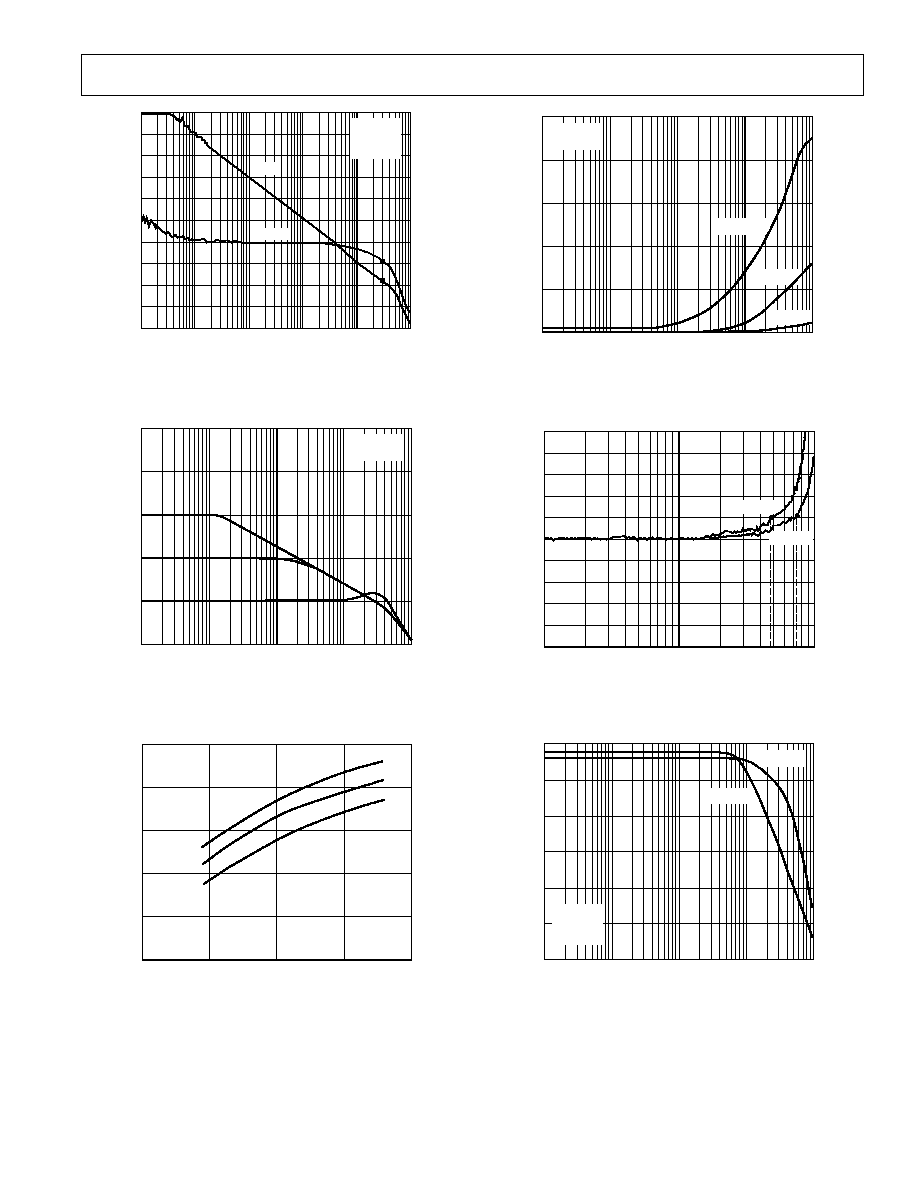

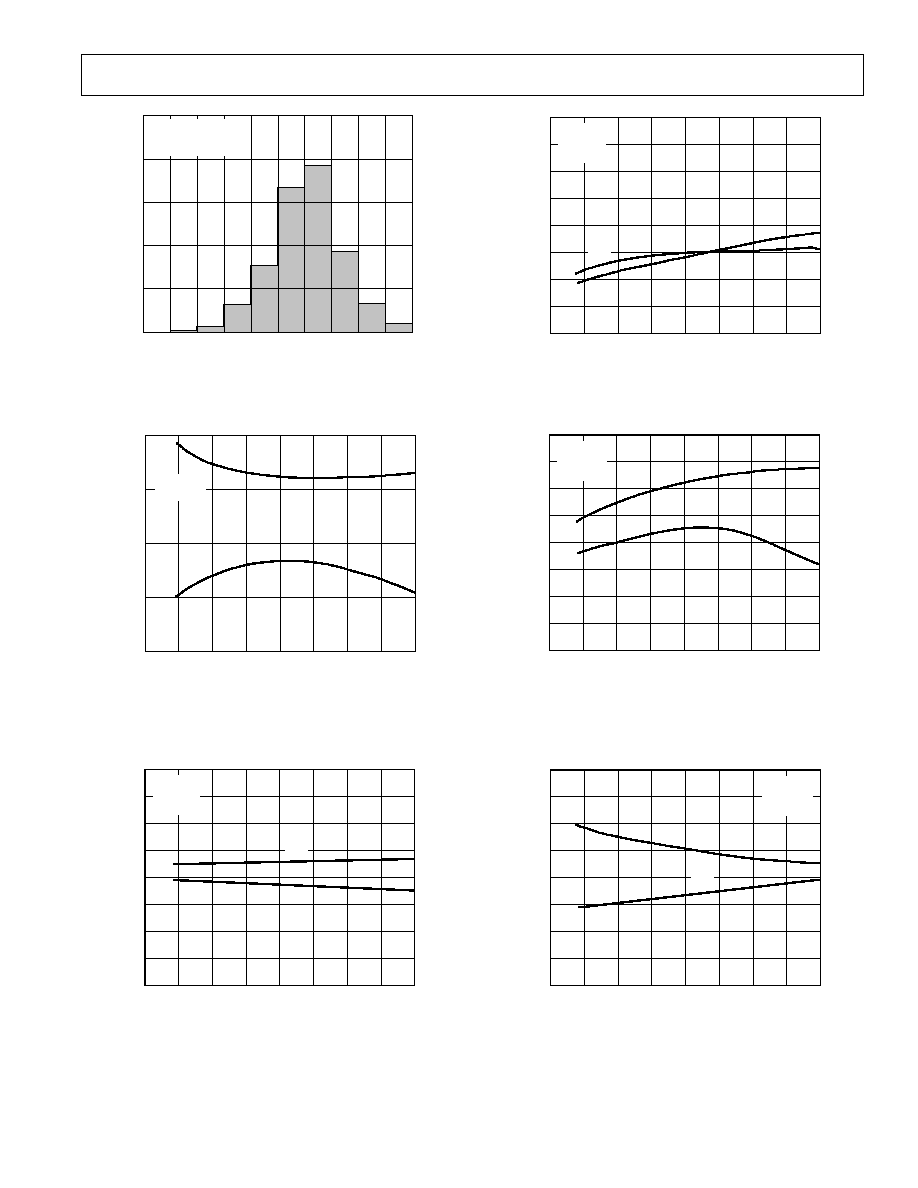

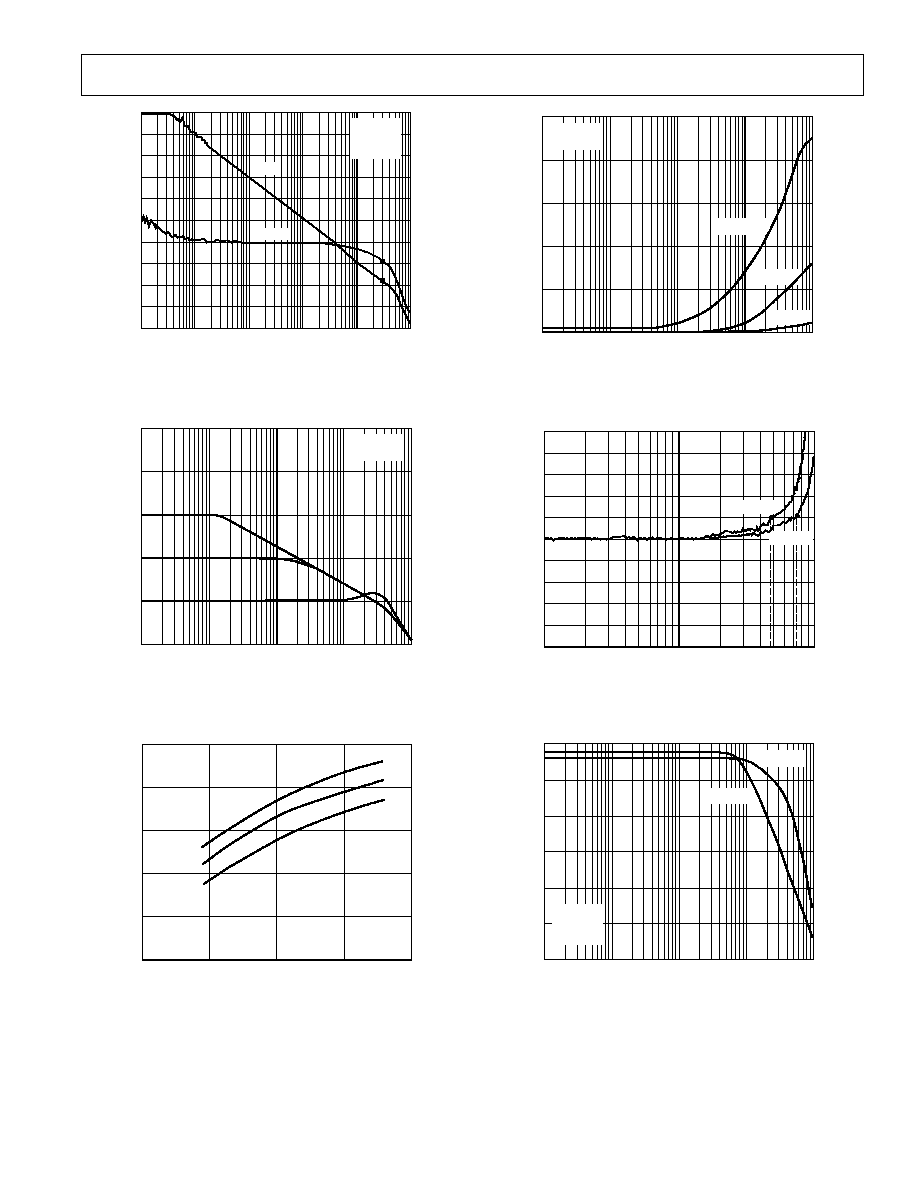

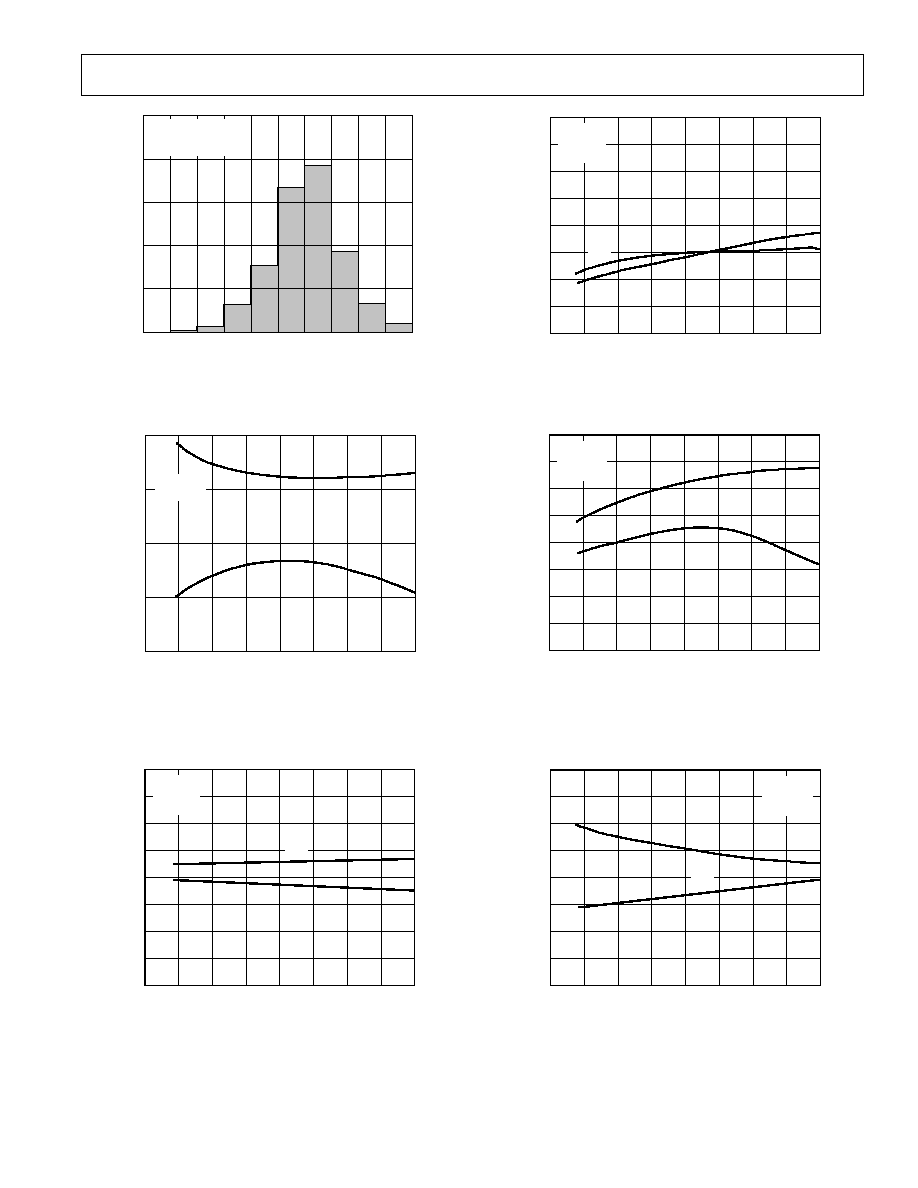

80

30

20

1k

10k

100M

10M

1M

100k

40

50

60

70

10

0

10

20

0

90

180

PHASE SHIFT Degrees

OPEN-LOOP GAIN dB

FREQUENCY Hz

GAIN

PHASE

V

S

= 15V

R

L

= 1M

C

L

= 30pF

Figure 2. Open-Loop Gain, Phase vs. Frequency

80

40

20

100k

100M

10M

1M

10k

20

0

60

FREQUENCY Hz

CLOSED-LOOP GAIN dB

V

S

= 15V

T

A

= +25 C

Figure 3. Closed-Loop Gain vs. Frequency

25

0

20

15

5

5

10

0

20

15

10

SUPPLY VOLTAGE Volts

OPEN-LOOP GAIN V/mV

T

A

= +125 C

T

A

= +25 C

T

A

= 55 C

Figure 4. Open-Loop Gain vs. Supply Voltage

100

60

0

1k

100k

10k

100

40

20

80

FREQUENCY Hz

IMPEDANCE

V

S

= 15V

T

A

= +25 C

1M

A

VCL

= +100

A

VCL

= +10

A

VCL

= +1

Figure 5. Closed-Loop Output Impedance vs. Frequency

0.0

100k

1M

10M

0.1

0.2

0.3

0.1

0.2

0.3

GAIN ERROR dB

FREQUENCY Hz

3.4

5.8

V

S

= 5

V

S

= 15

Figure 6. Gain Linearity vs. Frequency

30

15

0

10k

10M

1M

100k

1k

10

5

20

25

FREQUENCY Hz

MAXIMUM OUTPUT SWING Volts

A

VCL

= 1

A

VCL

= +1

V

S

= 15V

T

A

= +25 C

R

L

= 2k

Figure 7. Max V

OUT

Swing vs. Frequency

Typical Performance Characteristics

OP467

REV. C

6

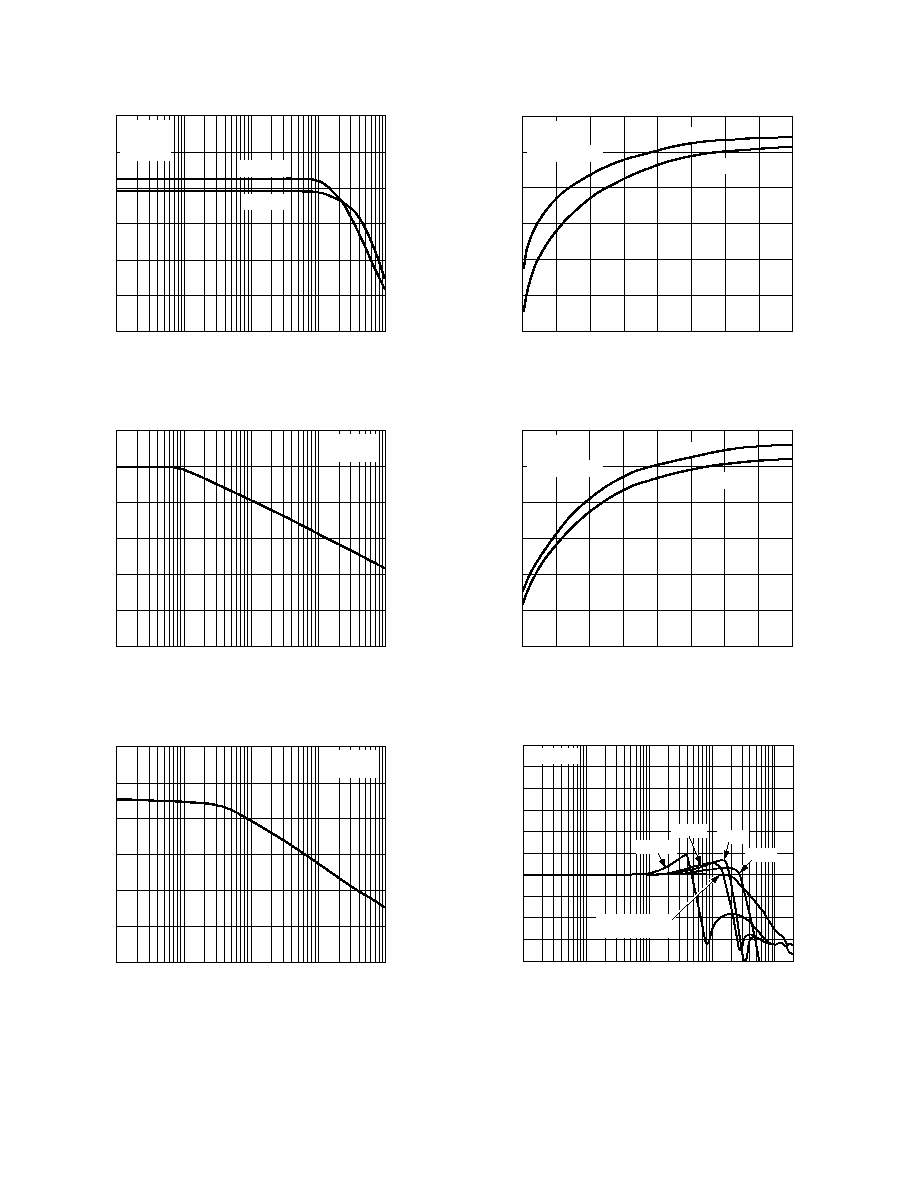

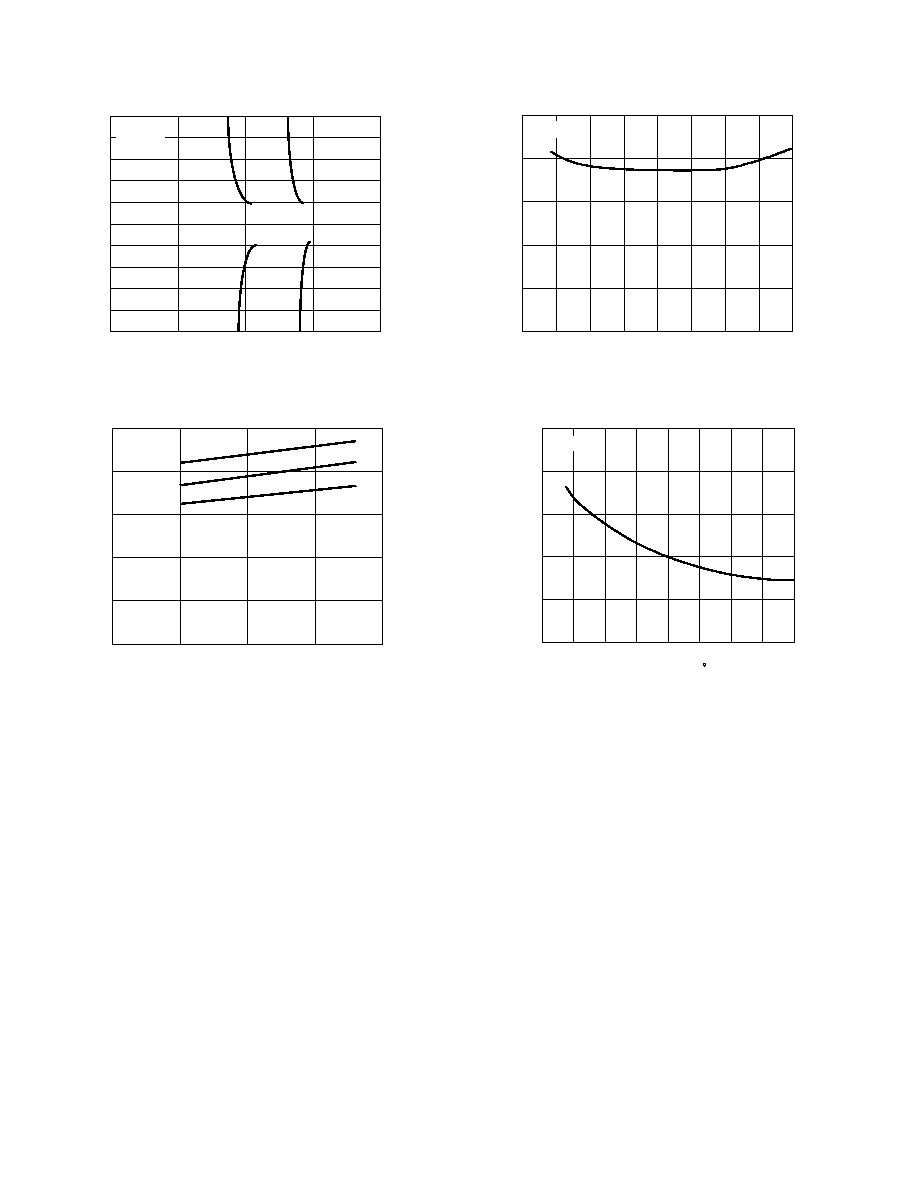

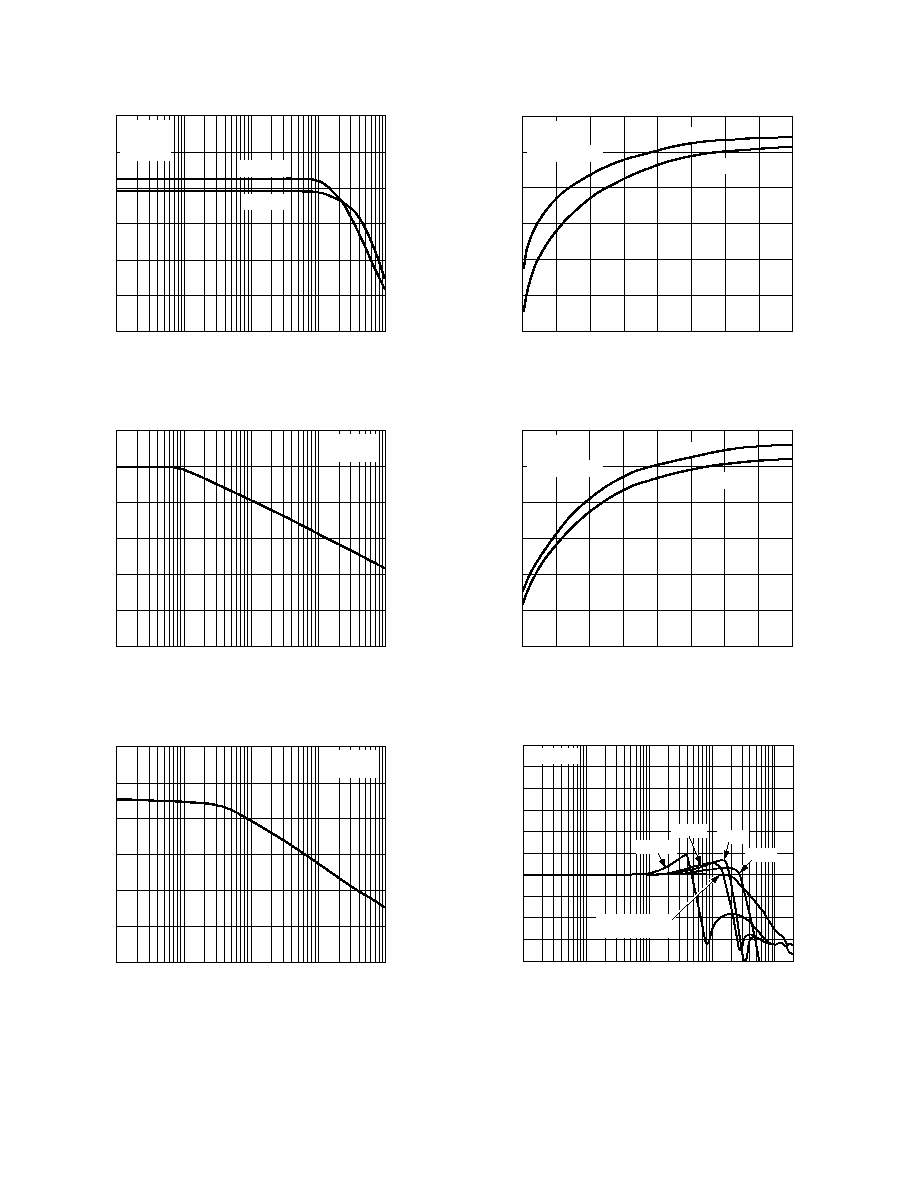

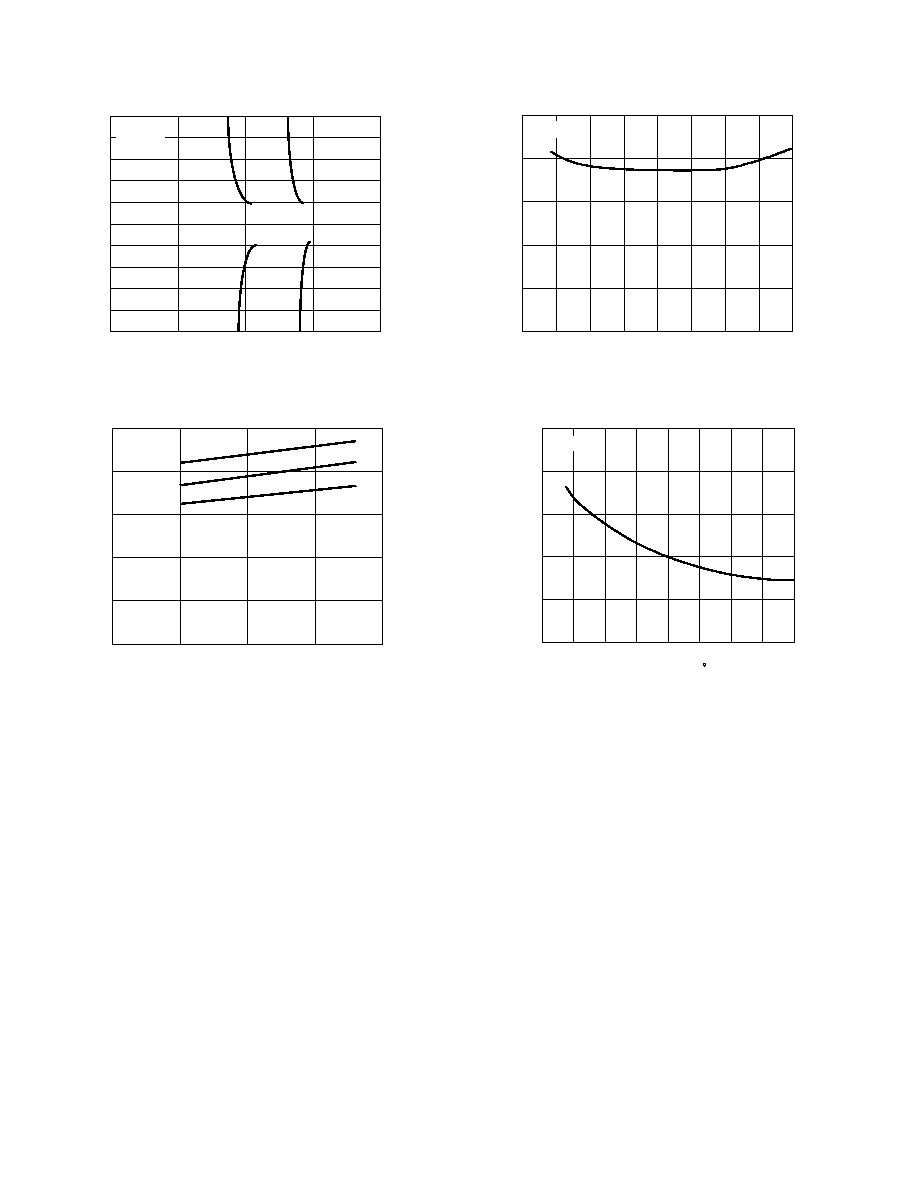

12

6

0

10k

10M

1M

100k

1k

4

2

8

10

FREQUENCY Hz

MAXIMUM OUTPUT SWING Volts

V

S

= 5V

T

A

= +25 C

R

L

= 2k

A

VCL

= 1

A

VCL

= +1

Figure 8. Max V

OUT

Swing vs. Frequency

120

60

0

10k

10M

1M

100k

1k

40

20

80

100

FREQUENCY Hz

COMMON-MODE REJECTION Volts

V

S

= 15V

T

A

= +25 C

Figure 9. Common-Mode Rejection vs. Frequency

120

60

0

1k

1M

100k

10k

100

40

20

80

100

FREQUENCY Hz

POWER SUPPLY REJECTION dB

V

S

= 15V

T

A

= +25 C

Figure 10. Power-Supply Rejection vs. Frequency

60

0

1600

30

10

200

20

0

50

40

1400

1000

800

600

1200

400

LOAD CAPACITANCE pF

OVERSHOOT %

V

S

= 15V

R

L

= 2k

V

IN

= 100mV p-p

A

VCL

= +1

A

VCL

= 1

Figure 11. Small Signal Overshoot vs. Load Capacitance

60

0

1600

30

10

200

20

0

50

40

1400

1000

800

600

1200

400

LOAD CAPACITANCE pF

OVERSHOOT %

V

S

= 5V

R

L

= 2k

V

IN

= 100mV p-p

A

VCL

= +1

A

VCL

= 1

Figure 12. Small Signal Overshoot vs. Load Capacitance

60

10

40

10k

100M

10M

1M

100k

20

30

40

50

30

20

10

0

GAIN dB

FREQUENCY Hz

V

S

= 15V

10000pF

1000pF

500pF

200pF

C

IN

= NETWORK

ANALYZER

Figure 13. Noninverting Gain vs. Capacitive Loads

OP467

REV. C

7

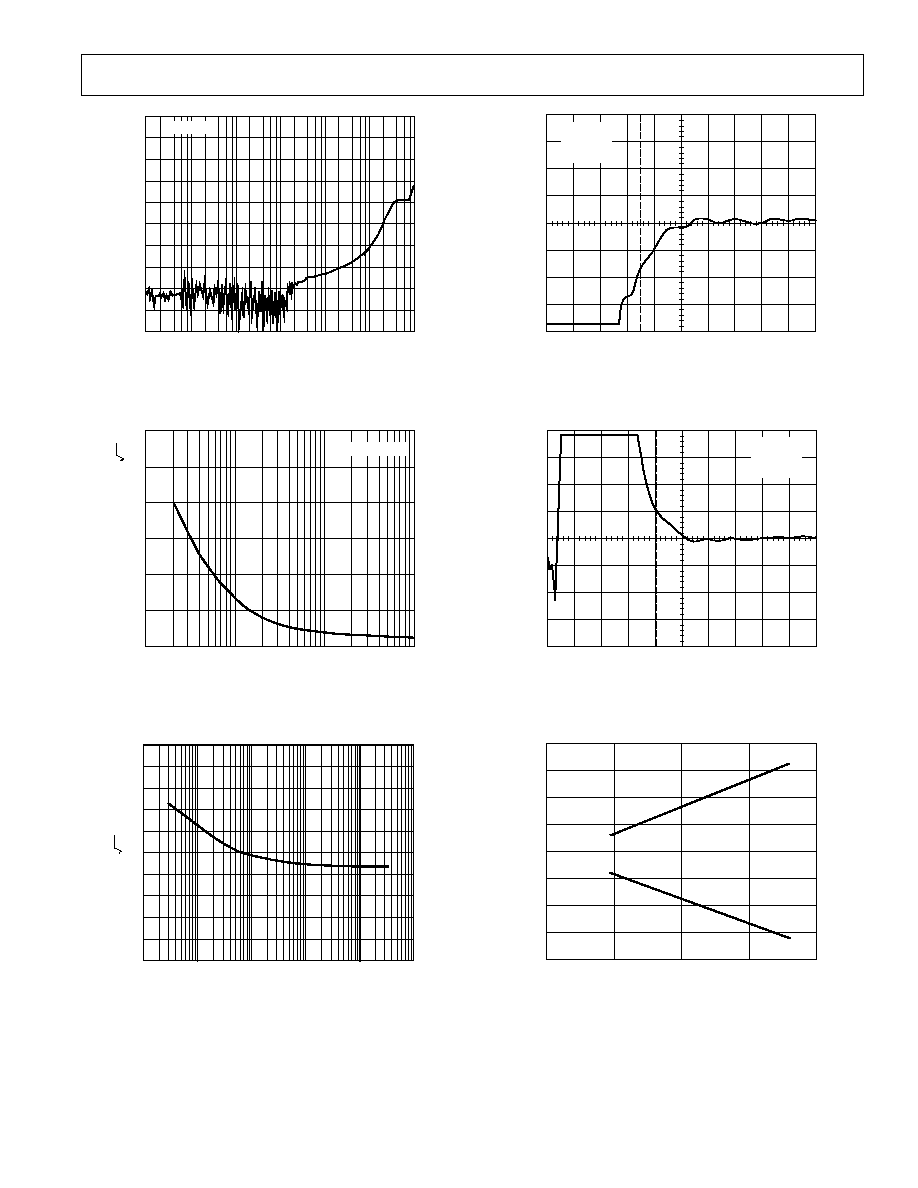

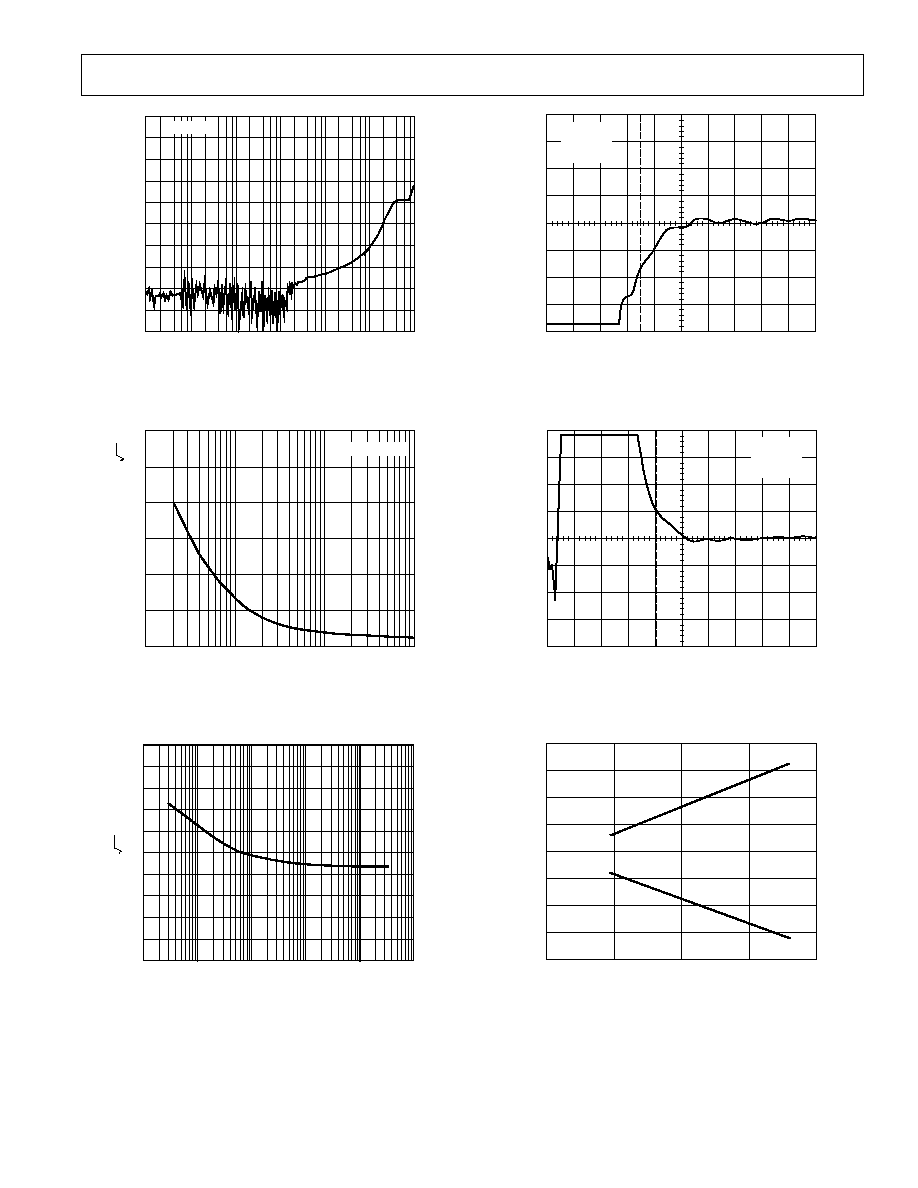

0

50

100

1k

100M

10M

1M

100k

10k

40

30

20

10

90

80

70

60

FREQUENCY Hz

CHANNEL SEPARATION dB

V

S

= 15V

100

Figure 14. Channel Separation vs. Frequency

12

6

0

100

1

1k

10

4

2

8

10

FREQUENCY Hz

INPUT CURRENT NOISE DENSITY pA/ Hz

5V

V

S

15V

Figure 15. Input Current Noise Density vs. Frequency

100

10

1.0

0.1

1

10k

1k

100

10

FREQUENCY Hz

nV/ Hz

Figure 16. Voltage Noise Density vs. Frequency

500

2

0

0

1

1

2

400

300

200

100

TIME ns

V

OUT

ERROR mV

V

S

= 15V

V

IN

= 5V

C

L

= 50pF

3

4

3

4

Figure 17. Settling Time, Negative Edge

500

2

0

0

1

1

2

400

300

200

100

TIME ns

V

OUT

ERROR mV

V

S

= 15V

V

IN

= 5V

C

L

= 50pF

3

4

3

4

Figure 18. Settling Time, Positive Edge

20

20

5

0

0

5

5

10

15

15

10

20

10

15

SUPPLY VOLTAGE Volts

INPUT VOLTAGE RANGE Volts

T

A

= +25 C

Figure 19. Input Voltage Range vs. Supply Voltage

OP467

REV. C

8

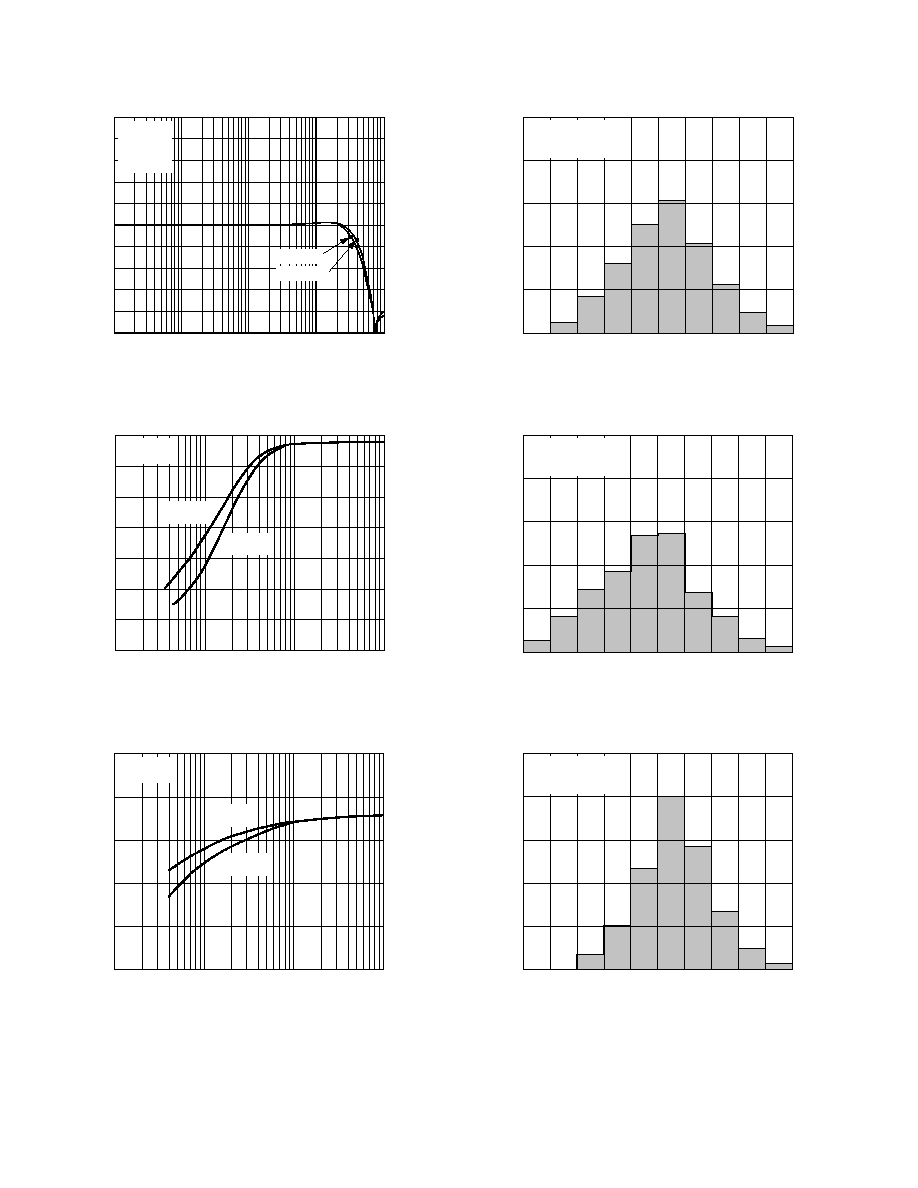

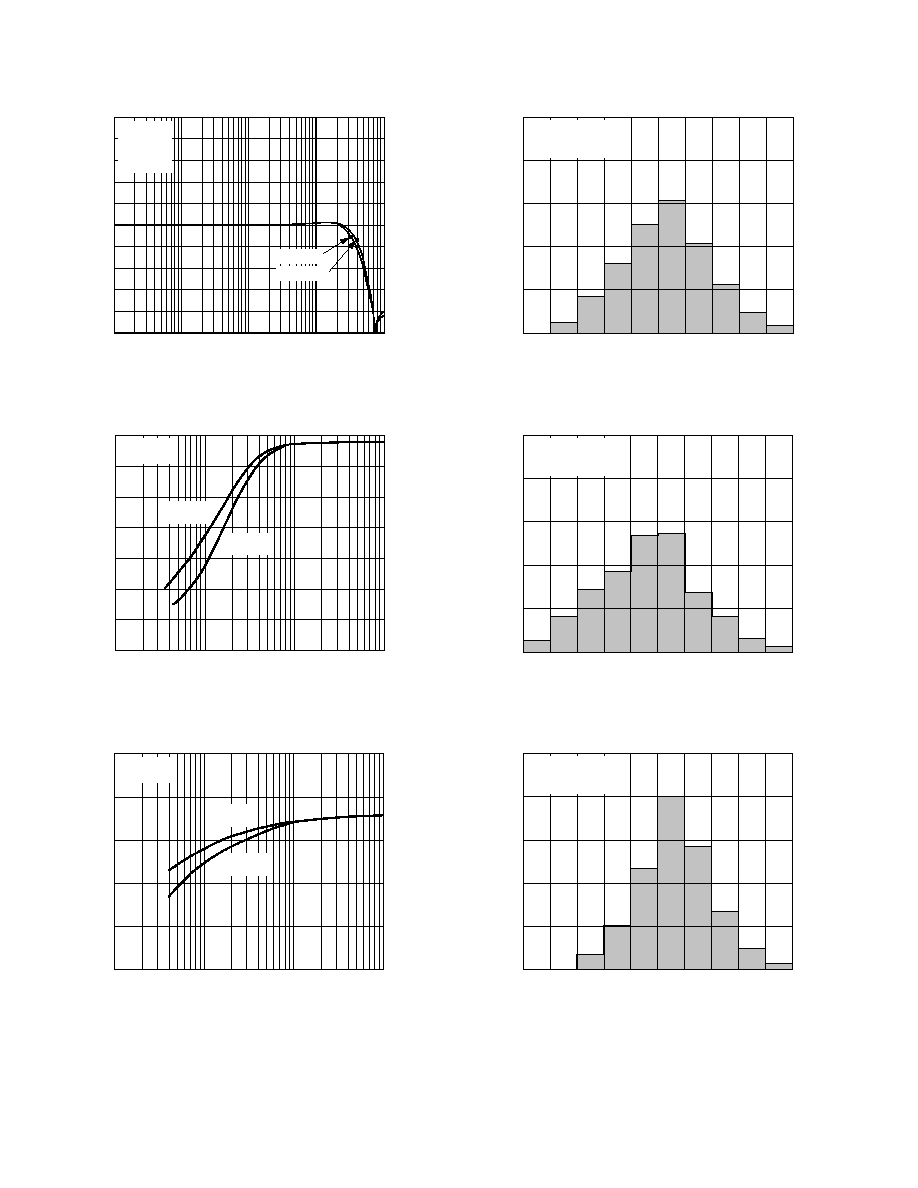

0

100k

100M

10M

1M

10k

10

20

10

GAIN dB

FREQUENCY Hz

V

S1

= 15V

V

S2

= 5V

R

L

= 10k

C

L

= 50pF

V

S1

= 15V

V

S2

= 5V

20

30

40

50

30

40

50

Figure 20. Noninverting Gain vs. Supply Voltage

14

4

0

10

2

6

8

12

OUTPUT SWING Volts

100

10k

1k

10

LOAD RESISTANCE

POSITIVE

SWING

NEGATIVE

SWING

V

S

= 15V

T

A

= +25 C

Figure 21. Output Swing vs. Load Resistance

2

0

5

1

3

4

OUTPUT SWING Volts

100

10k

1k

10

LOAD RESISTANCE

POSITIVE

SWING

NEGATIVE

SWING

V

S

= 5V

T

A

= +25 C

Figure 22. Output Swing vs. Load Resistance

500

0

400

300

100

50

200

100

400

350

300

250

200

150

100

50

0

INPUT OFFSET VOLTAGE V

OS

V

UNITS

V

S

= 15V

T

A

= +25 C

1252 OP AMPS

Figure 23. Input Offset Voltage Distribution

500

0

400

300

100

50

200

100

400

350

300

250

200

150

100

50

0

INPUT OFFSET VOLTAGE V

OS

V

UNITS

V

S

= 5V

T

A

= +25 C

1252 OP AMPS

Figure 24. Input Offset Voltage Distribution

TC V

OS

V/ C

500

0

5.0

300

100

0.5

200

0

400

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

UNITS

V

S

= 15V

T

A

= +25 C

1252 OP AMPS

Figure 25. TC V

OS

Distribution

OP467

REV. C

9

TC V

OS

V/ C

500

0

5.0

300

100

0.5

200

0

400

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

UNITS

V

S

= 5V

T

A

= +25 C

1252 OP AMPS

Figure 26. TC V

OS

Distribution

60

40

75

125

55

45

50

50

75

100

50

25

0

25

29.0

27.0

28.5

27.5

28.0

TEMPERATURE C

PHASE MARGIN Degrees

GAIN BANDWIDTH PRODUCT MHz

GBW

M

V

S

= 15V

R

L

= 2k

Figure 27. Phase Margin and Gain Bandwidth vs.

Temperature

400

0

125

100

50

50

75

200

150

250

300

350

100

75

50

25

0

25

TEMPERATURE C

SLEW RATE V/

s

+SR

SR

V

S

= 5V

R

L

= 2k

A

VCL

= 1

Figure 28. Slew Rate vs. Temperature

400

0

125

100

50

50

75

200

150

250

300

350

100

75

50

25

0

25

TEMPERATURE C

SLEW RATE V/

s

SR

+SR

V

S

= 5V

R

L

= 2k

A

VCL

= +1

Figure 29. Slew Rate vs. Temperature

650

250

125

350

300

50

75

450

400

500

550

600

100

75

50

25

0

25

TEMPERATURE C

SLEW RATE V/

s

V

S

= 15V

R

L

= 2k

A

VCL

= 1

+SR

SR

Figure 30. Slew Rate vs. Temperature

400

0

125

100

50

50

75

200

150

250

300

350

100

75

50

25

0

25

TEMPERATURE C

SLEW RATE V/

s

V

S

= 15V

R

L

= 2k

A

VCL

= +1

+SR

SR

Figure 31. Slew Rate vs. Temperature

OP467

REV. C

10

10

10

400

4

8

100

6

0

2

2

0

4

6

8

300

200

5

1

4

2

3

1

5

0

2

3

4

SETTLING TIME ns

OUTPUT STEP FOR

15V SUPPLY Volts

OUTPUT STEP FOR

5V SUPPLY Volts

0.1%

0.01%

0.1%

0.01%

R

F

= 5k

T

A

= +25 C

Figure 32. Settling Time vs. Output Step

10

0

20

6

2

5

4

0

8

15

10

SUPPLY VOLTAGE Volts

SUPPLY CURRENT mA

T

A

= +125 C

T

A

= +25 C

T

A

= 55 C

Figure 33. Supply Current vs. Supply Voltage

200

0

125

120

40

50

80

75

160

100

75

50

25

0

25

TEMPERATURE C

INPUT BIAS CURRENT nA

V

S

= 15V

Figure 34. Input Bias Current vs. Temperature

25

0

125

15

5

50

10

75

20

100

75

50

25

0

25

TEMPERATURE C

INPUT OFFSET CURRENT nA

V

S

= 15V

Figure 35. Input Offset Current vs. Temperature

OP467

REV. C

11

APPLICATIONS INFORMATION

OUTPUT SHORT-CIRCUIT PERFORMANCE

To achieve a wide bandwidth and high slew rate, the OP467

output is not short circuit protected. Shorting the output to

ground or to the supplies may destroy the device.

For safe operation, the output load current should be limited so

that the junction temperature does not exceed the absolute

maximum junction temperature.

To calculate the maximum internal power dissipation, the fol-

lowing formula can be used:

P

T

T

D

A

A

=

J

J

max

where T

J

and T

A

are junction and ambient temperatures respec-

tively, P

D

is device internal power dissipation, and

JA

is pack-

aged device thermal resistance given in the data sheet.

UNUSED AMPLIFIERS

It is recommended that any unused amplifiers in a quad package

be connected as a unity gain follower with a 1 k

feedback

resistor with noninverting input tied to the ground plain.

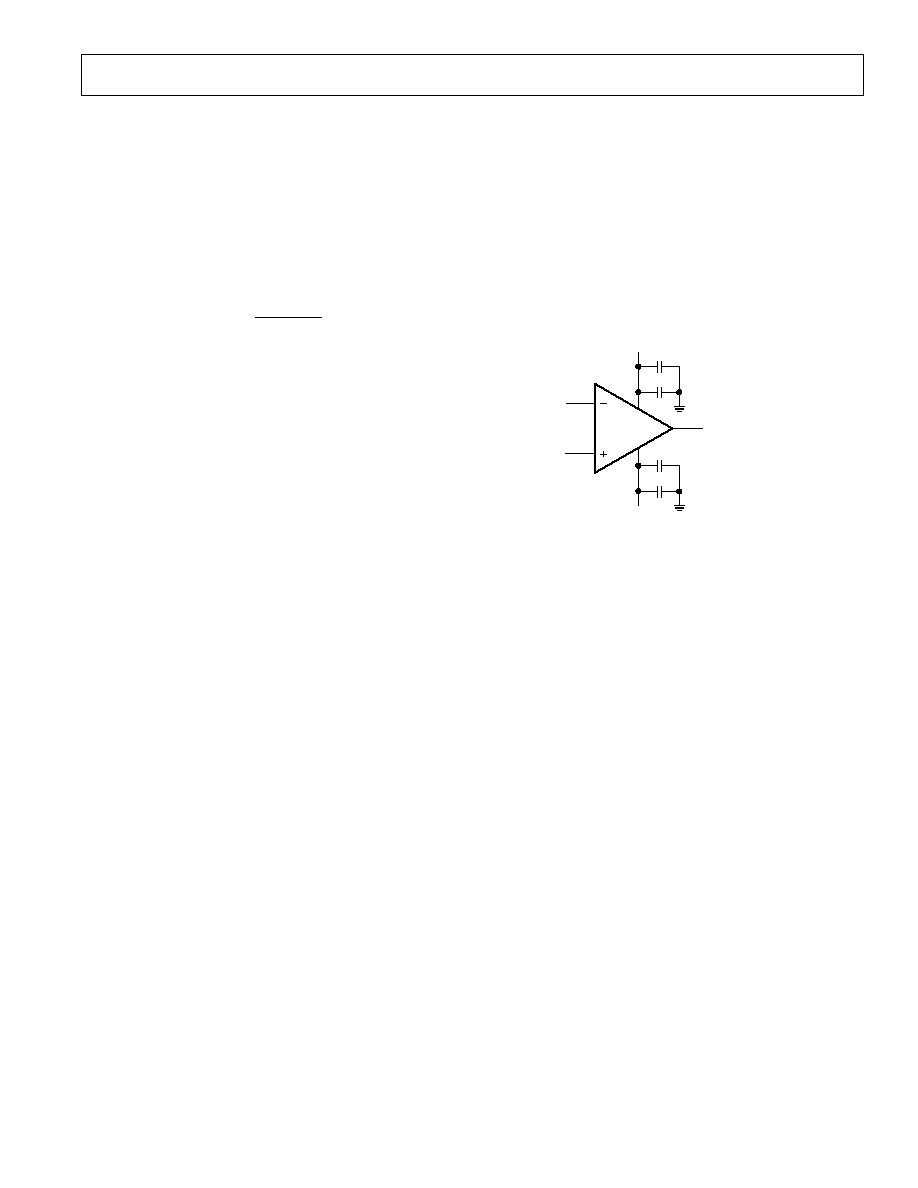

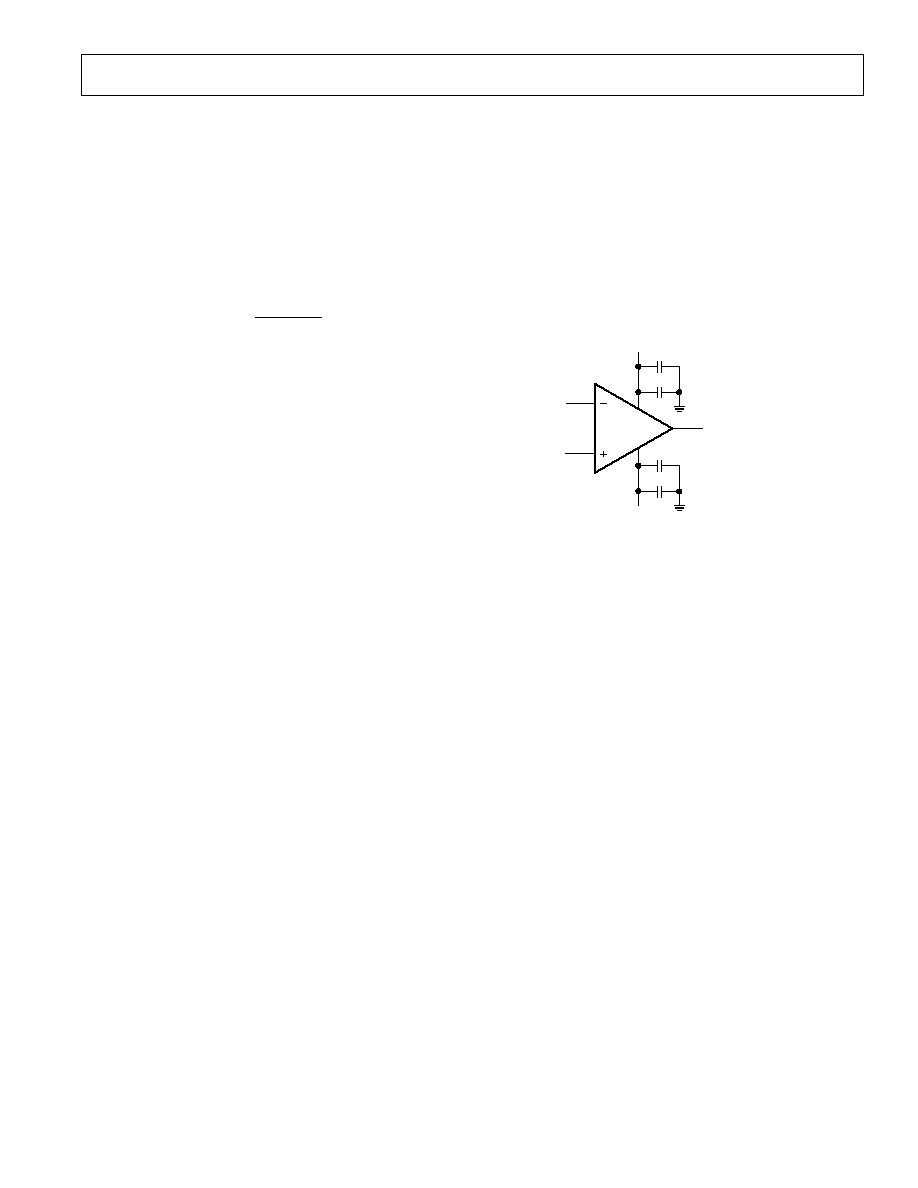

PRINTED CIRCUIT BOARD LAYOUT

CONSIDERATIONS

Satisfactory performance of a high speed op amp largely depends

on a good PC layout. To achieve the best dynamic performance,

following high frequency layout technique is recommended.

GROUNDING

A good ground plain is essential to achieve the optimum perfor-

mance in high speed applications. It can significantly reduce the

undesirable effects of ground loops and IR drops by providing a

low impedance reference point. Best results are obtained with a

multilayer board design with one layer assigned to ground plain.

To maintain a continuous and low impedance ground, avoid

running any traces on this layer.

POWER SUPPLY CONSIDERATIONS

In high frequency circuits, device lead length introduces an

inductance in series with the circuit. This inductance, combined

with stray capacitance, forms a high frequency resonance circuit.

Poles generated by these circuits will cause gain peaking and

additional phase shift, reducing the op amp's phase margin and

leading to an unstable operation.

A practical solution to this problem is to reduce the resonance

frequency low enough to take advantage of the amplifier's power

supply rejection.

This is easily done by placing capacitors across the supply line

and the ground plain as close as possible to the device pin. Since

capacitors also have internal parasitic components, such as stray

inductance, selecting the right capacitor is important. To be

effective, they should have low impedance over the frequency

range of interest. Tantalum capacitors are an excellent choice

for their high capacitance/size ratio, but their ESR (Effective

Series Resistance) increases with frequency making them less

effective. On the other hand, ceramic chip capacitors have excel-

lent ESR and ESL (Effective Series Inductance) performance at

higher frequencies, and because of their small size, they can be

placed very close to the device pin, further reducing the stray

inductance. Best results are achieved by using a combination of

these two capacitors. A 5

µ

F10

µ

F tantalum parallel with a

0.1

µ

F ceramic chip caps are recommended. If additional isola-

tion from high frequency resonances of the power supply is

needed, a ferrite bead should be placed in series with the supply

lines between the bypass caps and the power supply. A word of

caution, addition of the ferrite bead will introduce a new pole

and zero to frequency response of the circuit and could cause

unstable operation if it is not selected properly.

+V

S

10 F TANTALUM

0.1 F CERAMIC CHIP

V

S

10 F TANTALUM

0.1 F CERAMIC CHIP

+

Figure 36. Recommended Power Supply Bypass

SIGNAL CONSIDERATIONS

Input and output traces need special attention to assure a mini-

mum stray capacitance. Input nodes are very sensitive to capaci-

tive reactance, particularly when connected to a high impedance

circuit. Stray capacitance can inject undesirable signals from a

noisy line into a high impedance input. Protect high impedance

input traces by providing guard traces around them. This will

also improve the channel separation significantly.

Additionally, any stray capacitance in parallel with the op amp's

input capacitance generates a pole in the frequency response of

the circuit. The additional phase shift caused by this pole will

reduce the circuit's gain margin. If this pole is within the gain

range of the op amp, it will cause unstable performance. To

reduce these undesirable effects, use the lowest impedance

where possible. Lowering the impedance at this node places the

poles at a higher frequency, far above the gain range of the am-

plifier. Stray capacitance on the PC board can be reduced by

making the traces narrow and as short as possible. Further re-

duction can be realized by choosing smaller pad size, increasing

the spacing between the traces, and using PC board material

with a low dielectric constant insulator (Dielectric Constant of

some common insulators: air = 1, Teflon

®

= 2.2, and FR4 =

4.7; with air being an ideal insulator).

Removing segments of the ground plain directly under the input

and output pads is recommended.

Outputs of high speed amplifiers are very sensitive to capacitive

loads. A capacitive load will introduce a pair of pole and zero to

the circuit's frequency response, reducing the phase margin,

leading to unstable operation or oscillation.

Teflon is a registered trademark of E.I. du Pont Co.

OP467

REV. C

12

Generally, it is a good design practice to isolate the amplifier's

output from any capacitive load by placing a resistor between

the amplifier's output and the rest of the circuits. A series resis-

tor of 10 to 100 ohms is normally sufficient to isolate the output

from a capacitive load.

The OP467 is internally compensated to provide stable opera-

tion, and is capable of driving large capacitive loads without

oscillation.

Sockets are not recommended since they increase the lead in-

ductance/capacitance and reduce the power dissipation of the

package by increasing the leads thermal resistance. If sockets

must be used, use Teflon or pin sockets with the shortest leads

possible.

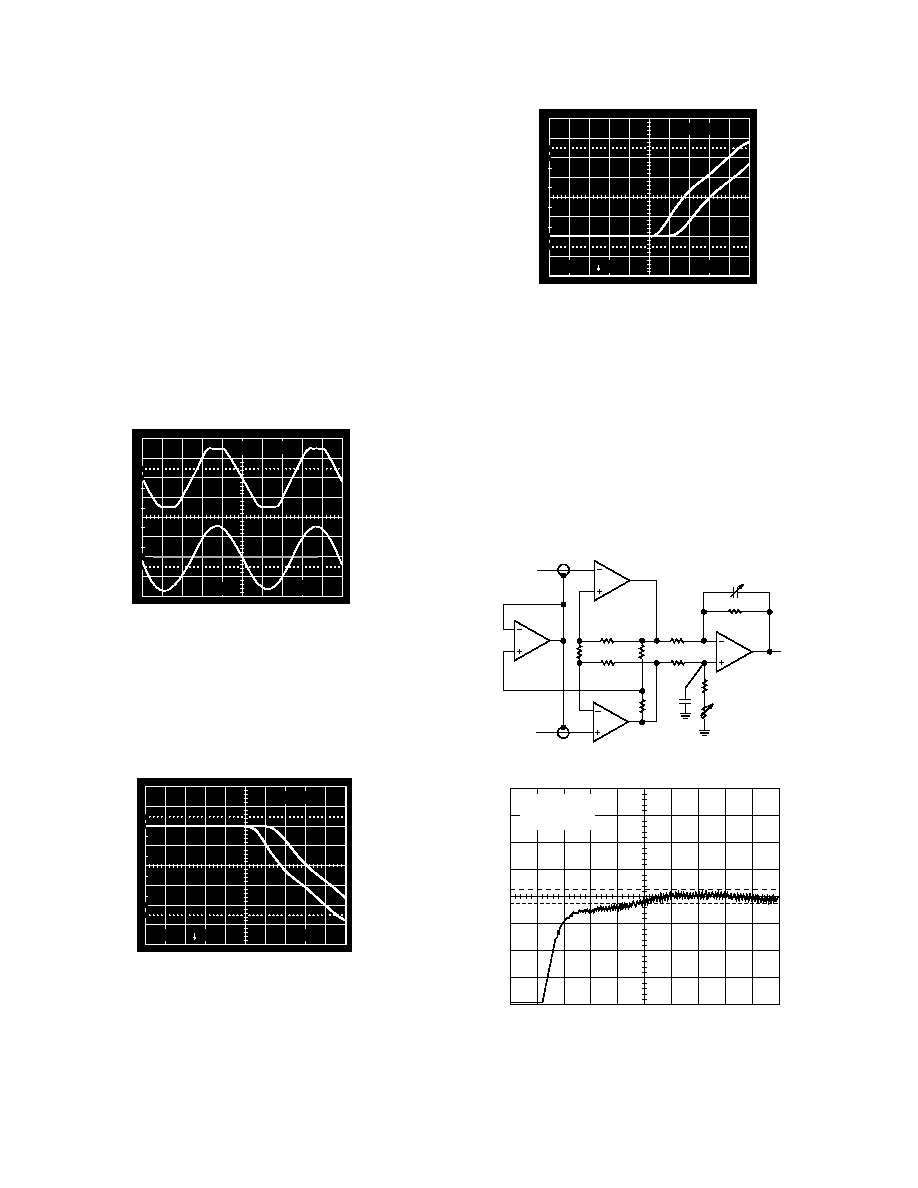

PHASE REVERSAL

The OP467 is immune to phase reversal; its inputs can exceed

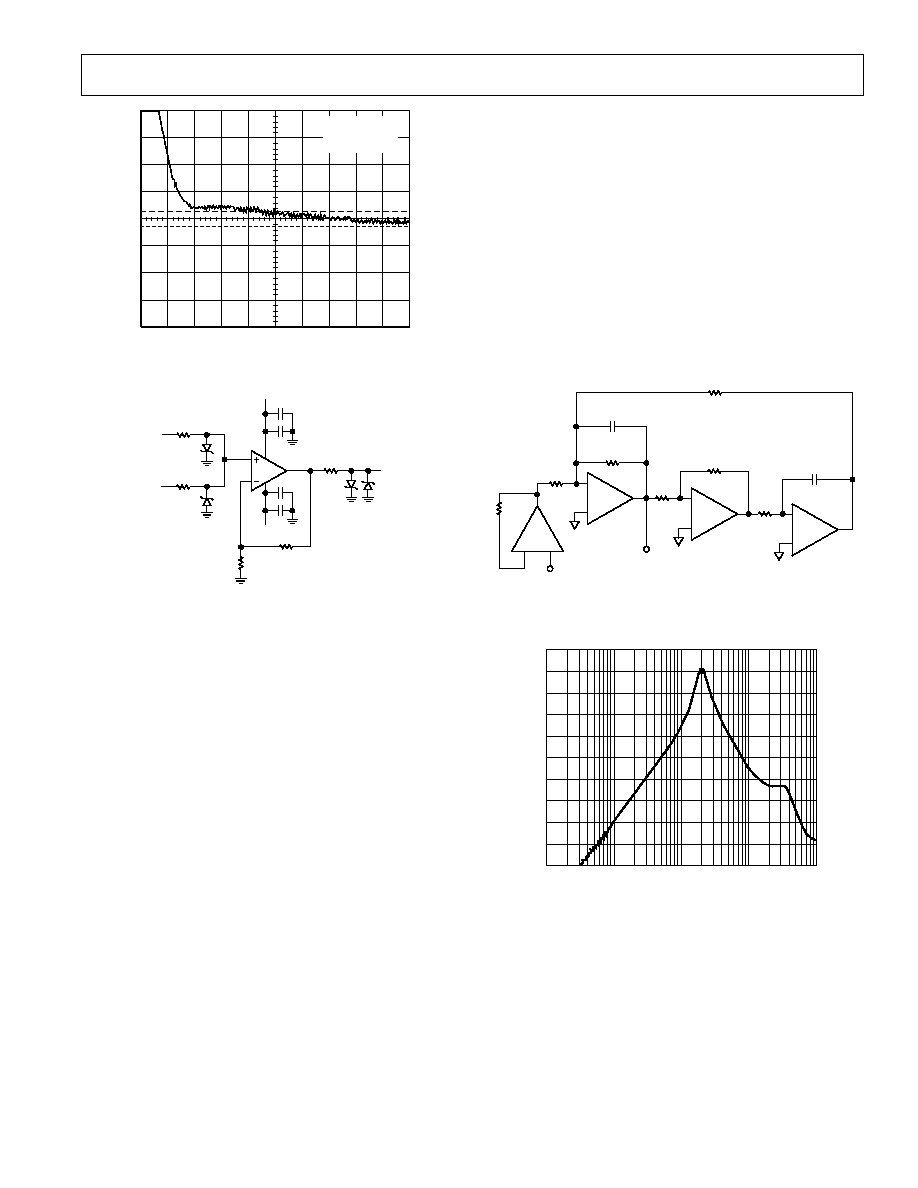

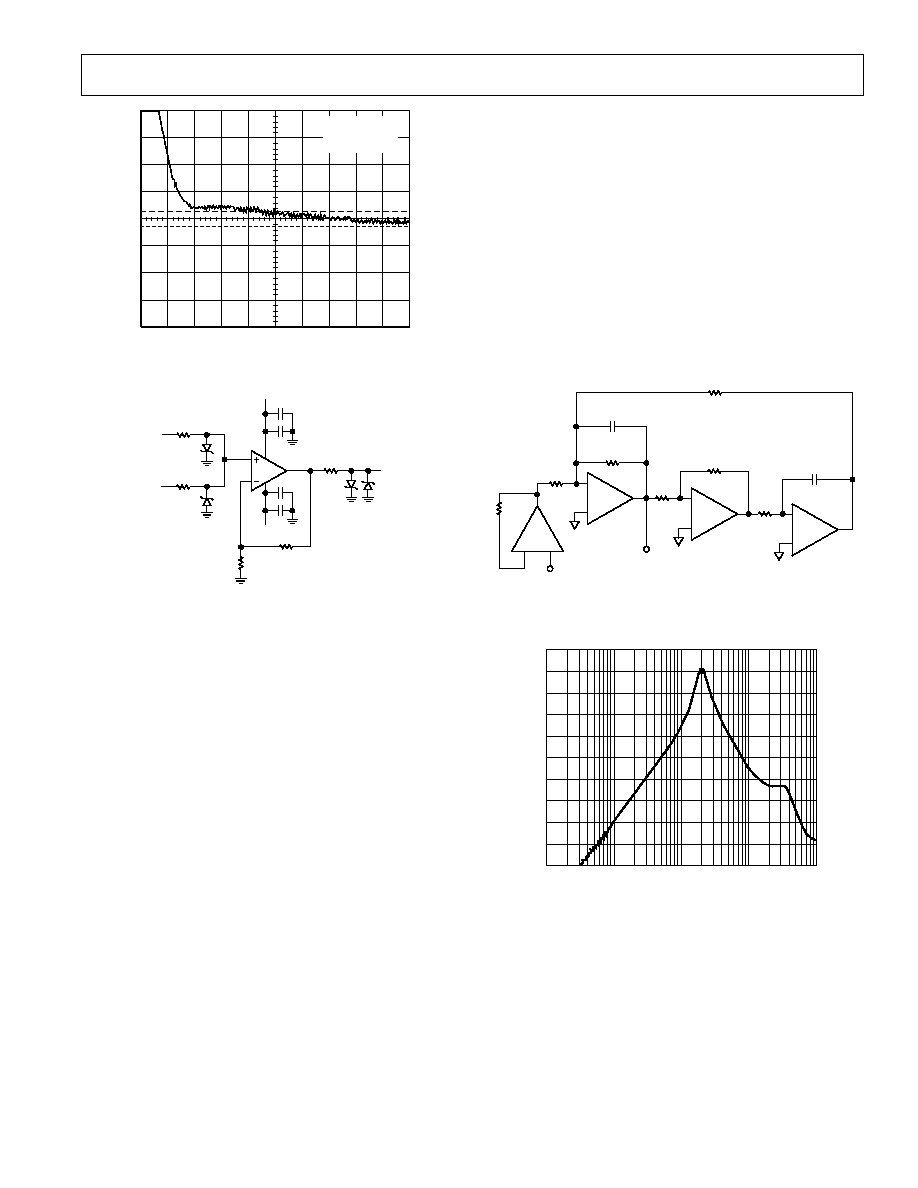

the supply rails by a diode drop without any phase reversal.

OUTPUT

INPUT

10

0%

100

90

200 s

10V

10V

V1

15.8V

Figure 37. No Phase Reversal (A

V

= +1)

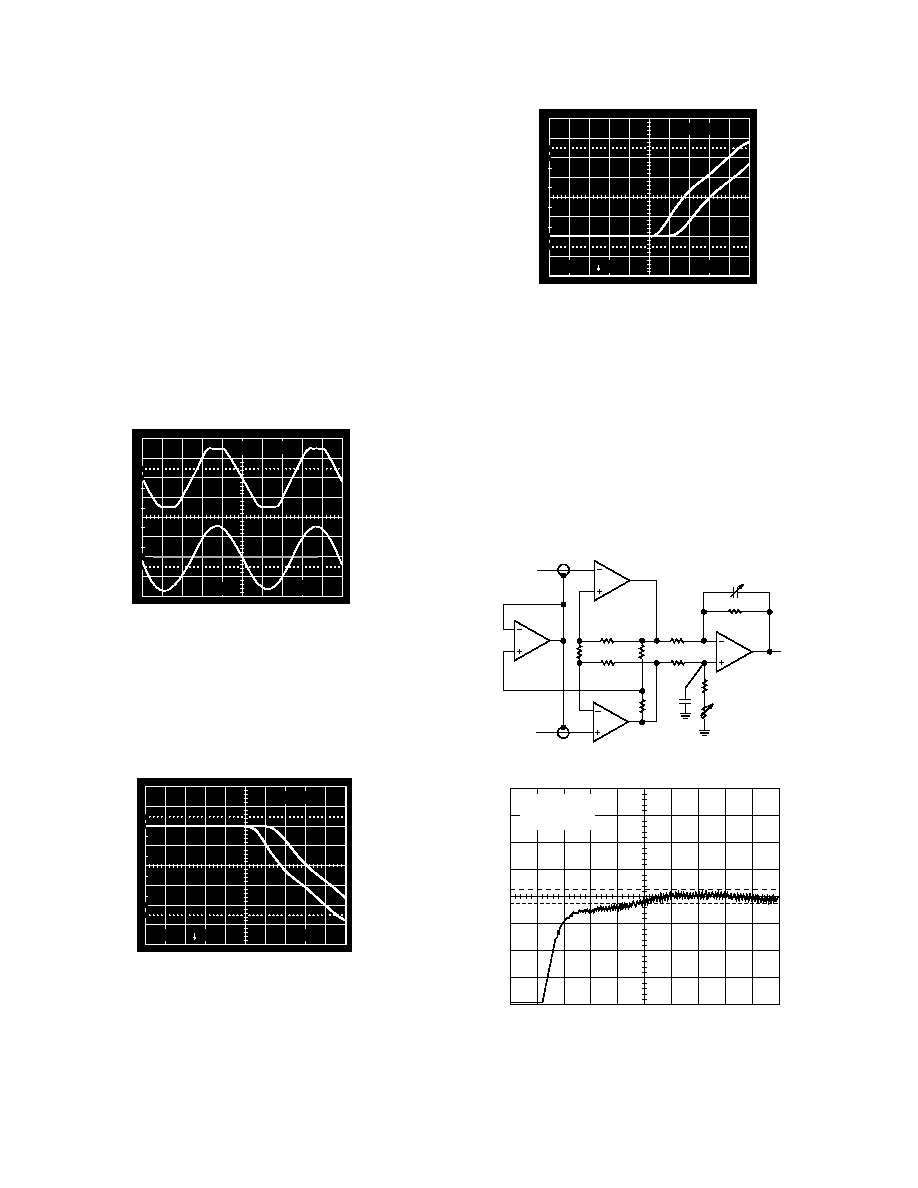

SATURATION RECOVERY TIME

The OP467 has a fast and symmetrical recovery time from ei-

ther rail. This feature is very useful in applications such as high

speed instrumentation and measurement circuits, where the

amplifier is frequently exposed to large signals that overload the

amplifier.

10

0%

100

90

5V

DLY 9.842 s

20ns

5V

Figure 38. Saturation Recovery Time, Positive Rail

10

0%

100

90

5V

DLY 4.806 s

20ns

5V

Figure 39. Saturation Recovery Time, Negative Rail

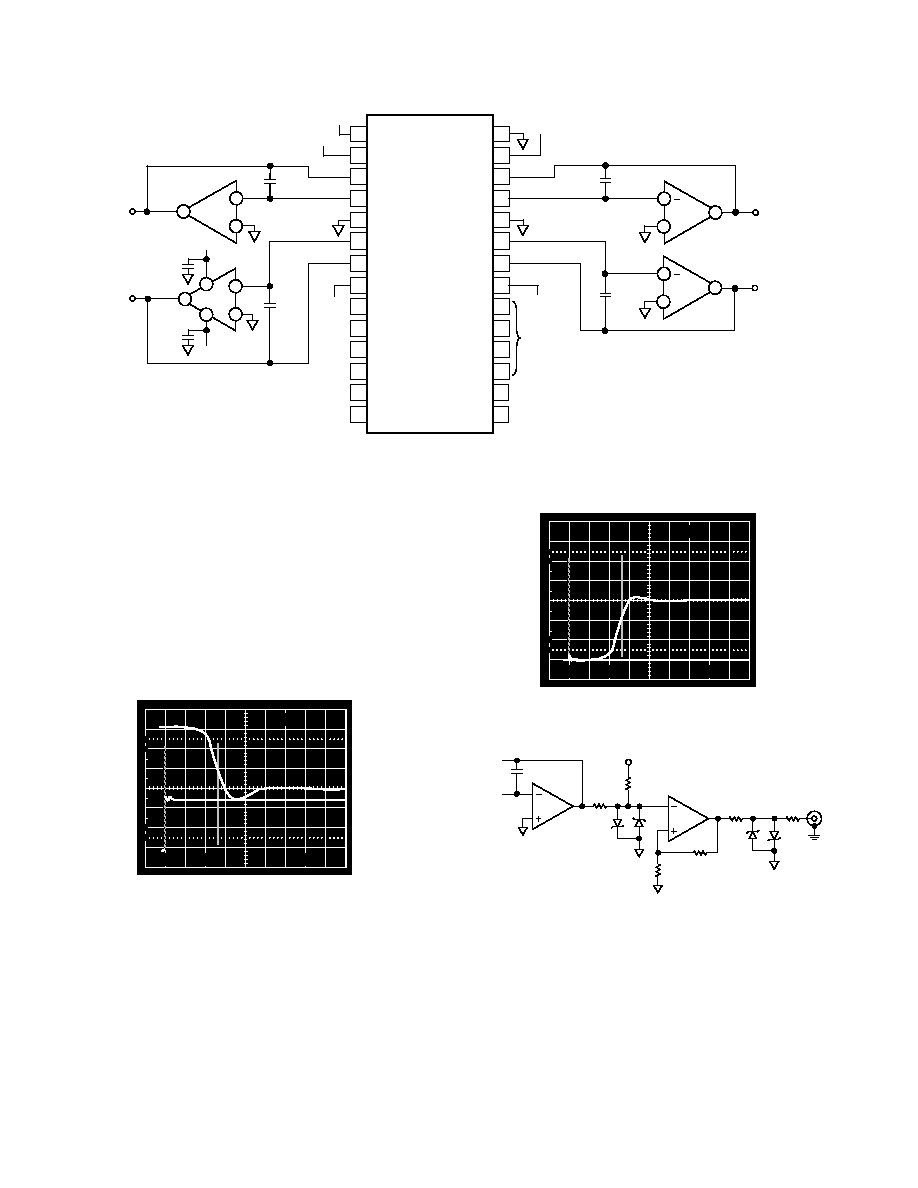

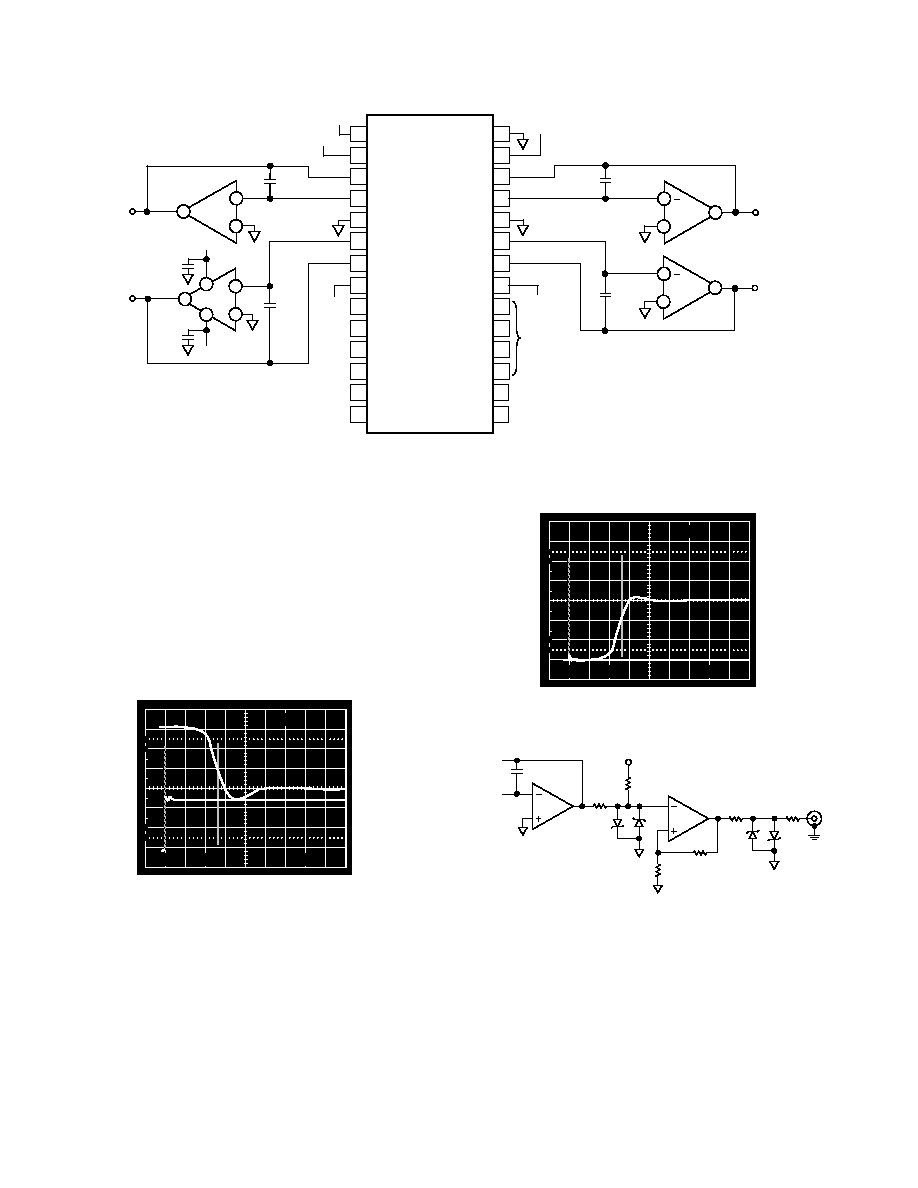

HIGH SPEED INSTRUMENTATION AMPLIFIER

The OP467 performance lends itself to a variety of high speed

applications, including high speed precision instrumentation

amplifiers. Figure 40 represents a circuit commonly used for

data acquisition, CCD imaging and other high speed application.

Circuit gain is set by R

G

. A 2 k

resistor will set the circuit gain

to 2; for unity gain, remove R

G

. For any other gain settings use

the following formula:

G = 2/R

G

Resistor Value is in k

R

C

is used for adjusting the dc common-mode rejection, and C

C

is used for ac common-mode rejection adjustments.

OUTPUT

V

IN

+V

IN

1k

2k

1k

2k

10k

10k

5pF

1.9k

2k

C

C

R

G

R

C

200

10T

Figure 40. A High Speed Instrumentation Amplifier

2.5mV

2.5mV

0.01% 10V STEP

V

S

= 15V

NEG SLOPE

Figure 41. Instrumentation Amplifier Settling Time to

0.01% for a 10 V Step Input (Negative Slope)

OP467

REV. C

13

2.5mV

2.5mV

0.01% 10V STEP

V

S

= 15V

POS SLOPE

Figure 42. Instrumentation Amplifier Settling Time to

0.01% for a 10 V Step Input (Positive Slope)

ERROR

TO

SCOPE

TO

INPUT

TO

IN-AMP

OUTPUT

2k

2k

AD9617

549

1k

61.9

+V

S

V

S

+

+

Figure 43. Settling Time Measurement Circuit

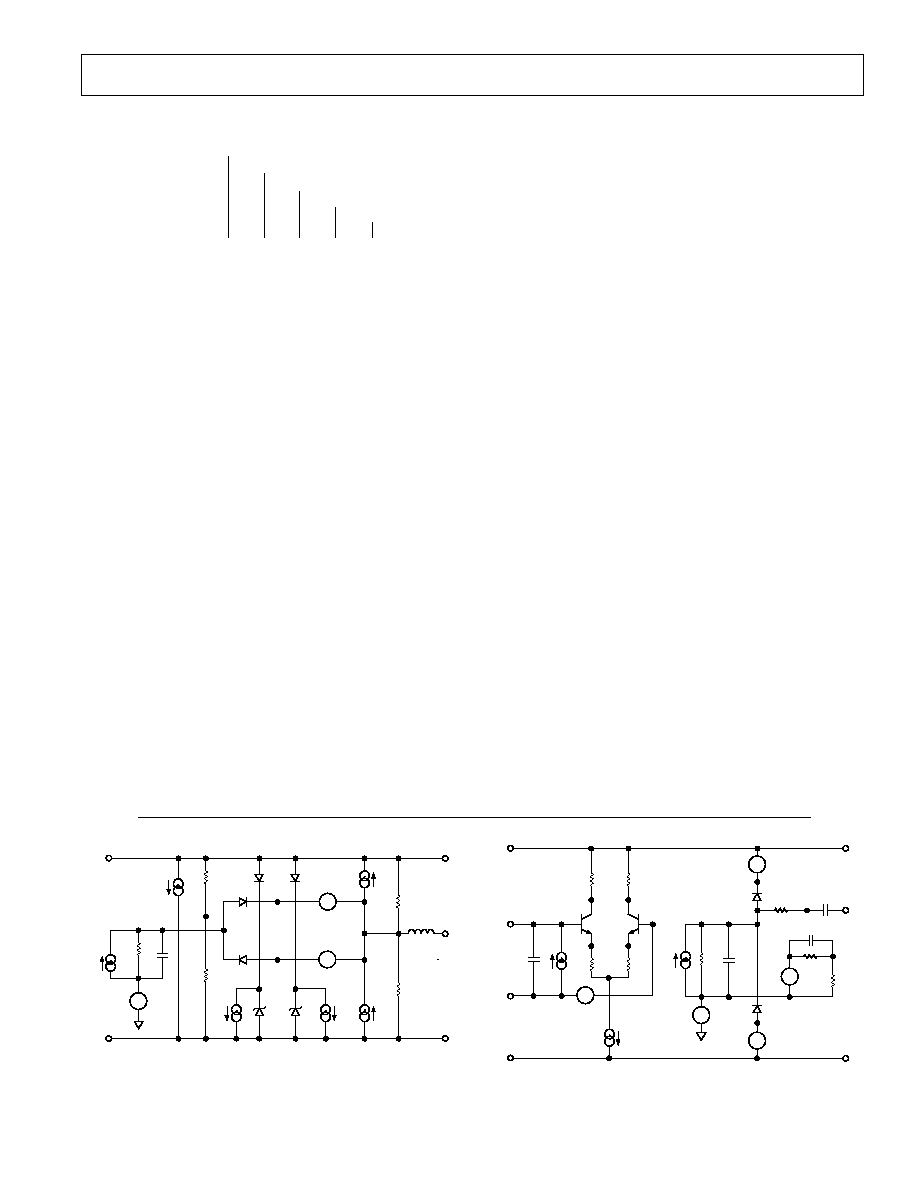

2 MHz BIQUAD BANDPASS FILTER

The circuit in Figure 44 is commonly used in medical imaging

ultrasound receivers. The 30 MHz bandwidth is sufficient to

accurately produce the 2 MHz center frequency, as the mea-

sured response shows in Figure 45. When the op amp's band-

width is too close to the filter's center frequency, the amplifier's

internal phase shift causes excess phase shift at 2 MHz, which

alters the filter's response. In fact, if the chosen op amp has a

bandwidth close to 2 MHz, the combined phase shift of the

three op amps will cause the loop to oscillate.

Careful consideration must be given to the layout of this circuit

as with any other high speed circuit.

If the phase shift introduced by the layout is large enough, it

could alter the circuit performance, or worse, it will oscillate.

2k

R1

3k

V

IN

R3

2k

R2

2k

R4

2k

R5

2k

C2

50pF

C1

50pF

R6

1k

V

OUT

+

+

+

+

1/4

OP467

1/4

OP467

1/4

OP467

1/4

OP467

Figure 44. 2 MHz Biquad Filter

20

100k

100M

10M

1M

10k

10

0

40

30

FREQUENCY Hz

GAIN dB

Figure 45. Biquad Filter Response

OP467

REV. C

14

FAST I-TO-V CONVERTER

The fast slew rate and fast settling time of the OP467 are well

suited to the fast buffers and I-to-V converters used in variety of

applications. The circuit in Figure 46 is a unipolar quad D/A

converter consisting of only two ICs. The current output of the

DAC8408 is converted to a voltage by the OP467 configured as

an I-to-V converter. This circuit is capable of settling to 0.1%

within 200 ns. Figures 47 and 48 show the full-scale settling

time of the outputs. To obtain reliable circuit performance, keep

the traces from the DAC's I

OUT

to the inverting inputs of the

OP467 short to minimize parasitic capacitance.

10

0%

100

90

260.0ns

2V

50mV

100ns

Figure 47. Voltage Output Settling Time

15

V

DD

V

REF

A

R

FB

A

I

OUT

1A

I

OUT

2A/

I

OUT

2B

I

OUT

1B

R

FB

B

V

REF

B

DGND

R

FB

C

I

OUT

1C

I

OUT

2C/

I

OUT

2D

V

REF

C

I

OUT

1D

R

FB

D

V

REF

D

DAC8408

+5V

+10V

+10V

V

OUT

A

V

OUT

B

0.1 F

+15V

15V

C2

10pF

C1

10pF

0.1 F

7

OP467

5

4

11

6

OP467

2

3

1

1

2

3

7

8

9

10

11

12

4

5

6

13

14

+

+10V

+10V

V

OUT

A

V

OUT

B

DIGITAL

CONTROL

SIGNALS

C3

10pF

C4

10pF

14

12

13

OP467

DB0 (LSB)

DB1

DB2

DB3

DB4

DB5

8

10

9

OP467

(MSB) DB7

DB6

28

27

26

22

21

20

19

18

17

25

24

23

16

+

+

+

R/

W

A/

B

DS1

DS2

Figure 46. Quad DAC Unipolar Operation

10

0%

100

90

251.0ns

2V

50mV

100ns

Figure 48. Voltage Output Settling Time

R

FB

I

OUT

3pF

OP467

I-V

DAC-8408

1k

50

604

60.4

2k

DC OFFSET

2k

AD847

Figure 49. DAC V

OUT

Settling Time Circuit

OP467

REV. C

15

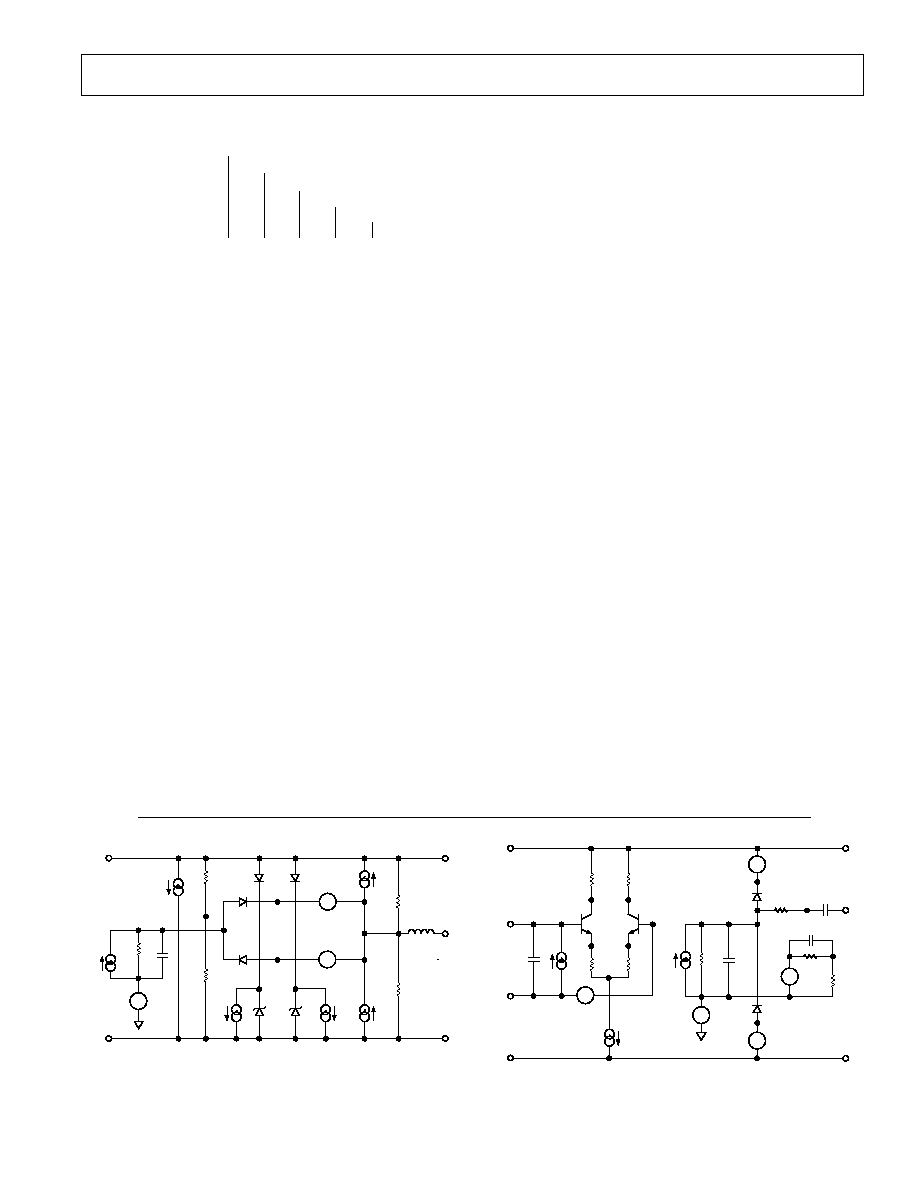

OP467 SPICE MACRO-MODEL

* Node assignments

noninverting input

inverting input

positive supply

negative supply

output

*

. SUBCKT OP467

1

2

99

50

27

*

* INPUT STAGE

*

I1

4

50

10E3

CIN

1

2

1E12

IOS

1

2

5E9

Q1

5

2

8 QN

Q2

6

7

9 QN

R3

99

5

185 . 681

R4

99

6

185 . 681

R5

8

4

180 . 508

R6

9

4

180 . 508

EOS

7

1

POLY (1) (14,20) 50E6

1

EREF

98

0

(20,0) 1

*

* GAIN STAGE AND DOMINANT POLE AT 1.5 kHz

*

R7

10

98

3 . 714E6

C2

10

98

28 . 571E12

G1

98

10

(5,6) 5 . 386E3

V1

99

11

1 . 6

V2

12

50

1 . 6

D1

10

11

DX

D2

12

10

DX

RC

10

28

1 . 4E3

CC

28

27

12E12

*

* COMMON-MODE STAGE WITH ZERO AT 1.26 kHz

*

ECM

13

98

POLY (2) (1,20)

(2,20) 0 0 . 5 0 . 5

R8

13

14

1E6

R9

14

98

25 . 119

C3

13

14

126 . 721E12

*

* POLE AT 400E6

*

R10

15

98

1E6

C4

15

98

0 . 398E15

G2

98

15

(10,20) 1E6

*

* OUTPUT STAGE

*

ISY

99

50

8 . 183E3

RMP1

99

20

96 . 429E3

RMP2

20

50

96 . 429E3

RO1

99

26

200

RO2

26

50

200

L1

26

27

1E7

GO1

26

99

(99,15) 5E3

GO2

50

26

(15,50) 5E3

G4

23

50

(15,26) 5E3

G5

24

50

(26,15) 5E3

V3

21

26

50

V4

26

22

50

D3

15

21

DX

D4

22

15

DX

D5

99

23

DX

D6

99

24

DX

D7

50

23

DY

D8

50

24

DY

*

* MODELS USED

*

. MODEL QN NPN (BF=33.333E3)

. MODEL DX D

. MODEL DY D (BV=50)

. ENDS OP467

G2

R10

C4

98

E

REF

I

SY

RMP2

RMP1

20

15

G4

D7

D5

D3

D4

G5

D8

D6

23

24

22

21

V3

V4

G01

R02

R01

G02

L1

99

50

26

15

99

50

27

+

+

+

Figure 50. SPICE Macro-Model Output Stage

I

OS

C

IN

I1

E

OS

R3

5

G1

99

50

99

50

N

N+

2

1

R4

6

R5

R6

4

7

C2

R7

10

98

12

V2

E

REF

R

C

28

C3

R8

E

CM

14

C

C

27

V1

11

13

D2

D1

R9

+

+

+

+

+

Q1

Q2

8

9

Figure 51. SPICE Macro-Model Input and Gain Stage

OP467

REV. C

16

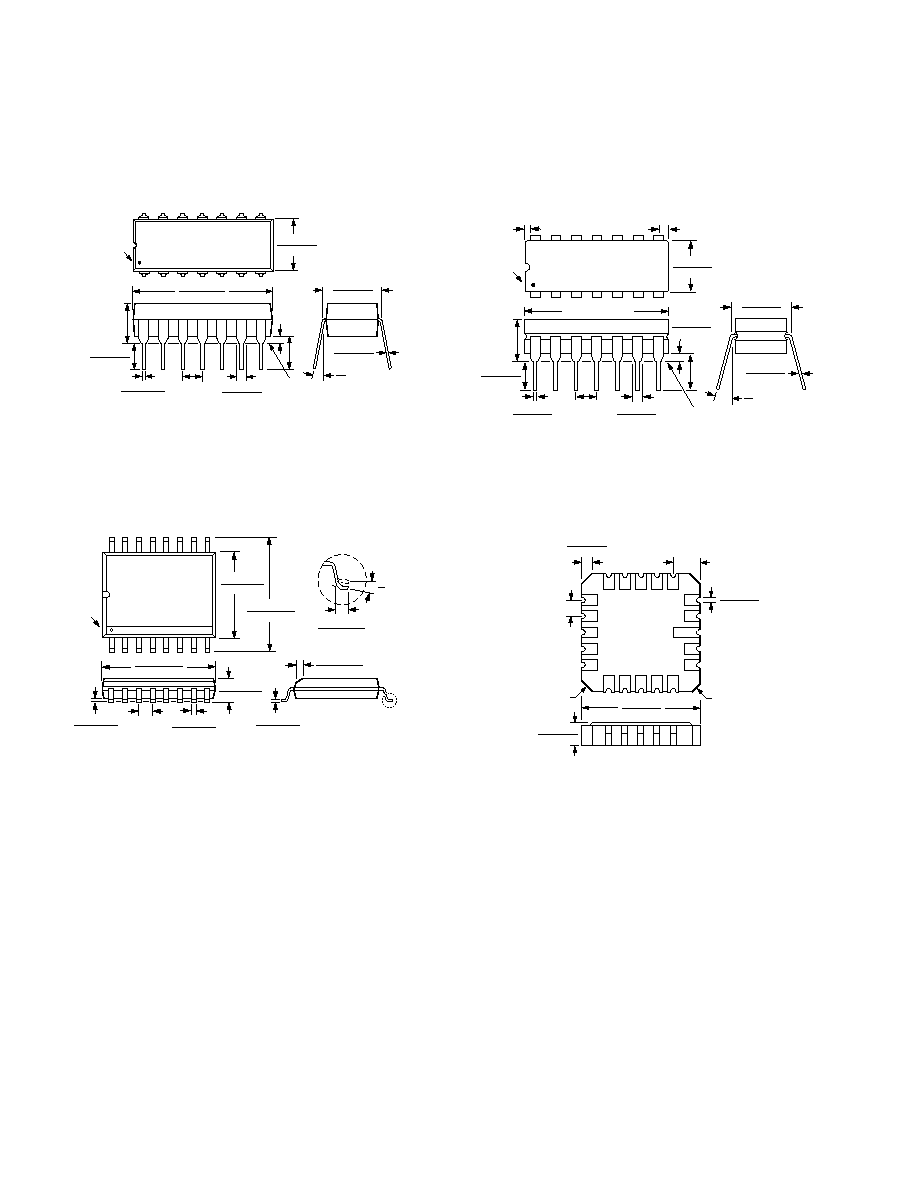

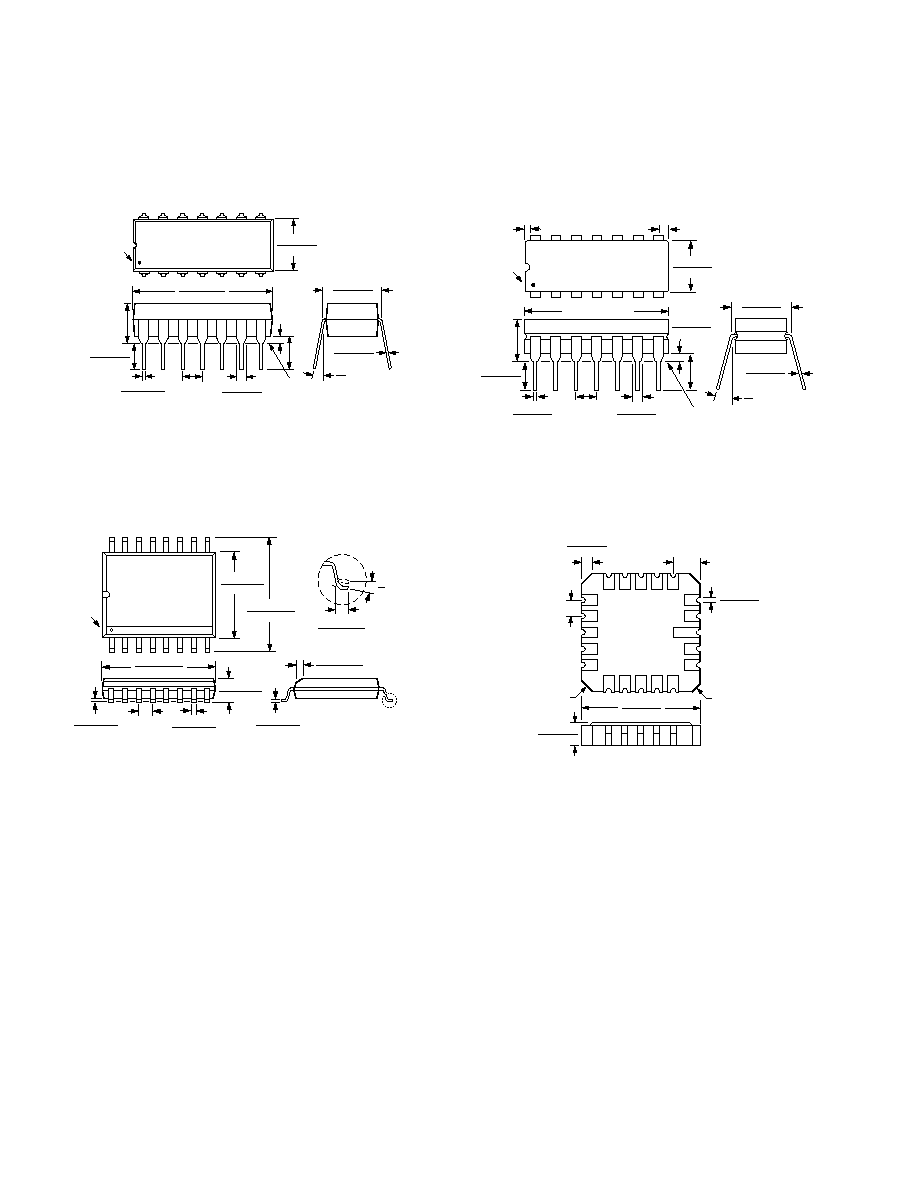

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

C1759c010/98

PRINTED IN U.S.A.

14-Lead Plastic DIP (P Suffix)

(N-14)

PIN 1

0.280 (7.11)

0.240 (6.10)

7

8

14

1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.92)

0.795 (20.19)

0.725 (18.42)

0.022 (0.558)

0.014 (0.36)

0.100

(2.54)

BSC

0.070 (1.77)

0.045 (1.15)

SEATING

PLANE

0.130

(3.30)

MIN

0.015

(0.381)

MIN

0.325 (8.25)

0.300 (7.62)

0.015 (0.38)

0.008 (0.20)

15

0

16-Lead Wide-Body SOL (S Suffix)

(R-16)

0.0500 (1.27 )

0.0157 (0.40 )

8

0

0.0192 (0.49)

0.0138 (0.35)

0.0500

(1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.4133 (10.50)

0.3977 (10.10)

0.0118 (0.30)

0.0040 (0.10)

PIN 1

0.4193 (10.65)

0.3937 (10.00)

0.2992 (7.60)

0.2914 (7.40)

1

20

9

8

0.0291 (0.74 )

0.0098 (0.25 )

45

0.0125 (0.32)

0.0091 (0.23)

SEE

DETAIL

ABOVE

14-Lead Cerdip (Y Suffix)

(Q-14)

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

15

0

0.785 (19.94) MAX

0.200

(5.08)

MAX

0.023 (0.58)

0.014 (0.36)

0.070 (1.78)

0.030 (0.76)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

0.200 (5.08)

0.125 (3.18)

0.100

(2.54)

BSC

SEATING

PLANE

0.005 (0.13) MIN

0.098 (2.49) MAX

PIN 1

0.310 (7.87)

0.220 (5.59)

7

8

1

14

20-Terminal Leadless Ceramic Chip Carrier (RC Suffix)

(E-20A)

NO. 1 PIN INDEX

0.040 x 45

(1.02 x 45 )

REF 3 PLCS

0.020 x 45

(0.51 x 45 )

REF

0.050

(1.27)

BSC

0.358 (9.09)

0.32 (8.69)

0.055 (1.40)

0.045 (1.14)

0.100 (2.54)

0.064 (1.63)

0.028 (0.71)

0.022 (0.56)

BOTTOM

VIEW

0.075 (1.91) REF