Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

a

S

DSP Microcomputer

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

REV. A

SHARC and the SHARC logo are registered trademarks of Analog Devices, Inc.

ADSP-21161N

SUMMARY

High Performance 32-Bit DSP--Applications in Audio,

Medical, Military, Wireless Communications,

Graphics, Imaging, Motor-Control, and Telephony

Super Harvard Architecture--Four Independent Buses

for Dual Data Fetch, Instruction Fetch, and

Nonintrusive, Zero-Overhead I/O

Code Compatible with All Other SHARC Family DSPs

Single-Instruction-Multiple-Data (SIMD) Computational

Architecture--Two 32-Bit IEEE Floating-Point

Computation Units, Each with a Multiplier, ALU,

Shifter, and Register File

Serial Ports Offer I

2

S Support Via 8 Programmable and

Simultaneous Receive or Transmit Pins, which

Support up to 16 Transmit or 16 Receive Channels of

Audio

Integrated Peripherals--Integrated I/O Processor,

1M Bit On-Chip Dual-Ported SRAM, SDRAM

Controller, Glueless Multiprocessing Features, and

I/O Ports (Serial, Link, External Bus, SPI, and JTAG)

ADSP-21161N Supports 32-Bit Fixed, 32-Bit Float, and

40-Bit Floating-Point Formats

KEY FEATURES

100 MHz (10 ns) Core Instruction Rate

Single-Cycle Instruction Execution, Including SIMD

Operations in Both Computational Units

600 MFLOPs Peak and 400 MFLOPs Sustained

Performance

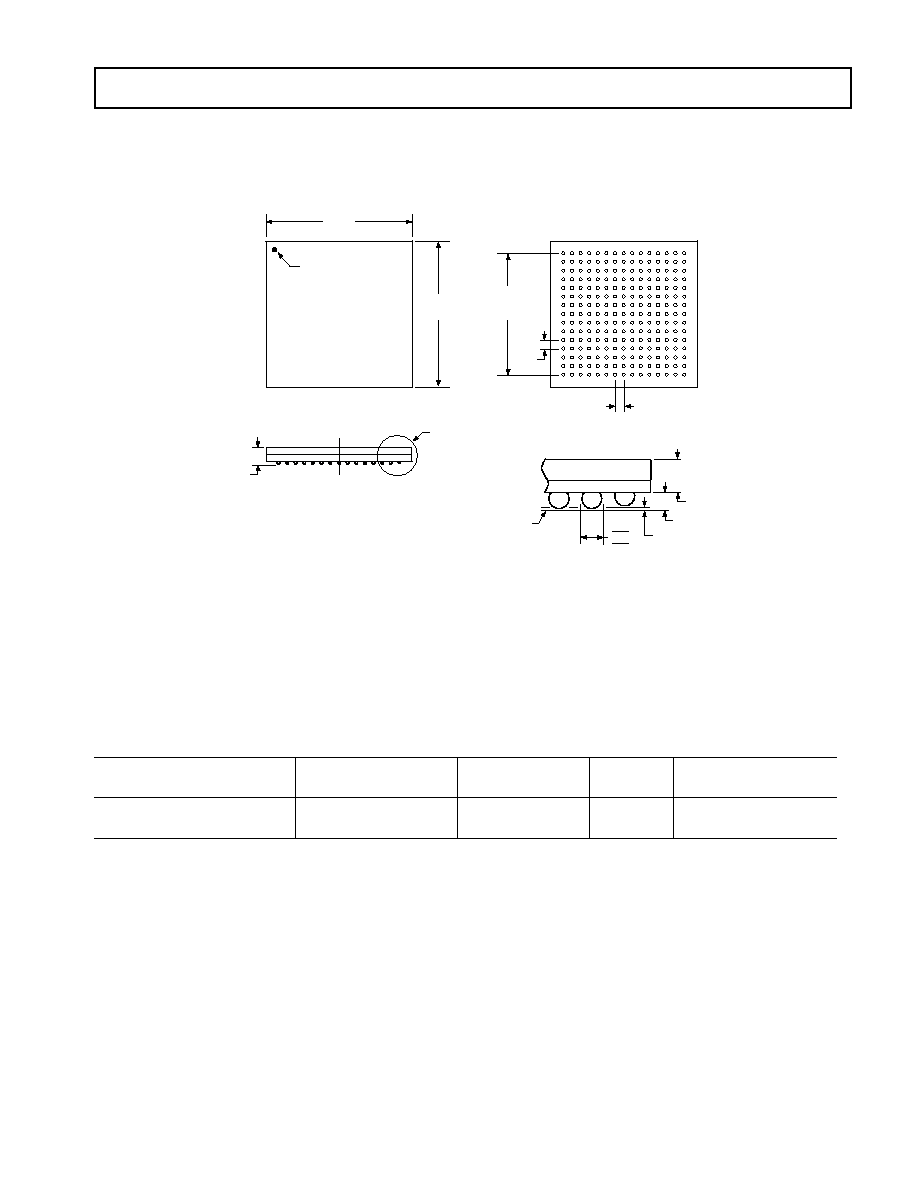

225-Ball 17 mm

×

17 mm MBGA Package

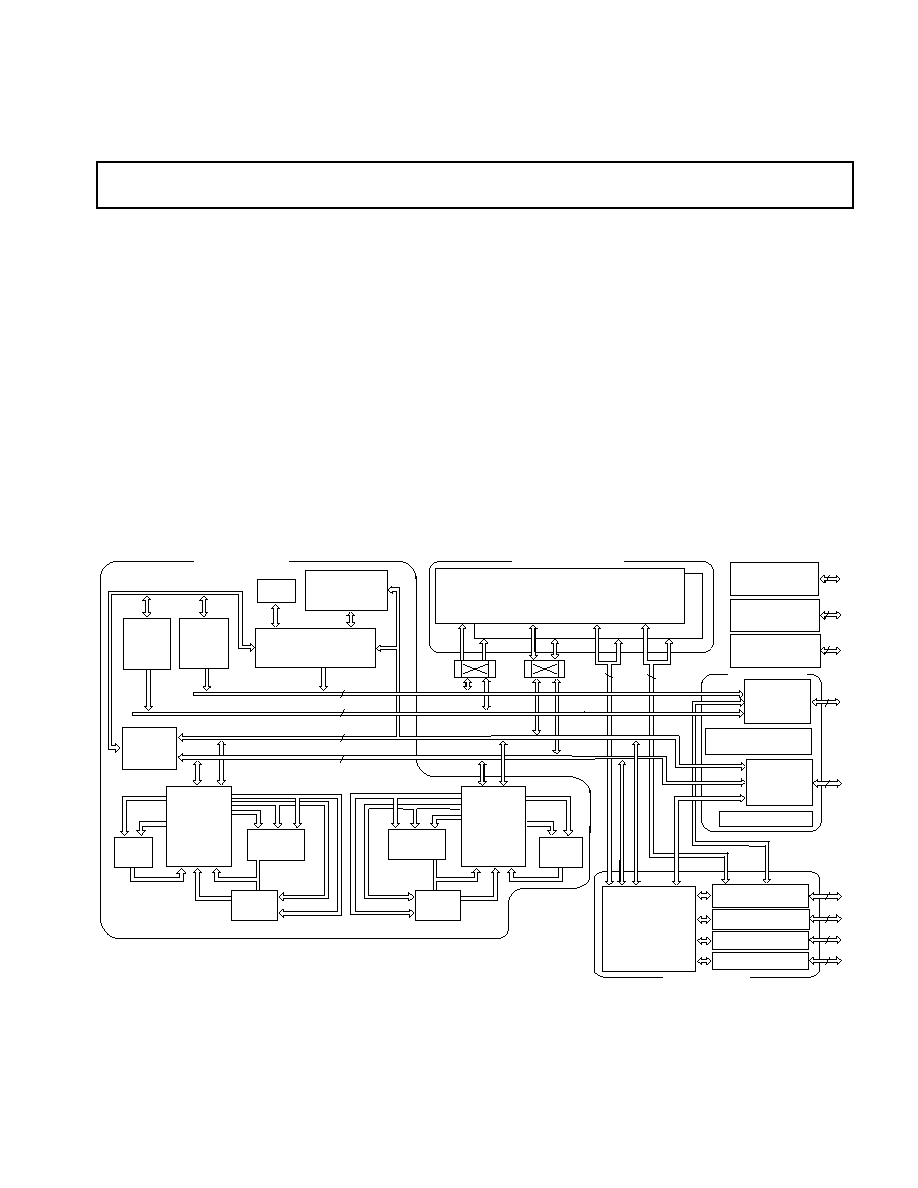

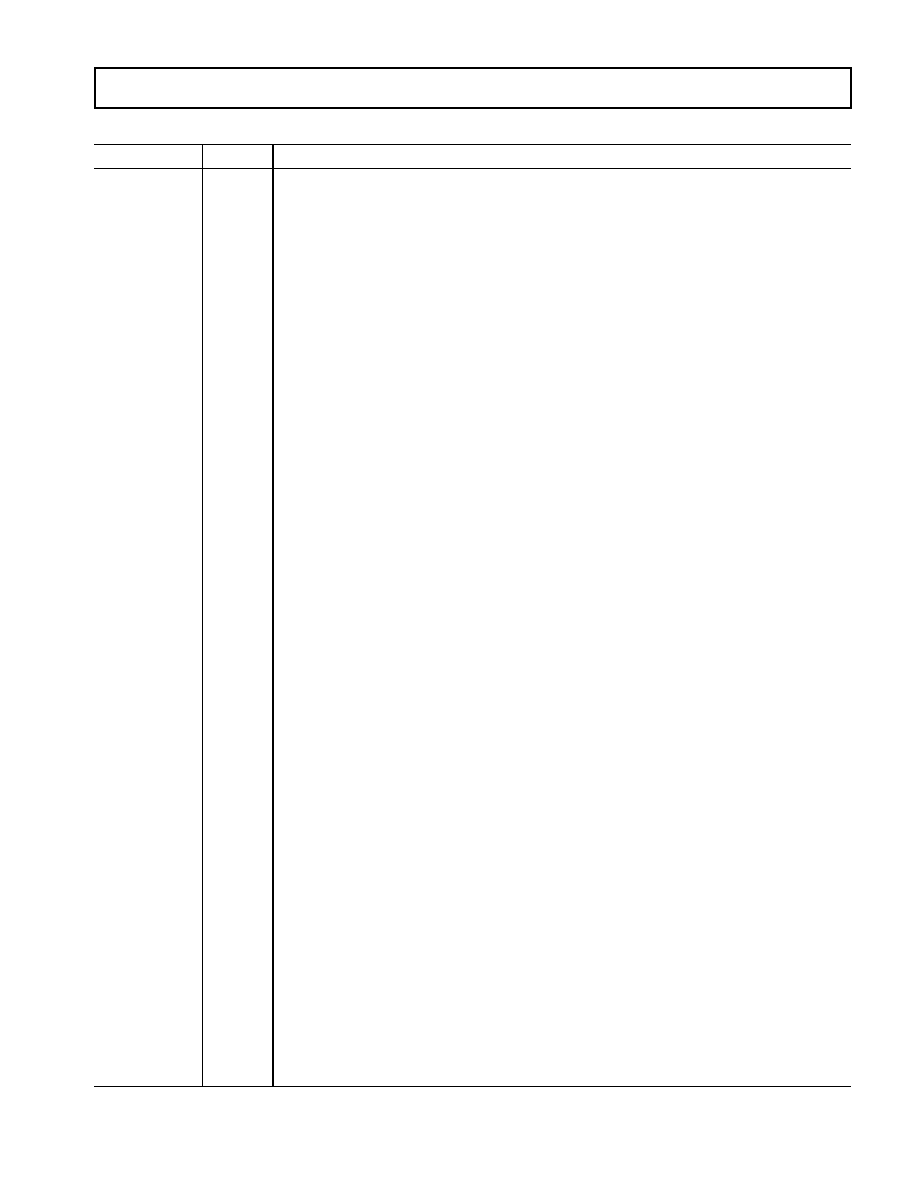

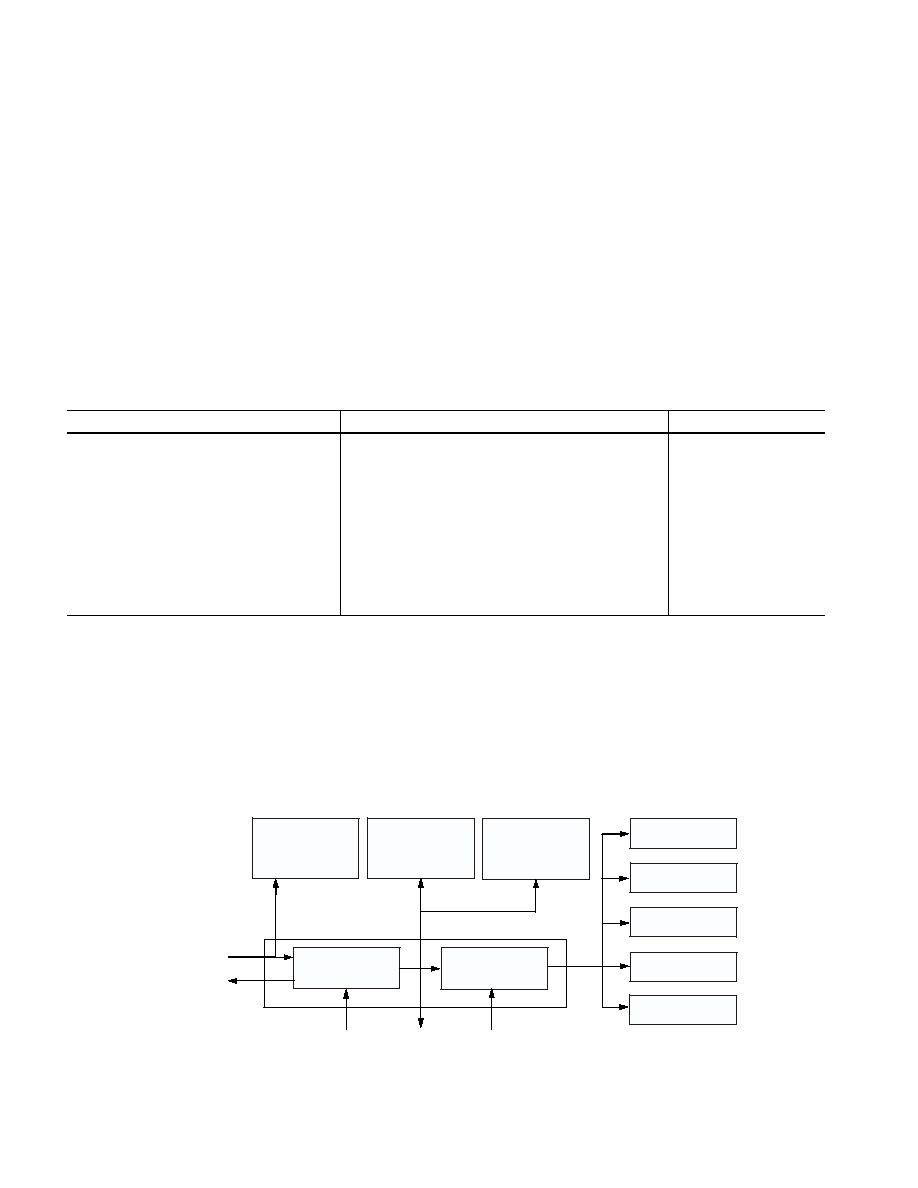

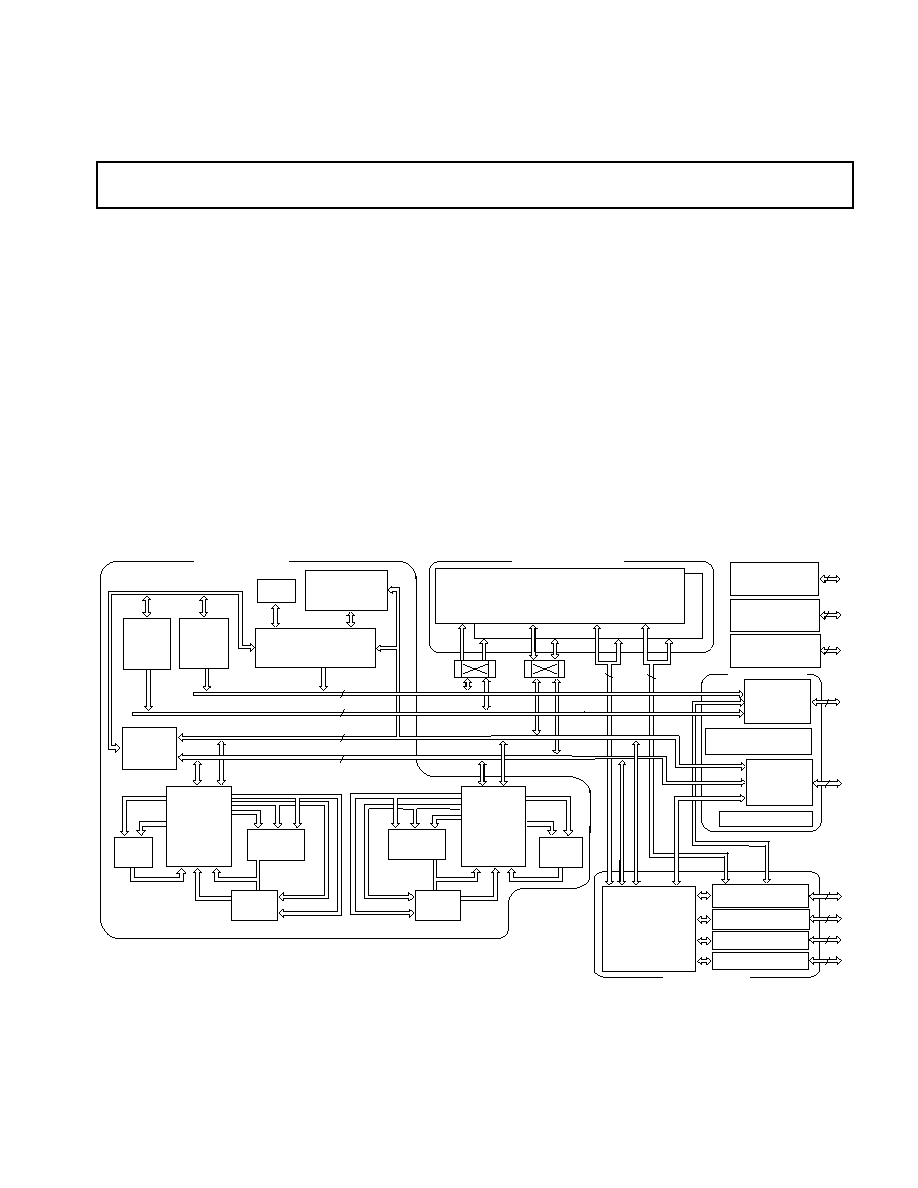

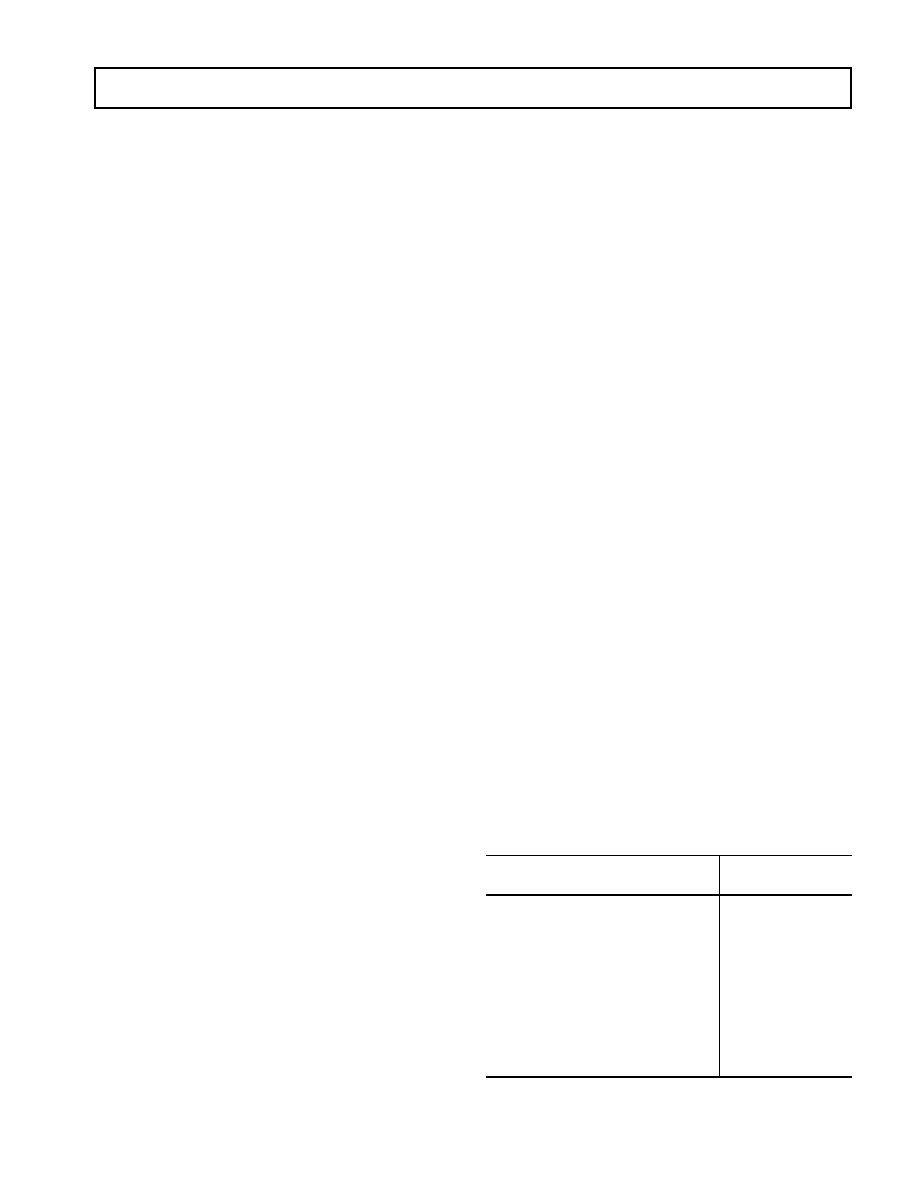

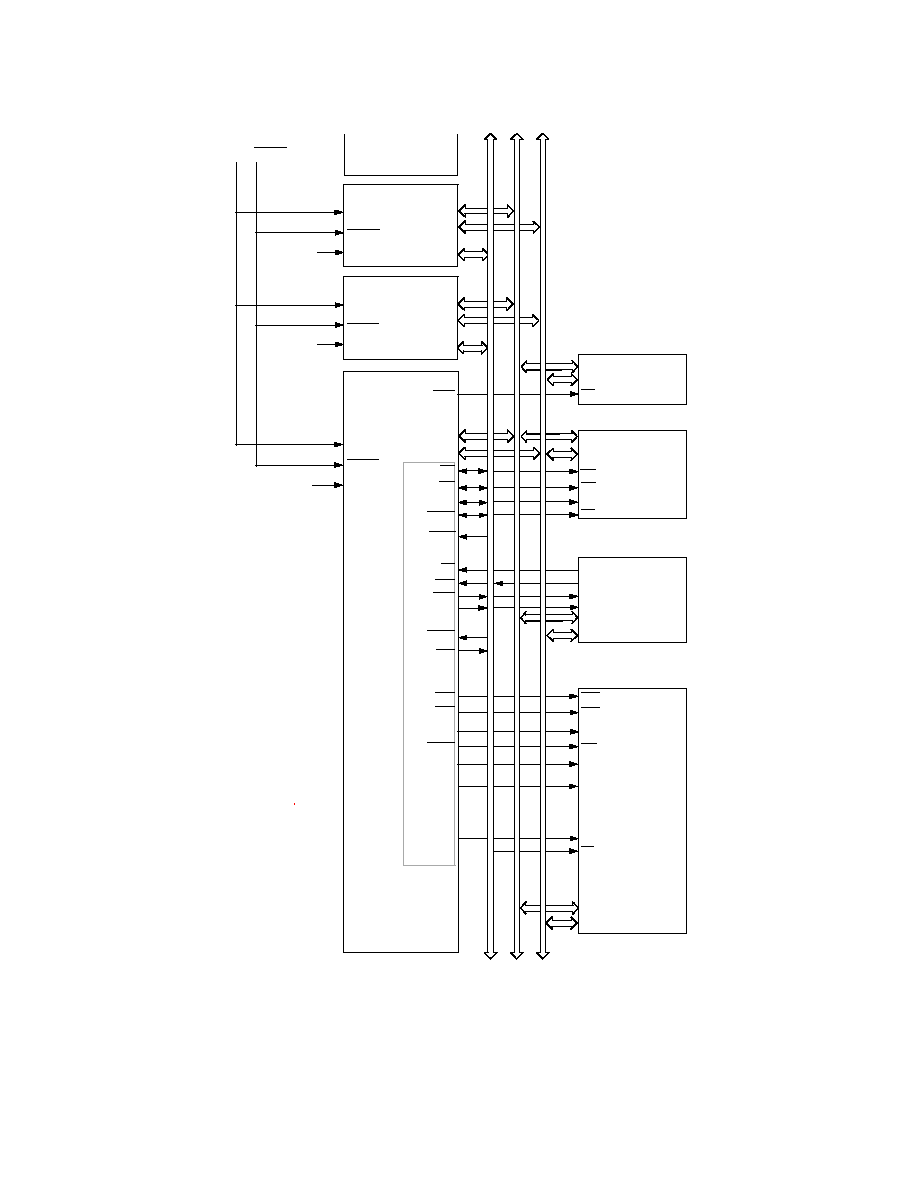

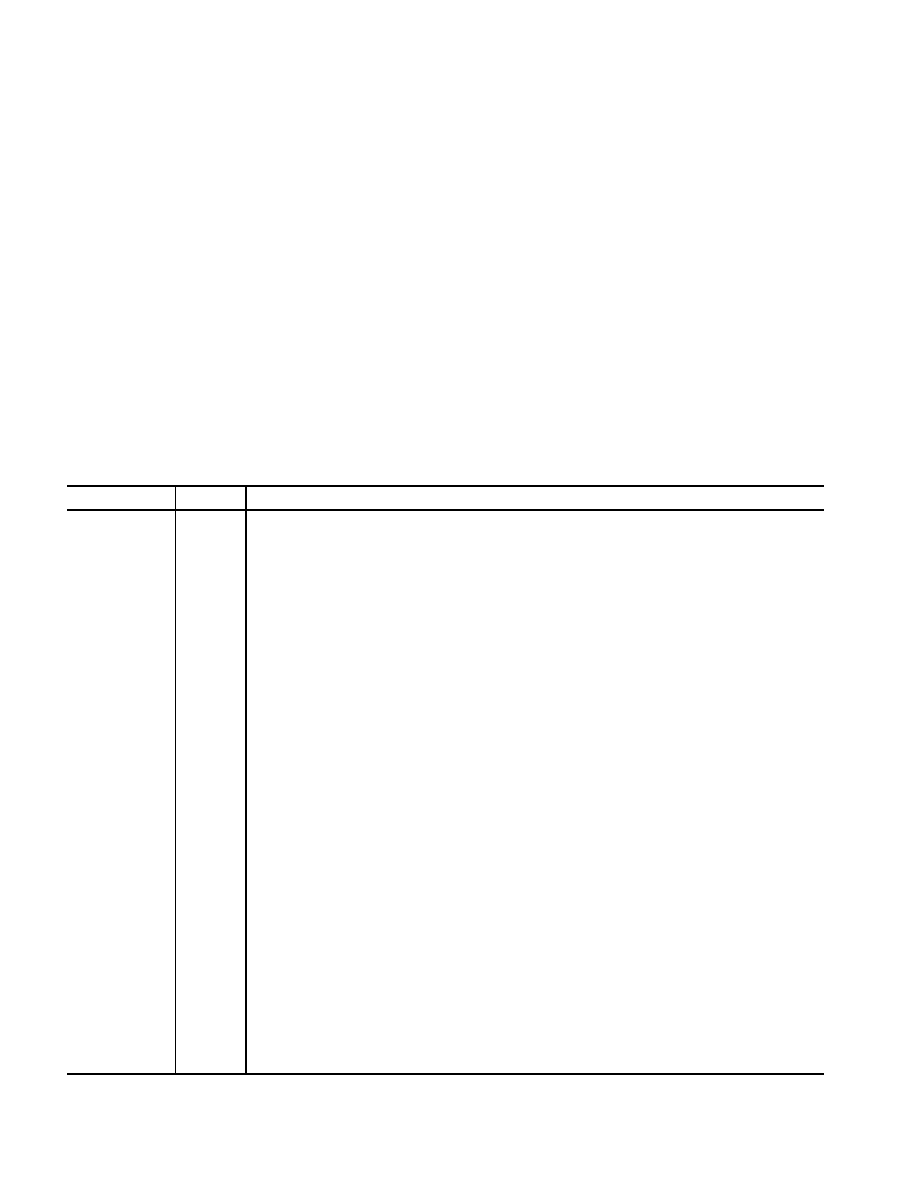

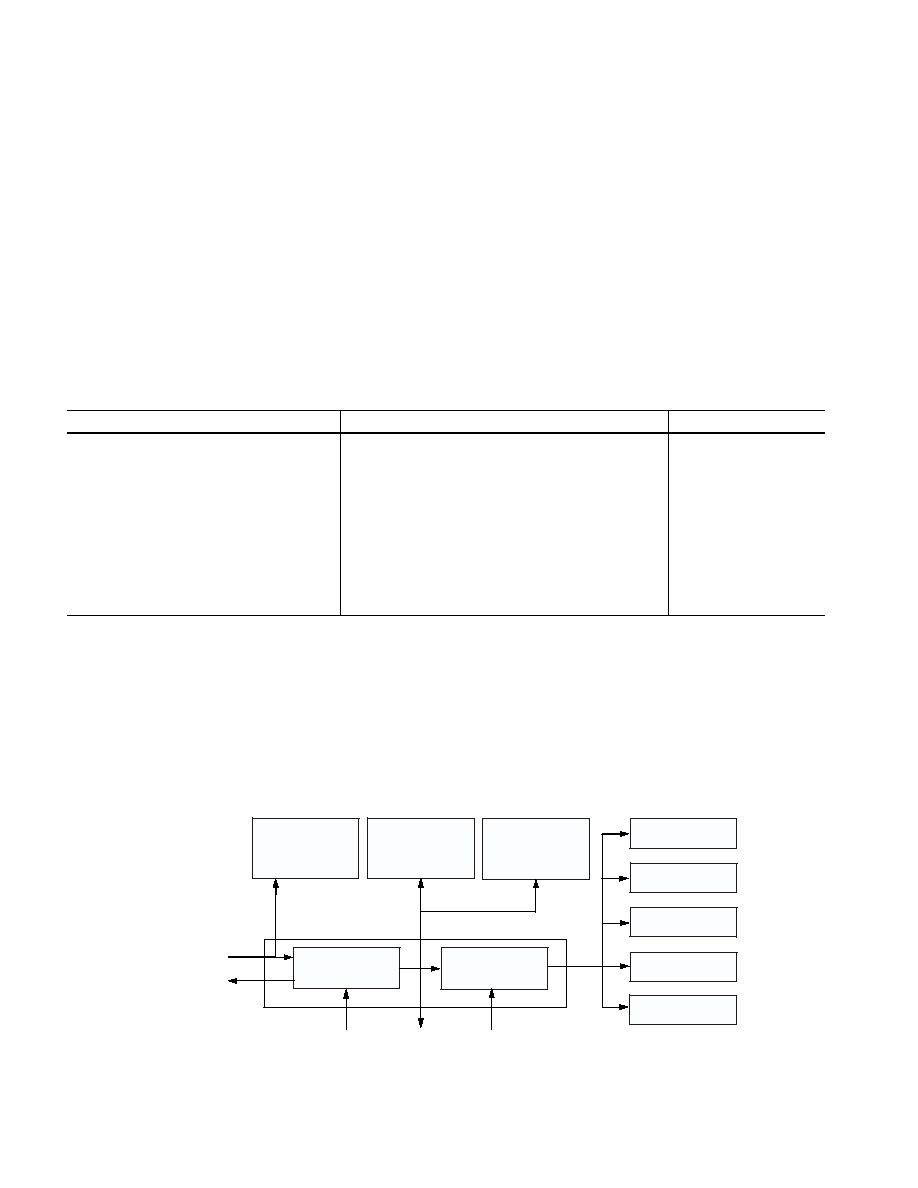

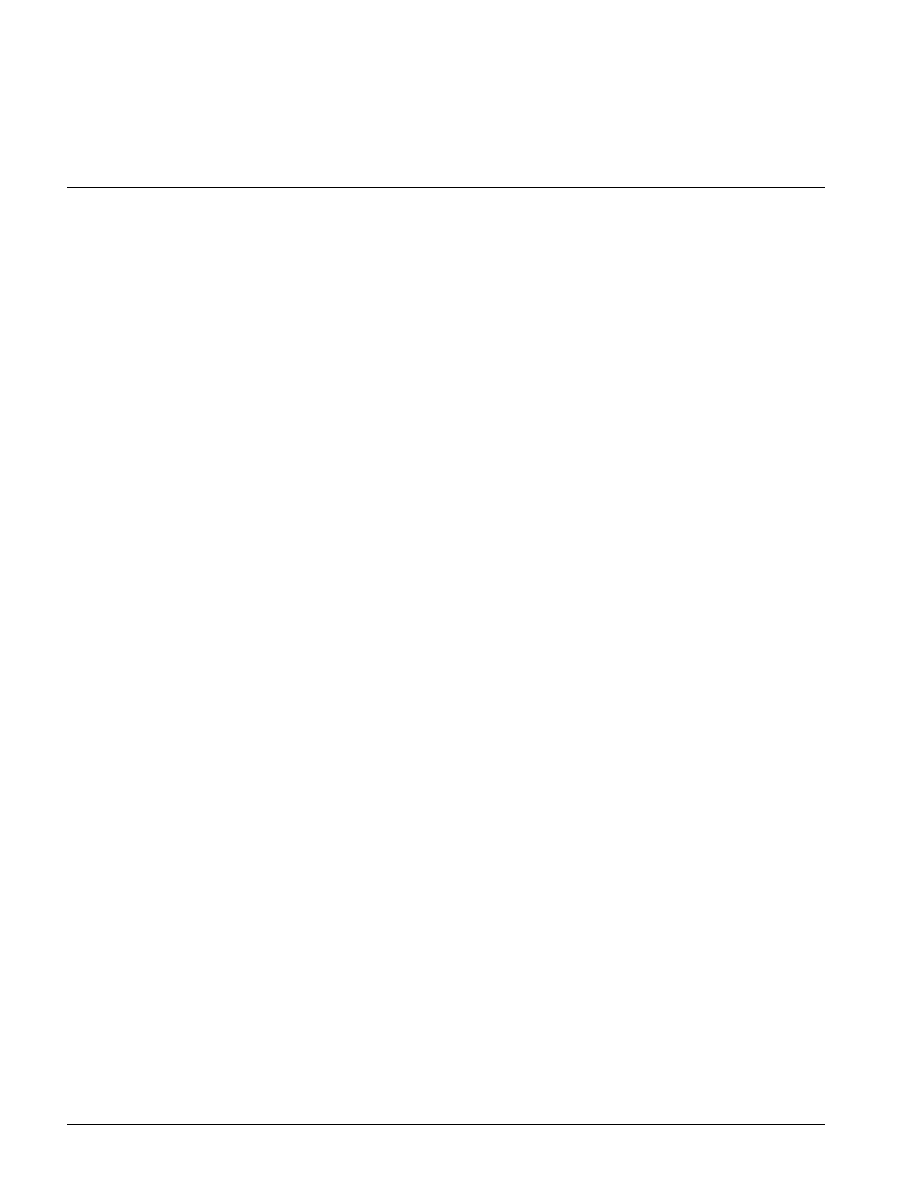

FUNCTIONAL BLOCK DIAGRAM

ALU

MULT

DATA

REGISTER

FILE

(PEY)

16

40-BIT

BARREL

SHIFTER

BARREL

SHIFTER

ALU

DATA

REGISTER

FILE

(PEX)

16

40-BIT

TIMER

INSTRUCTION

CACHE

32

48-BIT

DAG1

8

4

32

PROGRAM

SEQUENCER

32

PM ADDRESS BUS

DM ADDRESS BUS

32

BUS

CONNECT

(PX)

PM DATA BUS

DM DATA BUS

64

64

CORE PROCESSOR

SPI PORTS (1)

SERIAL PORTS (4)

LINK PORTS (2)

DMA

CONTROLLER

5

16

20

4

IOP

REGISTERS

(MEMORY MAPPED)

CONTROL,

STATUS, &

DATA BUFFERS

I/O PROCESSOR

TWO INDEPENDENT

DUAL-PORTED BLOCKS

ADDR

DATA

DATA

DATA

ADDR

ADDR

DATA

ADDR

PROCESSOR PORT

I/O PORT

B

L

O

C

K

0

B

L

O

C

K

1

DUAL-PORTED SRAM

HOST PORT

ADDR BUS

MUX

MULTIPROCESSOR

INTERFACE

DATA BUS

MUX

32

24

EXTERNAL PORT

6

12

8

JTAG TEST

AND EMULATION

GPIO

FLAGS

SDRAM

CONTROLLER

IOA

18

IOD

64

DAG2

8

4

32

MULT

One Technology Way, P.O.Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel:781/329-4700

www.analog.com

Fax:781/326-8703

©

2003 Analog Devices, Inc. All rights reserved.

ADSP-21161N

2

REV. A

KEY FEATURES (continued)

1 M Bit On-Chip Dual-Ported SRAM (0.5 M Bit Block 0,

0.5 M Bit Block 1) for Independent Access by Core

Processor and DMA

200 Million Fixed-Point MACs Sustained Performance

Dual Data Address Generators (DAGs) with Modulo and

Bit-Reverse Addressing

Zero-Overhead Looping with Single-Cycle Loop Setup,

Providing Efficient Program Sequencing

IEEE 1149.1 JTAG Standard Test Access Port and On-Chip

Emulation

Single Instruction Multiple Data (SIMD) Architecture

Provides:

Two Computational Processing Elements

Concurrent Execution--Each Processing Element

Executes the Same Instruction, but Operates on

Different Data

Code Compatibility--At Assembly Level, Uses the

Same Instruction Set as Other SHARC DSPs

Parallelism in Buses and Computational Units Enables:

Single-Cycle Execution (with or without SIMD) of: a

Multiply Operation, an ALU Operation, a Dual

Memory Read or Write, and an Instruction Fetch

Transfers Between Memory and Core at Up to Four

32-Bit Floating- or Fixed-Point Words Per Cycle,

Sustained 1.6 Gbytes/s Bandwidth

Accelerated FFT Butterfly Computation through a

Multiply with Add and Subtract

DMA Controller Supports:

14 Zero-Overhead DMA Channels for Transfers between

ADSP-21161N Internal Memory and External Memory,

External Peripherals, Host Processor, Serial Ports,

Link Ports, or Serial Peripheral Interface (SPI-

Compatible)

64-Bit Background DMA Transfers at Core Clock Speed,

in Parallel with Full-Speed Processor Execution

800 M Bytes/s Transfer Rate over IOP Bus

Host Processor Interface to 8-, 16-, and 32-Bit

Microprocessors; the Host Can Directly Read/Write

ADSP-21161N IOP Registers

32-Bit (or up to 48-Bit) Wide Synchronous External Port

Provides:

Glueless Connection to Asynchronous, SBSRAM and

SDRAM External Memories

Memory Interface Supports Programmable Wait State

Generation and Wait Mode for Off-Chip Memory

Up to 50 MHz Operation for Non-SDRAM Accesses

1:2, 1:3, 1:4, 1:6, 1:8 Clock into Core Clock Frequency

Multiply Ratios

24-Bit Address, 32-Bit Data Bus. 16 Additional Data

Lines via Multiplexed Link Port Data Pins Allow

Complete 48-Bit Wide Data Bus for Single-Cycle

External Instruction Execution

Direct Reads and Writes of IOP Registers from Host or

Other 21161N DSPs

62.7 Mega-Word Address Range for Off-Chip SRAM and

SBSRAM Memories

32-48, 16-48, 8-48 Execution Packing for Executing

Instruction Directly from 32-Bit, 16-Bit, or 8-Bit Wide

External Memories

32-48, 16-48, 8-48, 32-32/64, 16-32/64, 8-32/64, Data

Packing for DMA Transfers Directly from 32-Bit,

16-Bit, or 8-Bit Wide External Memories to and from

Internal 32-, 48-, or 64-Bit Internal Memory

Can be Configured to have 48-Bit Wide External Data

Bus, if Link Ports are not Used. The Link Port Data

Lines are Multiplexed with the Data Lines D0 to D15

and are Enabled through Control Bits in SYSCON

SDRAM Controller for Glueless Interface to Low Cost

External Memory

Zero Wait State, 100 MHz Operation for Most Accesses

Extended External Memory Banks (64 M Words) for

SDRAM Accesses

Page Sizes up to 2048 Words

An SDRAM Controller Supports SDRAM in Any and All

Memory Banks

Support for Interface to Run at Core Clock and Half the

Core Clock Frequency

Support for 16 M Bits, 64 M Bits, 128 M Bits, and

256 M Bits with SDRAM Data Bus Configurations of

4, 8, 16, and 32

254 Mega-Word Address Range for Off-Chip SDRAM

Memory

Multiprocessing Support Provides:

Glueless Connection for Scalable DSP Multiprocessing

Architecture

Distributed On-Chip Bus Arbitration for Parallel Bus

Connect of Up to Six ADSP-21161Ns, Global Memory,

and a Host

Two 8-Bit Wide Link Ports for Point-to-Point

Connectivity Between ADSP-21161Ns

400 M Bytes/s Transfer Rate over Parallel Bus

200 M Bytes/s Transfer Rate Over Link Ports

Serial Ports Provide:

Four 50 M Bit/s Synchronous Serial Ports with

Companding Hardware

8 Bidirectional Serial Data Pins, Configurable as Either a

Transmitter or Receiver

I

2

S Support, Programmable Direction for 8

Simultaneous Receive and Transmit Channels, or Up

to Either 16 Transmit Channels or 16 Receive

Channels

128 Channel TDM Support for T1 and E1 Interfaces

Companding Selection on a Per Channel Basis in TDM

Mode

Serial Peripheral Interface (SPI)

Slave Serial Boot through SPI from a Master SPI Device

Full-Duplex Operation

Master-Slave Mode Multimaster Support

Open-Drain Outputs

Programmable Baud Rates, Clock Polarities and Phases

12 Programmable I/O Pins

1 Programmable Timer

3

REV. A

ADSP-21161N

TABLE OF CONTENTS

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . 3

ADSP-21161N Family Core Architecture . . . . . . . . . 5

SIMD Computational Engine . . . . . . . . . . . . . . . . 5

Independent, Parallel Computation Units . . . . . . . 5

Data Register File . . . . . . . . . . . . . . . . . . . . . . . . . 5

Single-Cycle Fetch of Instruction and

Four Operands . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Instruction Cache . . . . . . . . . . . . . . . . . . . . . . . . . 5

Data Address Generators With Hardware Circular

Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Flexible Instruction Set . . . . . . . . . . . . . . . . . . . . . 5

ADSP-21161N Memory and I/O Interface Features . 5

Dual-Ported On-Chip Memory . . . . . . . . . . . . . . . 5

Off-Chip Memory and Peripherals Interface . . . . . 6

SDRAM Interface . . . . . . . . . . . . . . . . . . . . . . . . . 6

Target Board JTAG Emulator Connector . . . . . . . 7

DMA Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Multiprocessing . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Link Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Serial Peripheral (Compatible) Interface . . . . . . . . 9

Host Processor Interface . . . . . . . . . . . . . . . . . . . . 9

General-Purpose I/O Ports . . . . . . . . . . . . . . . . . . . 9

Program Booting . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Phase-Locked Loop and Crystal Double Enable . . 9

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Development Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Designing an Emulator-Compatible

DSP Board (Target) . . . . . . . . . . . . . . . . . . . . . 10

Additional Information . . . . . . . . . . . . . . . . . . . . . . 11

PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . 12

BOOT MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . 19

ESD SENSITIVITY . . . . . . . . . . . . . . . . . . . . . . . . 19

TIMING SPECIFICATIONS . . . . . . . . . . . . . . . . 20

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . 21

Power-up Sequencing Silicon

Revision 0.3, 1.0, 1.1 . . . . . . . . . . . . . . . . . . . . 22

Clock Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clock Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

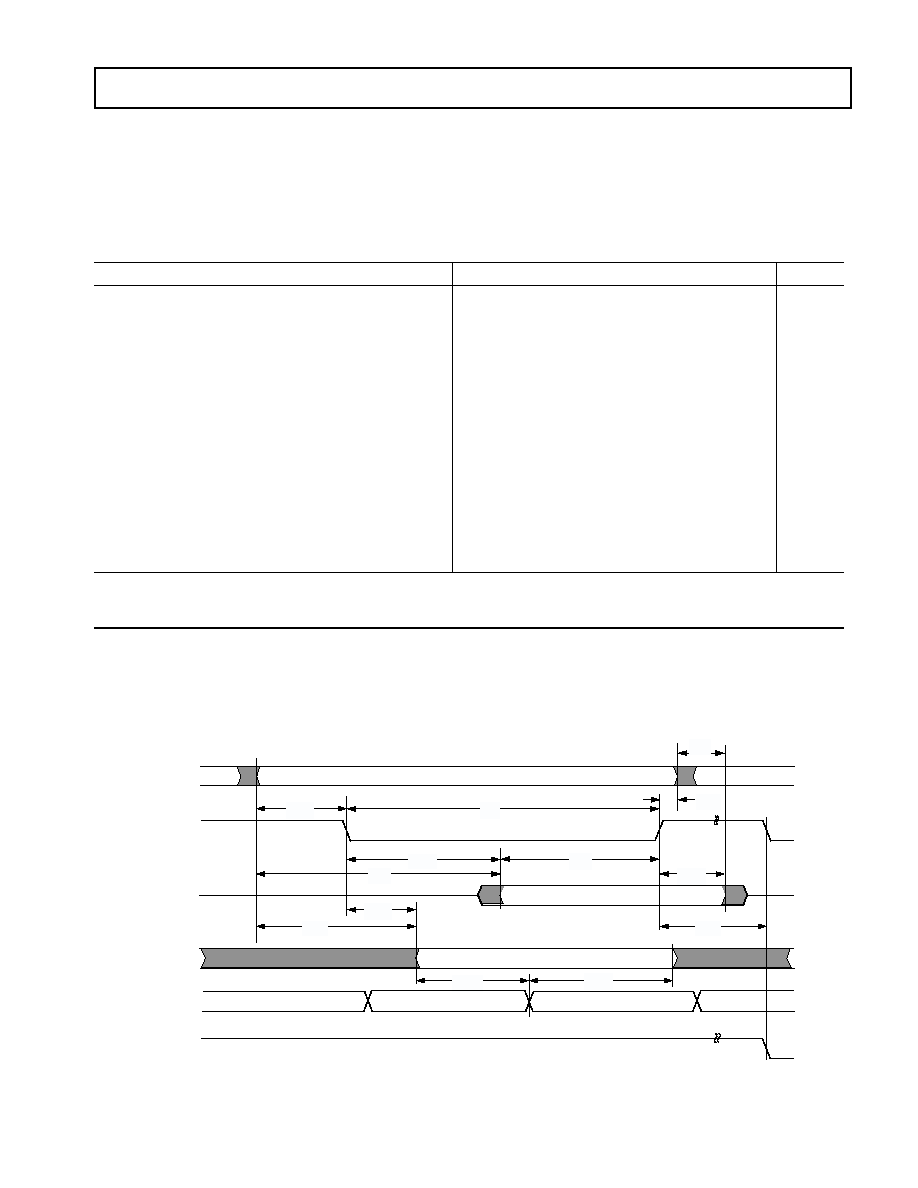

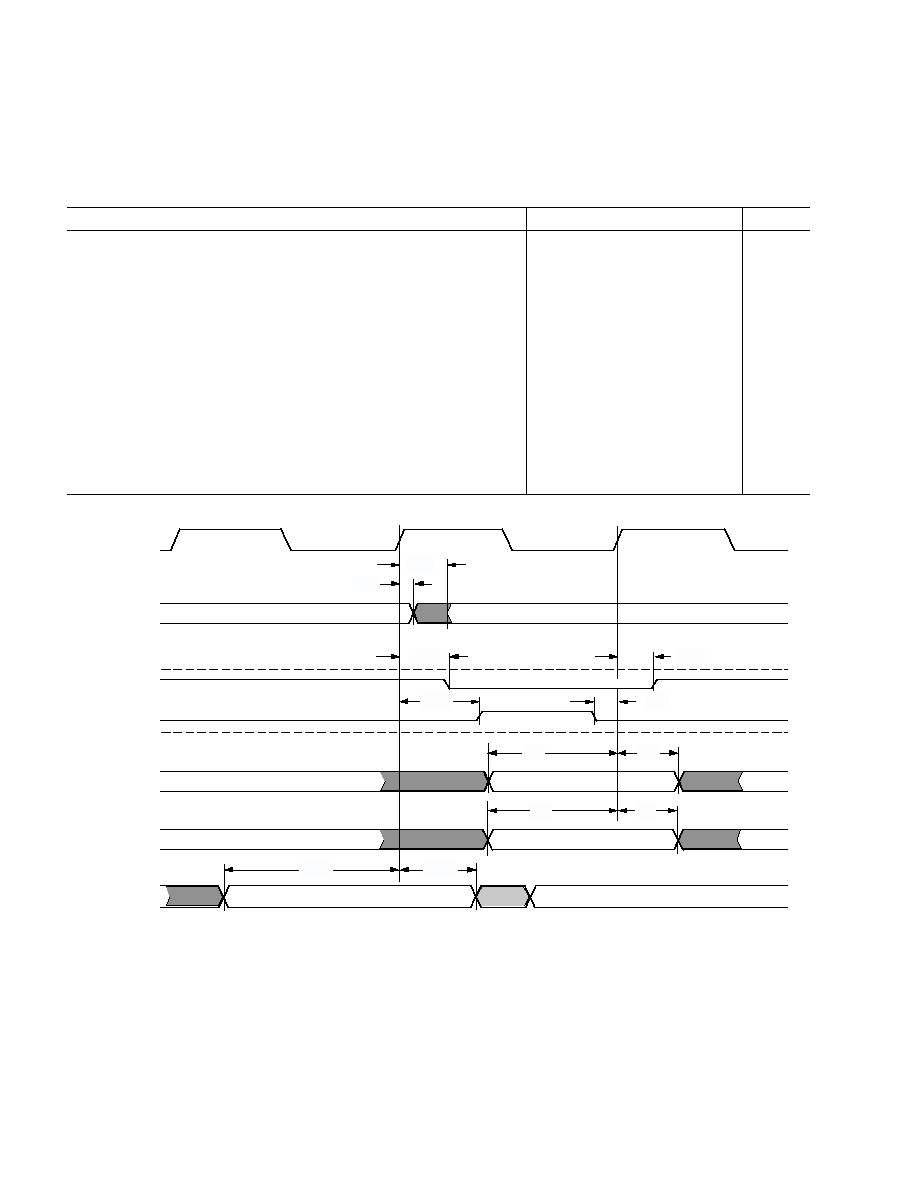

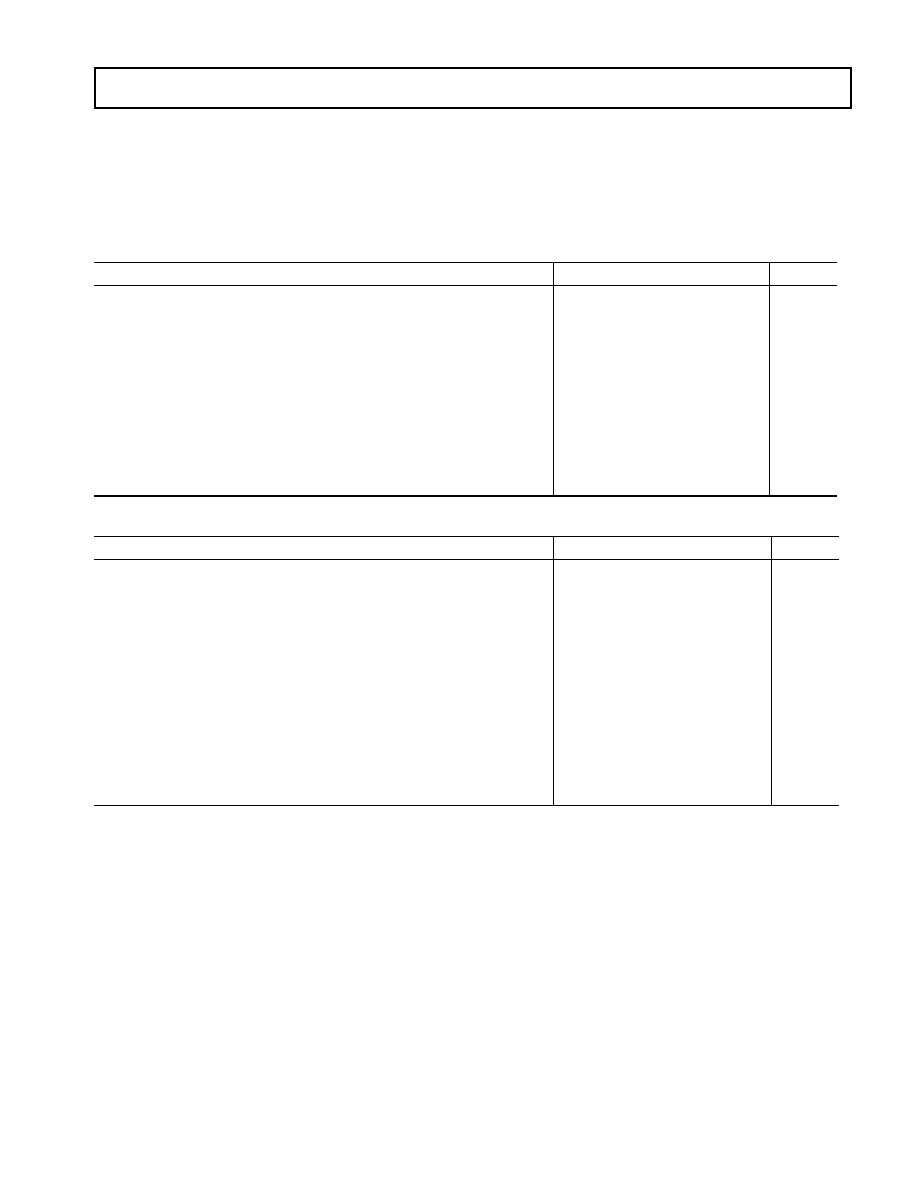

Memory Read Bus Master . . . . . . . . . . . . . . . . 27

Memory Write Bus Master . . . . . . . . . . . . . . . . 28

Synchronous Read/Write Bus Master . . . . . . . . 29

Synchronous Read/Write Bus Slave . . . . . . . . . . 30

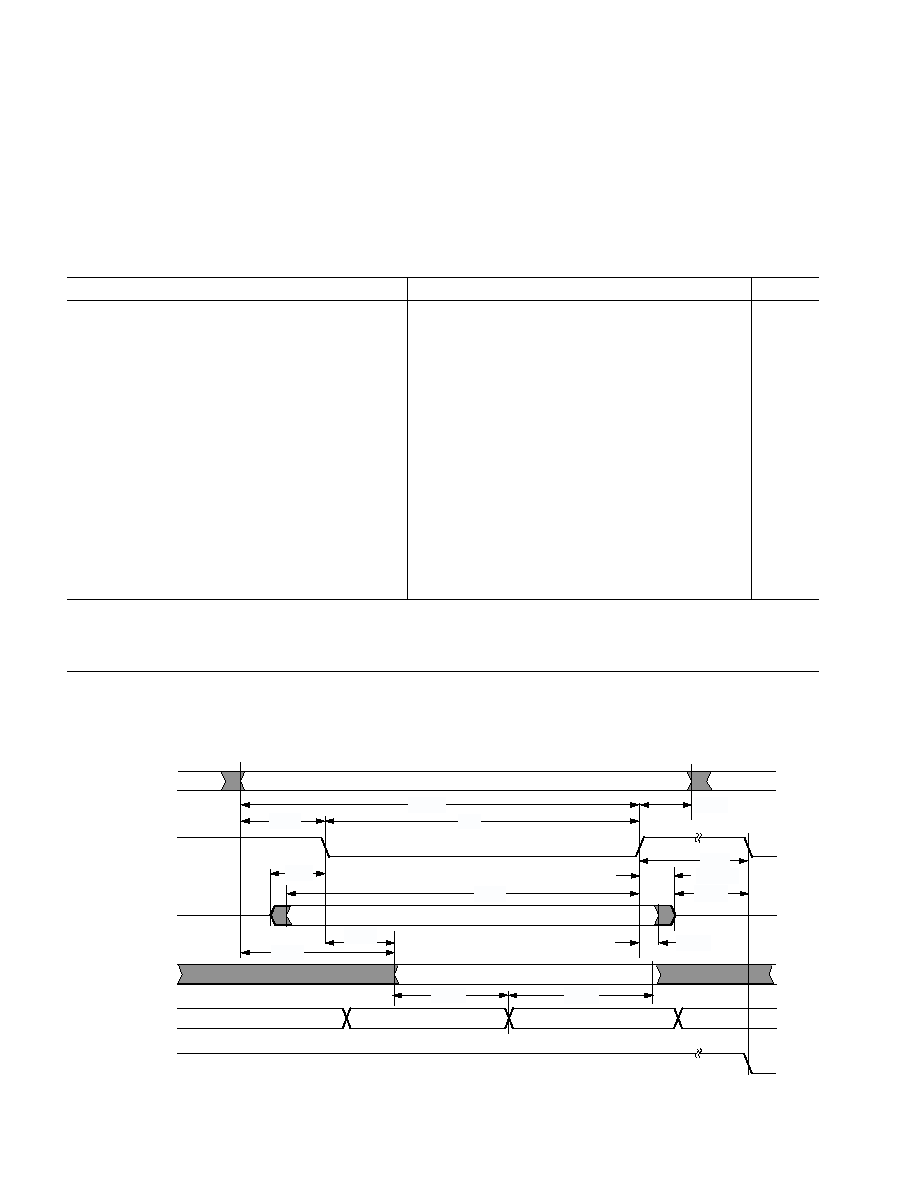

Host Bus Request . . . . . . . . . . . . . . . . . . . . . . . . 31

Asynchronous Read/Write

Host to ADSP-21161N . . . . . . . . . . . . . . . . . . 33

Three-State Timing Bus Master, Bus Slave . . . . 35

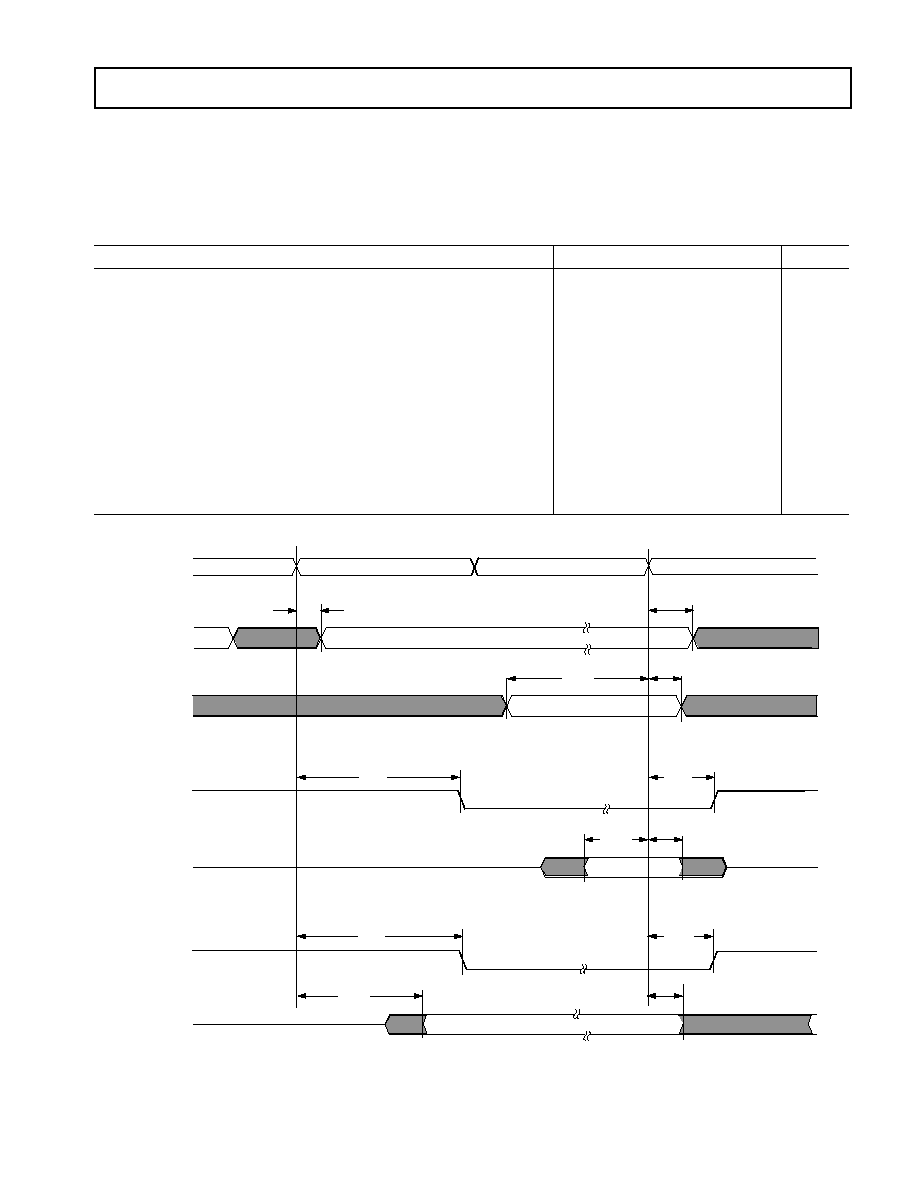

DMA Handshake . . . . . . . . . . . . . . . . . . . . . . . . 37

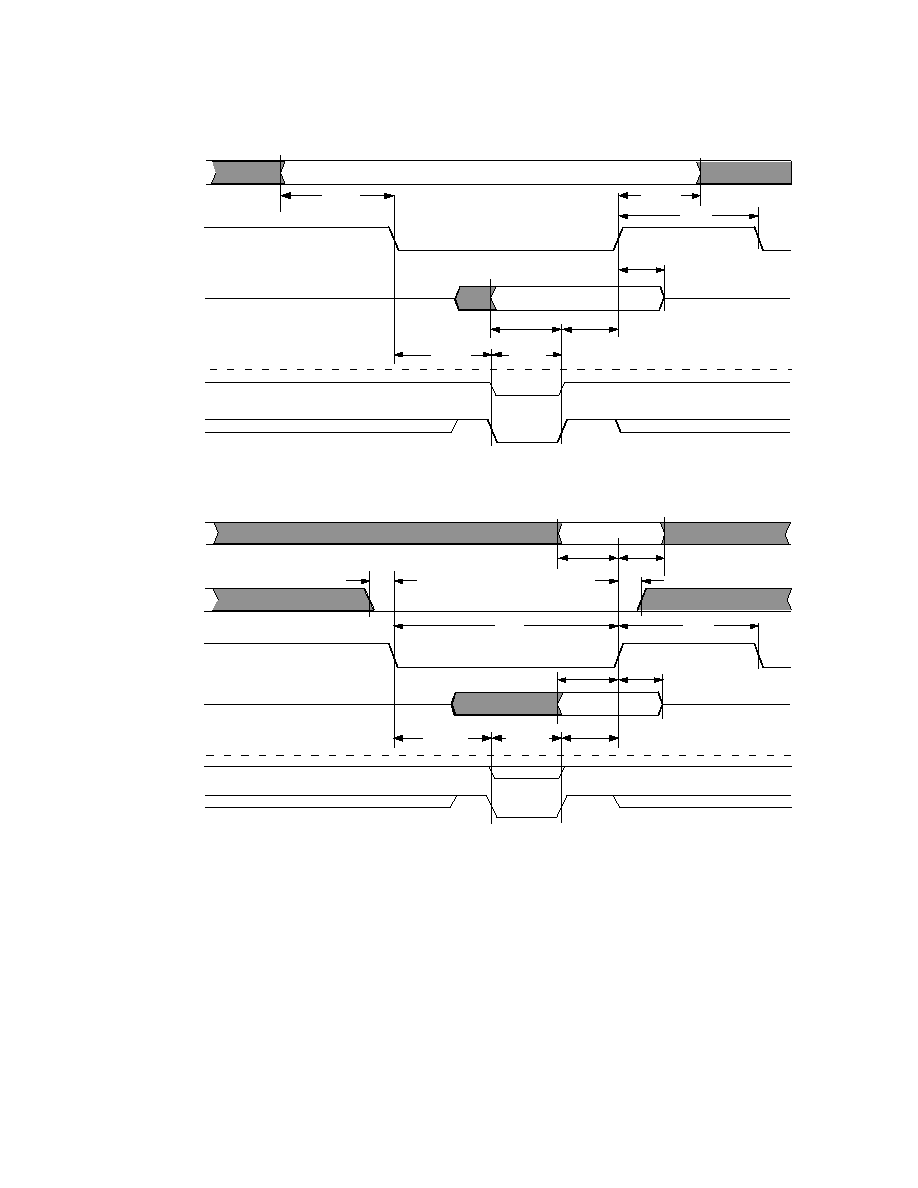

SDRAM Interface Bus Master . . . . . . . . . . . . . 39

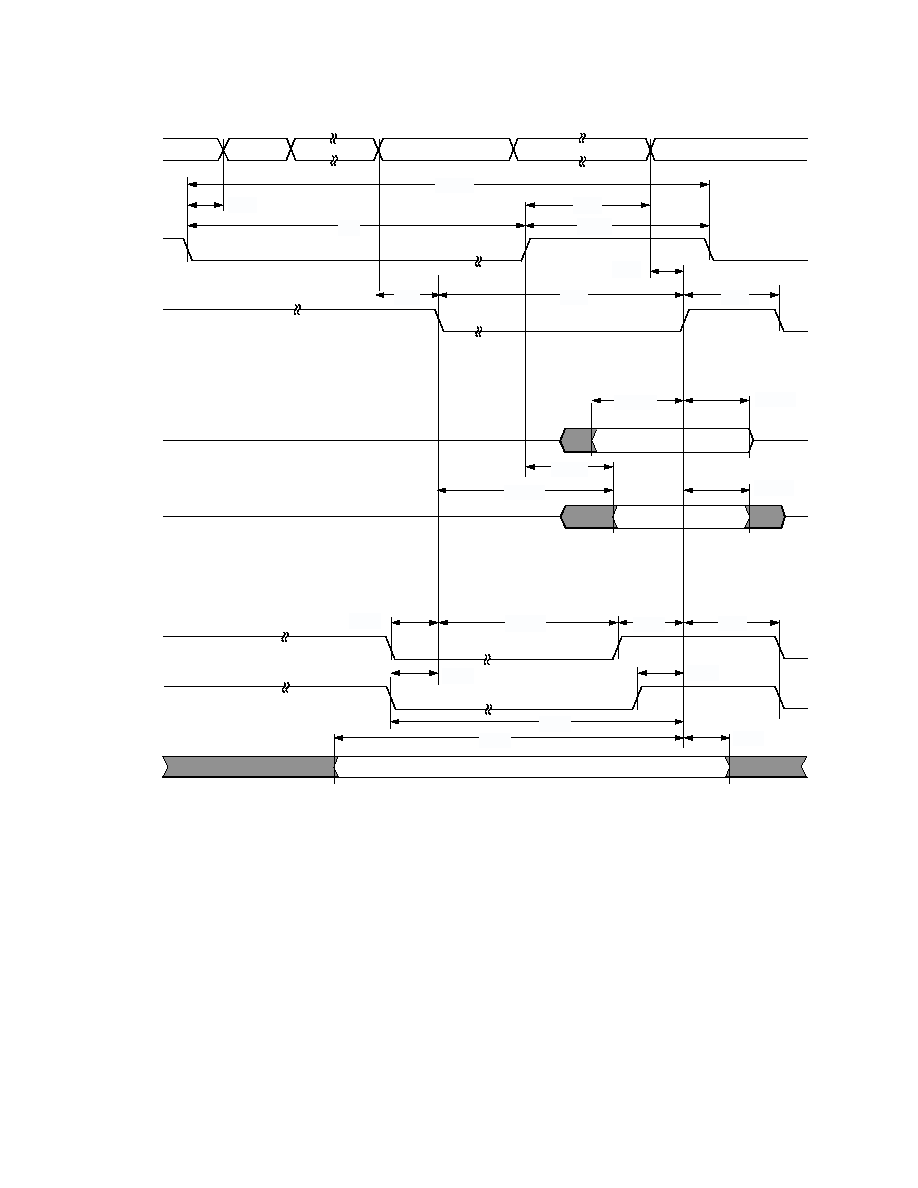

Link Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

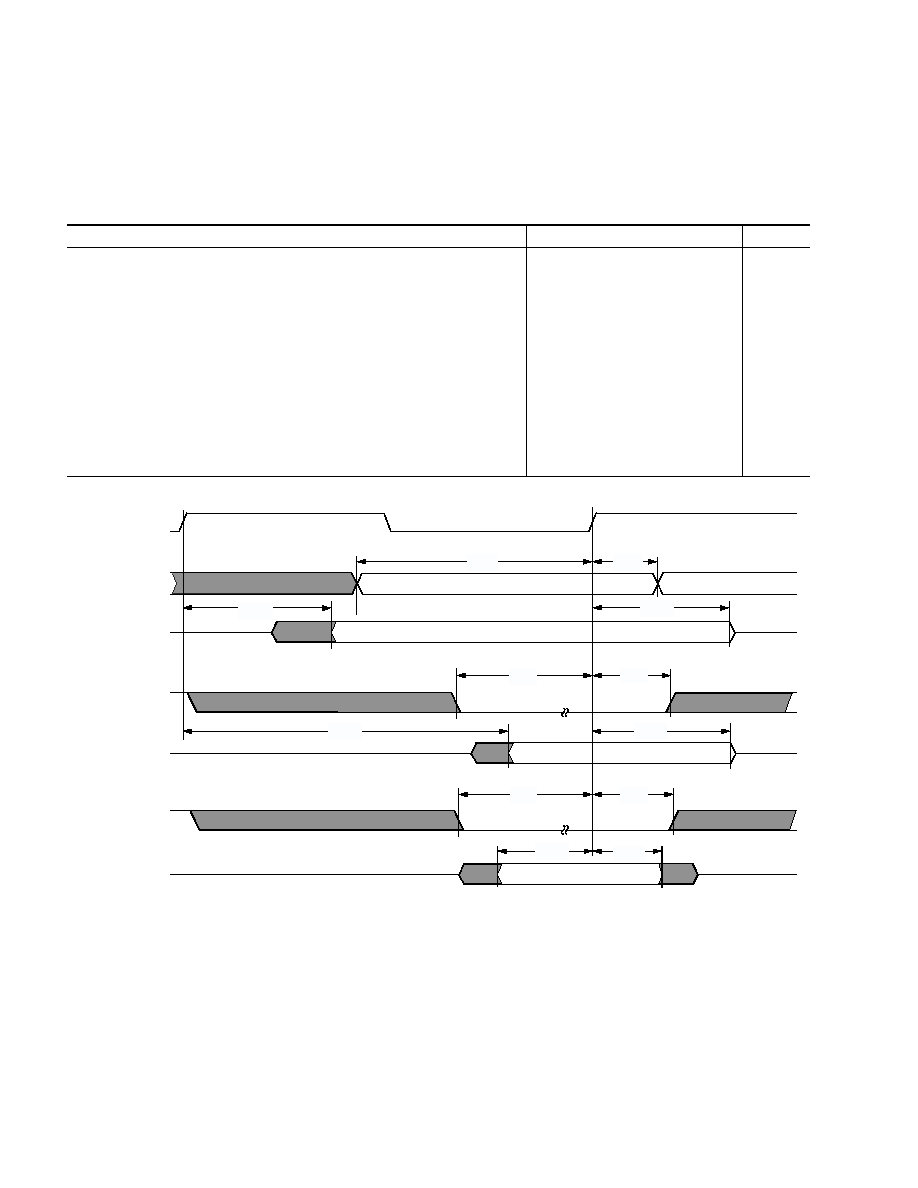

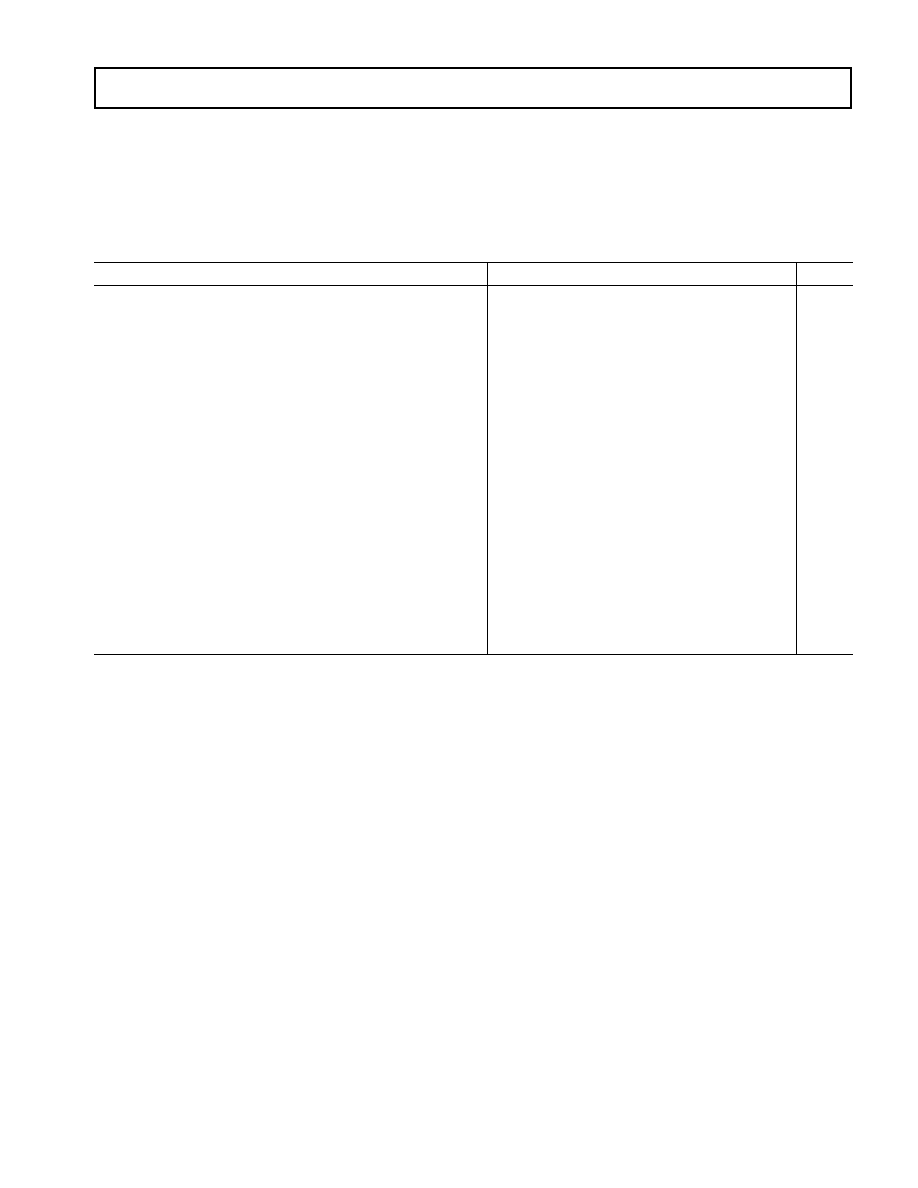

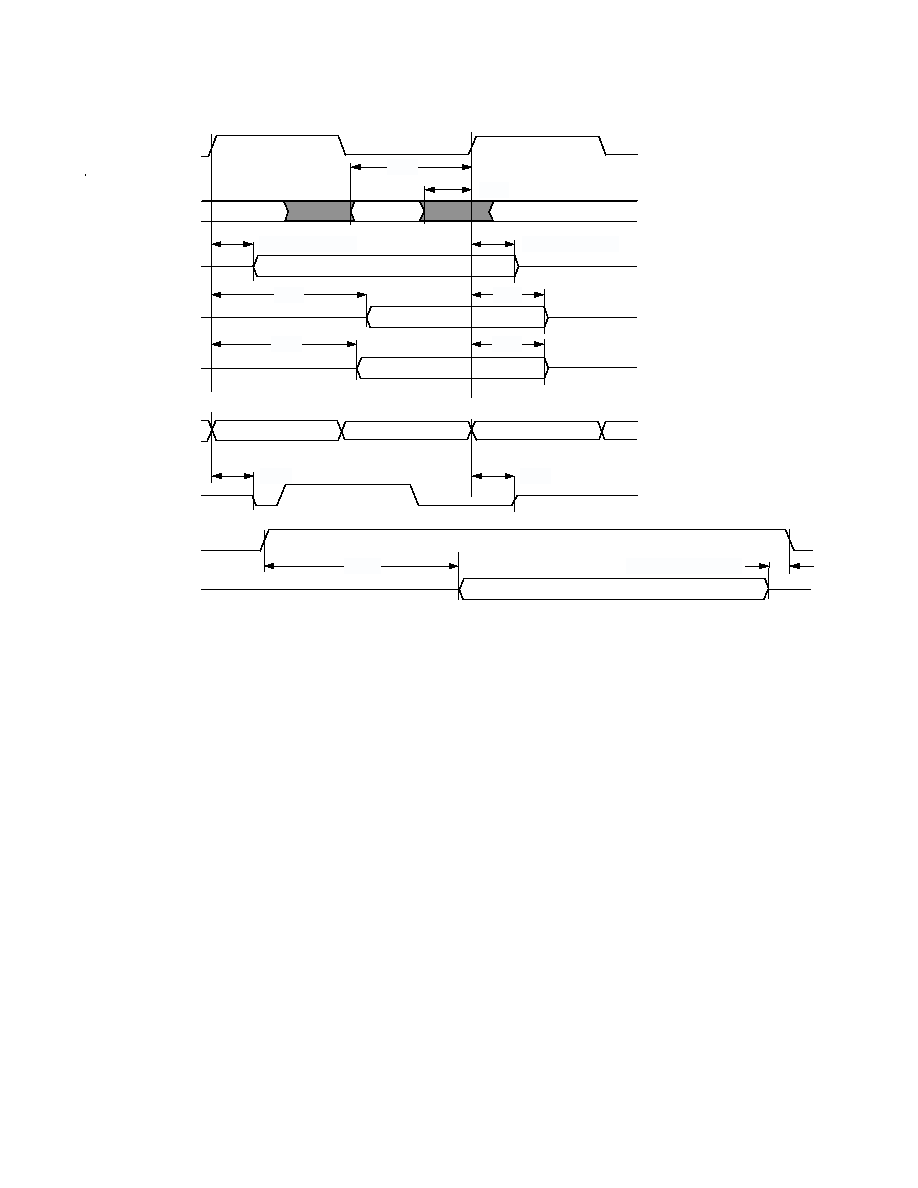

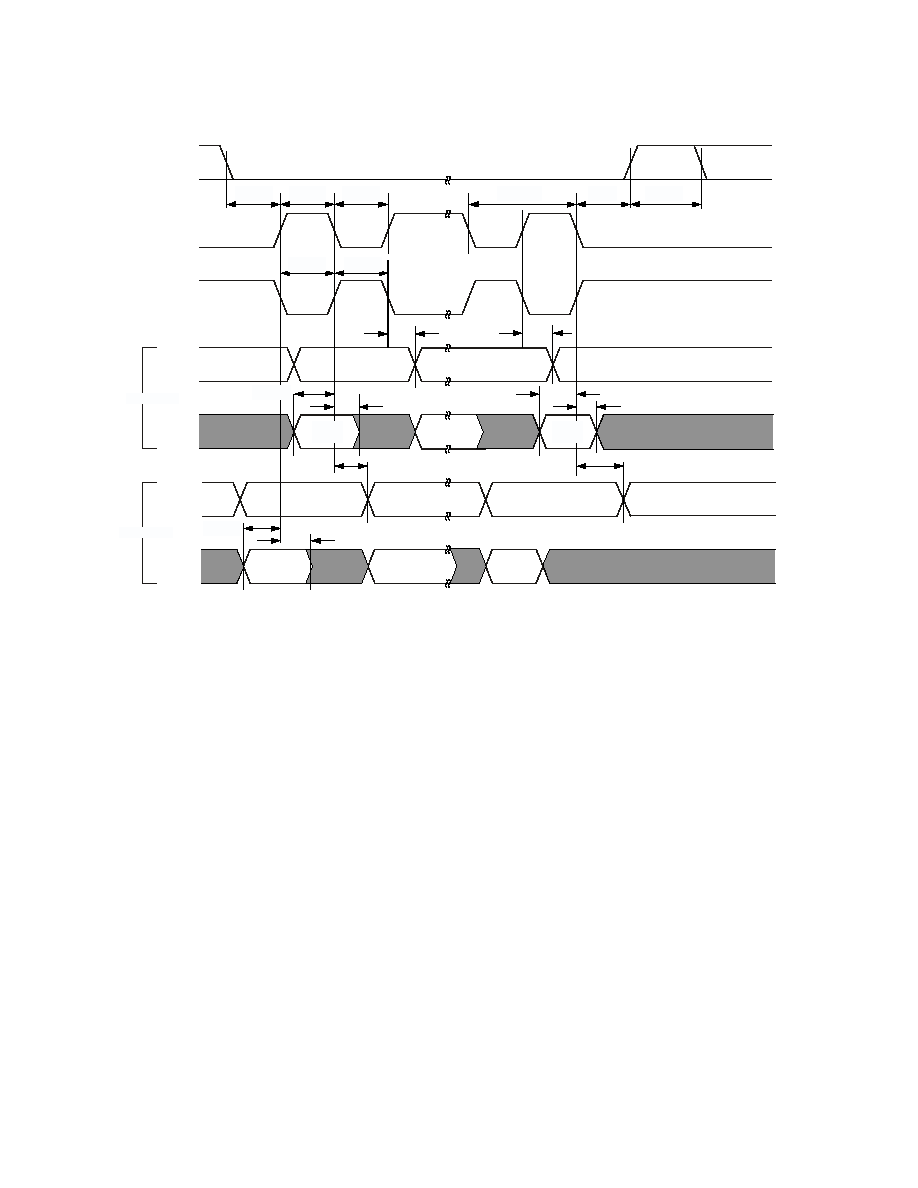

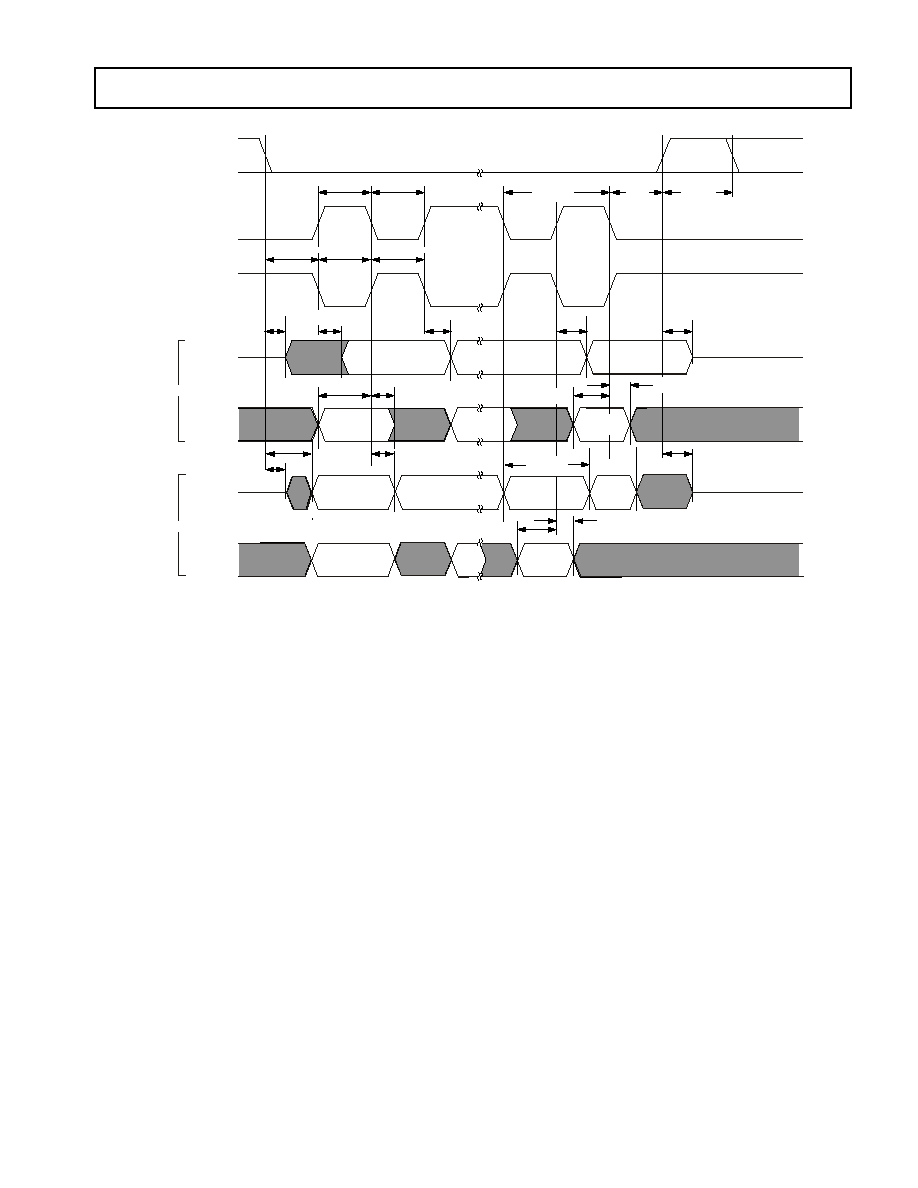

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

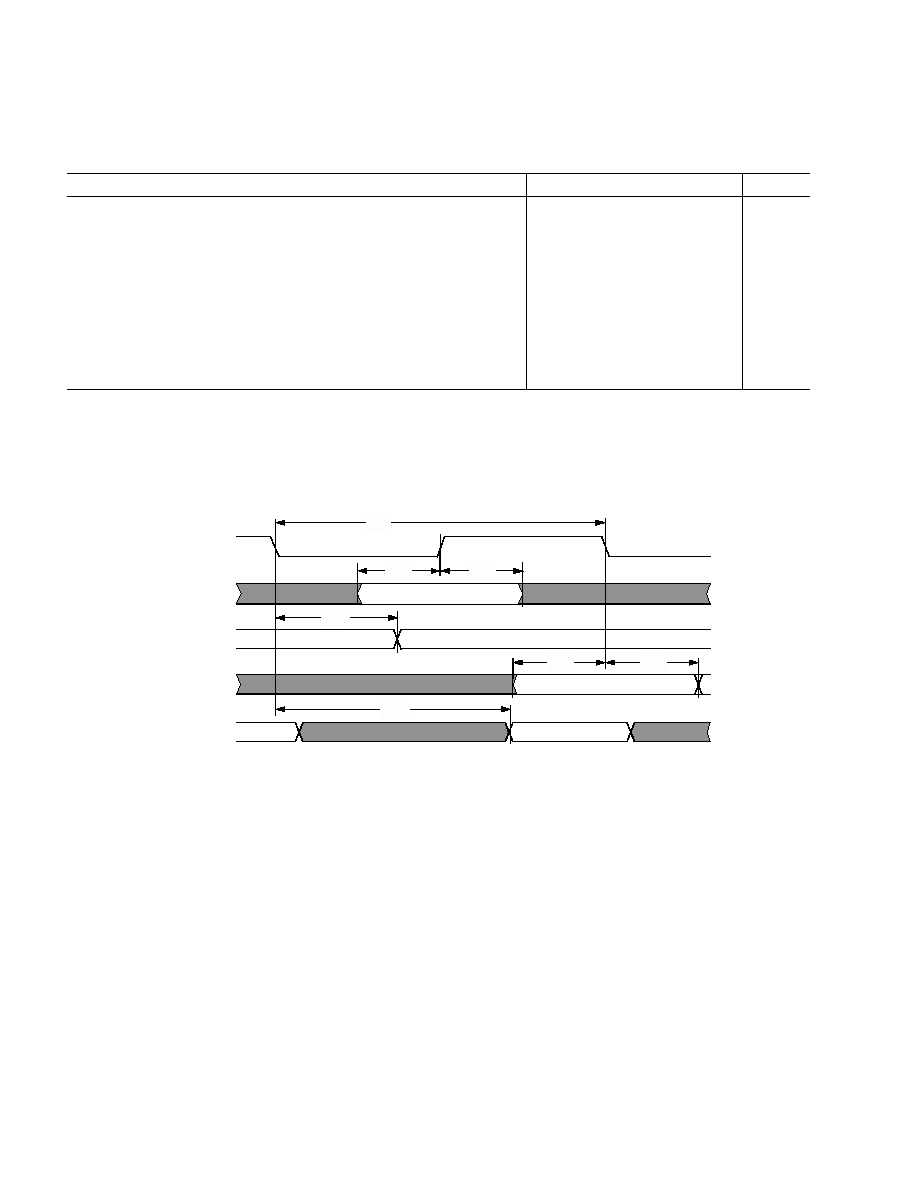

SPI Interface Specifications . . . . . . . . . . . . . . . . . 47

JTAG Test Access Port and Emulation . . . . . . . . 50

Output Drive Currents . . . . . . . . . . . . . . . . . . . . . . 51

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Output Enable Time . . . . . . . . . . . . . . . . . . . . . . 51

Output Disable Time . . . . . . . . . . . . . . . . . . . . . 51

Example System Hold Time Calculation . . . . . . . 51

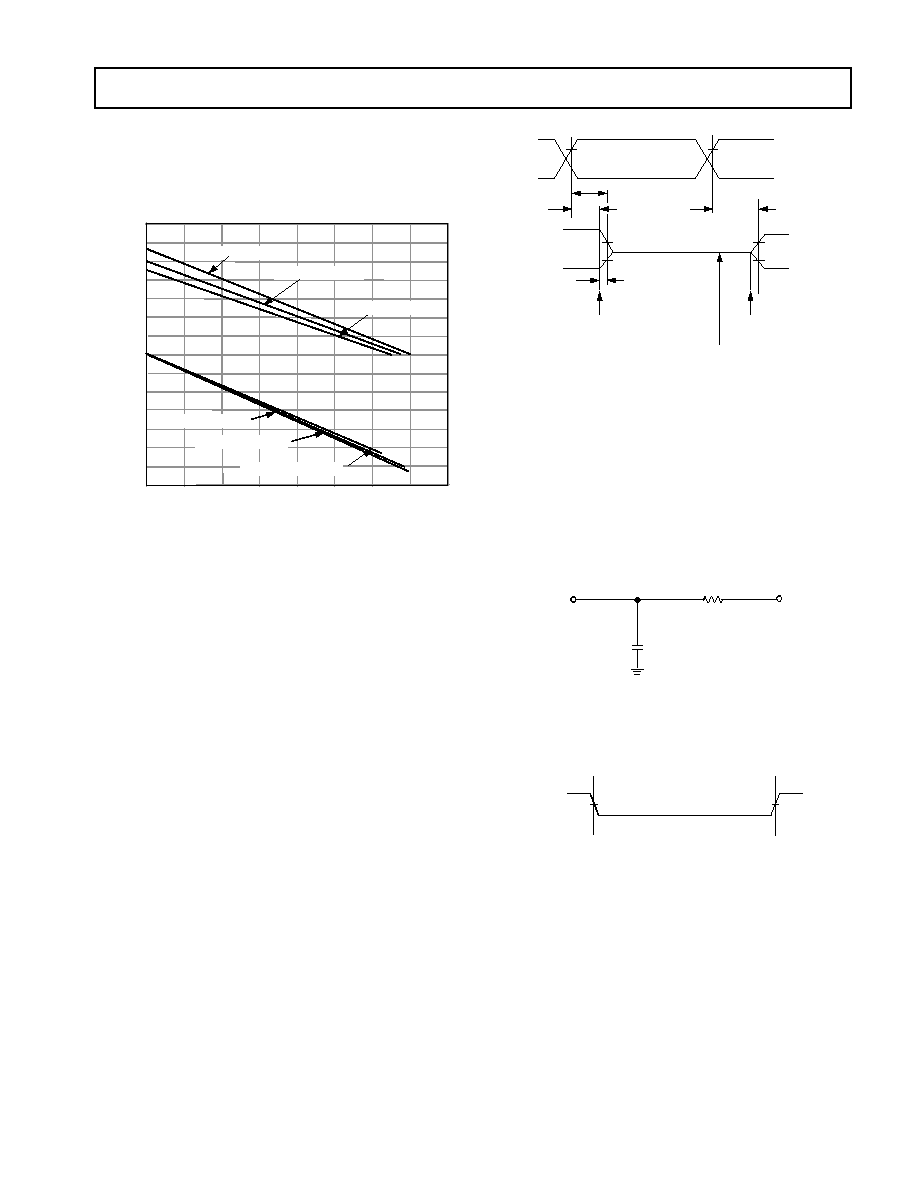

Capacitive Loading . . . . . . . . . . . . . . . . . . . . . . . 52

Environmental Conditions . . . . . . . . . . . . . . . . . . . 52

Thermal Characteristics . . . . . . . . . . . . . . . . . . . 52

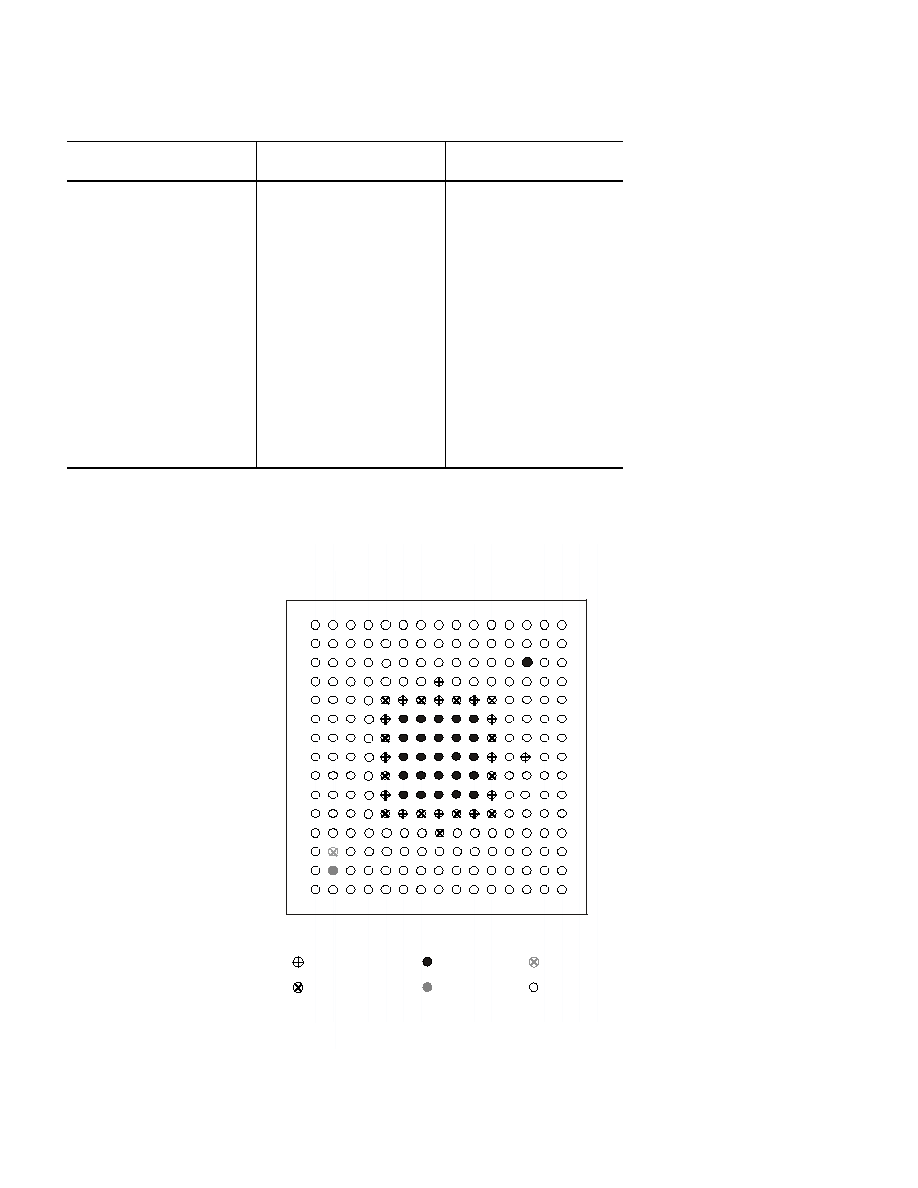

225-BALL METRIC MBGA

PIN CONFIGURATIONS . . . . . . . . . . . . . . . . . . 53

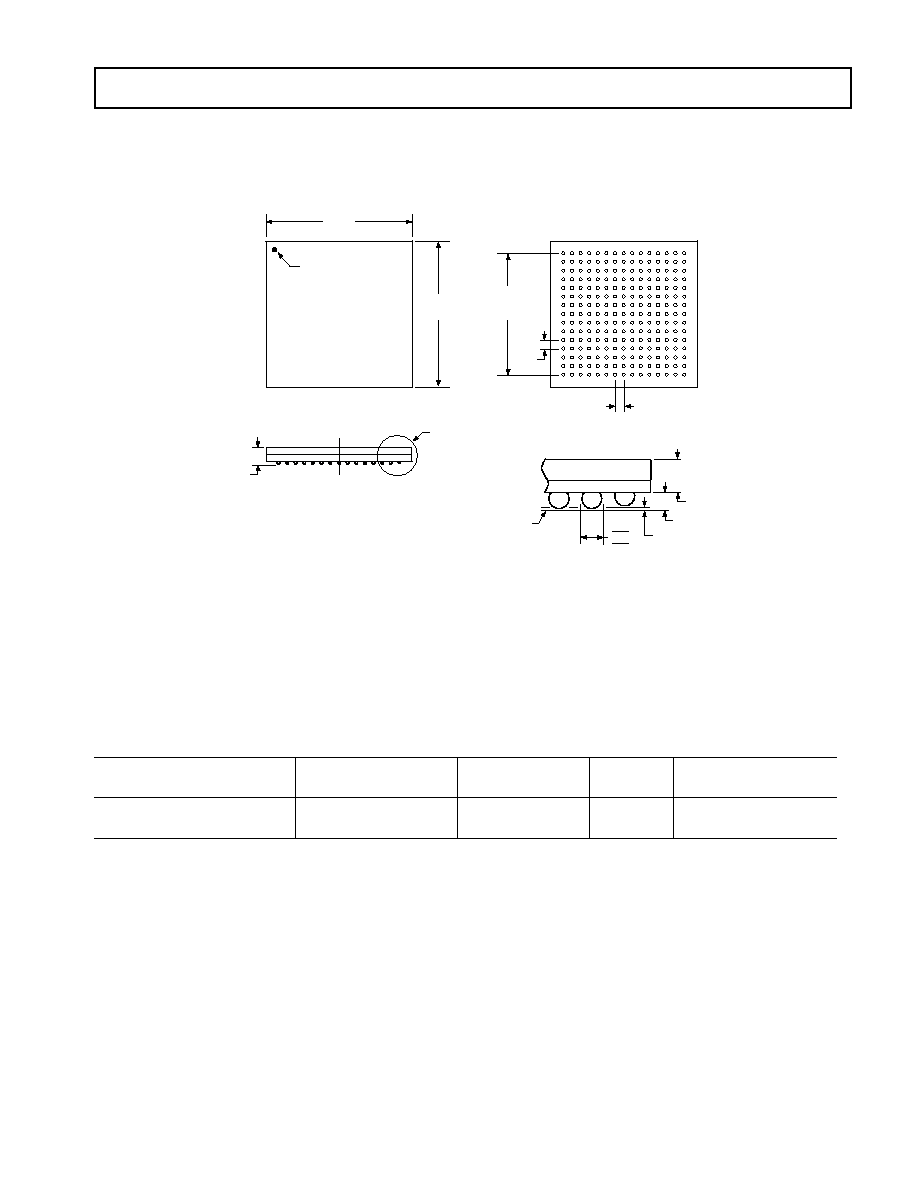

OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . 55

ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 55

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

GENERAL DESCRIPTION

The ADSP-21161N SHARC DSP is the first low cost derivative

of the ADSP-21160 featuring Analog Devices Super Harvard

Architecture. Easing portability, the ADSP-21161N is source

code compatible with the ADSP-21160 and with first generation

ADSP-2106x SHARCs in SISD (Single Instruction, Single

Data) mode. Like other SHARC DSPs, the ADSP-21161N is a

32-bit processor that is optimized for high performance DSP

applications. The ADSP-21161N includes a 100 MHz core, a

dual-ported on-chip SRAM, an integrated I/O processor with

multiprocessing support, and multiple internal buses to eliminate

I/O bottlenecks.

As was first offered in the ADSP-21160, the ADSP-21161N

offers a Single-Instruction-Multiple-Data (SIMD) architecture.

Using two computational units (ADSP-2106x SHARCs have

one), the ADSP-21161N can double cycle performance versus

the ADSP-2106x on a range of DSP algorithms.

Fabricated in a state of the art, high speed, low power CMOS

process, the ADSP-21161N has a 10 ns instruction cycle time.

With its SIMD computational hardware running at 100 MHz,

the ADSP-21161N can perform 600 million math operations per

second.

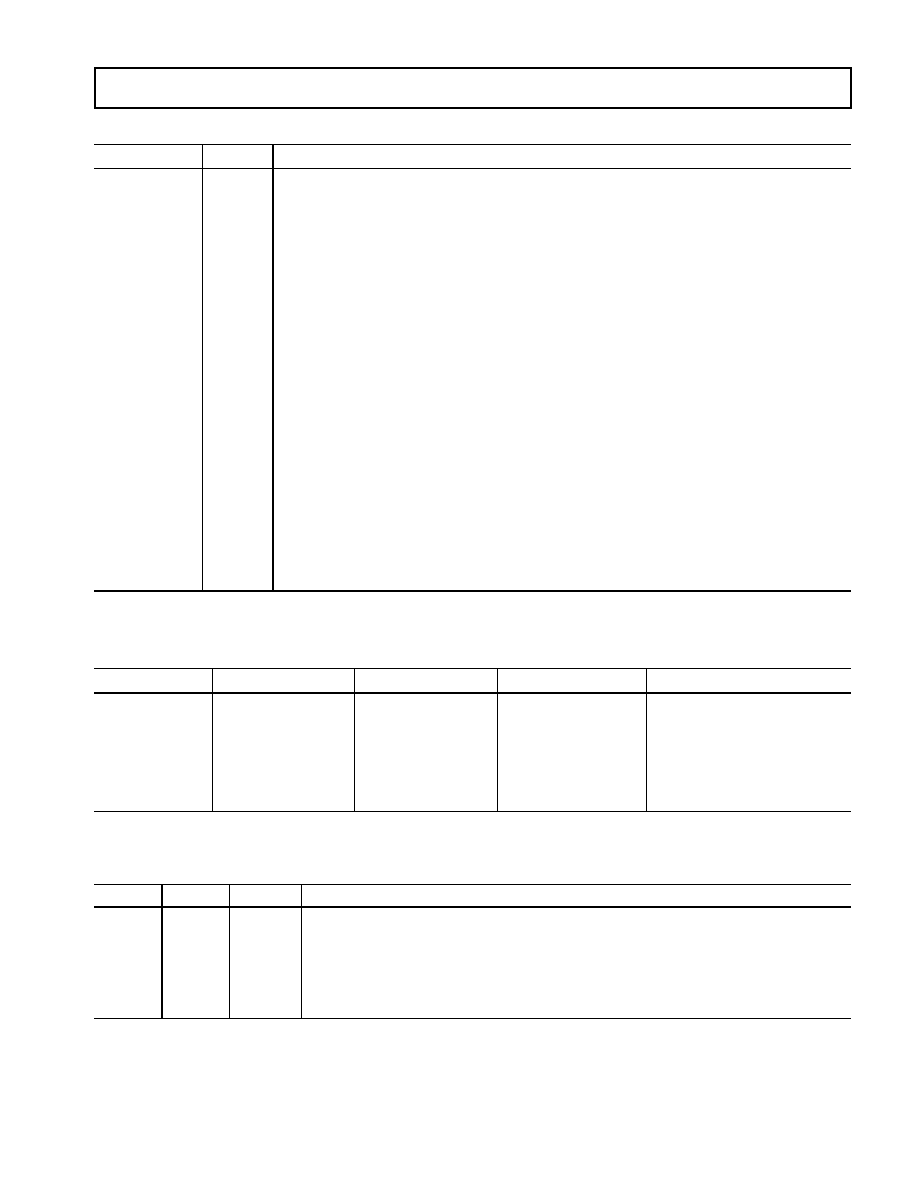

Table 1

shows performance benchmarks for the

ADSP-21161N.

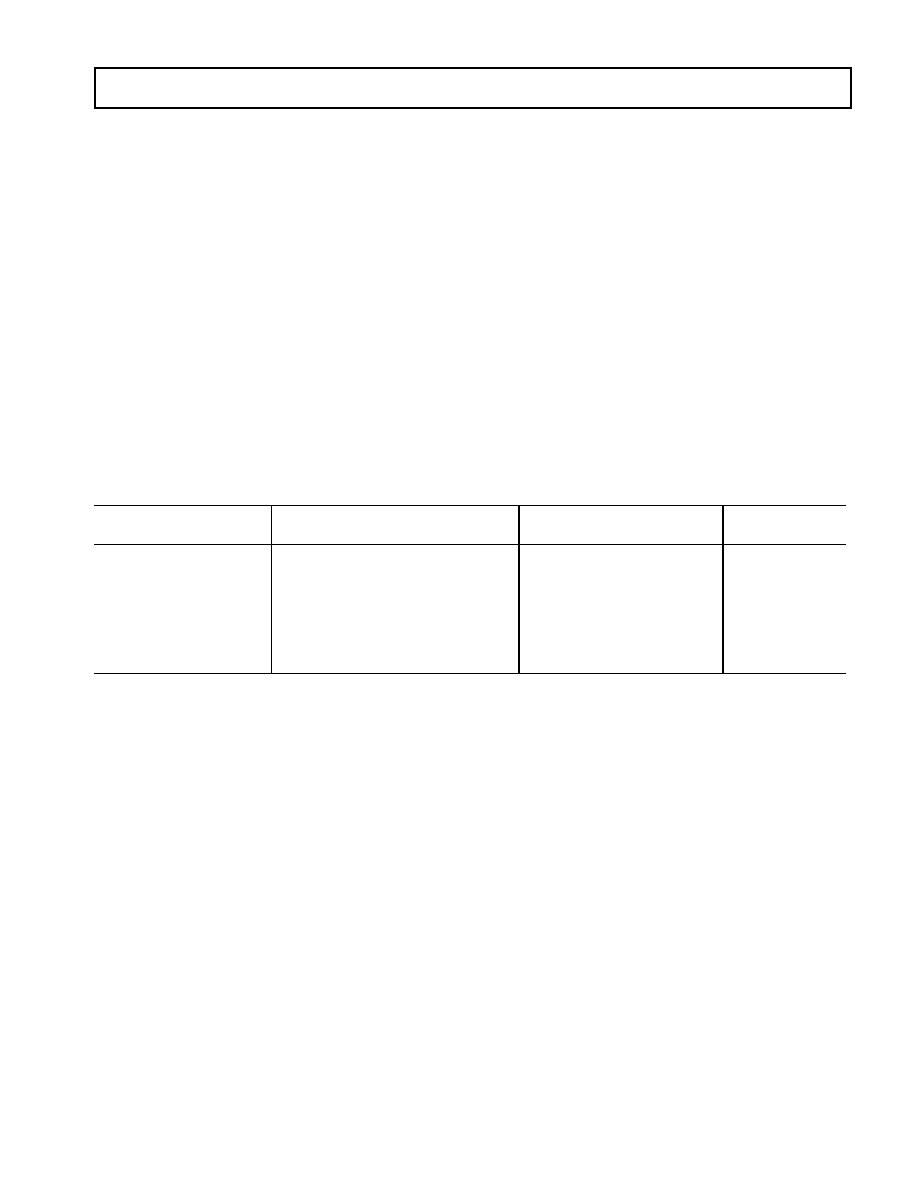

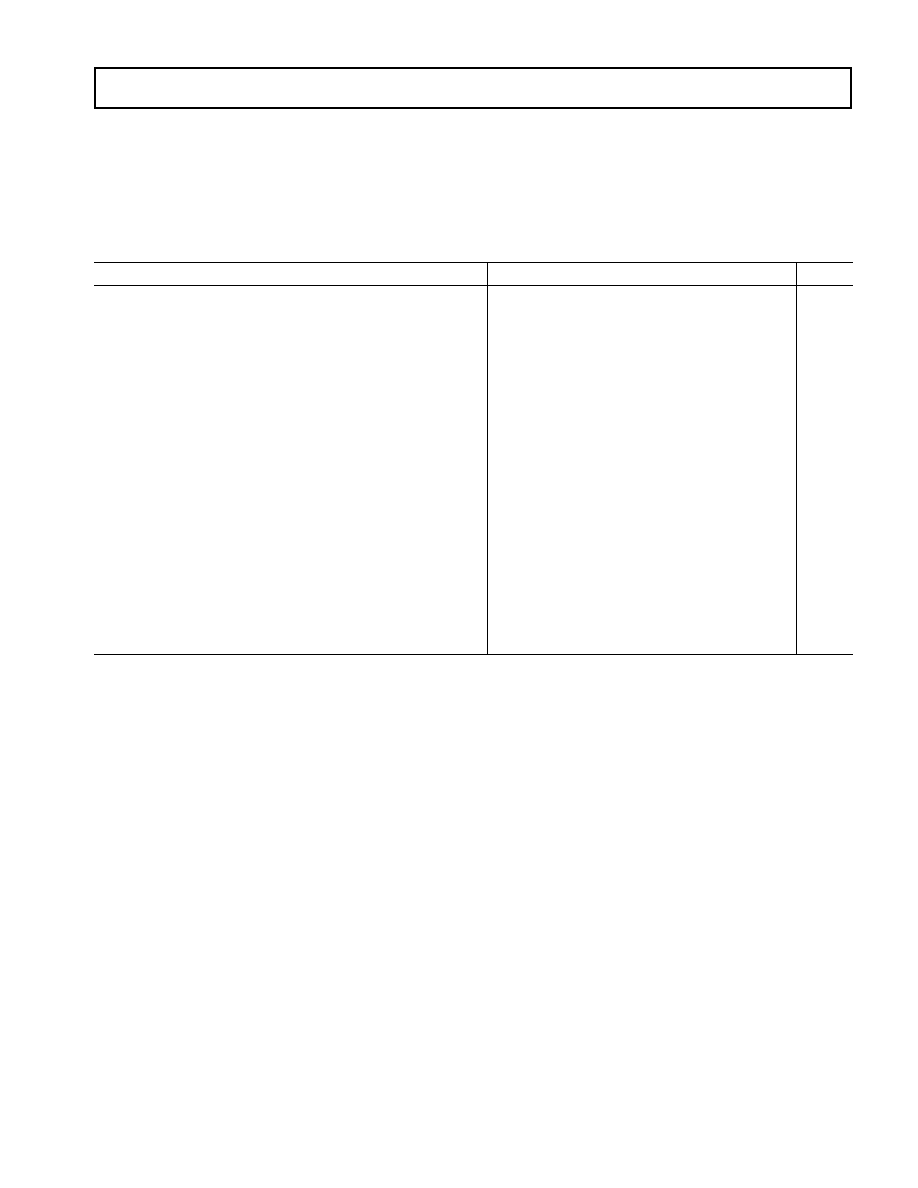

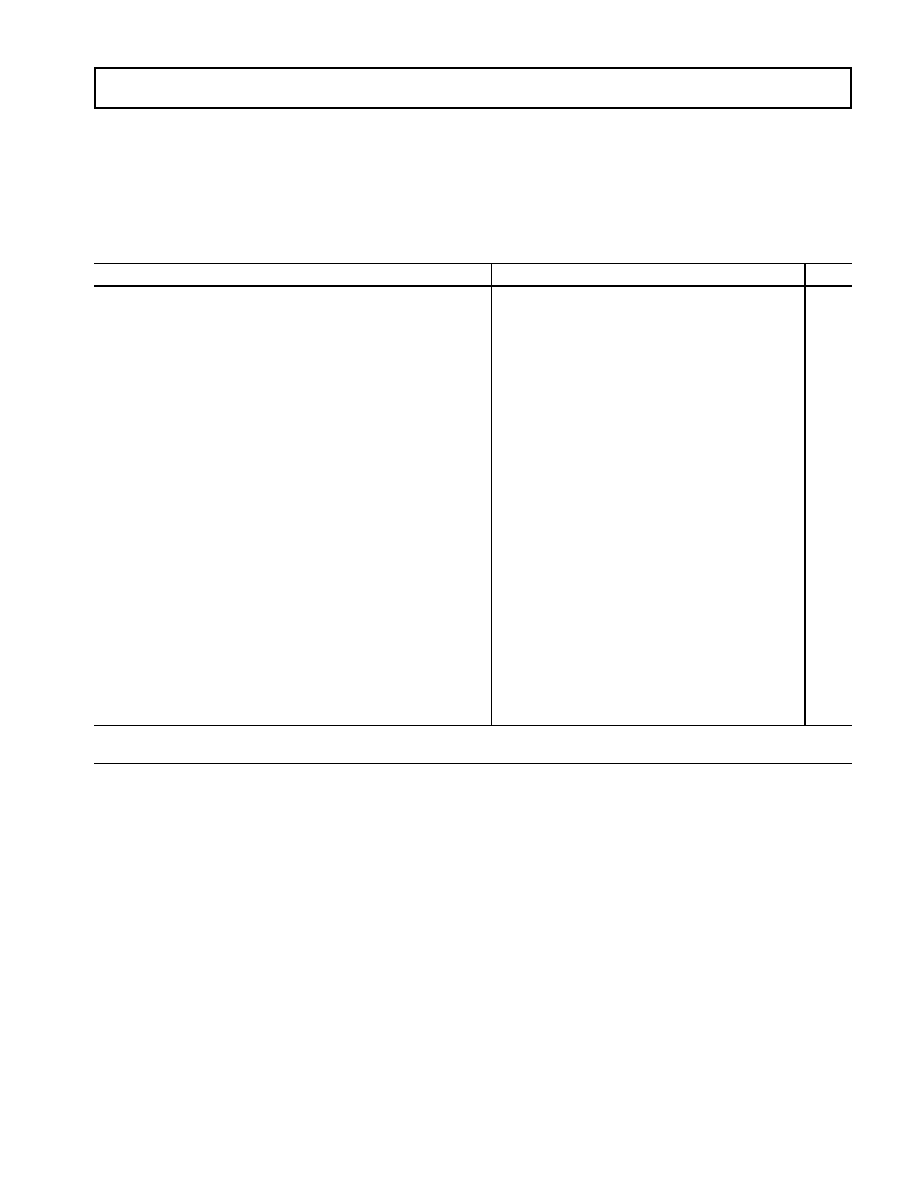

Table 1. Benchmarks (at 100 MHz)

Benchmark Algorithm

Speed

(at 100 MHz)

1024 Point Complex FFT

(Radix 4, with reversal)

171 µs

FIR Filter (per tap)

1

5 ns

IIR Filter (per biquad)

1

40 ns

1

1

Specified in SISD mode. Using SIMD, the same benchmark applies for

two sets of computations. For example, two sets of biquad operations can

be performed in the same amount of time as the SISD mode benchmark.

Matrix Multiply (pipelined)

[3

×

3]

×

[3

×

1]

30 ns

[4

×

4]

×

[4

×

1]

37 ns

Divide (y/x)

60 ns

1

Inverse Square Root

40 ns

1

DMA Transfers

800 M bytes/s

ADSP-21161N

4

REV. A

The ADSP-21161N continues SHARC's industry-leading

standards of integration for DSPs, combining a high performance

32-bit DSP core with integrated, on-chip system features. These

features include a 1 M bit dual ported SRAM memory, host

processor interface, I/O processor that supports 14 DMA

channels, four serial ports, two link ports, SDRAM controller,

SPI interface, external parallel bus, and glueless multiprocessing.

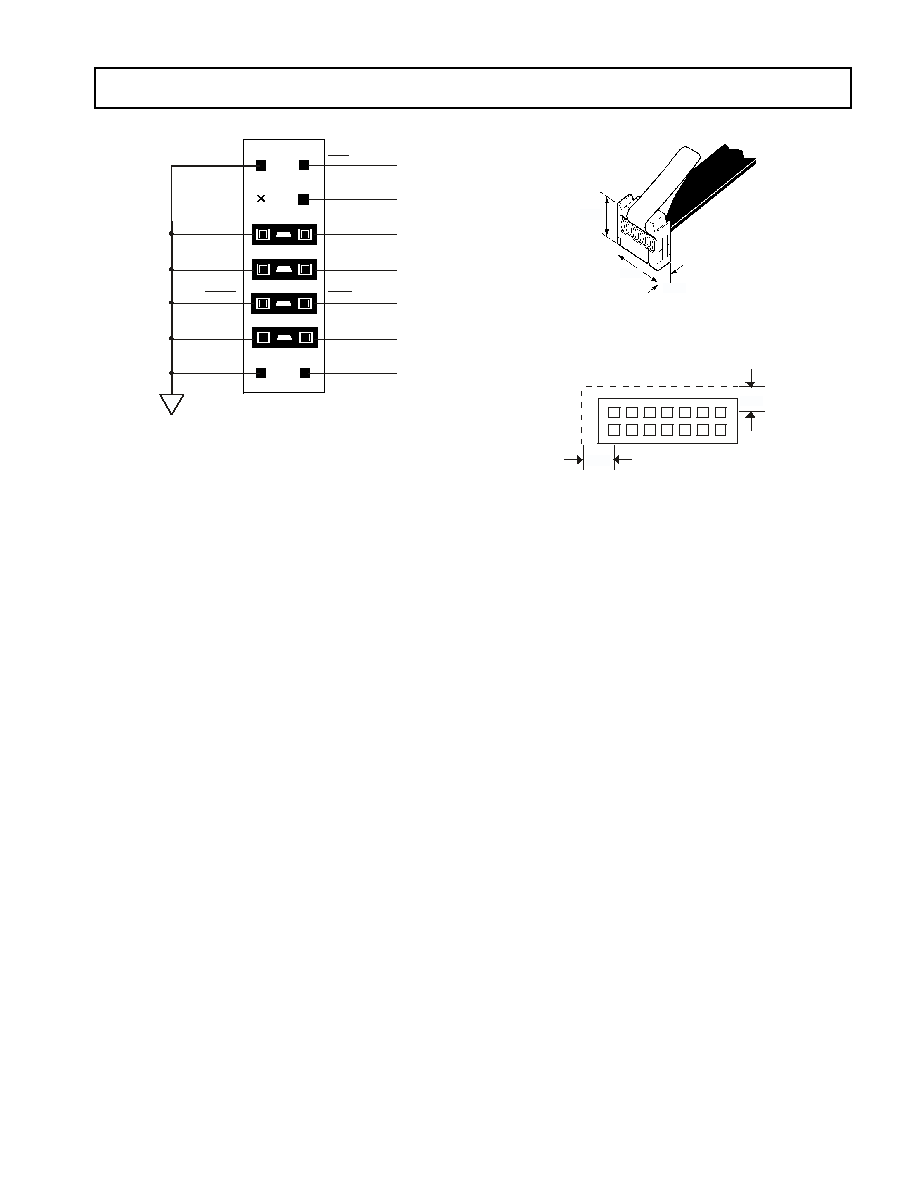

The block diagram of the ADSP-21161N

on Page 1

illustrates

the following architectural features:

·

Two processing elements, each made up of an ALU, Mul-

tiplier, Shifter, and Data Register File

·

Data Address Generators (DAG1, DAG2)

·

Program sequencer with instruction cache

·

PM and DM buses capable of supporting four 32-bit data

transfers between memory and the core every core

processor cycle

·

Interval timer

·

On-Chip SRAM (1 M bit)

·

SDRAM Controller for glueless interface to SDRAMs

·

External port that supports:

·

Interfacing to off-chip memory peripherals

·

Glueless multiprocessing support for six ADSP-

21161N SHARCs

·

Host port read/write of IOP registers

·

DMA controller

·

Four serial ports

·

Two link ports

·

SPI compatible interface

·

JTAG test access port

·

12 General-Purpose I/O Pins

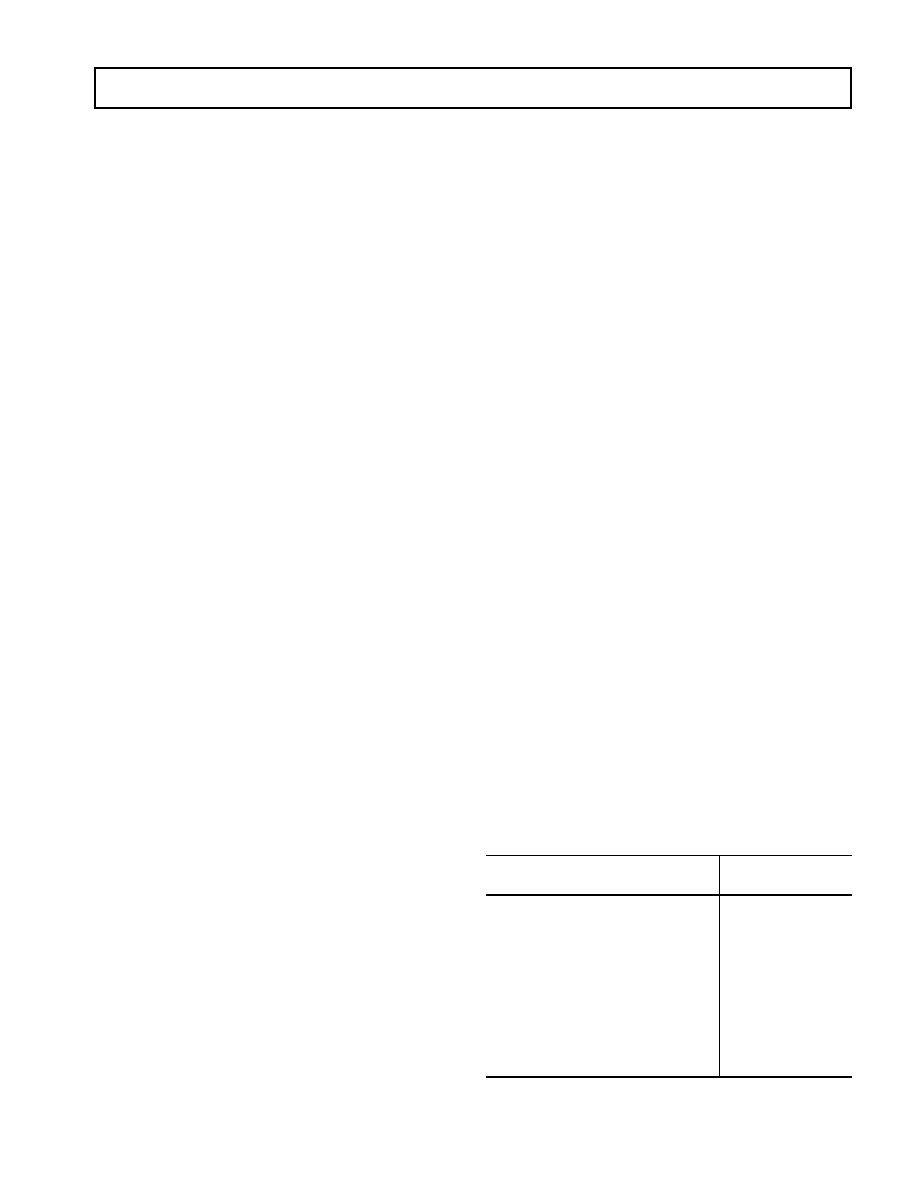

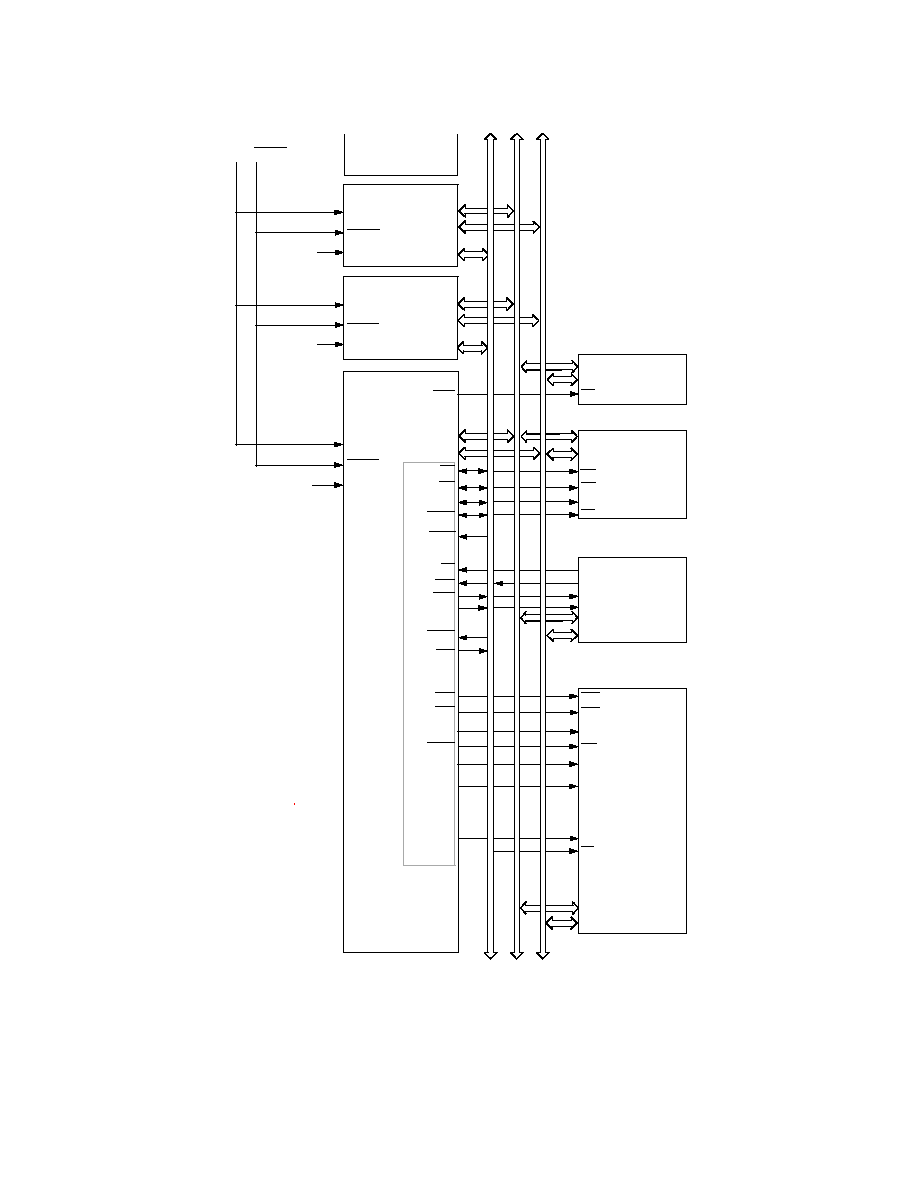

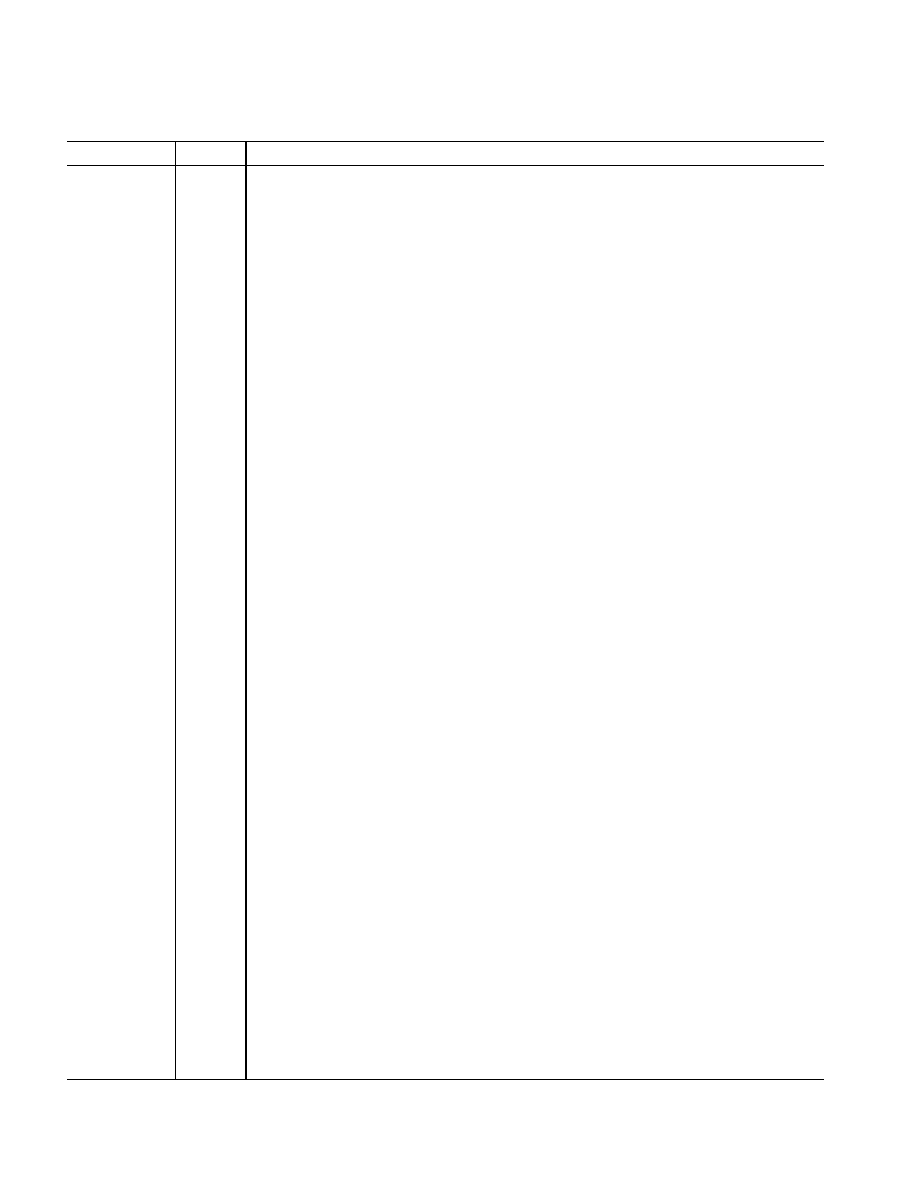

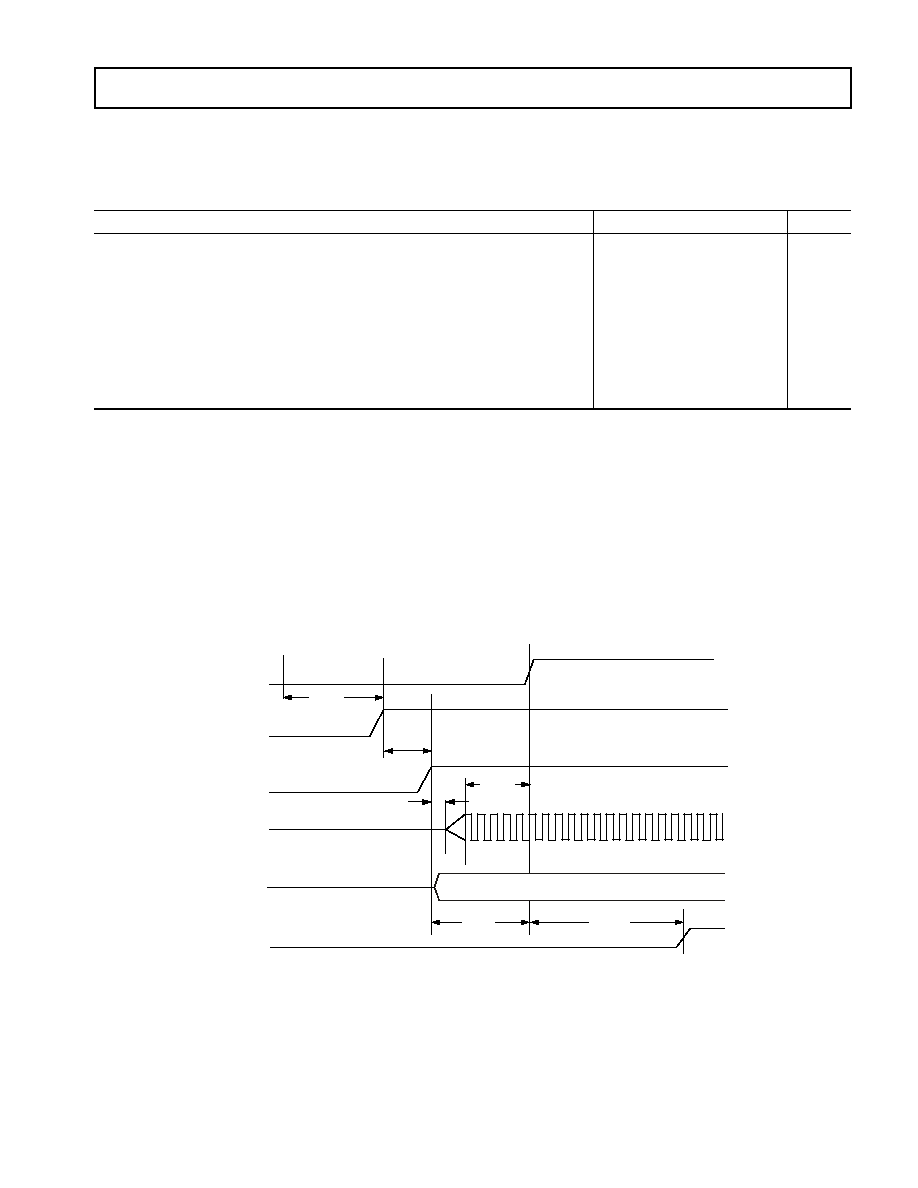

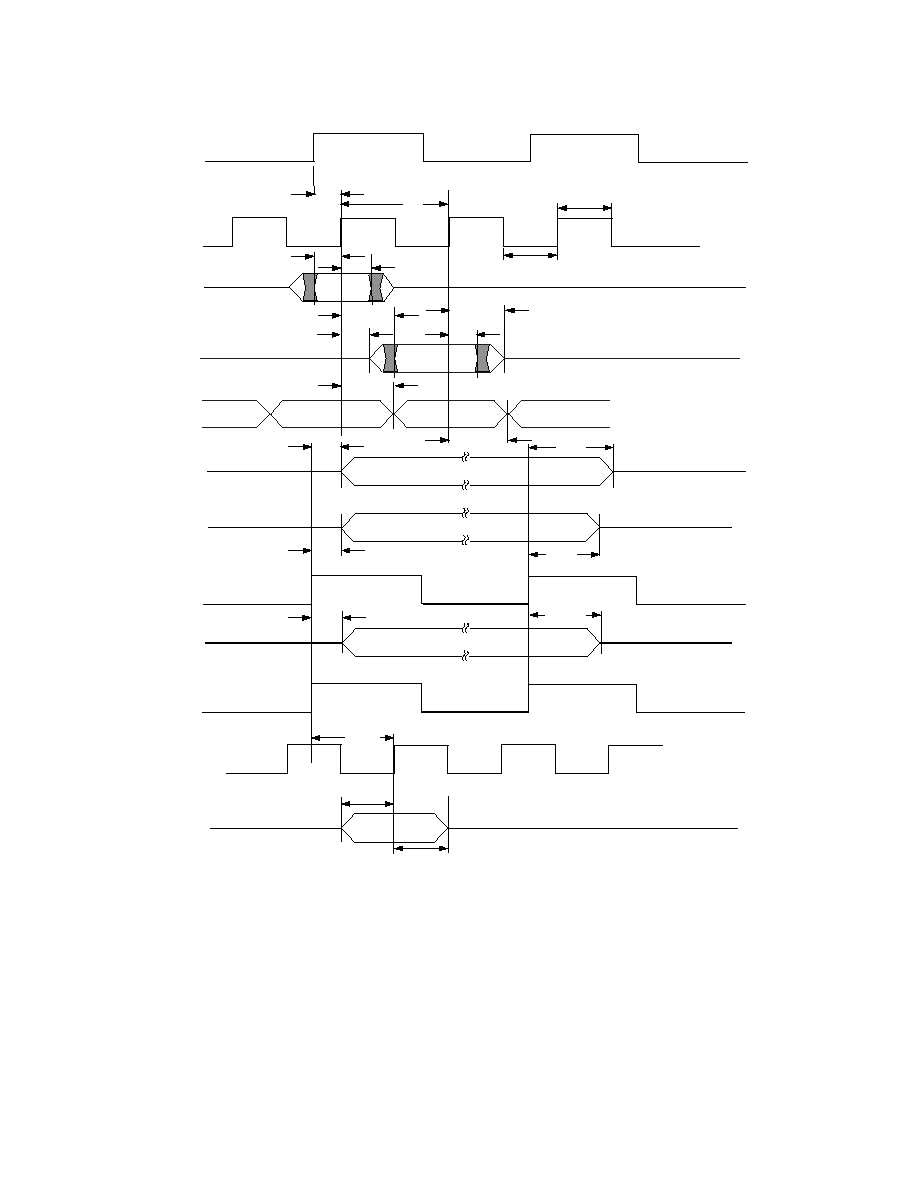

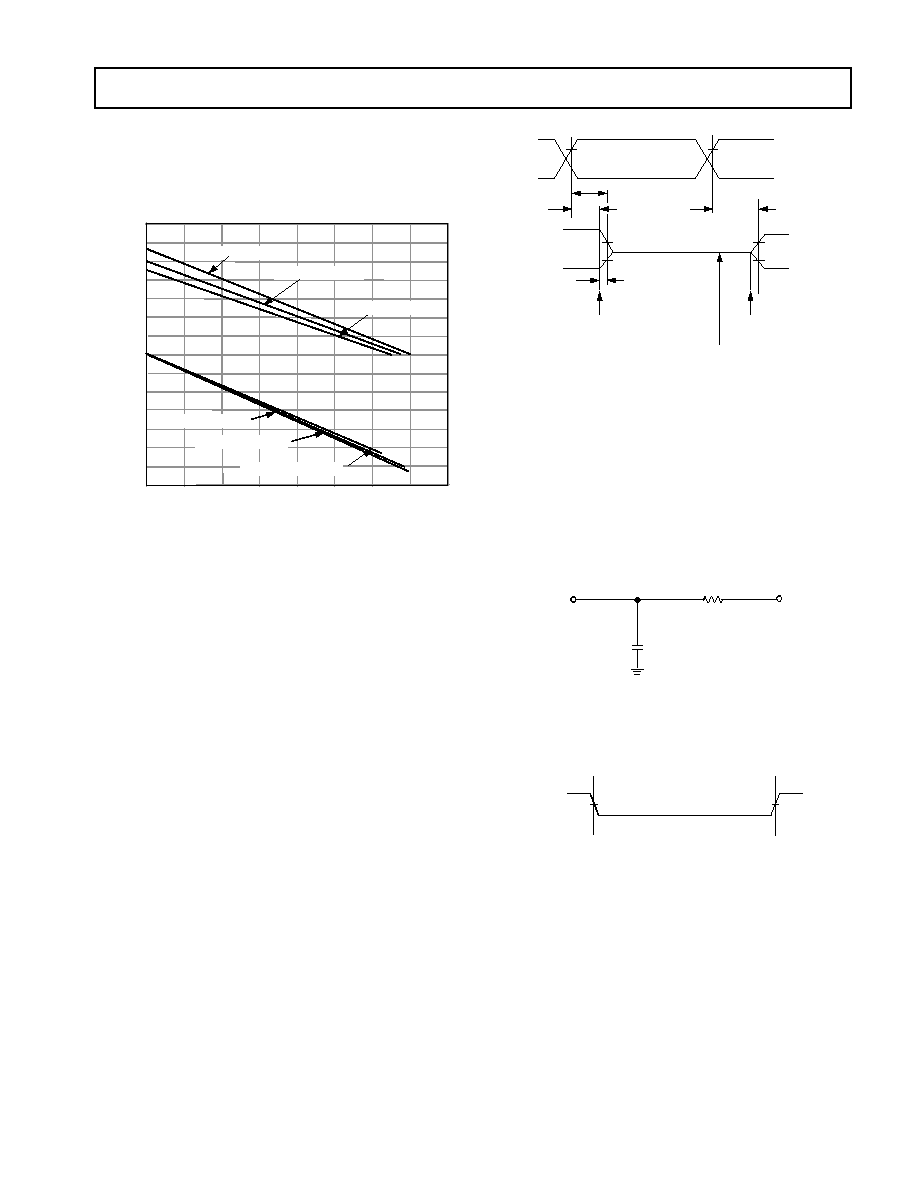

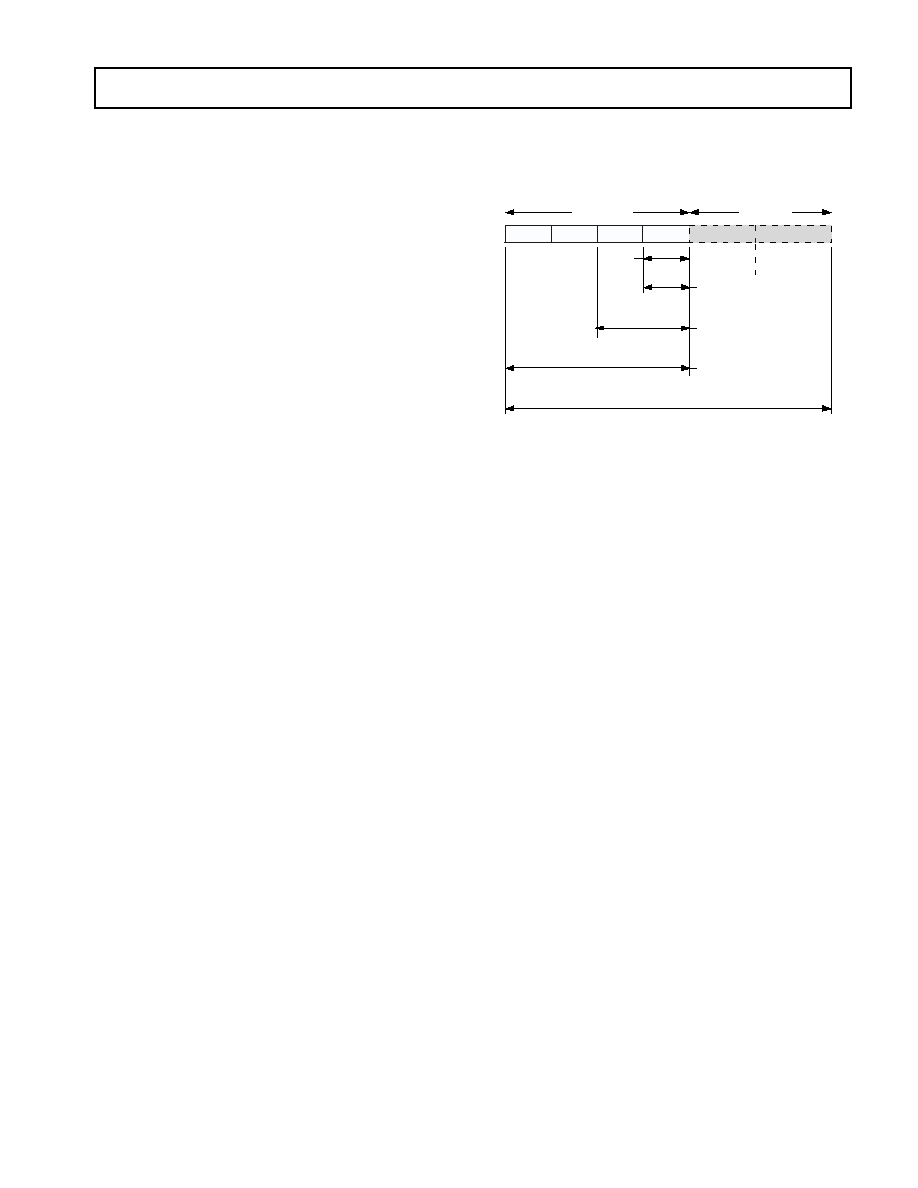

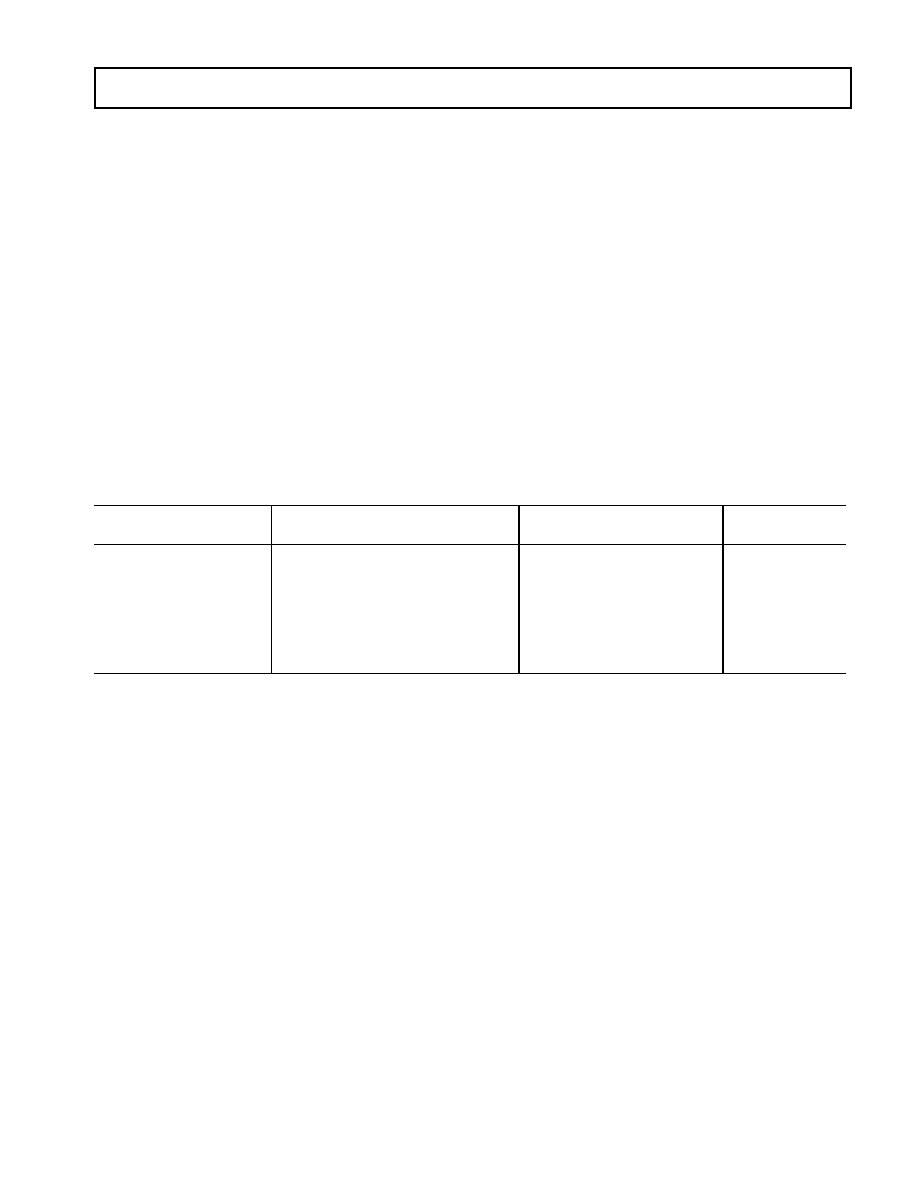

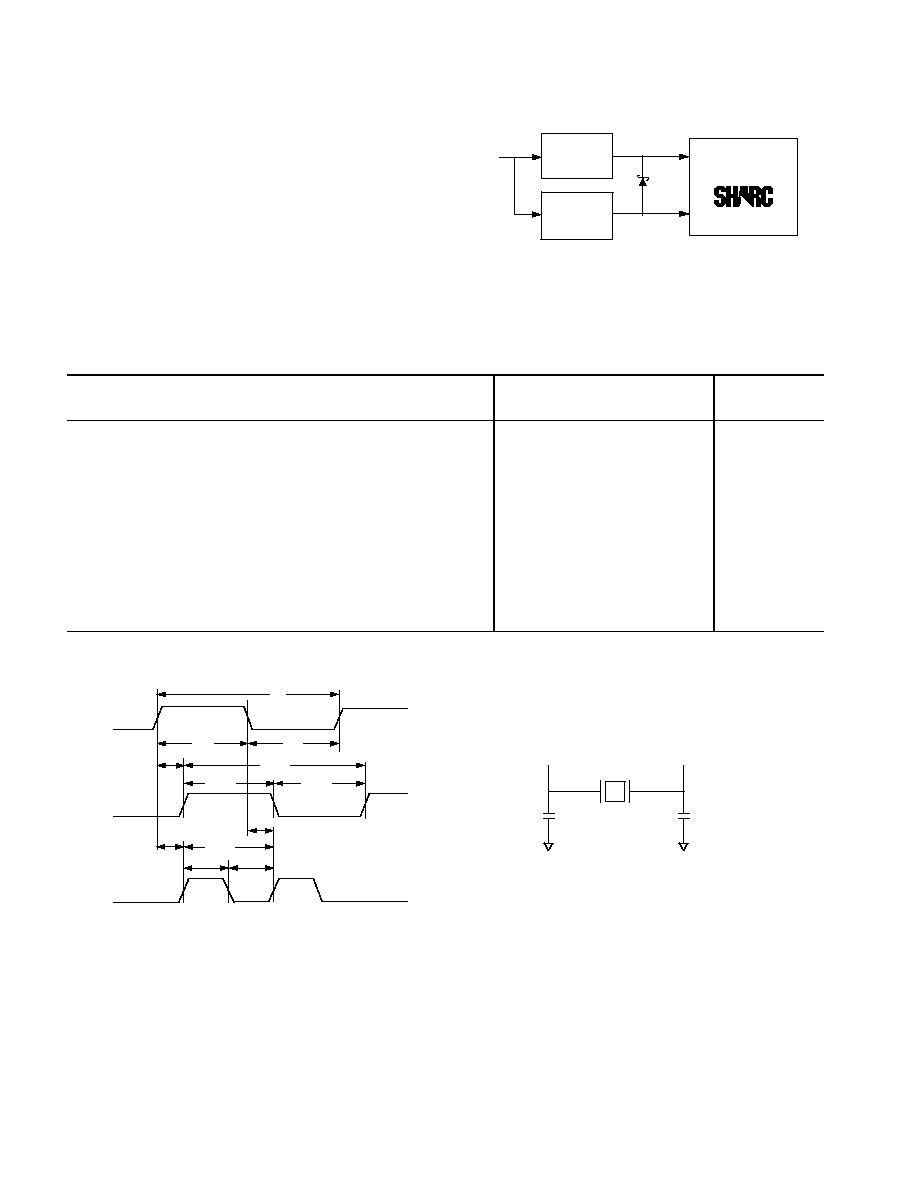

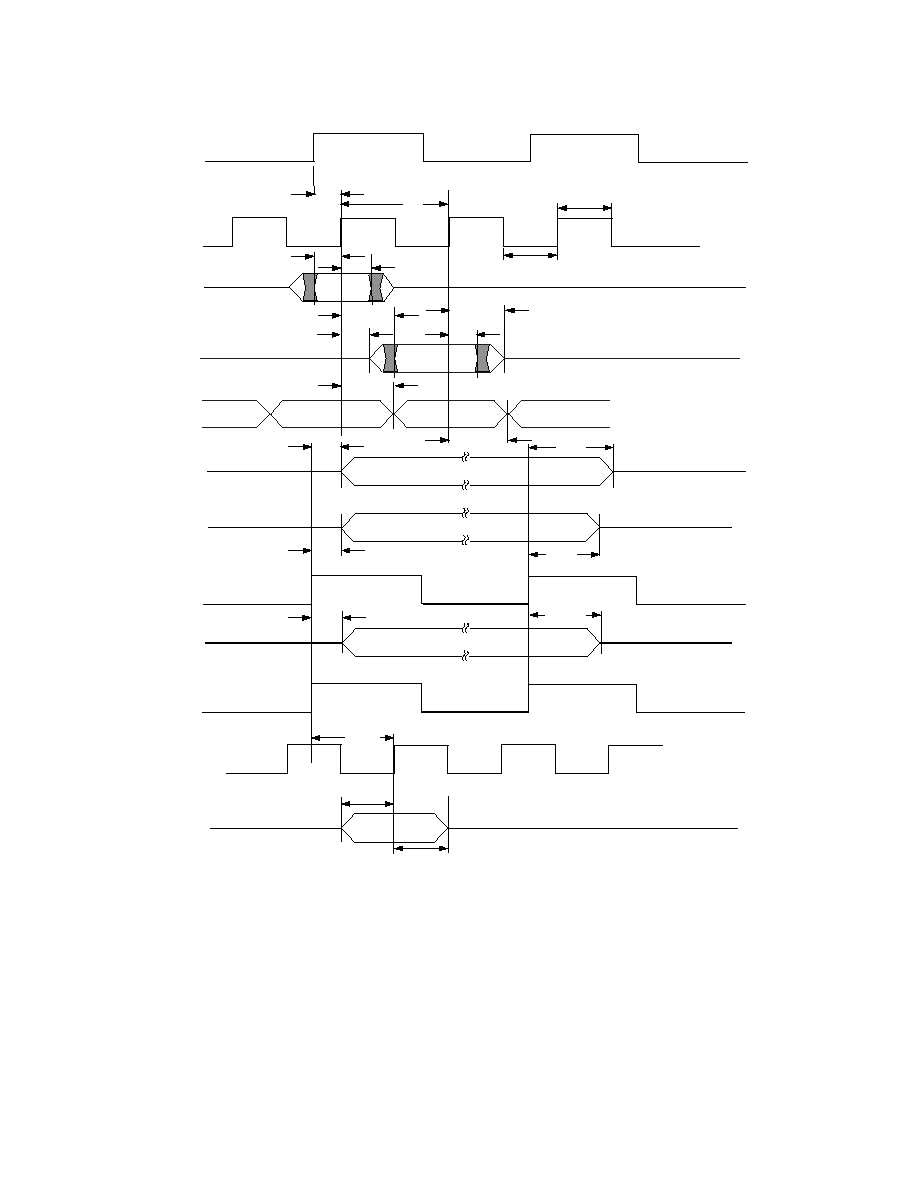

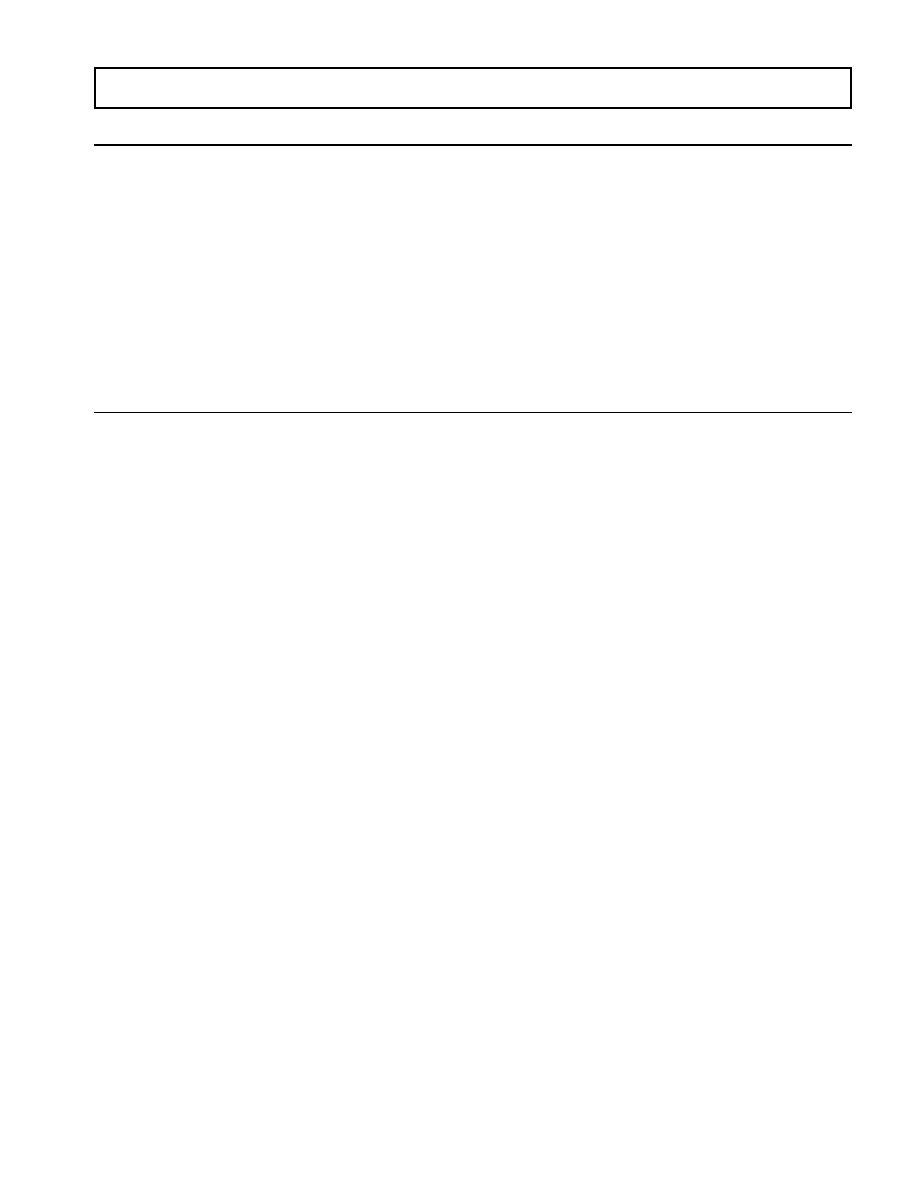

Figure 1

shows a typical single-processor system. A multiprocess-

ing system appears in

Figure 4 on Page 8

.

Figure 1. System Diagram

DMA DEVICE

(OPTIONAL)

DATA

CLKOUT

DMAR2-1

DMAG2-1

ADDR

DATA

HOST

PROCESSOR

INTERFACE

(OPTIONAL)

3

12

CLOCK

CLKIN

XTAL

IRQ2-0

2

CLK_CFG1-0

EBOOT

LBOOT

FLAG11-0

TIMEXP

CLKDBL

RESET

JTAG

7

SBTS

ADSP-21161N

BMS

LINK

DEVICES

(2 MAX)

(OPTIONAL)

LXCLK

LXACK

LXDAT7-0

SCLK0

D0B

D0A

FS0

SERIAL

DEVICE

(OPTIONAL)

CS

BOOT

EPROM

(OPTIONAL)

ADDR

MEMORY

AND

PERIPHERALS

(OPTIONAL)

OE

DATA

CS

RD

RAS

ACK

BR6-1

RPBA

ID2-0

PA

HBG

HBR

SDWE

MS3-0

WR

DATA47-16

DATA

ADDR

CS

ACK

WE

ADDR23-0

D

A

T

A

C

O

N

T

R

O

L

A

D

D

R

E

S

S

BRST

SDRAM

(OPTIONAL)

SCLK1

D1B

D1A

FS1

SERIAL

DEVICE

(OPTIONAL)

SCLK2

D2B

D2A

FS2

SERIAL

DEVICE

(OPTIONAL)

SCLK3

D3B

D3A

FS3

SERIAL

DEVICE

(OPTIONAL)

SPICLK

MISO

MOSI

SPIDS

SPI

COMPATIBLE

DEVICE

(HOST OR SLAVE)

(OPTIONAL)

DATA

CAS

RAS

DQM

WE

ADDR

CS

A10

CKE

CLK

DQM

CAS

REDY

SDCKE

SDA10

SDCLK1-0

RSTOUT

5

REV. A

ADSP-21161N

ADSP-21161N Family Core Architecture

The ADSP-21161N includes the following architectural features

of the ADSP-2116x family core. The ADSP-21161N is code

compatible at the assembly level with the ADSP-21160, ADSP-

21060, ADSP-21061, ADSP-21062, and ADSP-21065L.

SIMD Computational Engine

The ADSP-21161N contains two computational processing

elements that operate as a Single Instruction Multiple Data

(SIMD) engine. The processing elements are referred to as PEX

and PEY, and each contains an ALU, multiplier, shifter, and

register file. PEX is always active, and PEY may be enabled by

setting the PEYEN mode bit in the MODE1 register. When this

mode is enabled, the same instruction is executed in both pro-

cessing elements, but each processing element operates on

different data. This architecture is efficient at executing math

intensive DSP algorithms.

Entering SIMD mode also has an effect on the way data is trans-

ferred between memory and the processing elements. When in

SIMD mode, twice the data bandwidth is required to sustain

computational operation in the processing elements. Because of

this requirement, entering SIMD mode also doubles the

bandwidth between memory and the processing elements. When

using the DAGs to transfer data in SIMD mode, two data values

are transferred with each access of memory or the register file.

SIMD is supported only for internal memory accesses and is not

supported for off-chip accesses.

Independent, Parallel Computation Units

Within each processing element is a set of computational units.

The computational units consist of an arithmetic/logic unit

(ALU), multiplier, and shifter. These units perform single-cycle

instructions. The three units within each processing element are

arranged in parallel, maximizing computational throughput.

Single multifunction instructions execute parallel ALU and mul-

tiplier operations. In SIMD mode, the parallel ALU and

multiplier operations occur in both processing elements. These

computation units support IEEE 32-bit single-precision floating-

point, 40-bit extended precision floating-point, and 32-bit

fixed-point data formats.

Data Register File

A general-purpose data register file is contained in each process-

ing element. The register files transfer data between the

computation units and the data buses, and store intermediate

results. These 10-port, 32-register (16 primary, 16 secondary)

register files, combined with the ADSP-2116x enhanced Harvard

architecture, allow unconstrained data flow between computa-

tion units and internal memory. The registers in PEX are referred

to as R0

R15 and in PEY as S0

S15.

Single-Cycle Fetch of Instruction and Four Operands

The ADSP-21161N features an enhanced Harvard architecture

in which the data memory (DM) bus transfers data and the

program memory (PM) bus transfers both instructions and data

(see

Figure 1 on Page 4

). With the ADSP-21161N's separate

program and data memory buses and on-chip instruction cache,

the processor can simultaneously fetch four operands (two over

each data bus) and an instruction (from the cache), all in a

single cycle.

Instruction Cache

The ADSP-21161N includes an on-chip instruction cache that

enables three-bus operation for fetching an instruction and four

data values. The cache is selective--only the instructions whose

fetches conflict with PM bus data accesses are cached. This cache

enables full-speed execution of core, looped operations such as

digital filter multiply-accumulates, and FFT butterfly processing.

Data Address Generators With Hardware Circular

Buffers

The ADSP-21161N's two data address generators (DAGs) are

used for indirect addressing and implementing circular data

buffers in hardware. Circular buffers allow efficient programming

of delay lines and other data structures required in digital signal

processing, and are commonly used in digital filters and Fourier

transforms. The two DAGs of the ADSP-21161N contain suffi-

cient registers to allow the creation of up to 32 circular buffers

(16 primary register sets, 16 secondary). The DAGs automati-

cally handle address pointer wrap-around, reduce overhead,

increase performance, and simplify implementation. Circular

buffers can start and end at any memory location.

Flexible Instruction Set

The 48-bit instruction word accommodates a variety of parallel

operations, for concise programming. For example, the ADSP-

21161N can conditionally execute a multiply, an add, and a

subtract in both processing elements, while branching, all in a

single instruction.

ADSP-21161N Memory and I/O Interface Features

The ADSP-21161N adds the following architectural features to

the ADSP-2116x family core:

Dual-Ported On-Chip Memory

The ADSP-21161N contains one megabit of on-chip SRAM,

organized as two blocks of 0.5 M bits. Each block can be config-

ured for different combinations of code and data storage. Each

memory block is dual-ported for single-cycle, independent

accesses by the core processor and I/O processor. The dual-

ported memory in combination with three separate on-chip buses

allow two data transfers from the core and one from the I/O

processor, in a single cycle. On the ADSP-21161N, the memory

can be configured as a maximum of 32K words of 32-bit data,

64K words of 16-bit data, 21K words of 48-bit instructions (or

40-bit data), or combinations of different word sizes up to one

megabit. All of the memory can be accessed as 16-bit, 32-bit,

48-bit, or 64-bit words. A 16-bit floating-point storage format is

supported that effectively doubles the amount of data that may

be stored on-chip. Conversion between the 32-bit floating-point

and 16-bit floating-point formats is done in a single instruction.

While each memory block can store combinations of code and

data, accesses are most efficient when one block stores data using

the DM bus for transfers, and the other block stores instructions

and data using the PM bus for transfers. Using the DM bus and

ADSP-21161N

6

REV. A

PM bus, with one dedicated to each memory block, assures

single-cycle execution with two data transfers. In this case, the

instruction must be available in the cache.

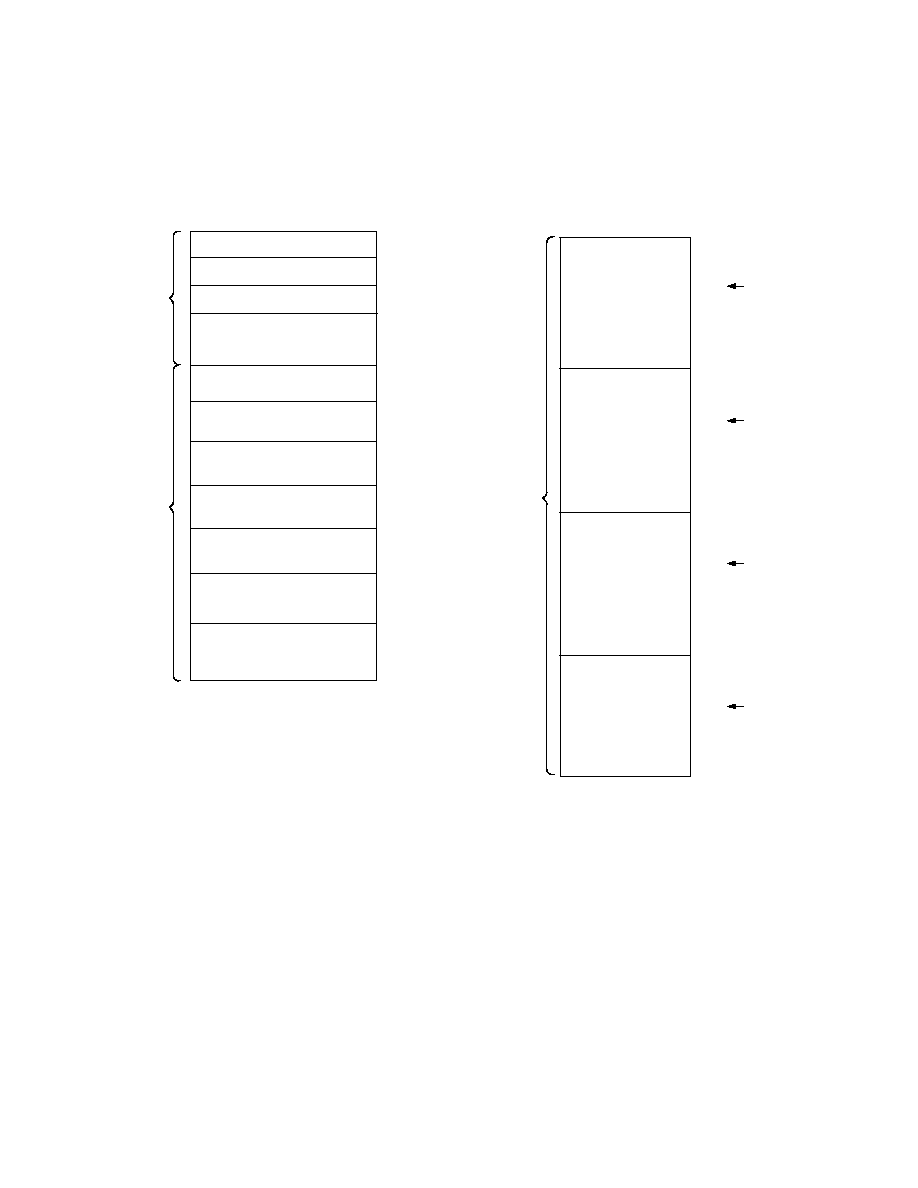

Off-Chip Memory and Peripherals Interface

The ADSP-21161N's external port provides the processor's

interface to off-chip memory and peripherals. The 62.7-M word

off-chip address space (254.7-M word if all SDRAM) is included

in the ADSP-21161N's unified address space. The separate on-

chip buses--for PM addresses, PM data, DM addresses, DM

data, I/O addresses, and I/O data--are multiplexed at the external

port to create an external system bus with a single 24-bit address

bus and a single 32-bit data bus. Every access to external memory

is based on an address that fetches a 32-bit word. When fetching

an instruction from external memory, two 32-bit data locations

are being accessed for packed instructions. Unused link port lines

can also be used as additional data lines DATA15

DATA0,

allowing single-cycle execution of instructions from external

memory, at up to 100 MHz.

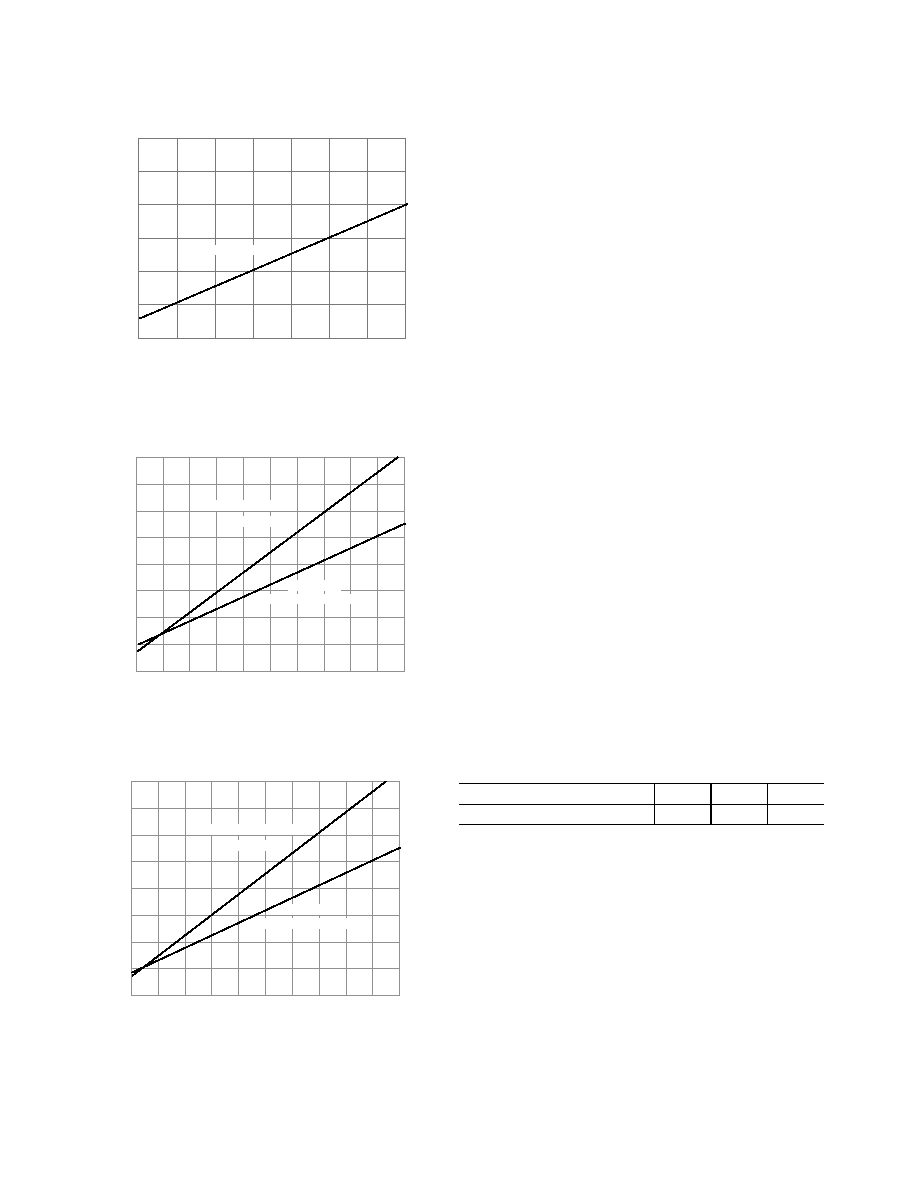

Figure 3 on Page 7

shows the

alignment of various accesses to external memory.

The external port supports asynchronous, synchronous, and syn-

chronous burst accesses. Synchronous burst SRAM can be

interfaced gluelessly. The ADSP-21161N also can interface glue-

lessly to SDRAM. Addressing of external memory devices is

facilitated by on-chip decoding of high-order address lines to

generate memory bank select signals. The ADSP-21161N

provides programmable memory wait states and external

memory acknowledge controls to allow interfacing to memory

and peripherals with variable access, hold, and disable time

requirements.

SDRAM Interface

The SDRAM interface enables the ADSP-21161N to transfer

data to and from synchronous DRAM (SDRAM) at the core

clock frequency or at one-half the core clock frequency. The

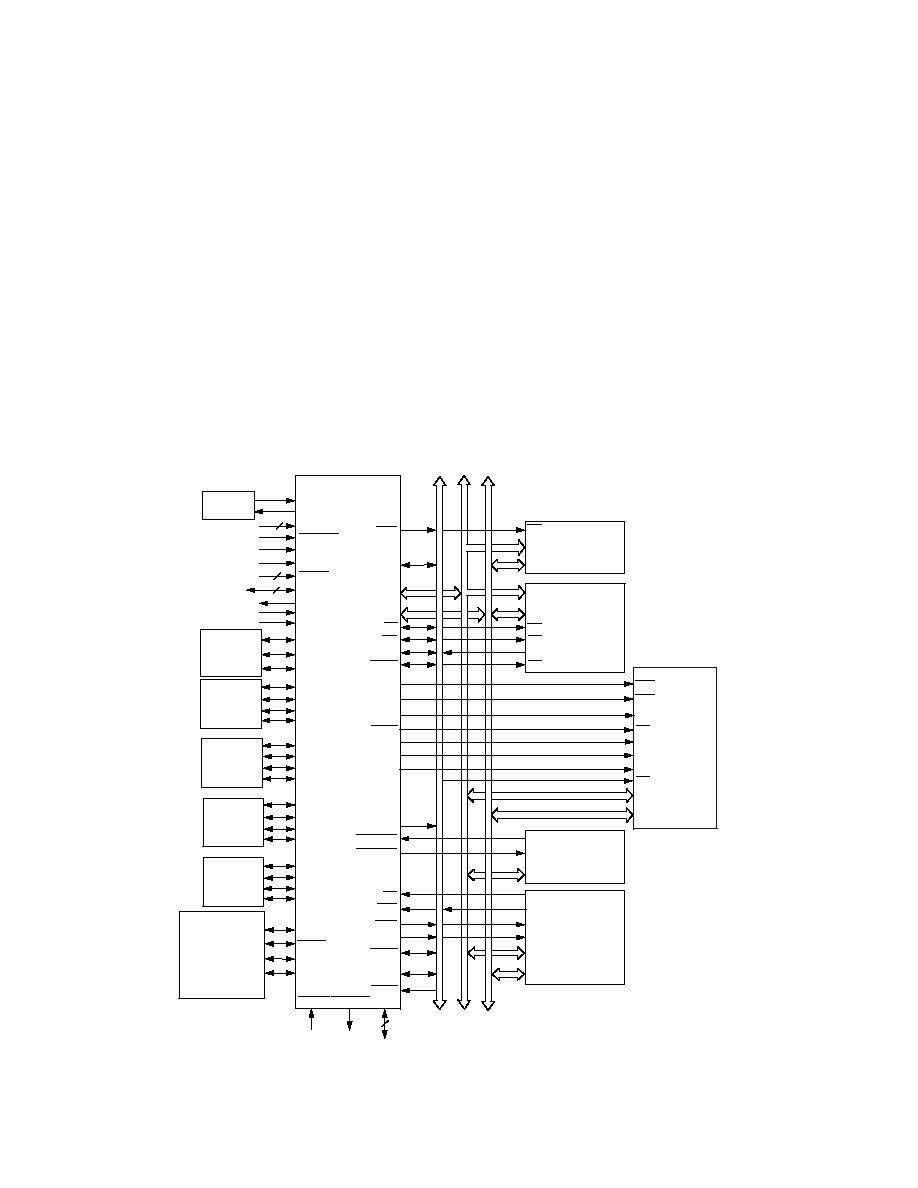

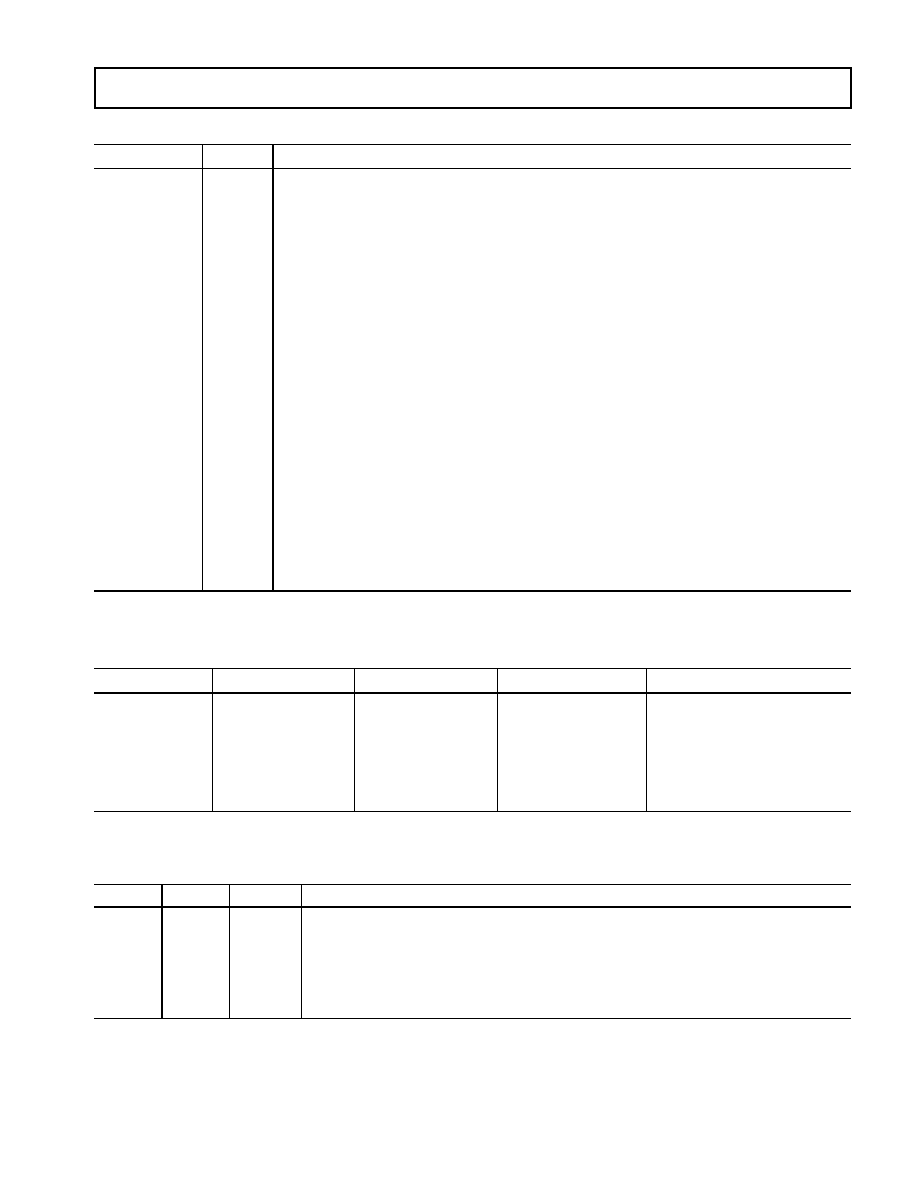

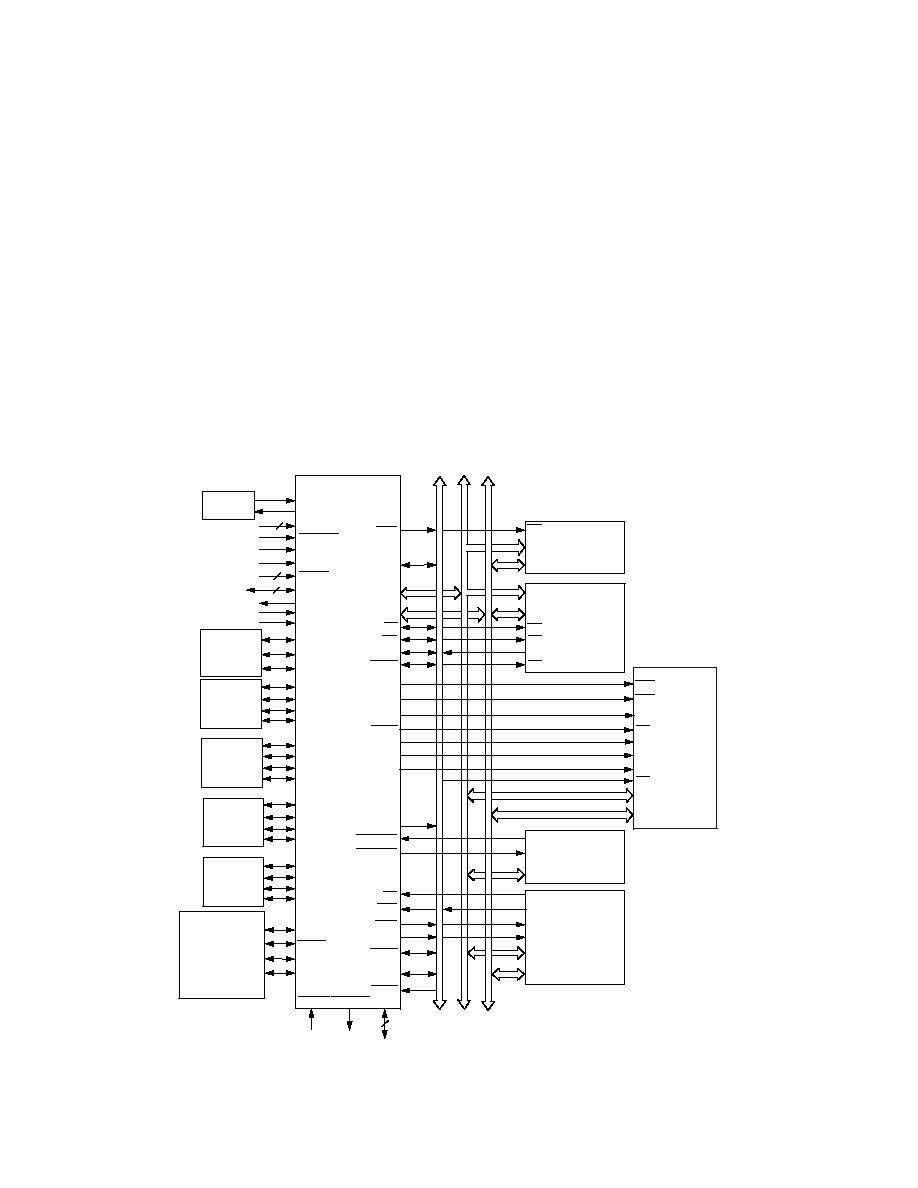

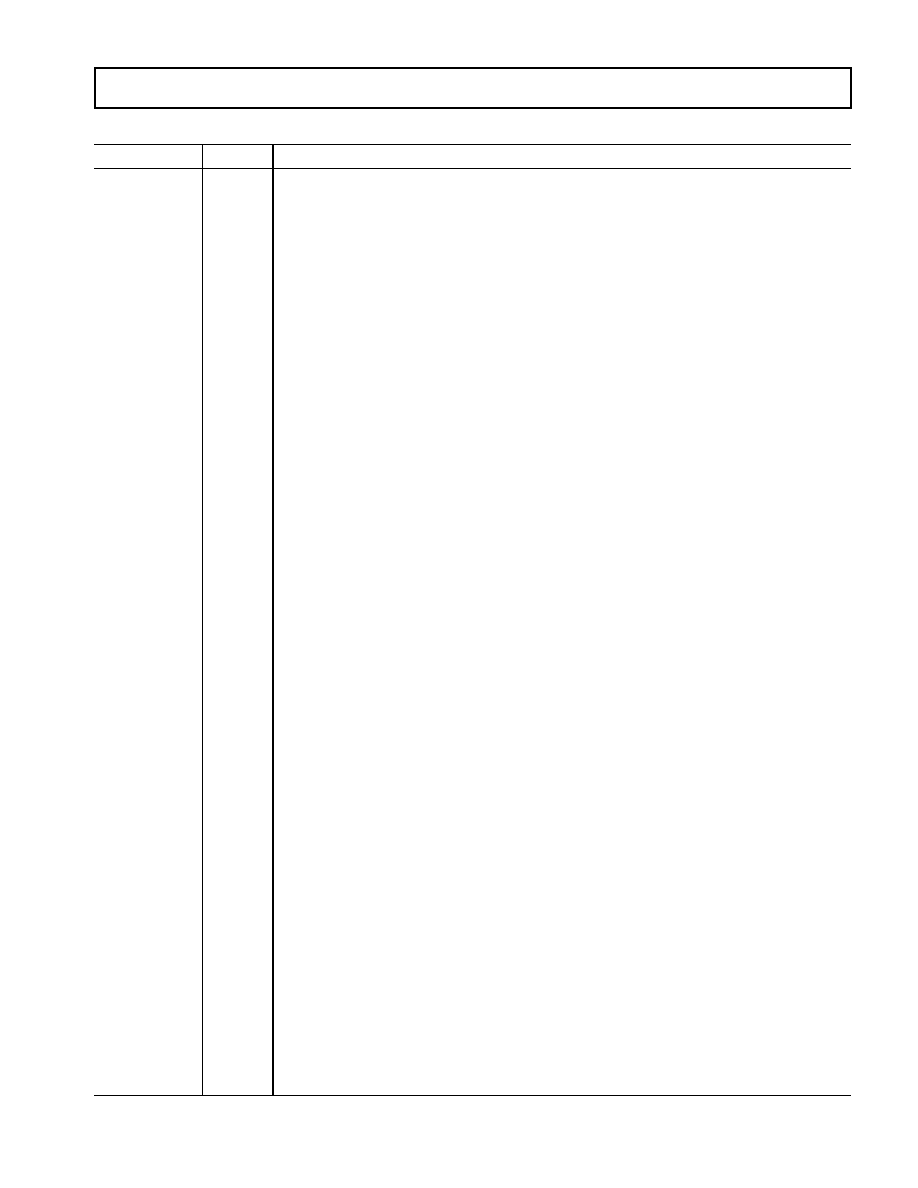

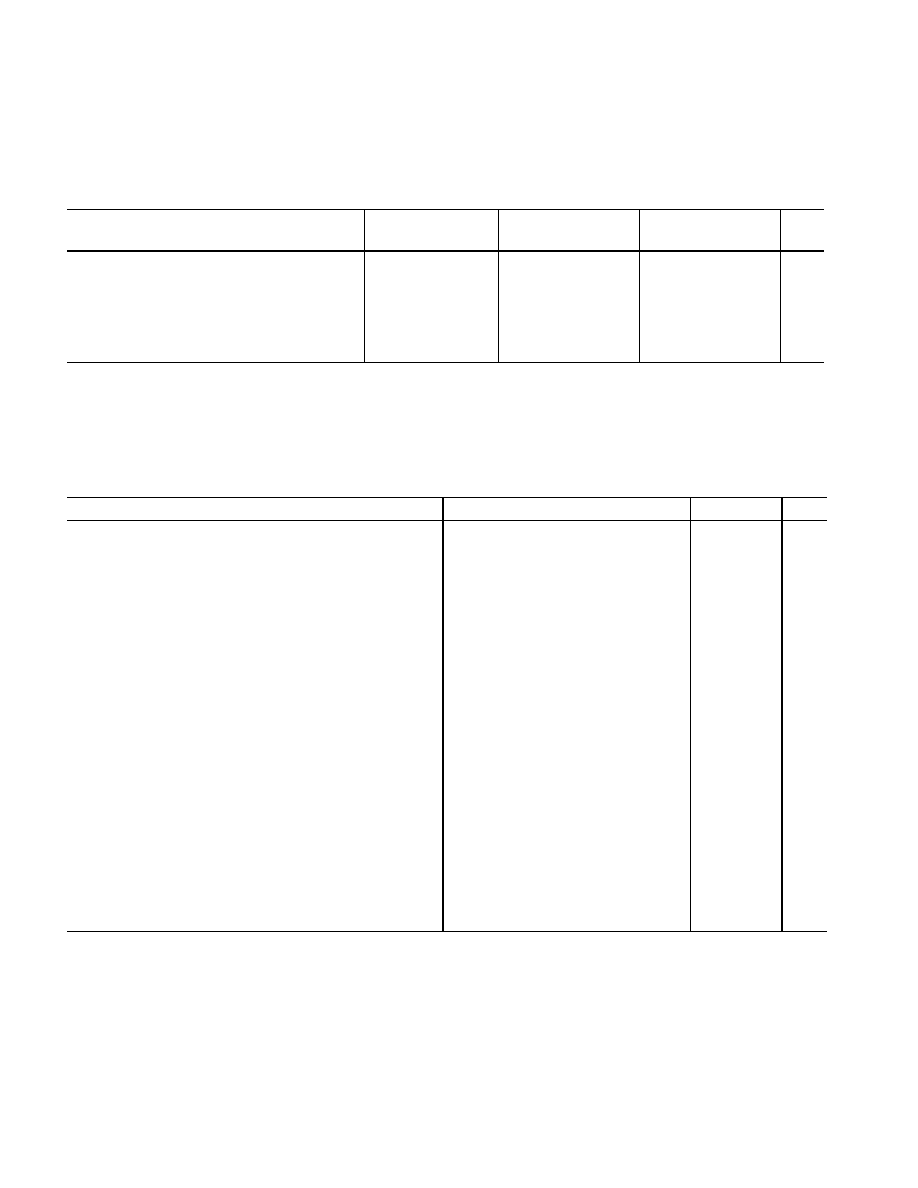

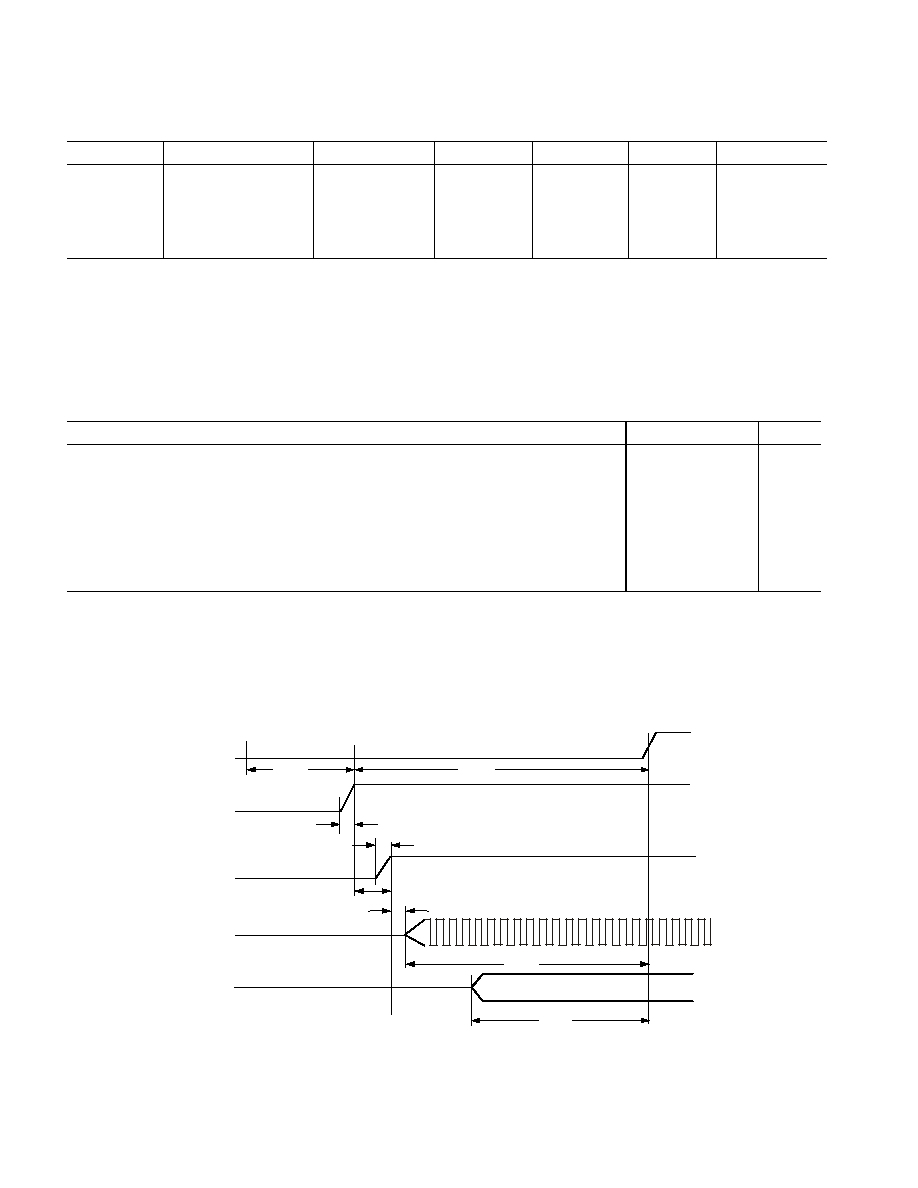

Figure 2. Memory Map

0x000A 0000 - 0x000A 7FFF (BLK 1)

0x0002 8000 - 0x0002 9FFF (BLK 1)

0x0005 0000 - 0x0005 3FFF (BLK 1)

0x0010 0000 - 0x0011 FFFF

0x0004 0000 - 0x0004 3FFF (BLK 0)

0x0008 0000 - 0x0008 7FFF (BLK 0)

0x0012 0000 - 0x0013 FFFF

0x0014 0000 - 0x0015 FFFF

0x0016 0000 - 0x0017 FFFF

0x001A 0000 - 0x001B FFFF

0x0000 0000 - 0x0001 FFFF

0x0002 0000 - 0x0002 1FFF (BLK 0)

0x0020 0000

BANK 1

MS0

BANK 2

MS1

BANK 3

MS2

MS3

IOP REGISTERS

LONG WORD ADDRESSING

SHORT WORD ADDRESSING

NORMAL WORD ADDRESSING

ADDRESS

BANK 0

0x03FF FFFF (SDRAM)

0x00FF FFFF (NON-SDRAM)

0x0400 0000

0x07FF FFFF (SDRAM)

0x04FF FFFF (NON-SDRAM)

0x0800 0000

0x0BFF FFFF (SDRAM)

0x08FF FFFF (NON-SDRAM)

0x0C00 0000

0x0FFF FFFF (SDRAM)

0x0CFF FFFF (NON-SDRAM)

NOTE: BANK SIZES ARE FIXED

0x0018 0000 - 0x0019 FFFF

INTERNAL

MEMORY

SPACE

MULTIPROCESSOR

MEMORY

SPACE

ADDRESS

IOP REGISTERS OF ADSP-21161N

WITH ID = 001

IOP REGISTERS OF ADSP-21161N

WITH ID = 010

IOP REGISTERS OF ADSP-21161N

WITH ID = 011

IOP REGISTERS OF ADSP-21161N

WITH ID = 100

IOP REGISTERS OF ADSP-21161N

WITH ID = 101

IOP REGISTERS OF ADSP-21161N

WITH ID = 110

RESERVED

0

x

001C 0000

0

x

001F FFFF

EXTERNAL MEMORY SPACE

7

REV. A

ADSP-21161N

synchronous approach, coupled with the core clock frequency,

supports data transfer at a high throughput--up to 400 M bytes/s

for 32-bit transfers and 600 M bytes/s for 48-bit transfers.

The SDRAM interface provides a glueless interface with

standard SDRAMs--16 Mb, 64 Mb, 128 Mb, and 256 Mb--

and includes options to support additional buffers between the

ADSP-21161N and SDRAM. The SDRAM interface is

extremely flexible and provides capability for connecting

SDRAMs to any one of the ADSP-21161N's four external

memory banks, with up to all four banks mapped to SDRAM.

Systems with several SDRAM devices connected in parallel may

require buffering to meet overall system timing requirements.

The ADSP-21161N supports pipelining of the address and

control signals to enable such buffering between itself and

multiple SDRAM devices.

Target Board JTAG Emulator Connector

Analog Devices DSP Tools product line of JTAG emulators uses

the IEEE 1149.1 JTAG test access port of the ADSP-21161N

processor to monitor and control the target board processor

during emulation. Analog Devices DSP Tools product line of

JTAG emulators provides emulation at full processor speed,

allowing inspection and modification of memory, registers, and

processor stacks. The processor's JTAG interface ensures that the

emulator will not affect target system loading or timing.

For complete information on SHARC Analog Devices DSP

Tools product line of JTAG emulator operation, see the appro-

priate Emulator Hardware User's Guide. For detailed infor-

mation on the interfacing of Analog Devices JTAG emulators

with Analog Devices DSP products with JTAG emulation ports,

please refer to Engineer to Engineer Note EE-68: Analog Devices

JTAG Emulation Technical Reference. Both of these documents can

be found on the Analog Devices website:

http://www.analog.com/dsp/tech_docs.html

DMA Controller

The ADSP-21161N's on-chip DMA controller enables zero-

overhead data transfers without processor intervention. The

DMA controller operates independently and invisibly to the

processor core, allowing DMA operations to occur while the core

is simultaneously executing its program instructions. DMA

transfers can occur between the ADSP-21161N's internal

memory and external memory, external peripherals, or a host

processor. DMA transfers can also occur between the ADSP-

21161N's internal memory and its serial ports, link ports, or the

SPI-compatible (Serial Peripheral Interface) port. External bus

packing and unpacking of 32-, 48-, or 64-bit words in internal

memory is performed during DMA transfers from either 8-,

16-, or 32-bit wide external memory. Fourteen channels of DMA

are available on the ADSP-21161N--two are shared between the

SPI interface and the link ports, eight via the serial ports, and

four via the processor's external port (for host processor, other

ADSP-21161Ns, memory, or I/O transfers). Programs can be

downloaded to the ADSP-21161N using DMA transfers. Asyn-

chronous off-chip peripherals can control two DMA channels

using DMA Request/Grant lines (

DMAR21, DMAG21).

Other DMA features include interrupt generation upon comple-

tion of DMA transfers, and DMA chaining for automatic linked

DMA transfers.

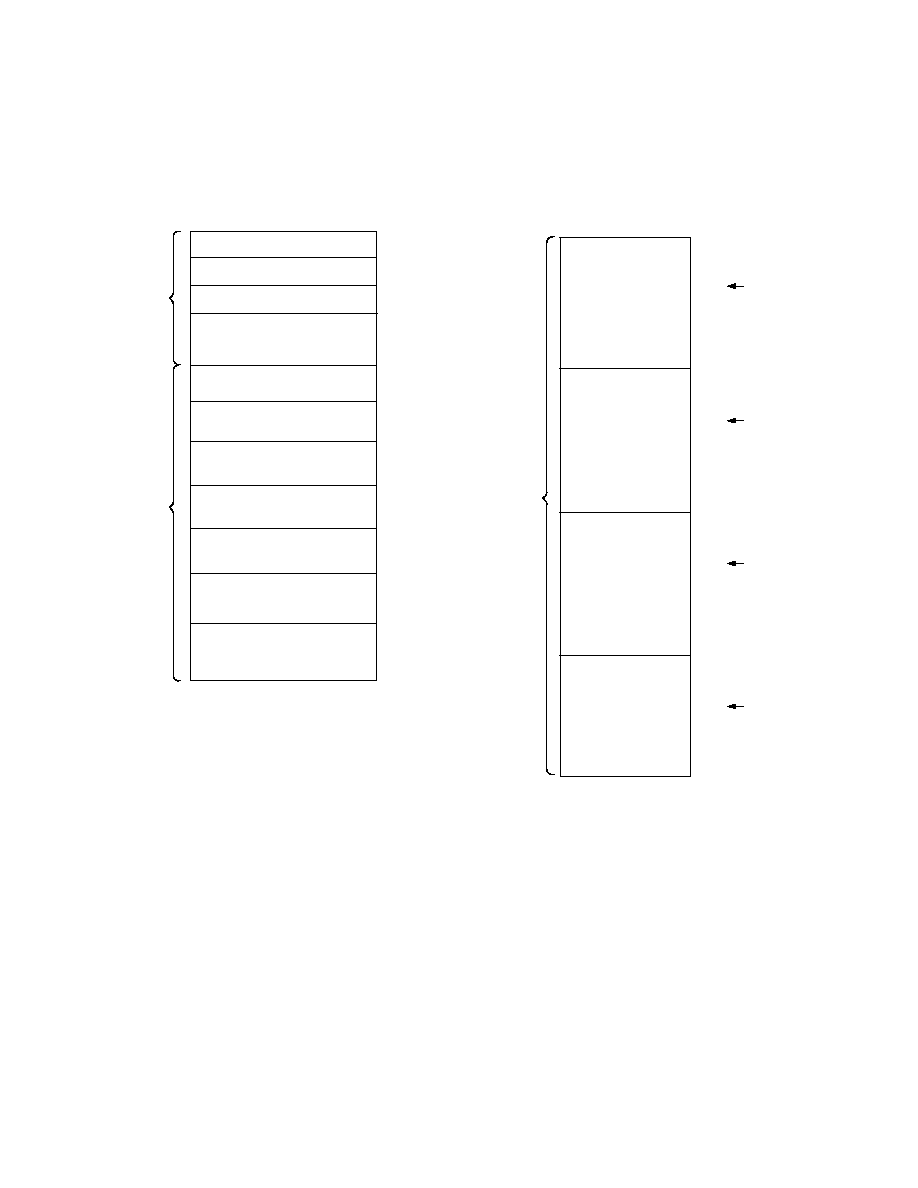

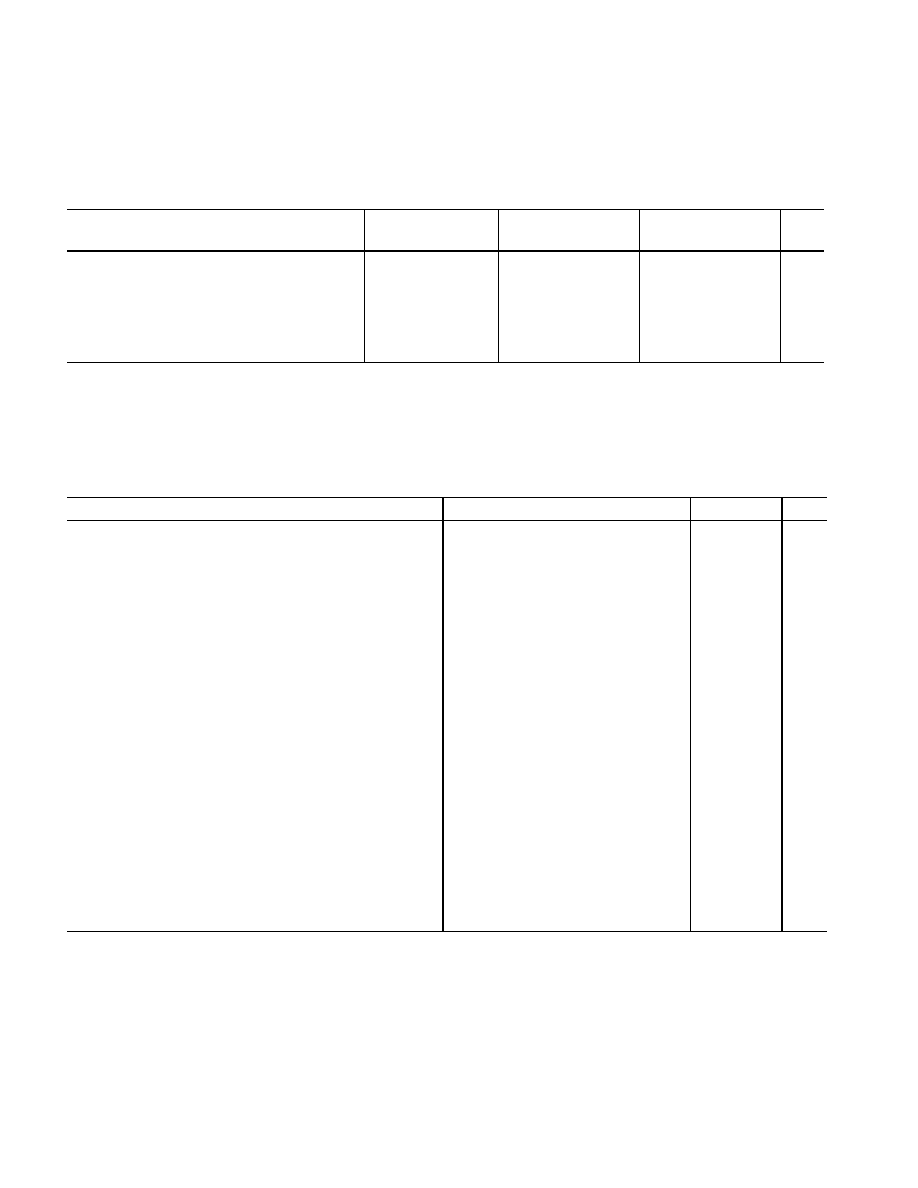

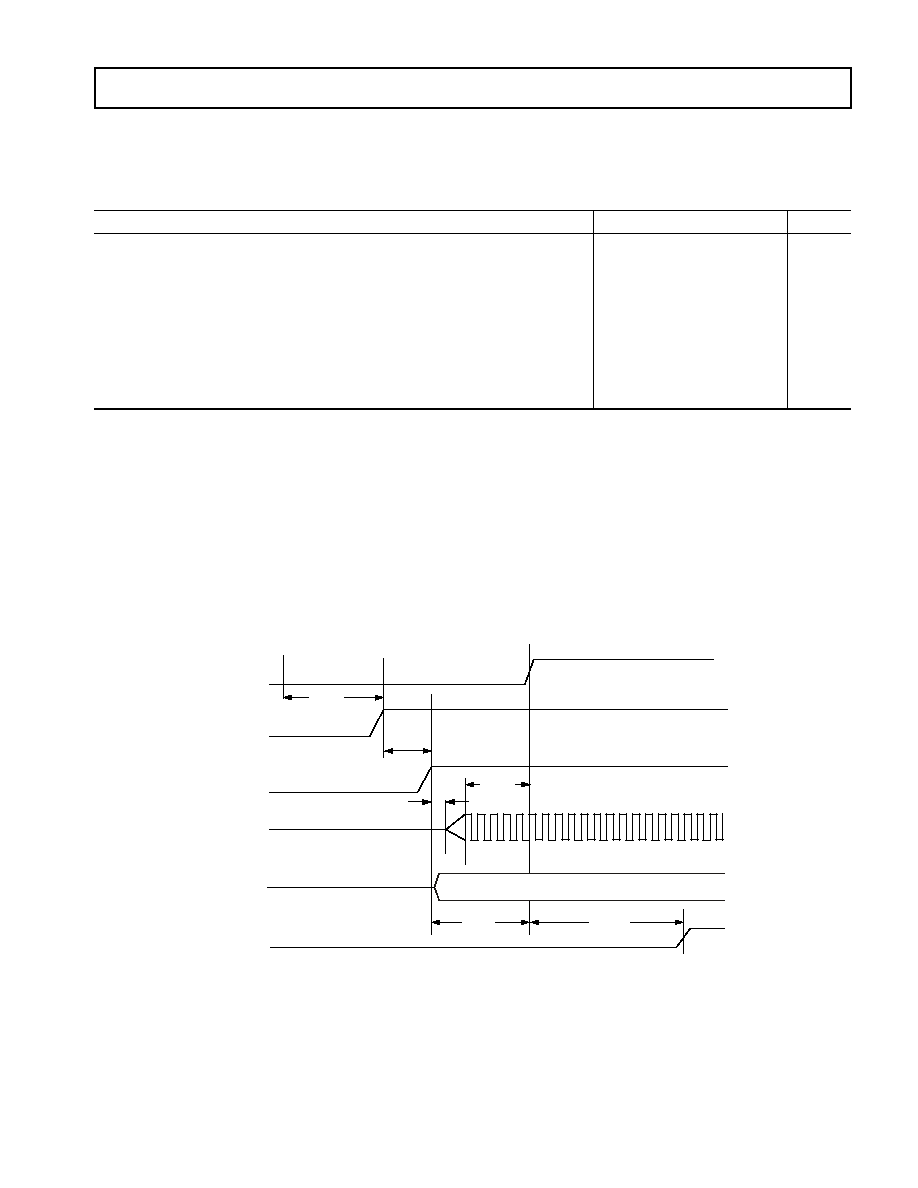

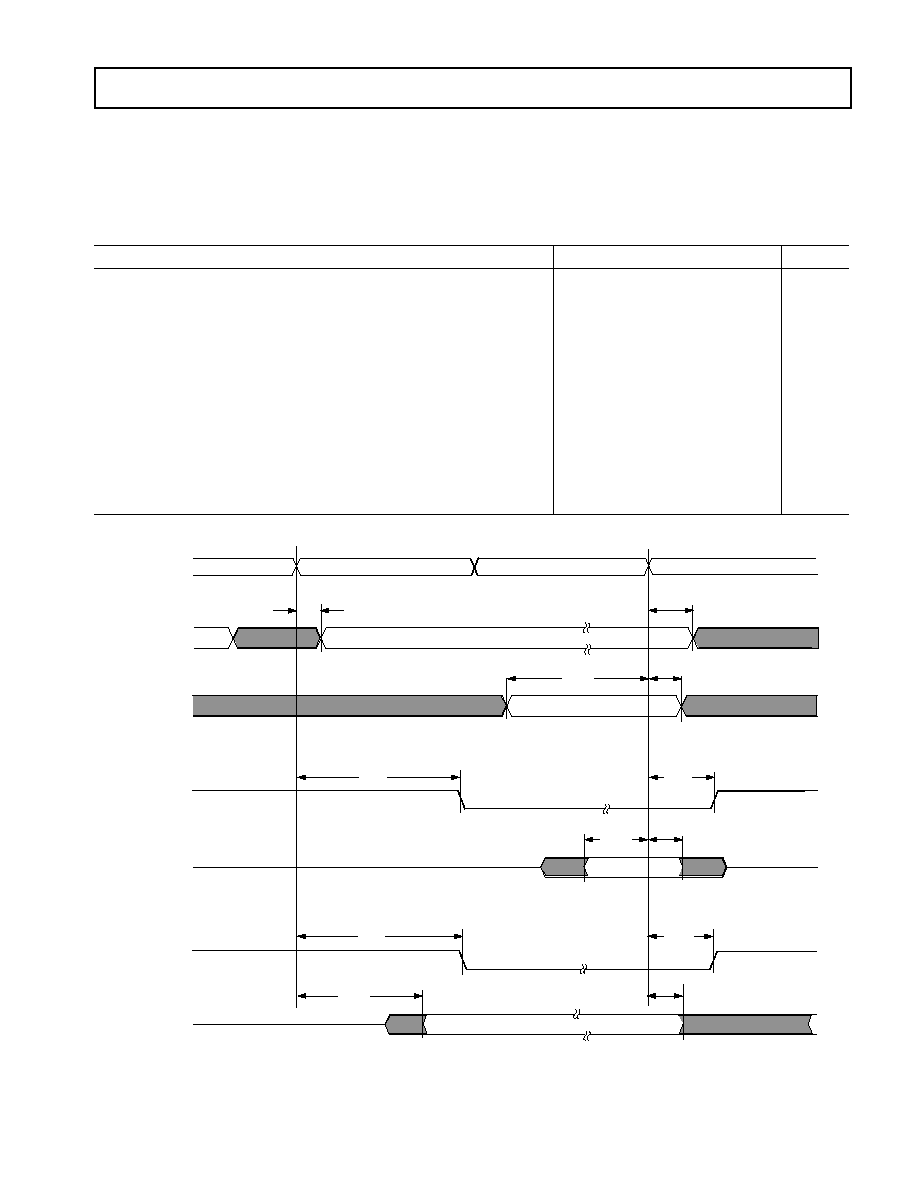

Multiprocessing

The ADSP-21161N offers powerful features tailored to

multiprocessing DSP systems. The external port and link ports

provide integrated glueless multiprocessing support.

The external port supports a unified address space (see

Figure 2

on Page 6

) that enables direct interprocessor accesses of each

ADSP-21161N's internal memory-mapped (I/O processor) reg-

isters. All other internal memory can be indirectly accessed via

DMA transfers initiated via the programming of the IOP DMA

parameter and control registers. Distributed bus arbitration logic

is included on-chip for simple, glueless connection of systems

containing up to six ADSP-21161Ns and a host processor.

Master processor change over incurs only one cycle of overhead.

Bus arbitration is selectable as either fixed or rotating priority.

Bus lock enables indivisible read-modify-write sequences for

semaphores. A vector interrupt is provided for interprocessor

commands. Maximum throughput for interprocessor data

transfer is 400 M bytes/s over the external port.

Two link ports provide a second method of multiprocessing com-

munications. Each link port can support communications to

another ADSP-21161N. The ADSP-21161N, running at

100 MHz, has a maximum throughput for interprocessor com-

munications over the links of 200 M bytes/s. The link ports and

cluster multiprocessing can be used concurrently or

independently.

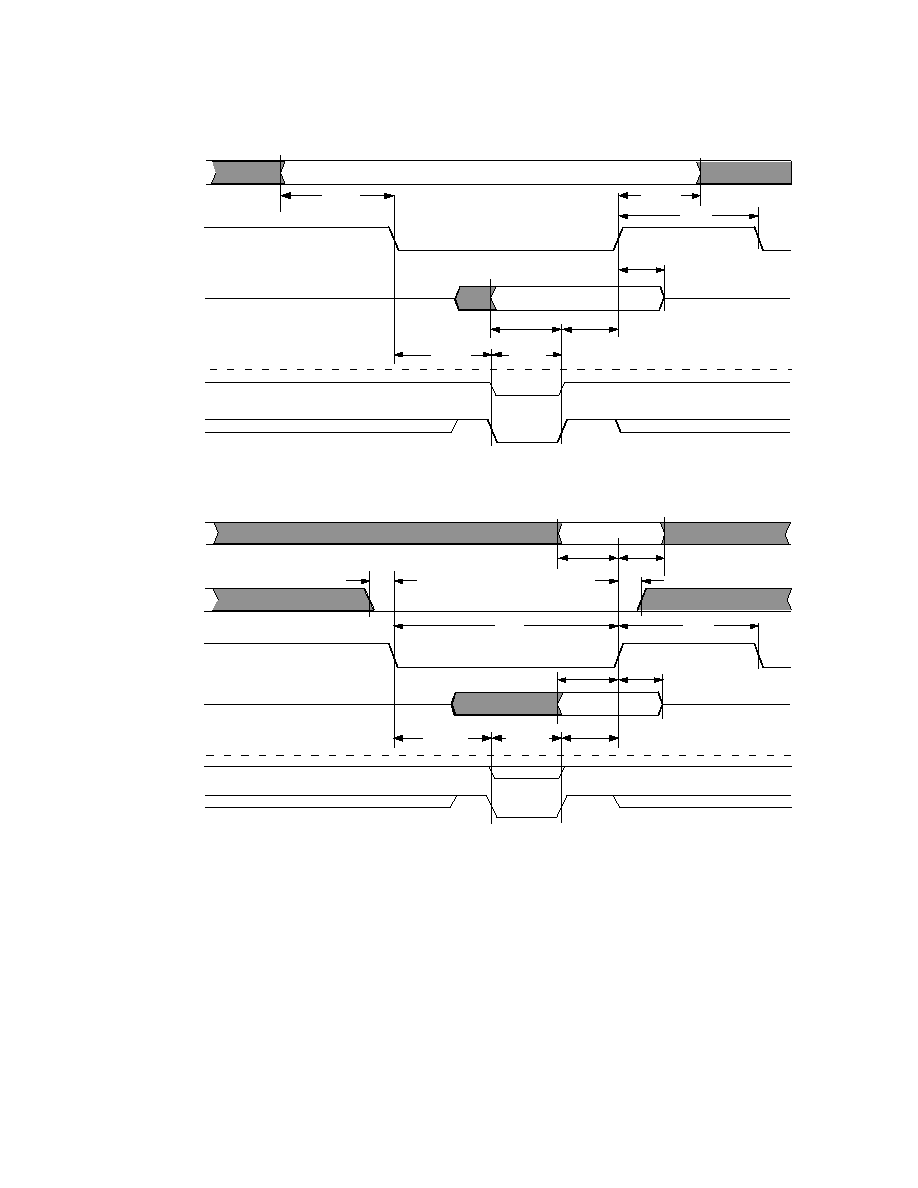

Link Ports

The ADSP-21161N features two 8-bit link ports that provide

additional I/O capabilities. With the capability of running at

100 MHz, each link port can support 100 M bytes/s. Link port

I/O is especially useful for point-to-point interprocessor commu-

nication in multiprocessing systems. The link ports can operate

independently and simultaneously, with a maximum data

throughput of 200 M bytes/s. Link port data is packed into

48- or 32-bit words and can be directly read by the core processor

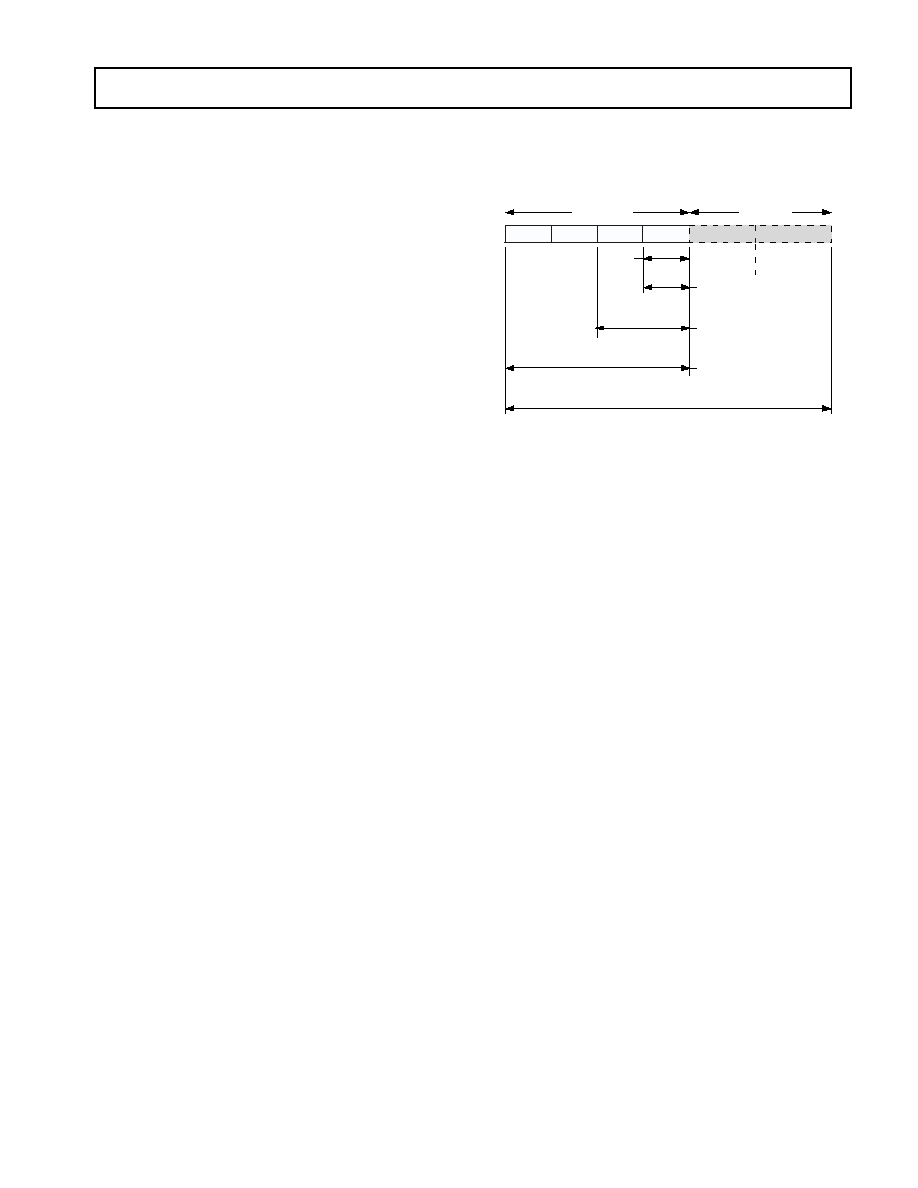

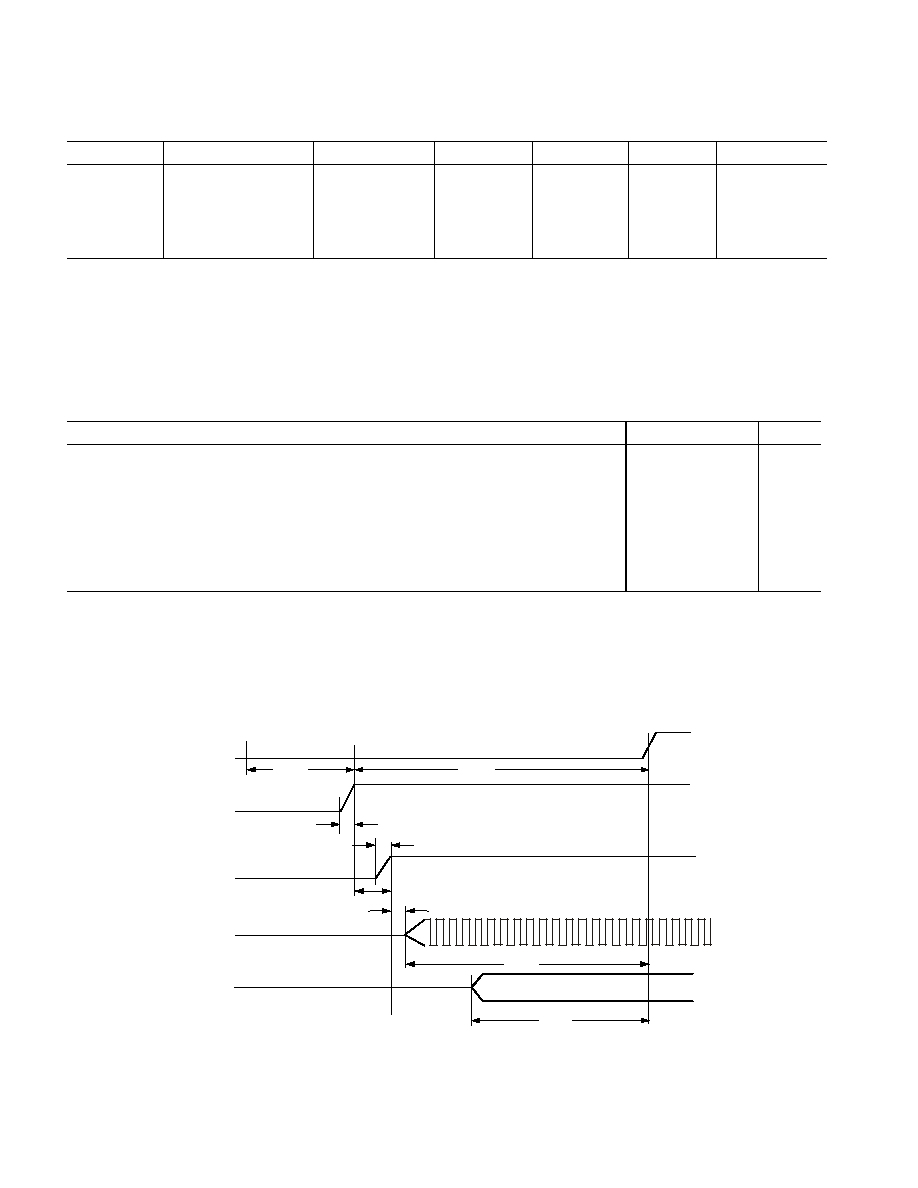

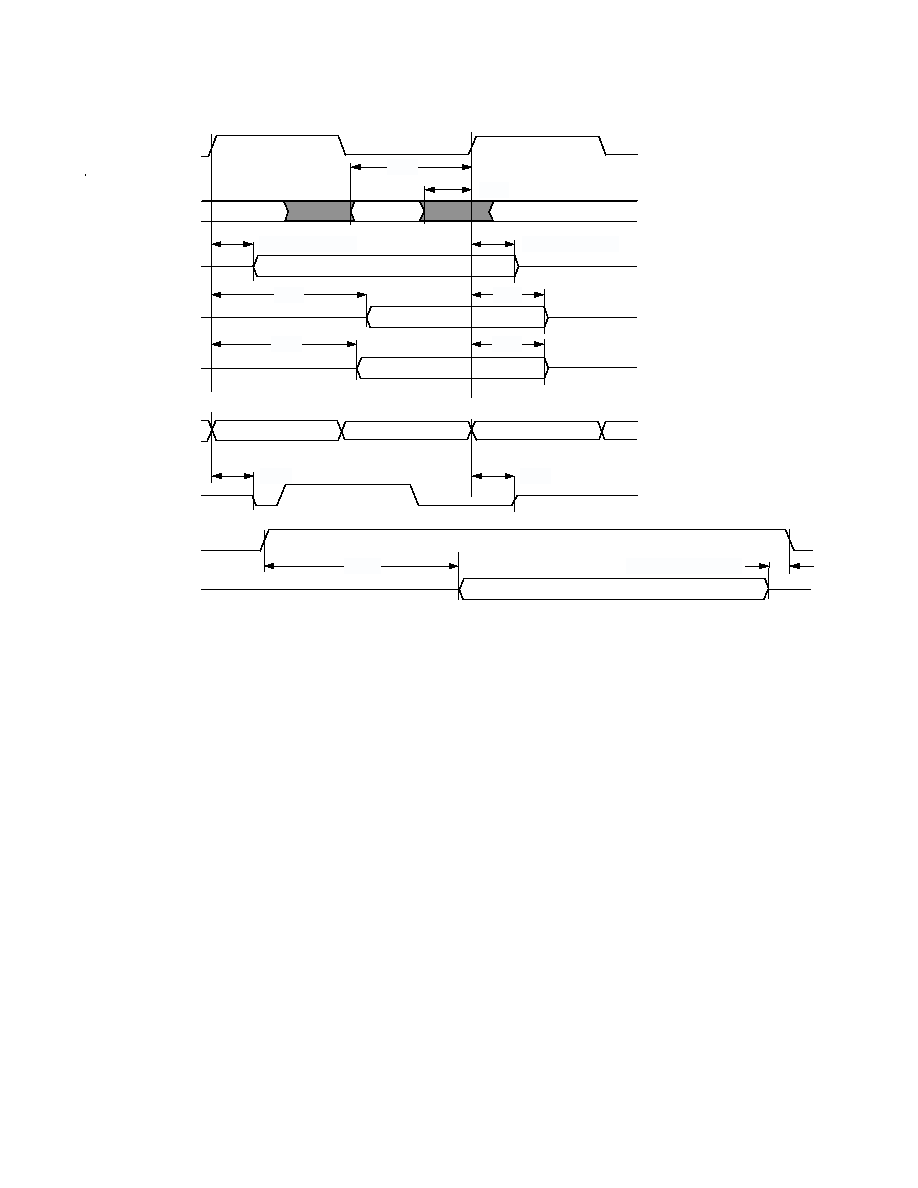

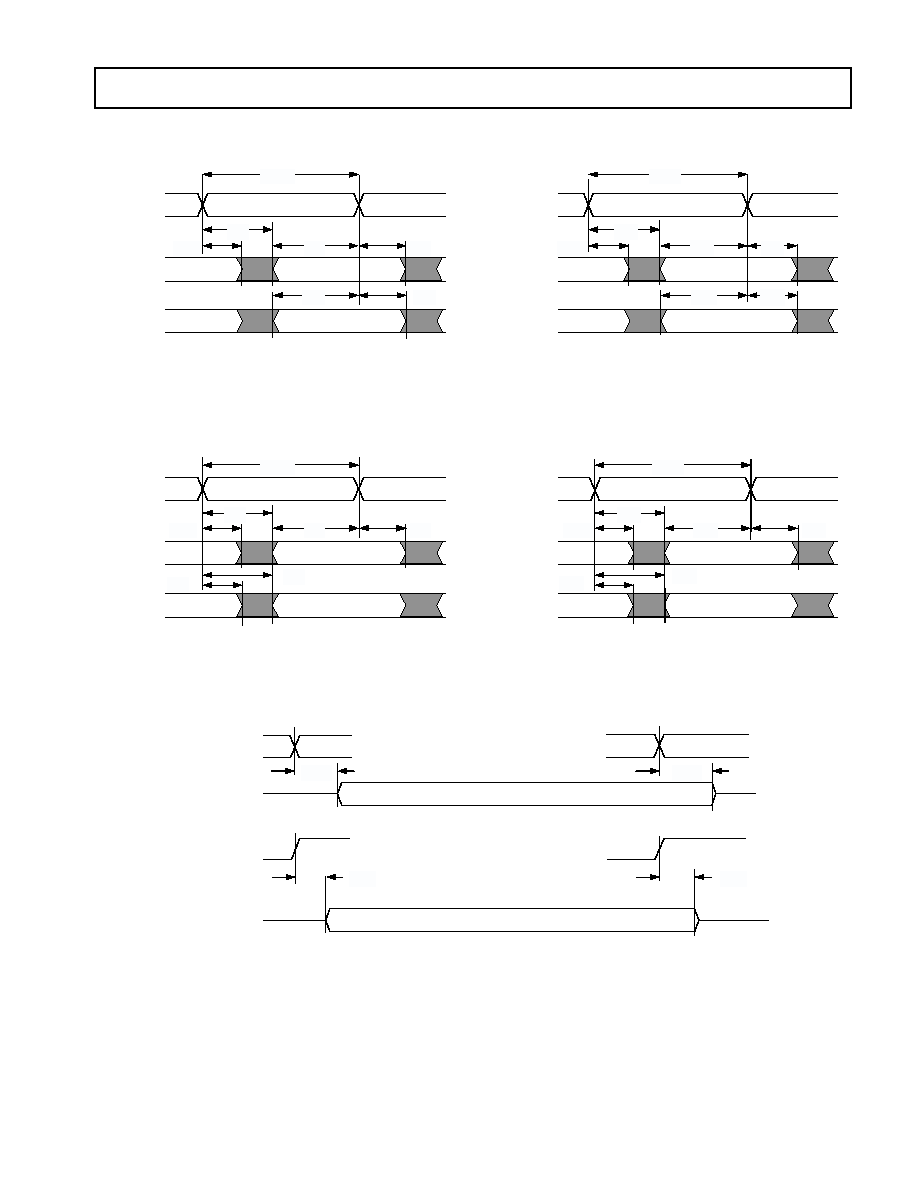

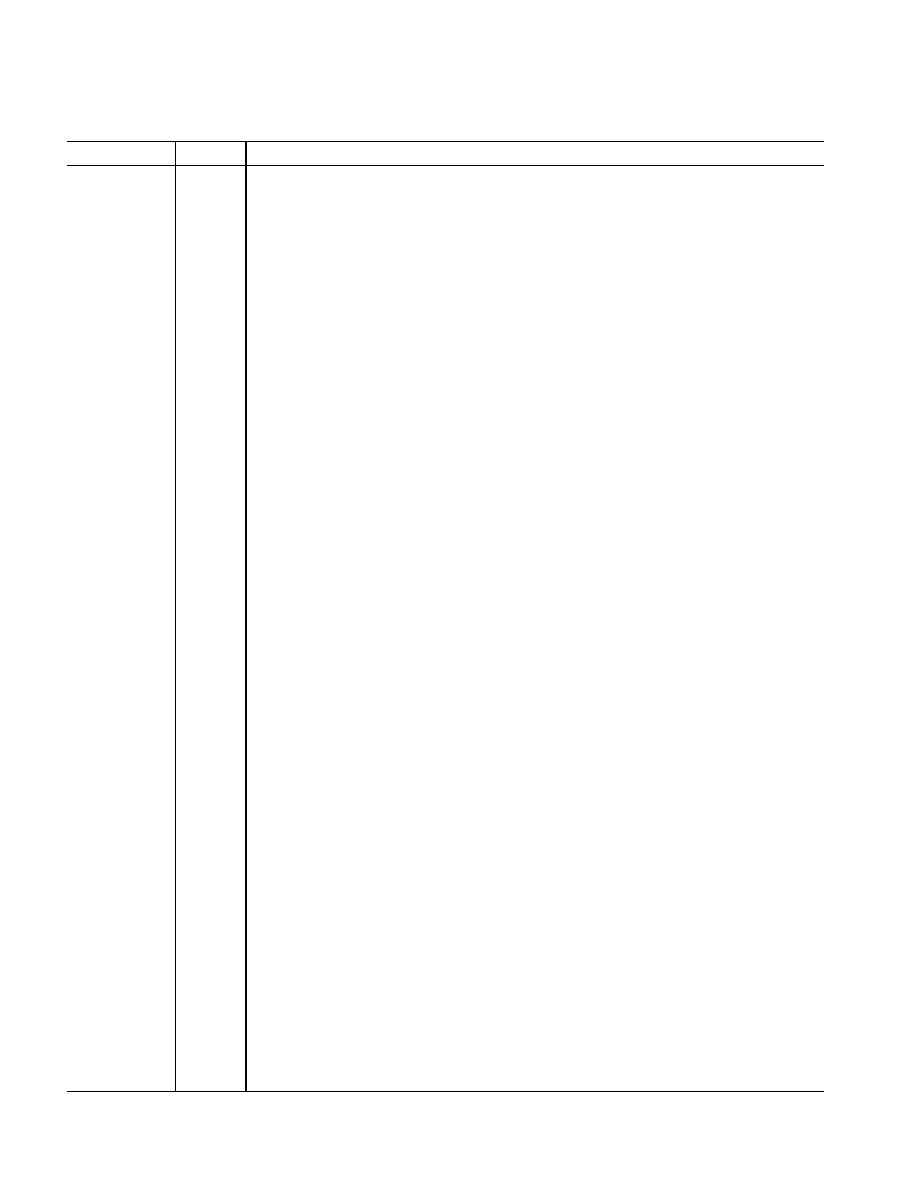

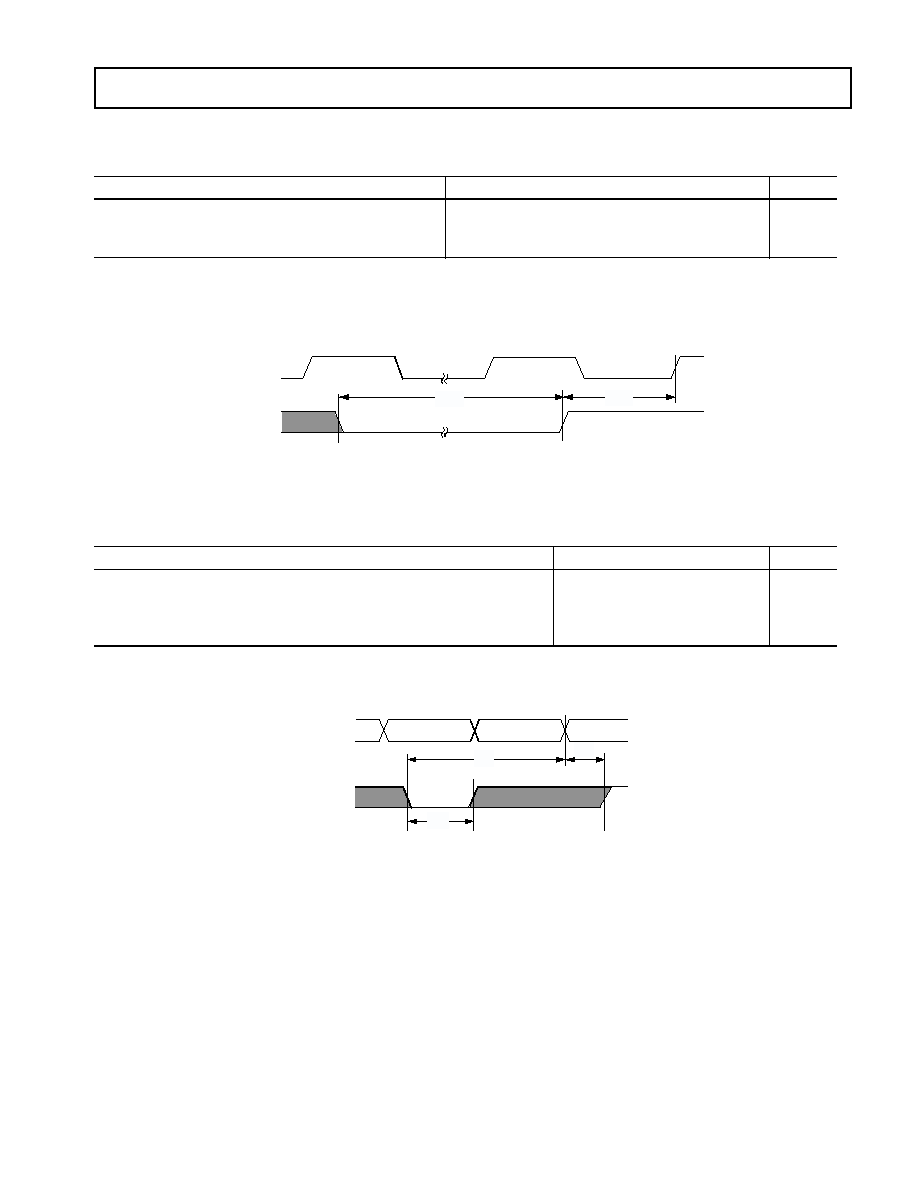

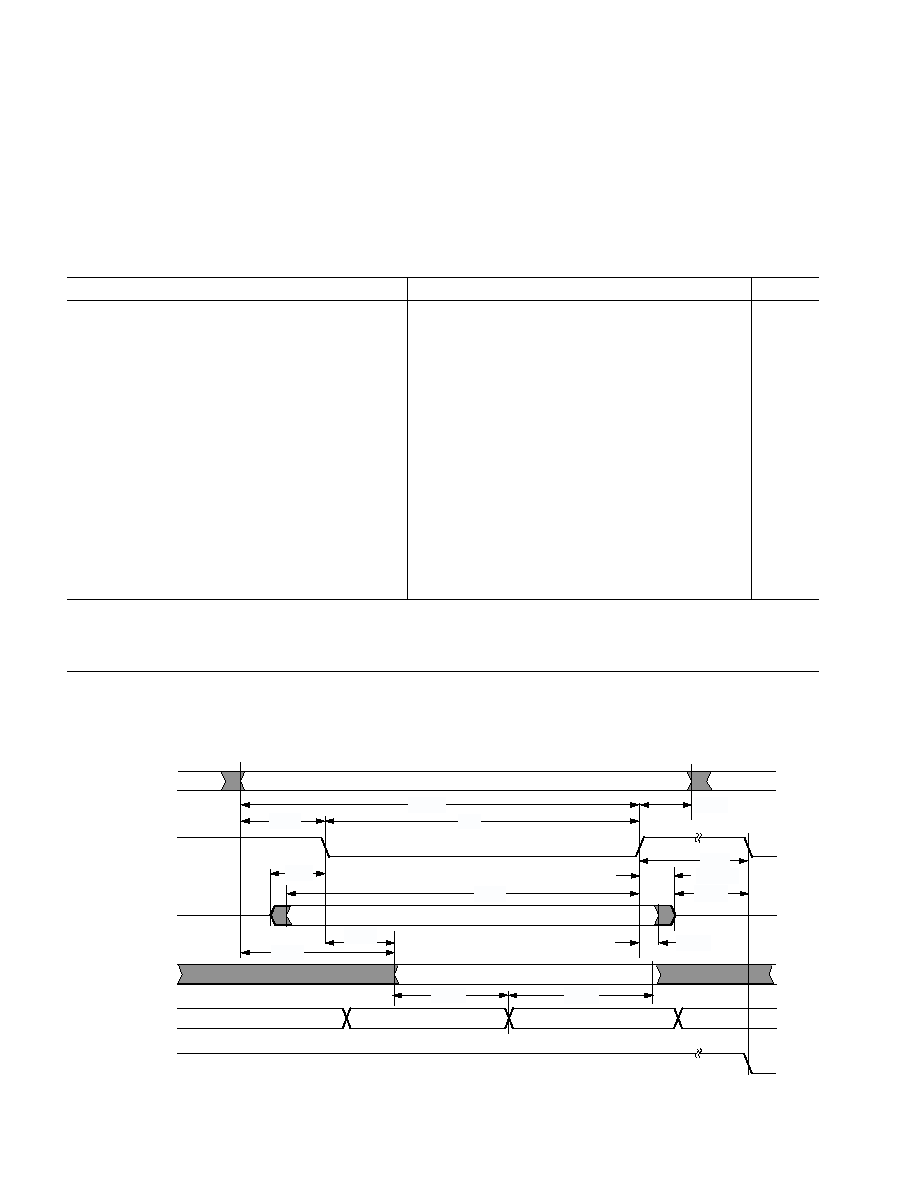

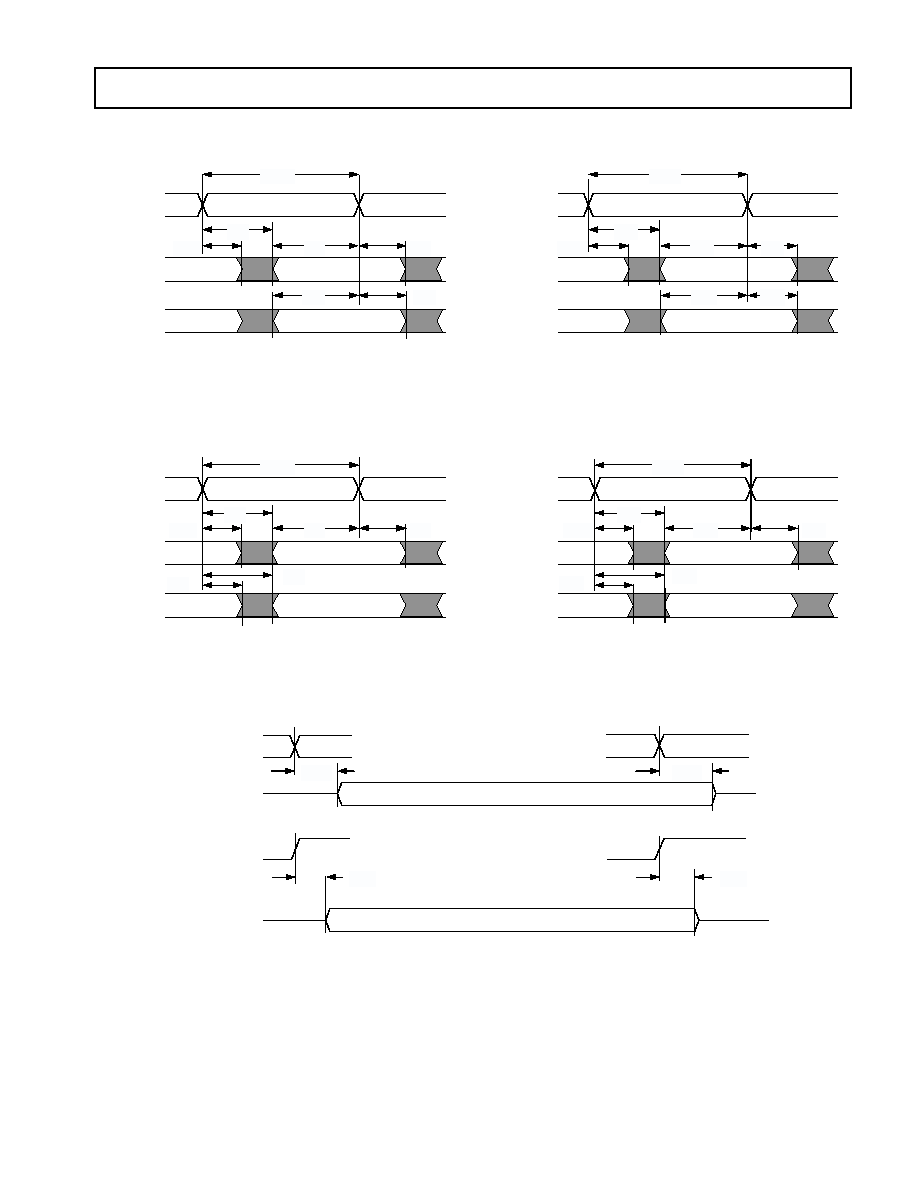

Figure 3. External Data Alignment Options

DATA150

15

8 7

0

L1DATA70

DAT A15-8

L0DATA70

DA TA70

16-BIT PACKED DMA DATA

16-BIT PACKED INSTRUC-

TION EXECUTION

F LOAT OR FIXED, D31D0,

32-BIT PA CKED

32-BIT PA CKED INSTRUC-

T ION

EXTRA DA TA LINES DATA150 AR E ONLY ACCESSIBLE IF LINK PORT S

ARE DISABLED. ENAB LE THESE ADDITIONAL DATA L INKS BY SELECT-

ING IPACK10 = 01 IN SYSCON.

48-BIT INSTRUCT ION FETCH

(NO PACKING)

47

40 39

32 31

24 23

16

DATA4716

8-BIT PACKED DMA D ATA

8-BIT PACKED INST RUCT ION

EXECUTION

PROM

BOOT

NOTE:

ADSP-21161N

8

REV. A

or DMA-transferred to on-chip memory. Each link port has its

own double-buffered input and output registers. Clock/acknowl-

edge handshaking controls link port transfers. Transfers are

programmable as either transmit or receive.

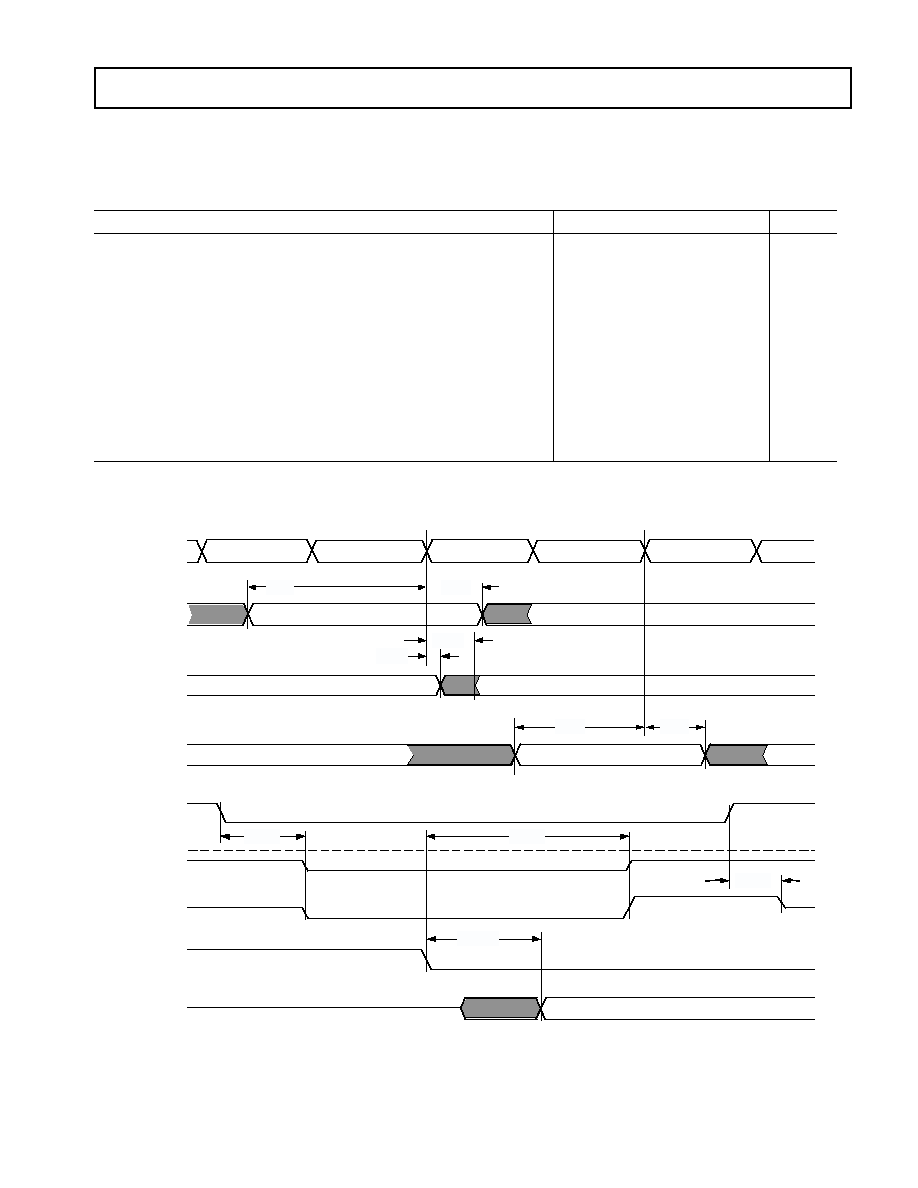

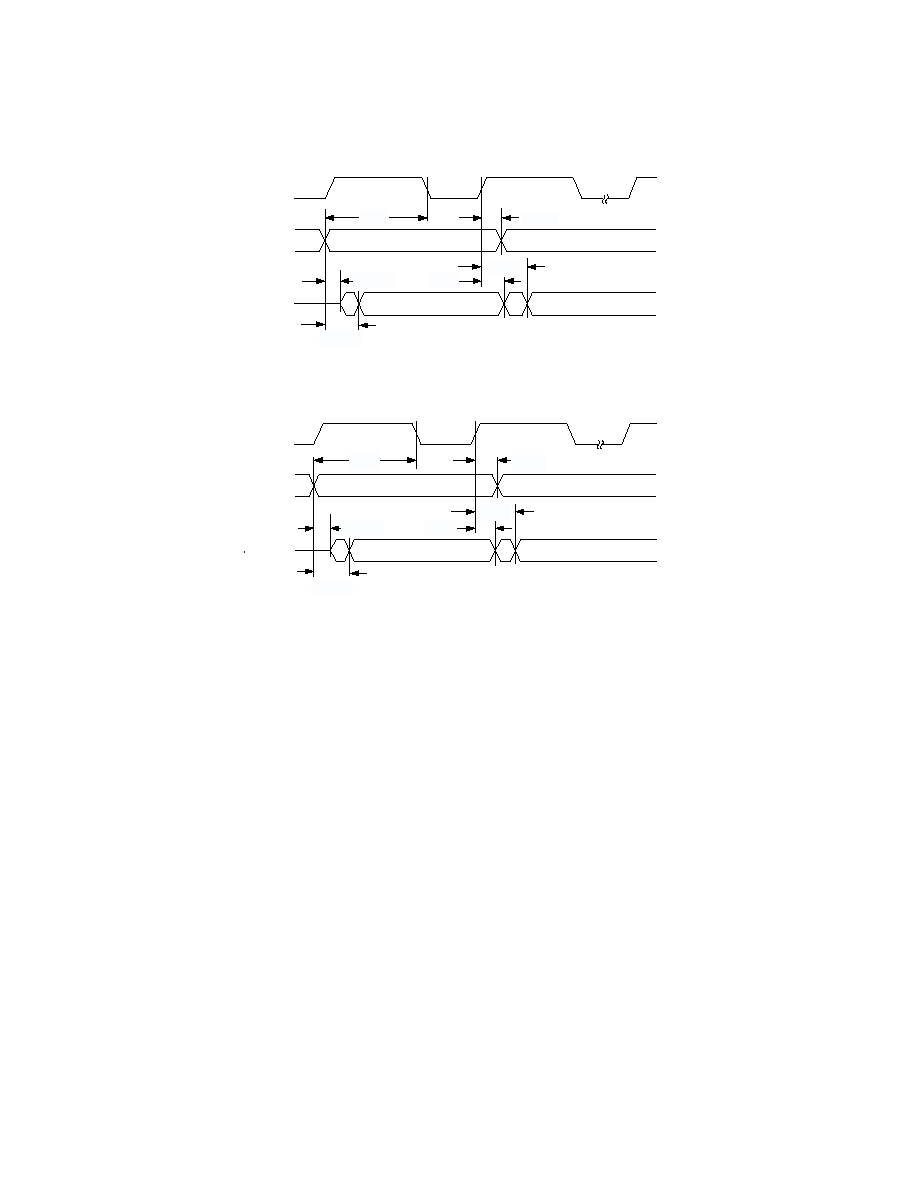

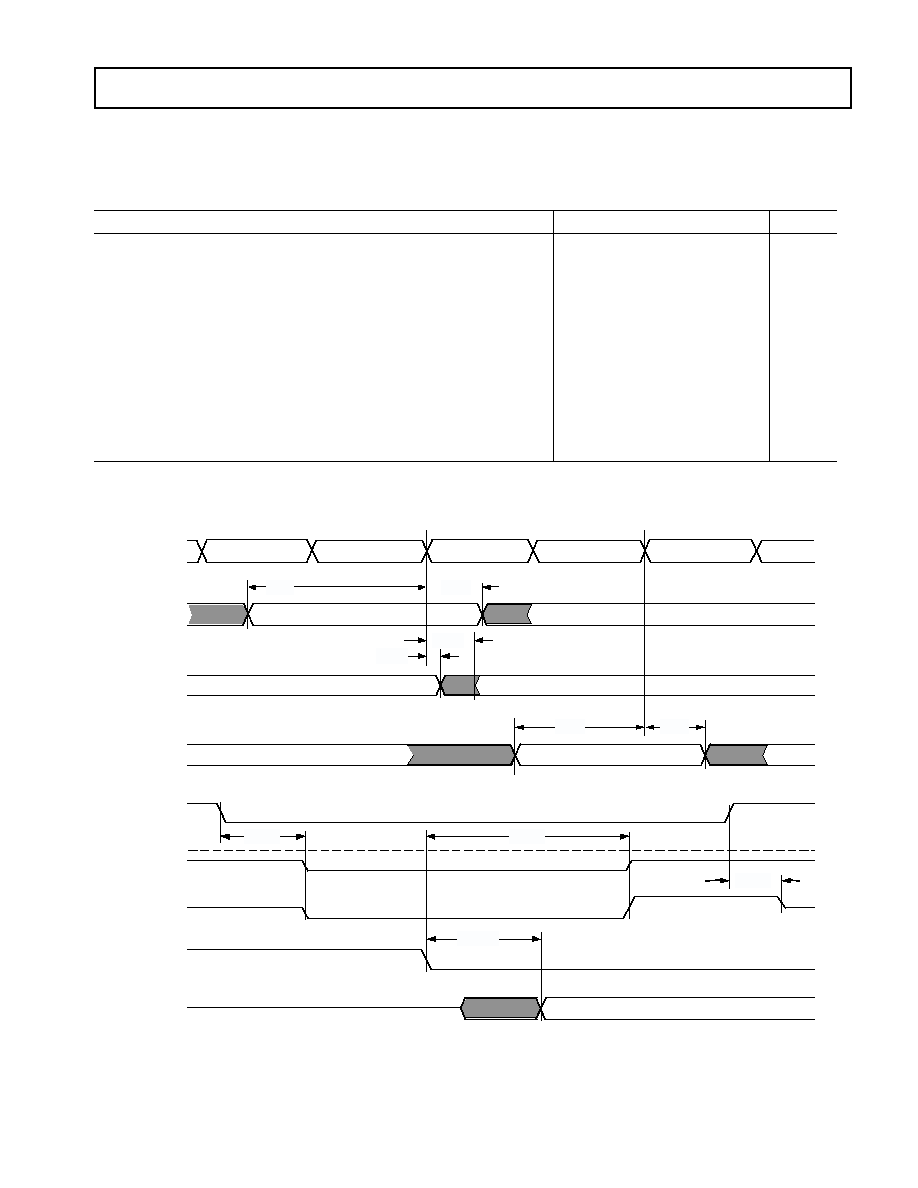

Serial Ports

The ADSP-21161N features four synchronous serial ports that

provide an inexpensive interface to a wide variety of digital and

mixed-signal peripheral devices. Each serial port is made up of

two data lines, a clock and frame sync. The data lines can be

programmed to either transmit or receive.

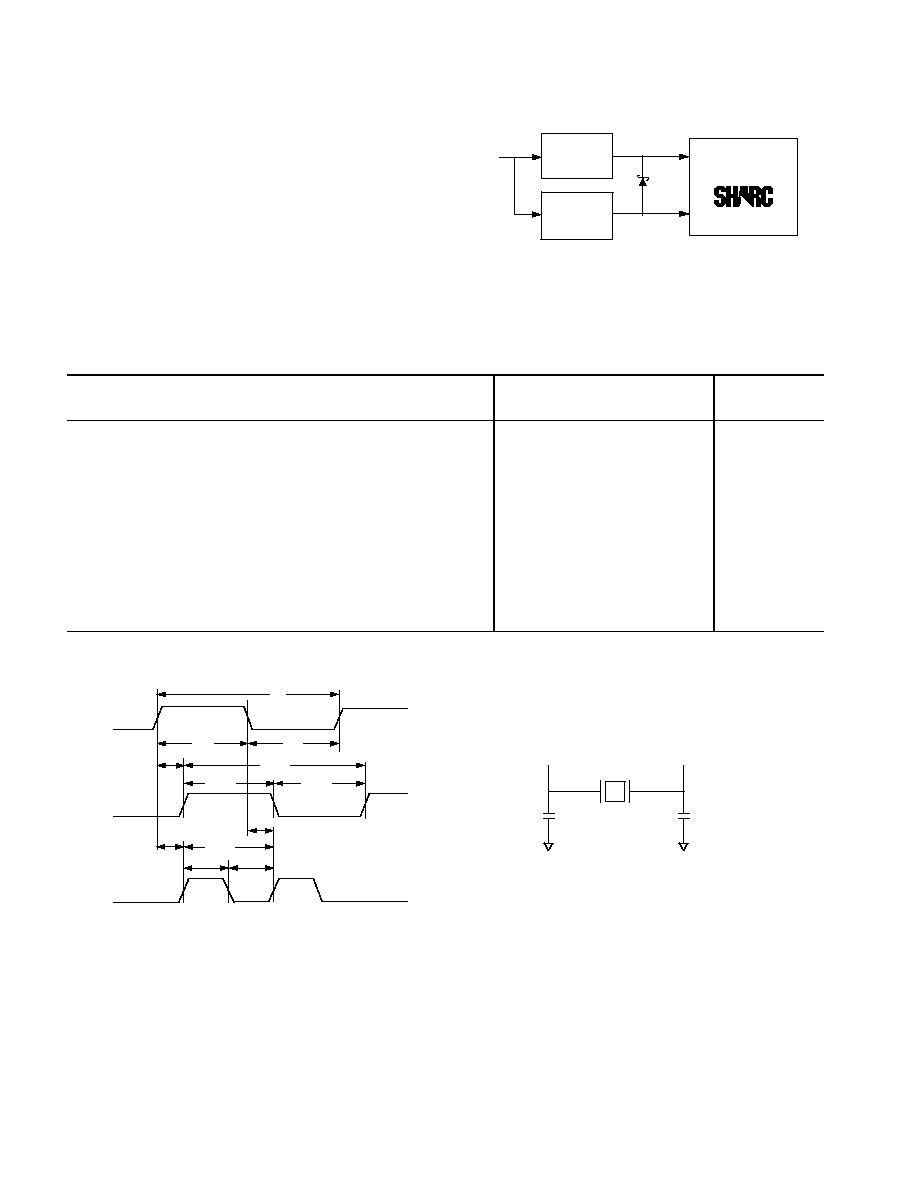

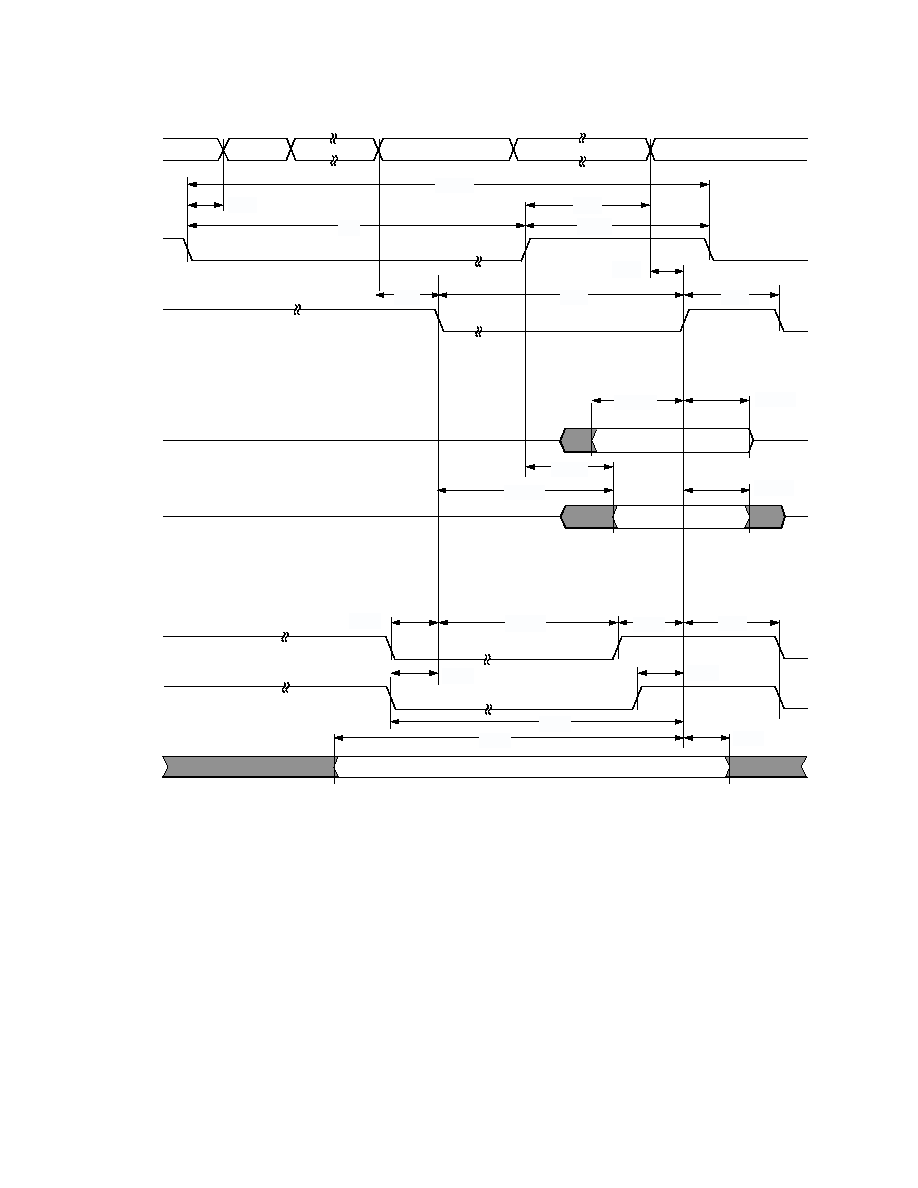

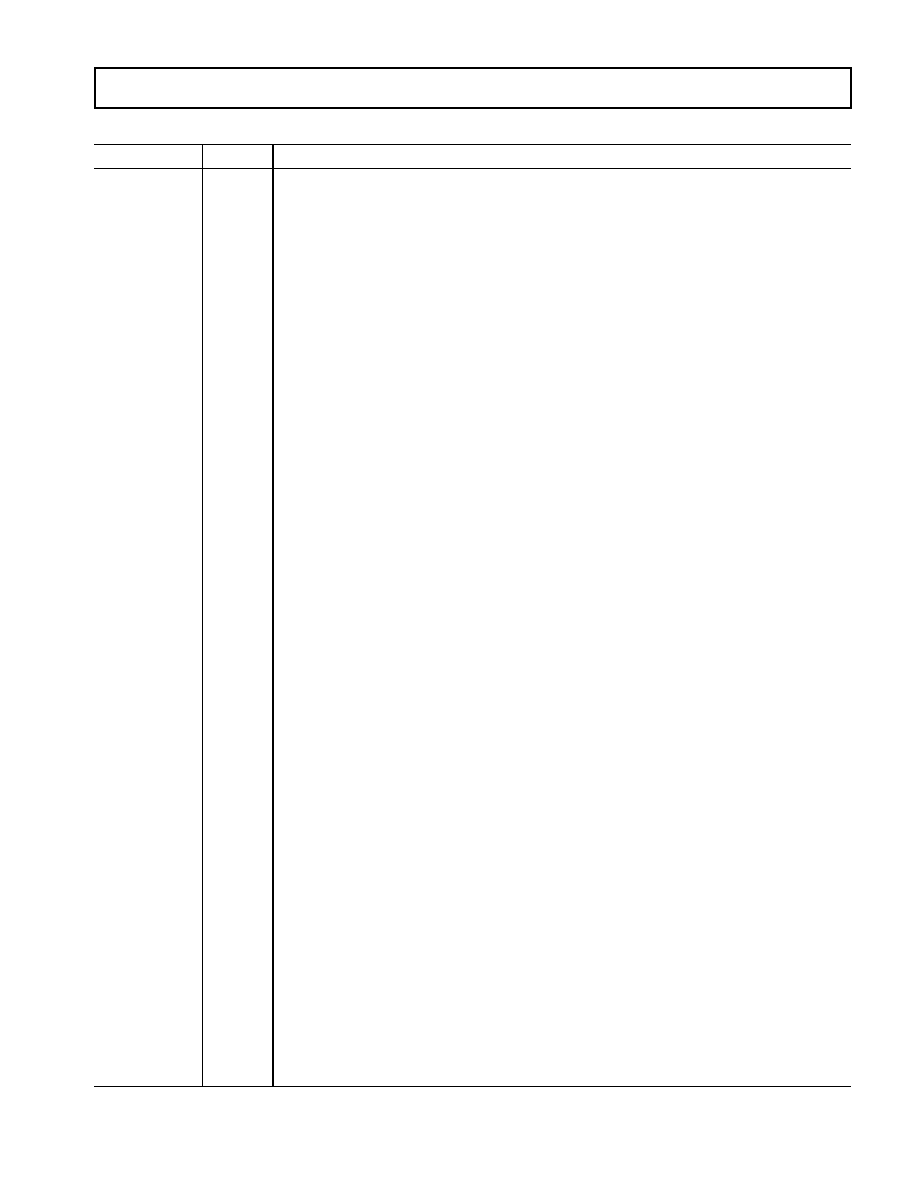

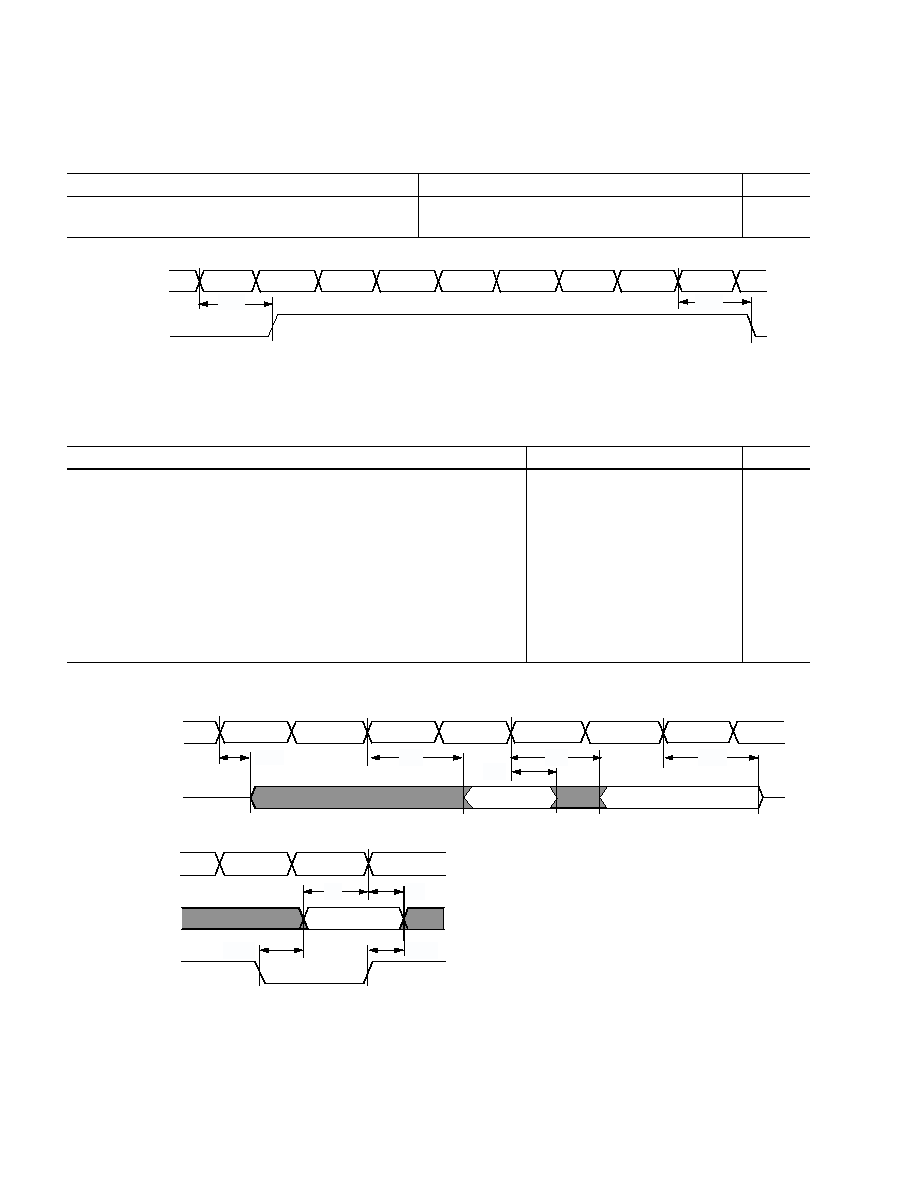

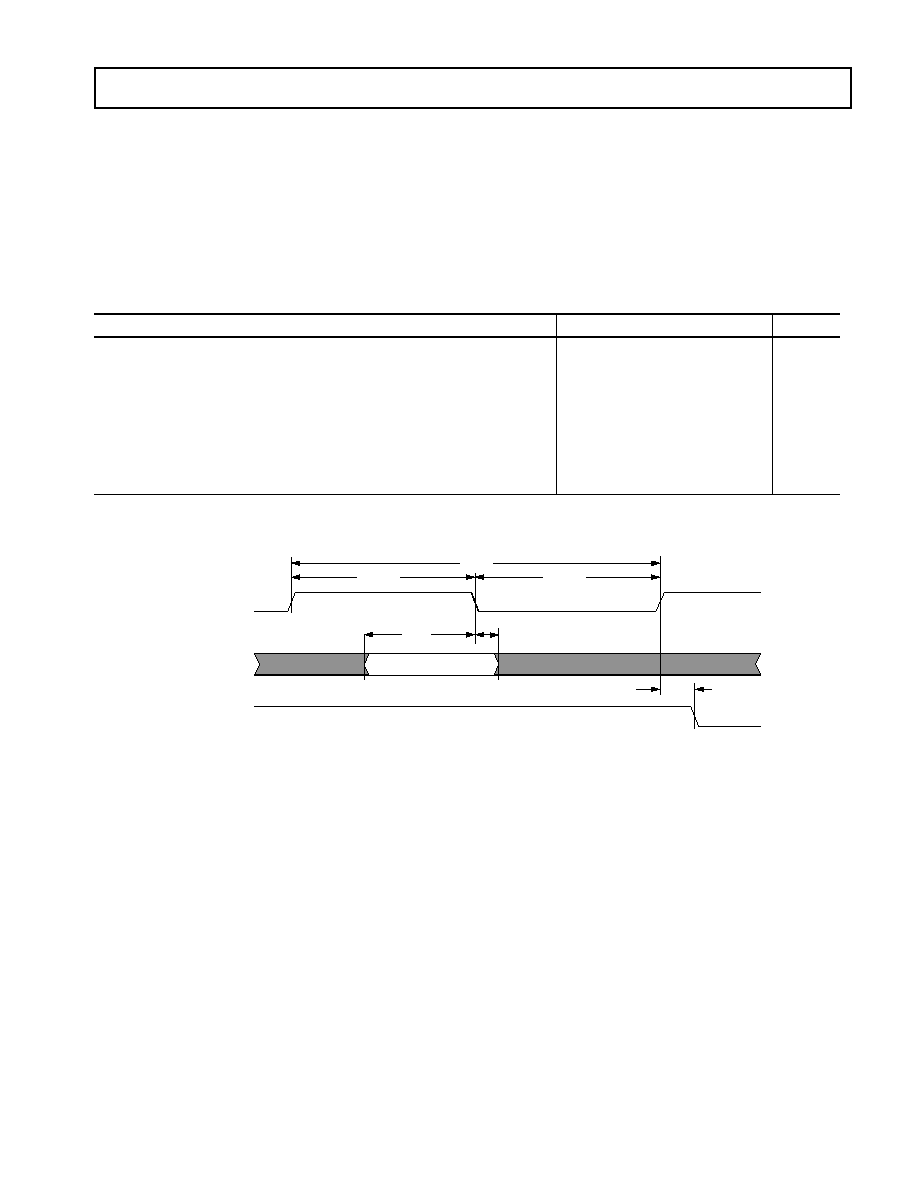

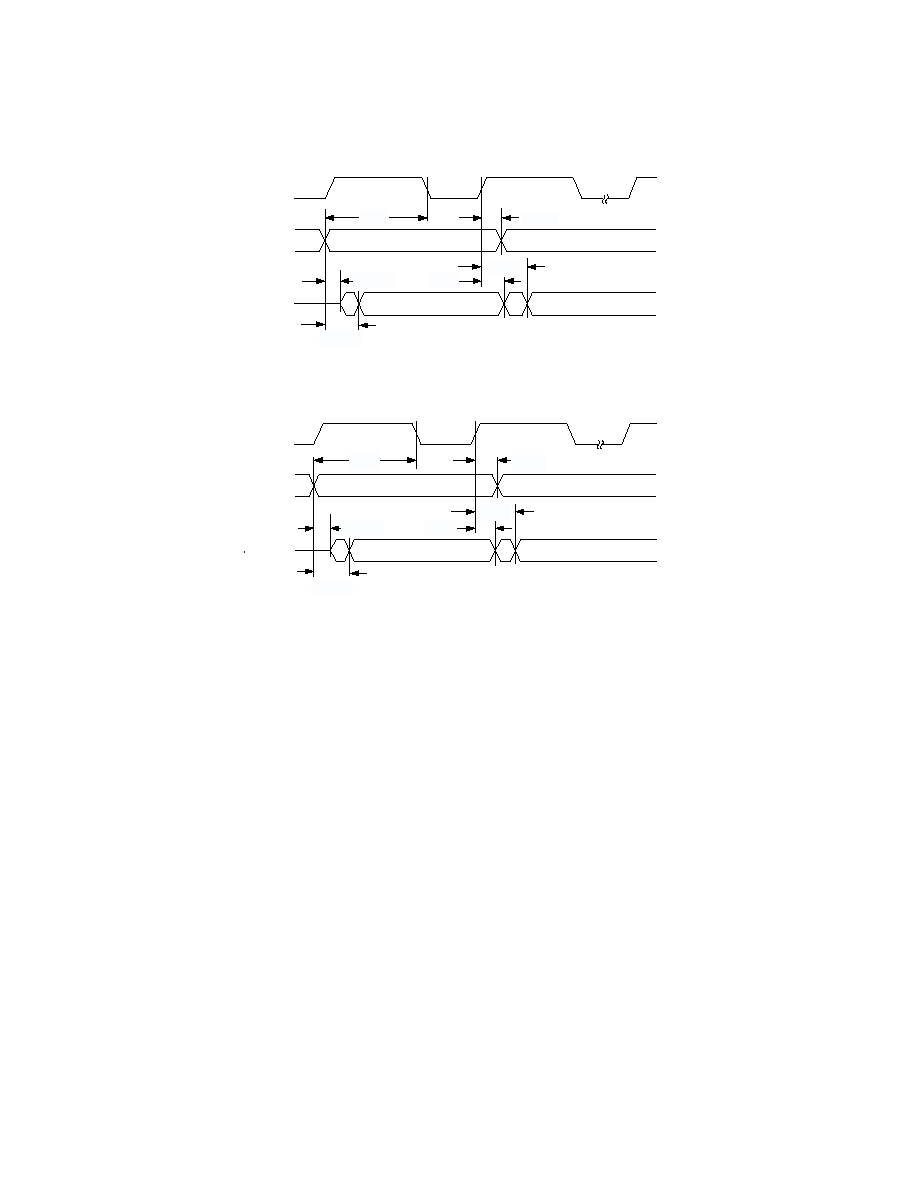

Figure 4. Shared Memory Multiprocessing System

ACK

OE

ADDR

DATA

CS

WE

GLOBAL

MEMORY

AND

PERIPHERALS

(OPTIONAL)

C

O

N

T

R

O

L

ADSP-21161N #1

ADDR23-0

CONTROL

ADSP-21161N #3

ID2-0

RESET

CLKIN

3

ADSP-21161N #4

CLOCK

ADDR

DATA

SDRAM

(OPTIONAL)

CS

ADDR

DATA

BOOT

EPROM

(OPTIONAL)

ID2-0

RESET

CLKIN

C

O

N

T

R

O

L

A

D

D

R

E

S

S

D

A

T

A

C

O

N

T

R

O

L

A

D

D

R

E

S

S

D

A

T

A

CONTROL

ADSP-21161N #2

ID2-0

RESET

CLKIN

2

1

ADDR

DATA

HOST

PROCESSOR

INTERFACE

(OPTIONAL)

WE

RAS

CAS

DQM

CLK

A10

CKE

CS

DATA47-16

SDWE

RAS

CAS

DQM

SDCLK1-0

SDA10

SDCKE

BR6-2

RD

MS3-0

SBTS

CS

ACK

BR1

REDY

HBG

HBR

WR

BMS

ADDR23-0

RESET

DATA47-16

ADDR23-0

DATA47-16

9

REV. A

ADSP-21161N

The serial ports operate at up to half the clock rate of the core,

providing each with a maximum data rate of 50 M bit/s. The serial

data pins are programmable as either a transmitter or receiver,

providing greater flexibility for serial communications. Serial port

data can be automatically transferred to and from on-chip

memory via a dedicated DMA. Each of the serial ports features

a Time Division Multiplex (TDM) multichannel mode, where

two serial ports are TDM transmitters and two serial ports are

TDM receivers (SPORT0 Rx paired with SPORT2 Tx,

SPORT1 Rx paired with SPORT3 Tx). Each of the serial ports

also support the I

2

S protocol (an industry standard interface

commonly used by audio codecs, ADCs and DACs), with two

data pins, allowing four I

2

S channels (using two I

2

S stereo

devices) per serial port, with a maximum of up to 16 I

2

S channels.

The serial ports permit little-endian or big-endian transmission

formats and word lengths selectable from 3 bits to 32 bits. For

I

2

S mode, data-word lengths are selectable between 8 bits and 32

bits. Serial ports offer selectable synchronization and transmit

modes as well as optional µ-law or A-law companding. Serial port

clocks and frame syncs can be internally or externally generated.

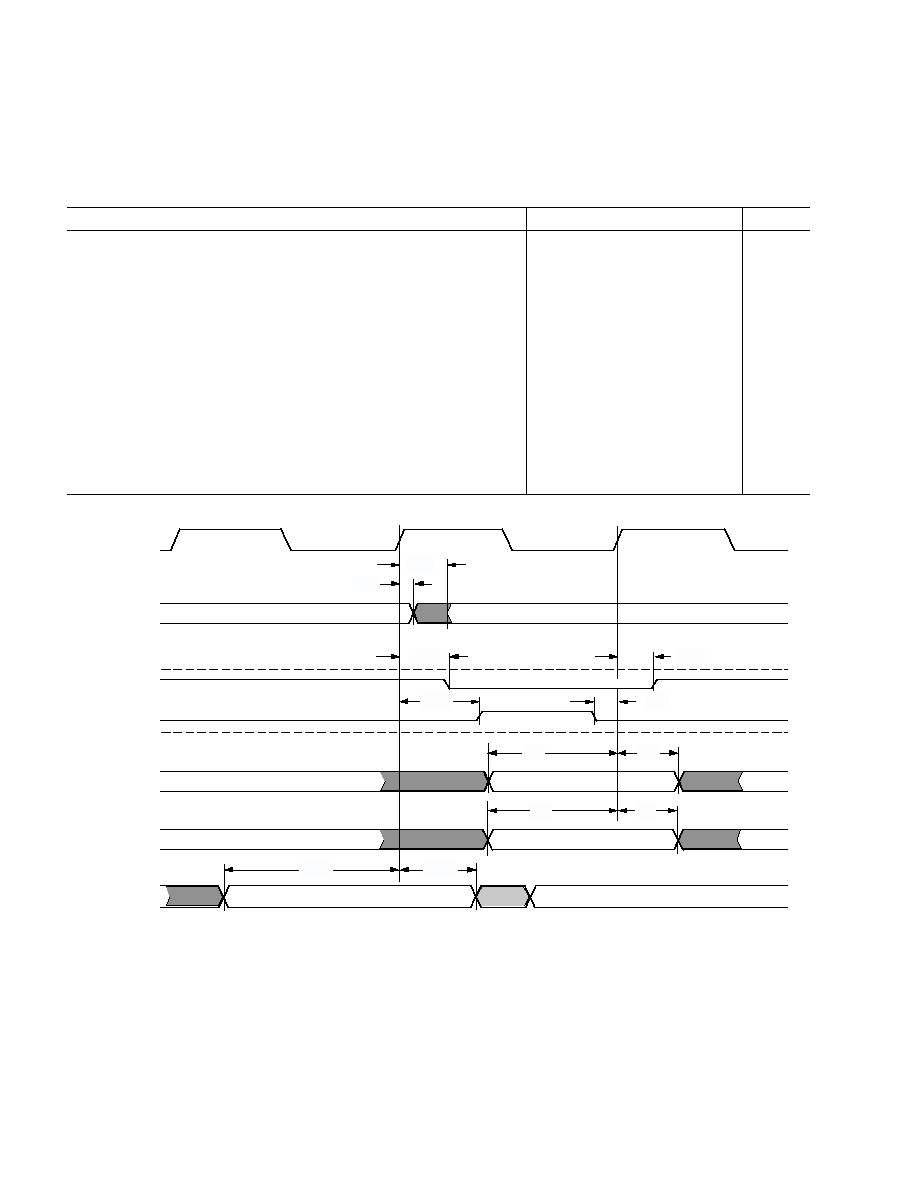

Serial Peripheral (Compatible) Interface

Serial Peripheral Interface (SPI) is an industry standard synchro-

nous serial link, enabling the ADSP-21161N SPI-compatible

port to communicate with other SPI-compatible devices. SPI is

a 4-wire interface consisting of two data pins, one device select

pin, and one clock pin. It is a full-duplex synchronous serial

interface, supporting both master and slave modes. The SPI port

can operate in a multimaster environment by interfacing with up

to four other SPI-compatible devices, either acting as a master or

slave device. The ADSP-21161N SPI-compatible peripheral

implementation also features programmable baud rate and clock

phase/polarities. The ADSP-21161N SPI-compatible port uses

open drain drivers to support a multimaster configuration and to

avoid data contention.

Host Processor Interface

The ADSP-21161N host interface enables easy connection to

standard 8-bit, 16-bit, or 32-bit microprocessor buses with little

additional hardware required. The host interface is accessed

through the ADSP-21161N's external port. Four channels of

DMA are available for the host interface; code and data transfers

are accomplished with low software overhead. The host processor

requests the ADSP-21161N's external bus with the host bus

request (

HBR), host bus grant (HBG), and chip select (CS)

signals. The host can directly read and write the internal IOP

registers of the ADSP-21161N, and can access the DMA channel

setup and message registers. DMA setup via a host would allow

it to access any internal memory address via DMA transfers.

Vector interrupt support provides efficient execution of host

commands.

General-Purpose I/O Ports

The ADSP-21161N also contains 12 programmable, general

purpose I/O pins that can function as either input or output. As

output, these pins can signal peripheral devices; as input, these

pins can provide the test for conditional branching.

Program Booting

The internal memory of the ADSP-21161N can be booted at

system power-up from either an 8-bit EPROM, a host processor,

the SPI interface, or through one of the link ports. Selection of

the boot source is controlled by the Boot Memory Select (

BMS),

EBOOT (EPROM Boot), and Link/Host Boot (LBOOT) pins.

8-, 16-, or 32-bit host processors can also be used for booting.

Phase-Locked Loop and Crystal Double Enable

The ADSP-21161N uses an on-chip Phase-Locked Loop (PLL)

to generate the internal clock for the core. The CLK_CFG1

0

pins are used to select ratios of 2:1, 3:1, and 4:1. In addition to

the PLL ratios, the

CLKDBL pin can be used for more clock

ratio options. The (1

×

/2

×

CLKIN) rate set by the

CLKDBL

pin determines the rate of the PLL input clock and the rate at

which the external port operates. With the combination of

CLK_CFG1

0 and

CLKDBL, ratios of 2:1, 3:1, 4:1, 6:1, and

8:1 between the core and CLKIN are supported. See also

Figure 10 on Page 20

.

Power Supplies

The ADSP-21161N has separate power supply connections for

the analog (AV

DD

/AGND), internal (V

DDINT

), and external

(V

DDEXT

) power supplies. The internal and analog supplies must

meet the 1.8 V requirement. The external supply must meet the

3.3 V requirement. All external supply pins must be connected

to the same supply.

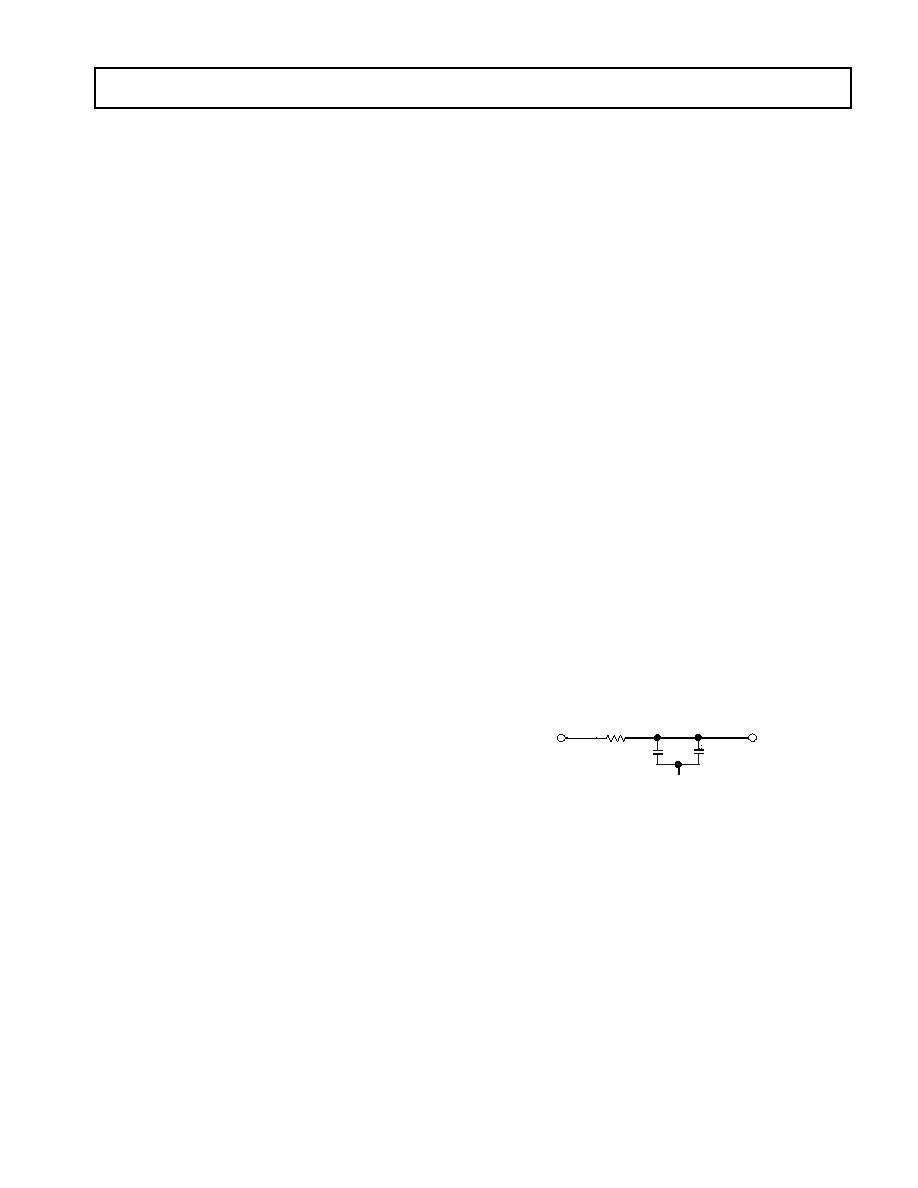

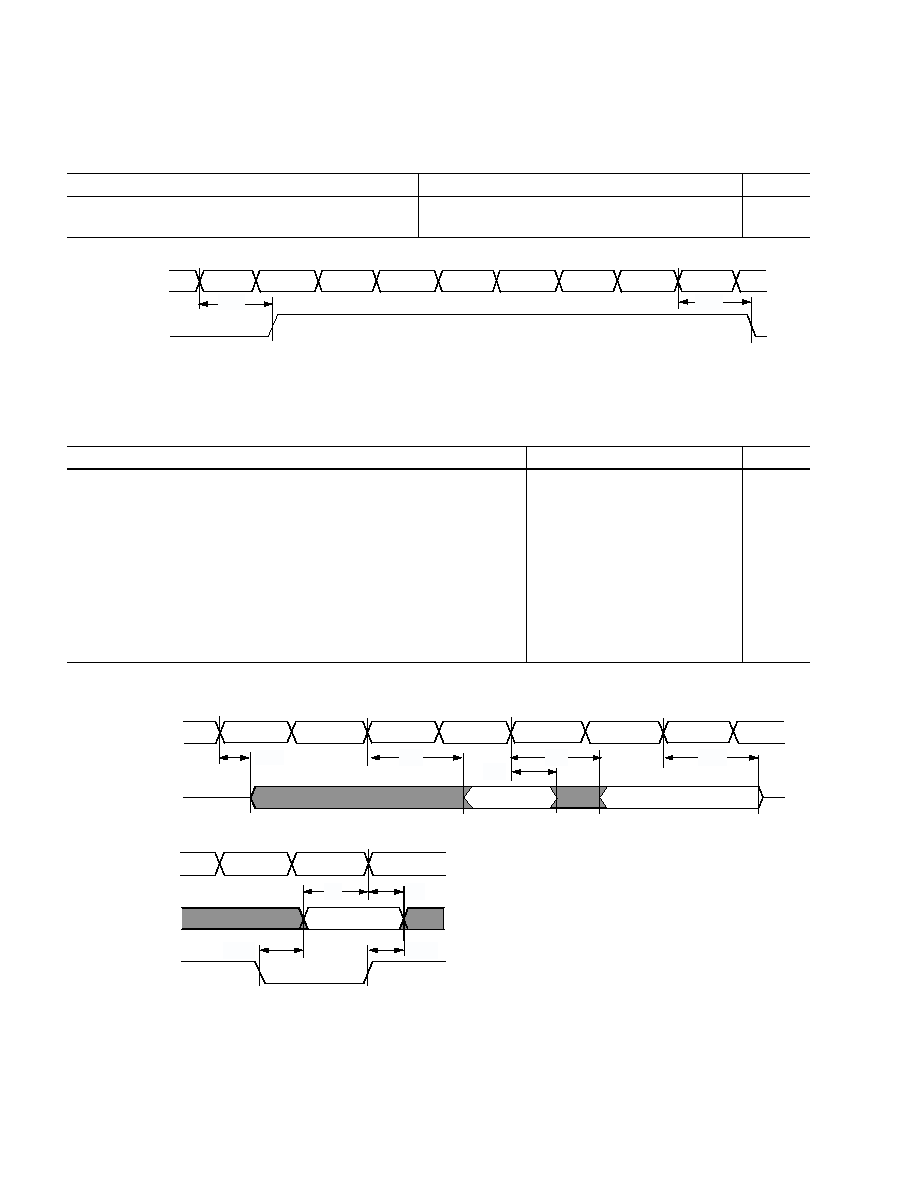

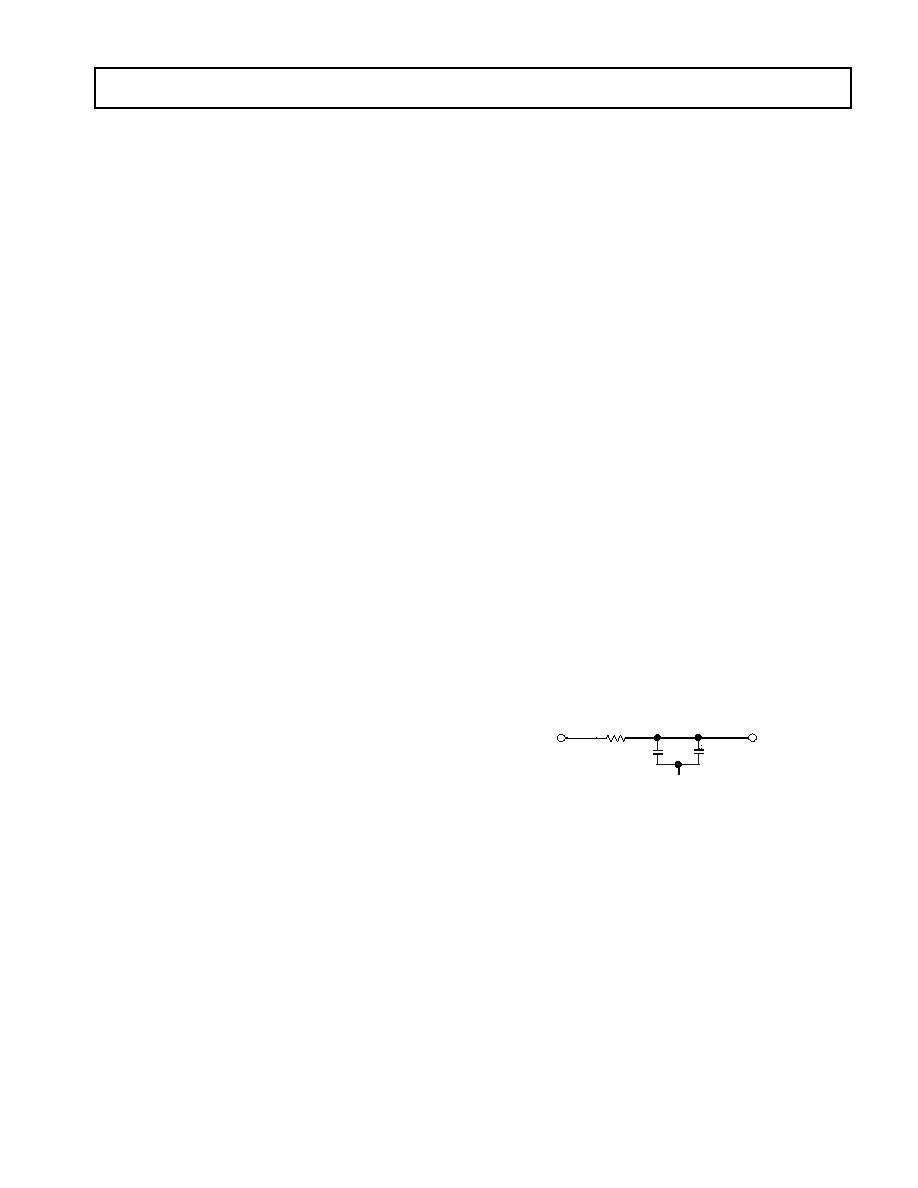

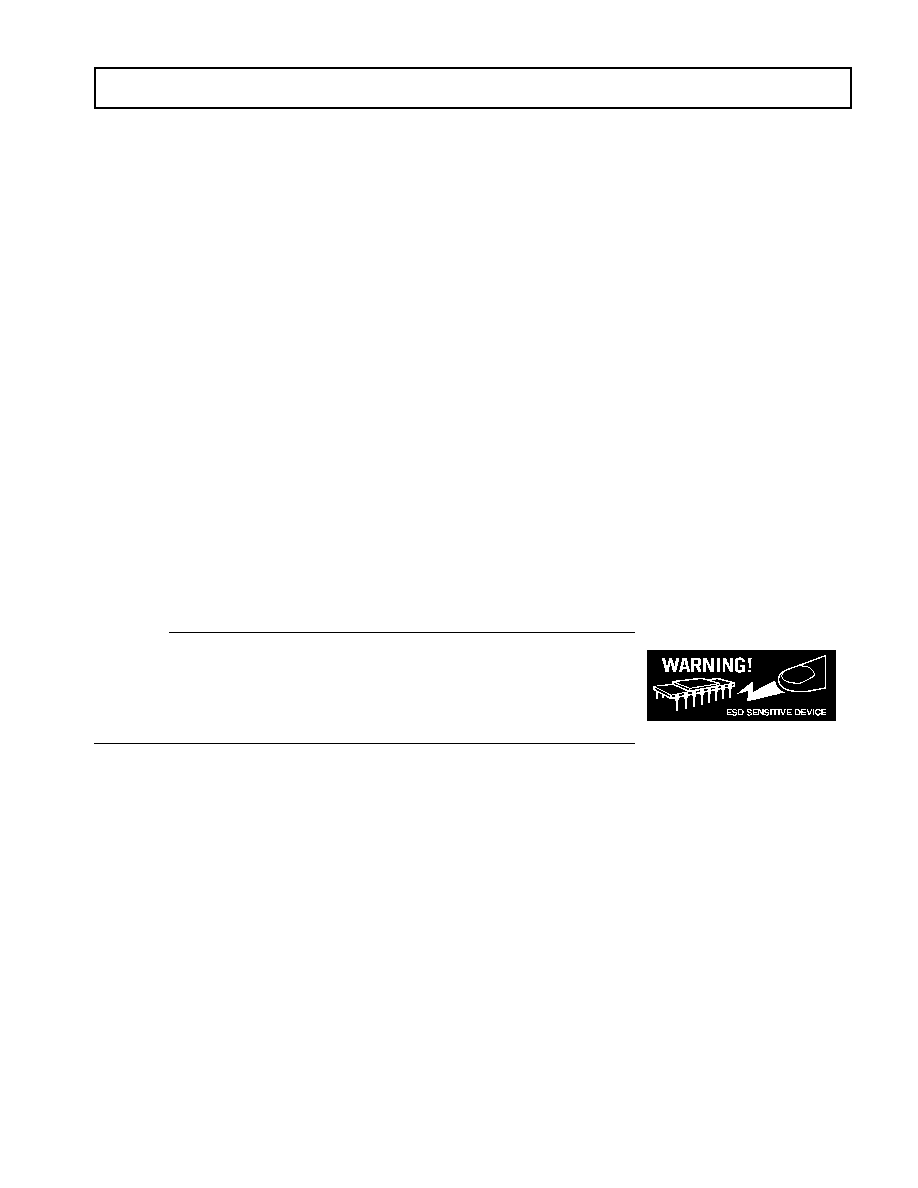

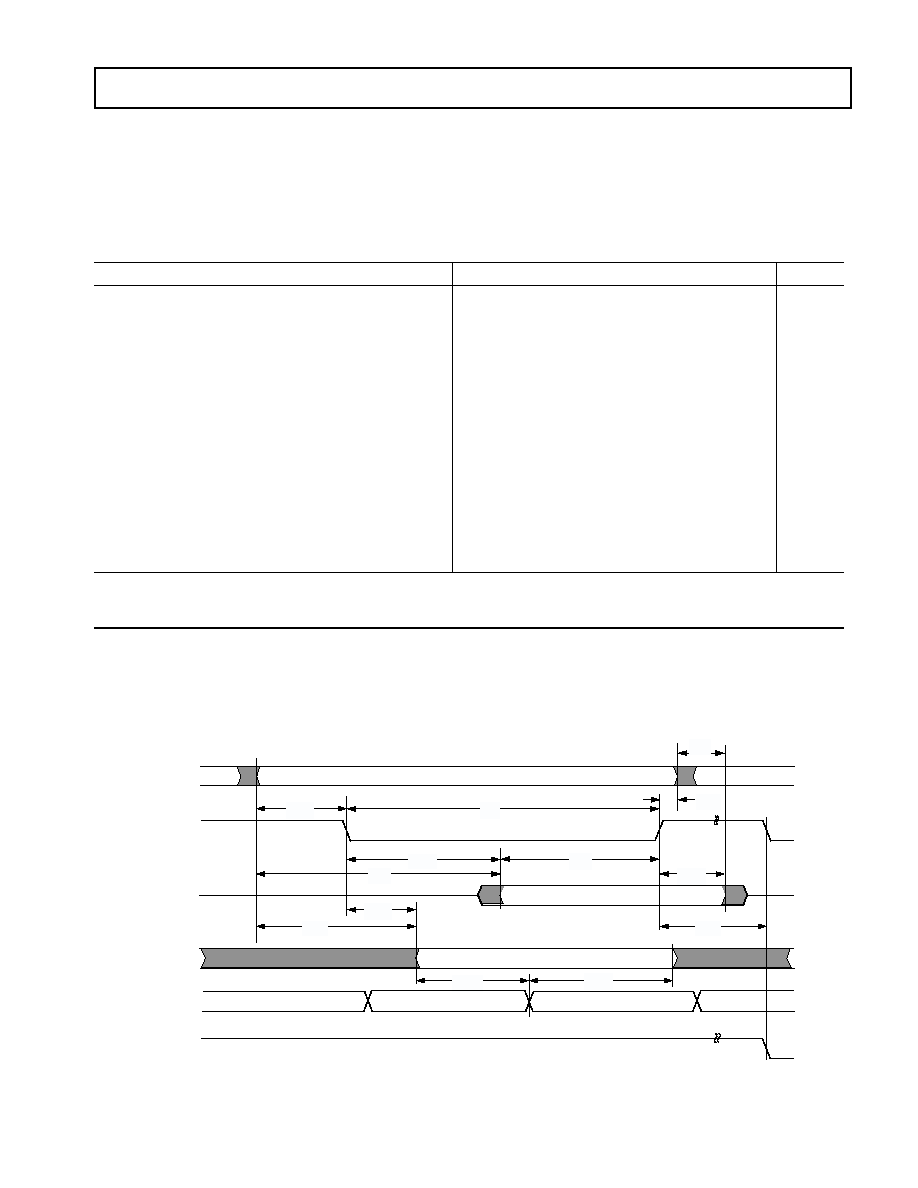

Note that the analog supply (AV

DD

) powers the ADSP-21161N's

clock generator PLL. To produce a stable clock, provide an

external circuit to filter the power input to the AV

DD

pin. Place

the filter as close as possible to the pin. For an example circuit,

see

Figure 5

. To prevent noise coupling, use a wide trace for the

analog ground (AGND) signal and install a decoupling capacitor

as close as possible to the pin.

Development Tools

The ADSP-21161N is supported with a complete set of software

and hardware development tools, including Analog Devices

emulators and VisualDSP++

1

development environment. The

same emulator hardware that supports other ADSP-21xxx DSPs,

also fully emulates the ADSP-21161N.

The VisualDSP++ project management environment lets pro-

grammers develop and debug an application. This environment

includes an easy-to-use assembler that is based on an algebraic

syntax; an archiver (librarian/library builder), a linker, a loader,

Figure 5. Analog Power (AV

DD

) Filter Circuit

1

VisualDSP++ is a registered trademark of Analog Devices, Inc.

10

V

DDINT

0.1 F

0.01 F

AGND

AV

DD

ADSP-21161N

10

REV. A

a cycle-accurate instruction-level simulator, a C/C++ compiler,

and a C/C++ run-time library that includes DSP and mathemat-

ical functions. Two key points for these tools are:

·

Compiled ADSP-21161N C/C++ code efficiency--The

compiler has been developed for efficient translation of

C/C++ code to ADSP-21161N assembly. The DSP has

architectural features that improve the efficiency of

compiled C/C++ code.

·

ADSP-2106x family code compatibility--The assembler

has legacy features to ease the conversion of existing

ADSP-2106x applications to the ADSP-21161N.

Debugging both C/C++ and assembly programs with the

VisualDSP++ debugger, programmers can:

·

View mixed C/C++ and assembly code (interleaved

source and object information)

·

Insert break points

·

Set conditional breakpoints on registers, memory, and

stacks

·

Trace instruction execution

·

Perform linear or statistical profiling of program

execution

·

Fill, dump, and graphically plot the contents of memory

·

Source level debugging

·

Create custom debugger windows

The VisualDSP++ IDE lets programmers define and manage

DSP software development. Its dialog boxes and property pages

let programmers configure and manage all of the ADSP-21xxx

development tools, including the syntax highlighting in the

VisualDSP++ editor. This capability permits:

·

Controlling how the development tools process inputs

and generate outputs.

·

Maintaining a one-to-one correspondence with the tool's

command line switches.

Analog Devices DSP emulators use the IEEE 1149.1 JTAG test

access port of the ADSP-21161N processor to monitor and

control the target board processor during emulation. The

emulator provides full-speed emulation, allowing inspection and

modification of memory, registers, and processor stacks. Nonin-

trusive in-circuit emulation is assured by the use of the processor's

JTAG interface--the emulator does not affect target system

loading or timing.

In addition to the software and hardware development tools

available from Analog Devices, third parties provide a wide range

of tools supporting the ADSP-21xxx processor family. Hardware

tools include ADSP-21xxx PC plug-in cards. Third Party

software tools include DSP libraries, real-time operating systems,

and block diagram design tools.

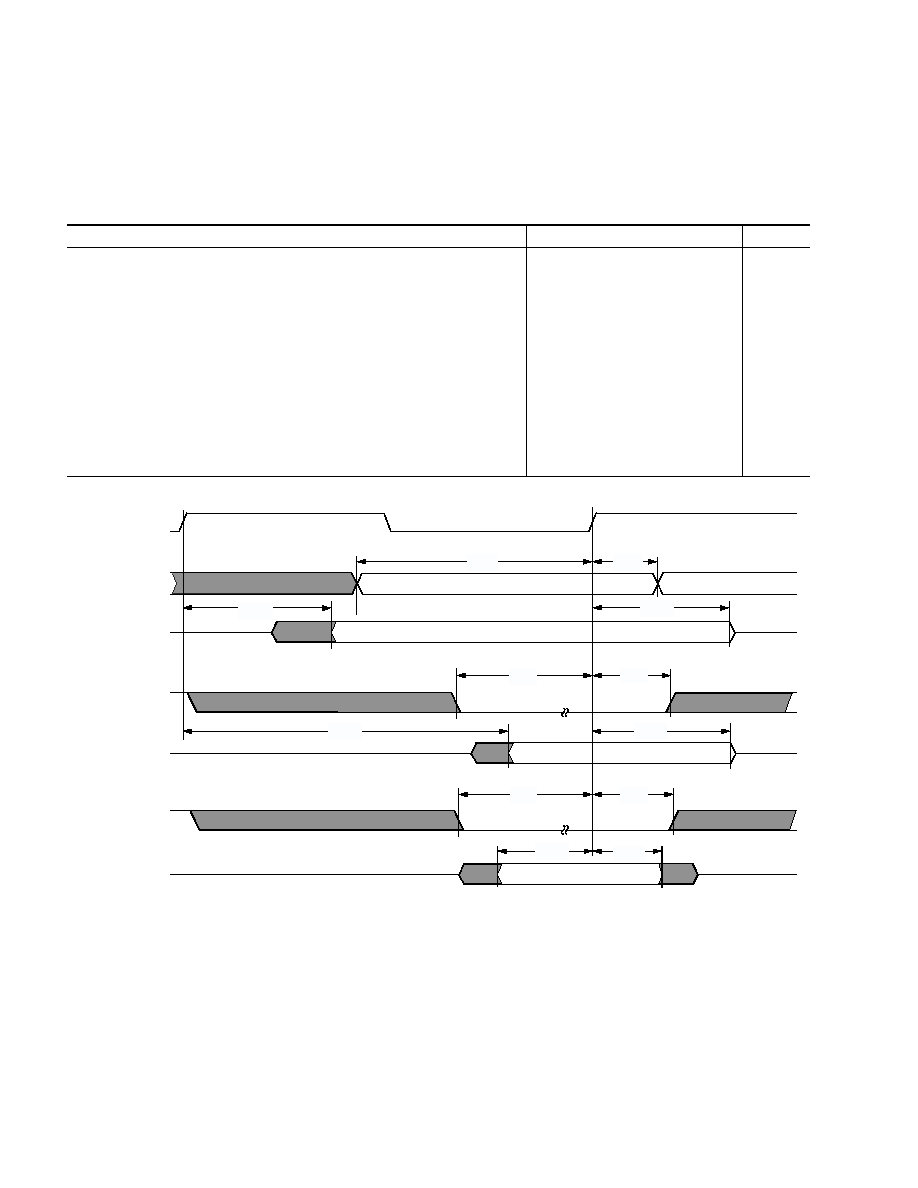

Designing an Emulator-Compatible DSP Board

(Target)

The Analog Devices DSP Tools family of emulators are tools that

every DSP developer needs to test and debug hardware and

software systems. Analog Devices has supplied an IEEE 1149.1

JTAG Test Access Port (TAP) on each JTAG DSP. The emulator

uses the TAP to access the internal features of the DSP, allowing

the developer to load code, set breakpoints, observe variables,

observe memory, and examine registers. The DSP must be halted

to send data and commands, but once an operation has been

completed by the emulator, the DSP system is set running at full

speed with no impact on system timing.

To use these emulators, the target's design must include the

interface between an Analog Devices JTAG DSP and the

emulation header on a custom DSP target board.

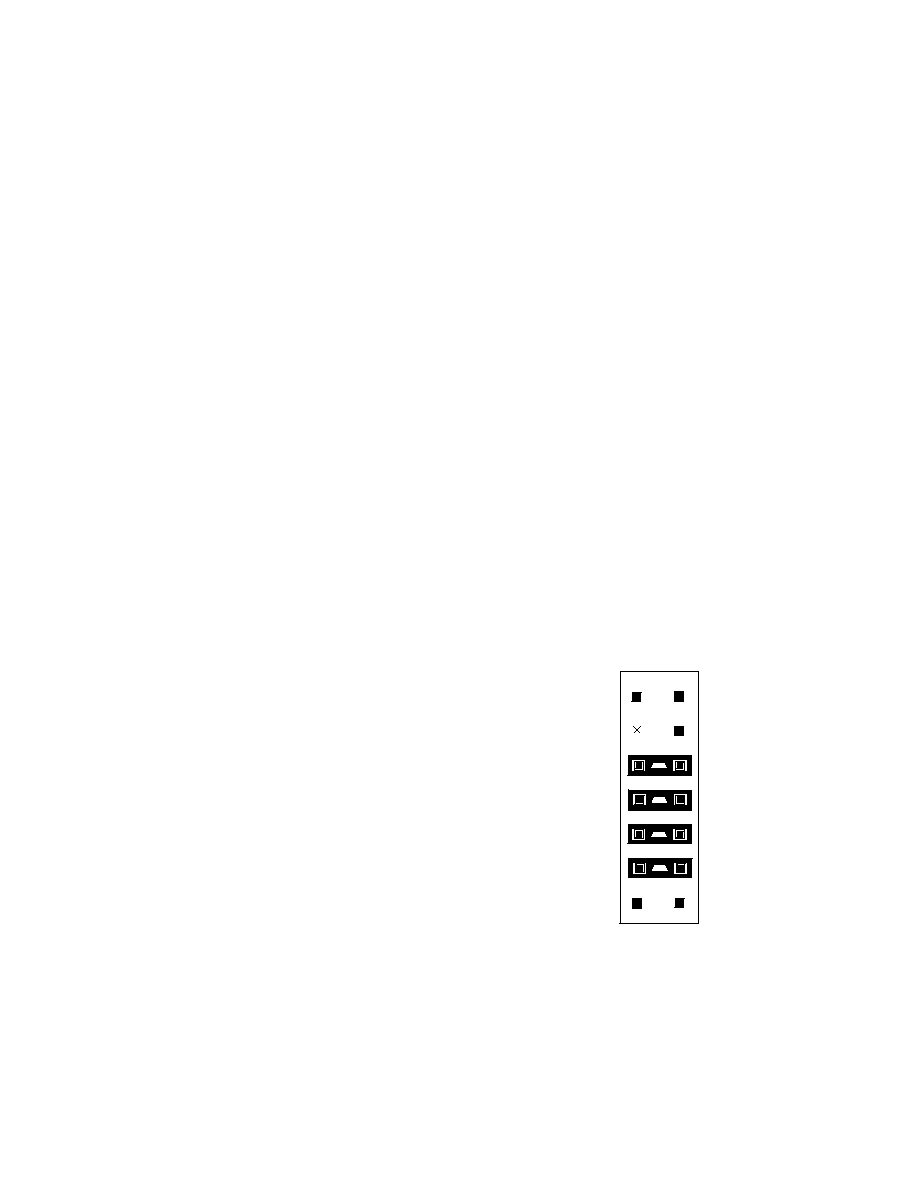

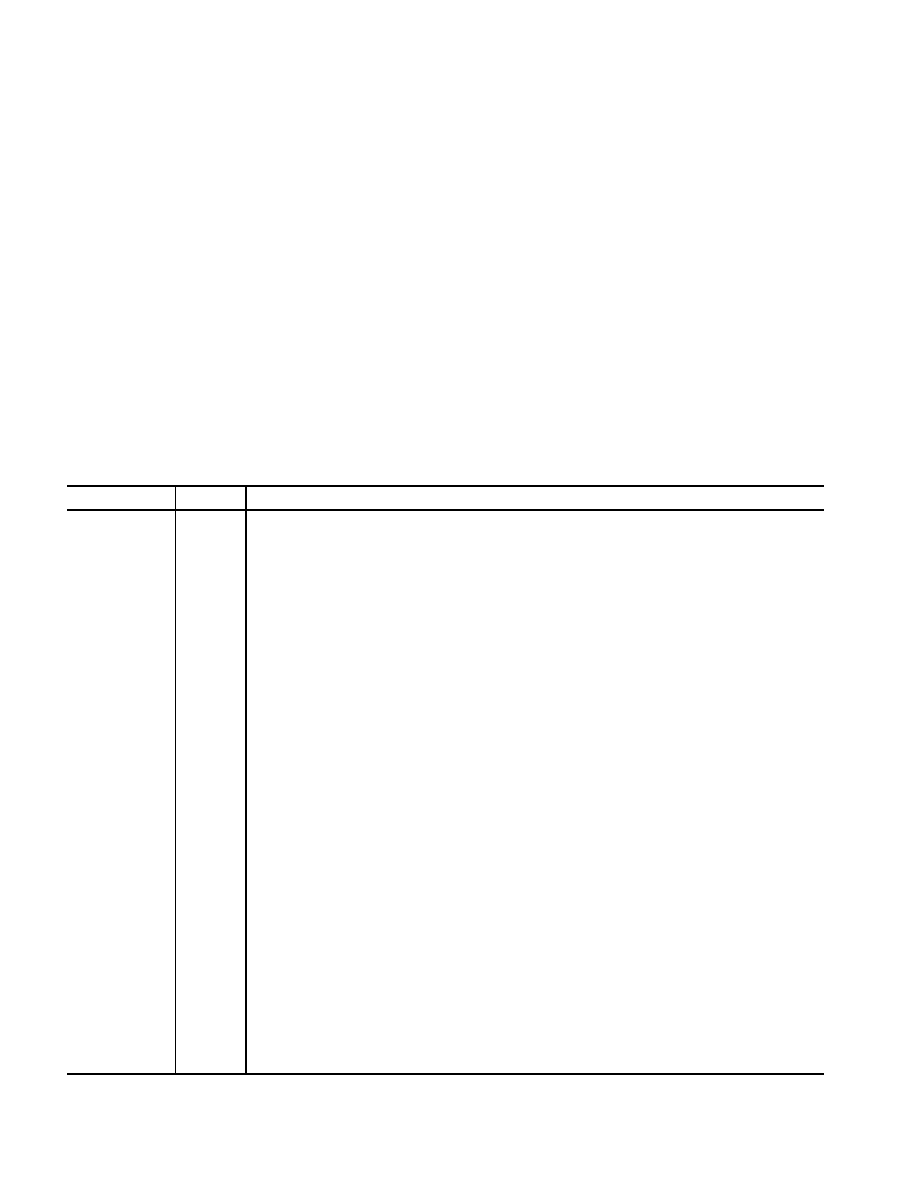

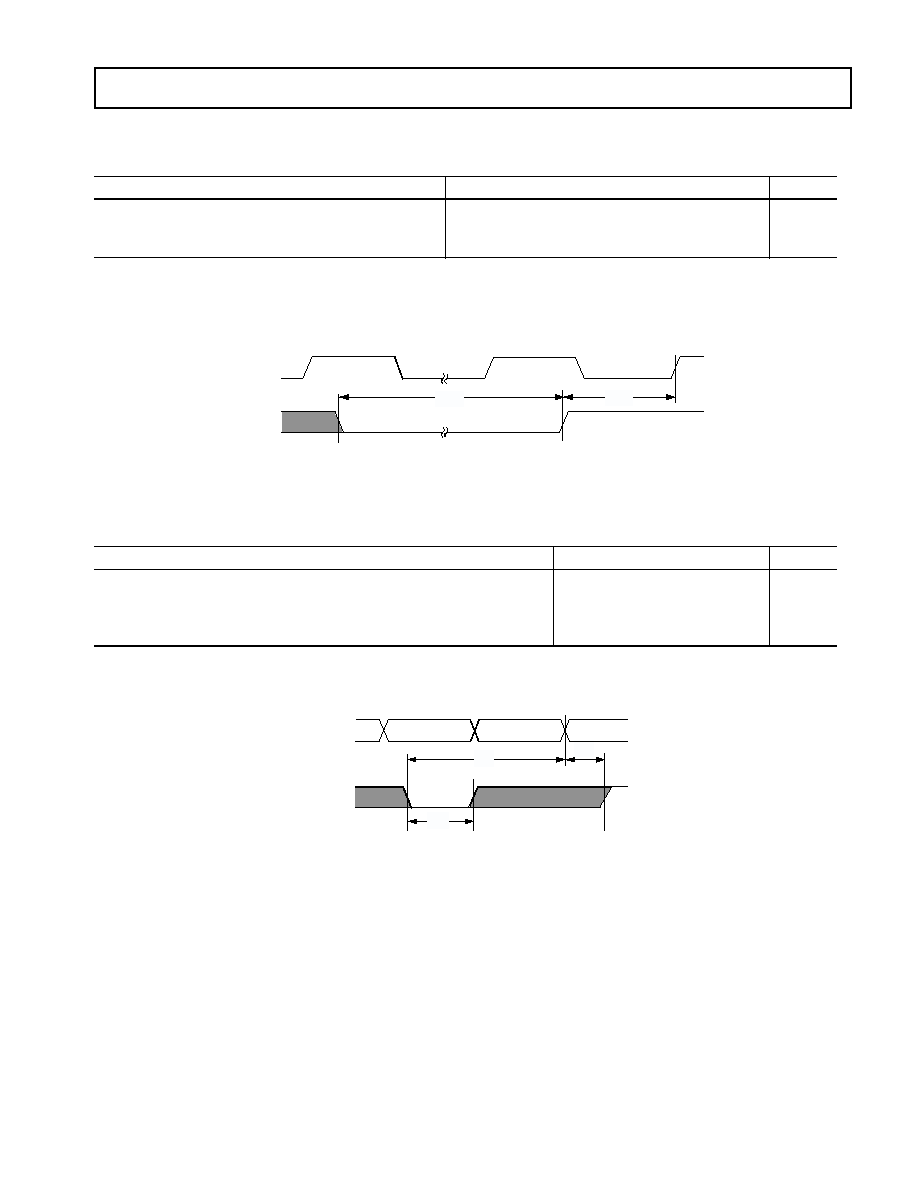

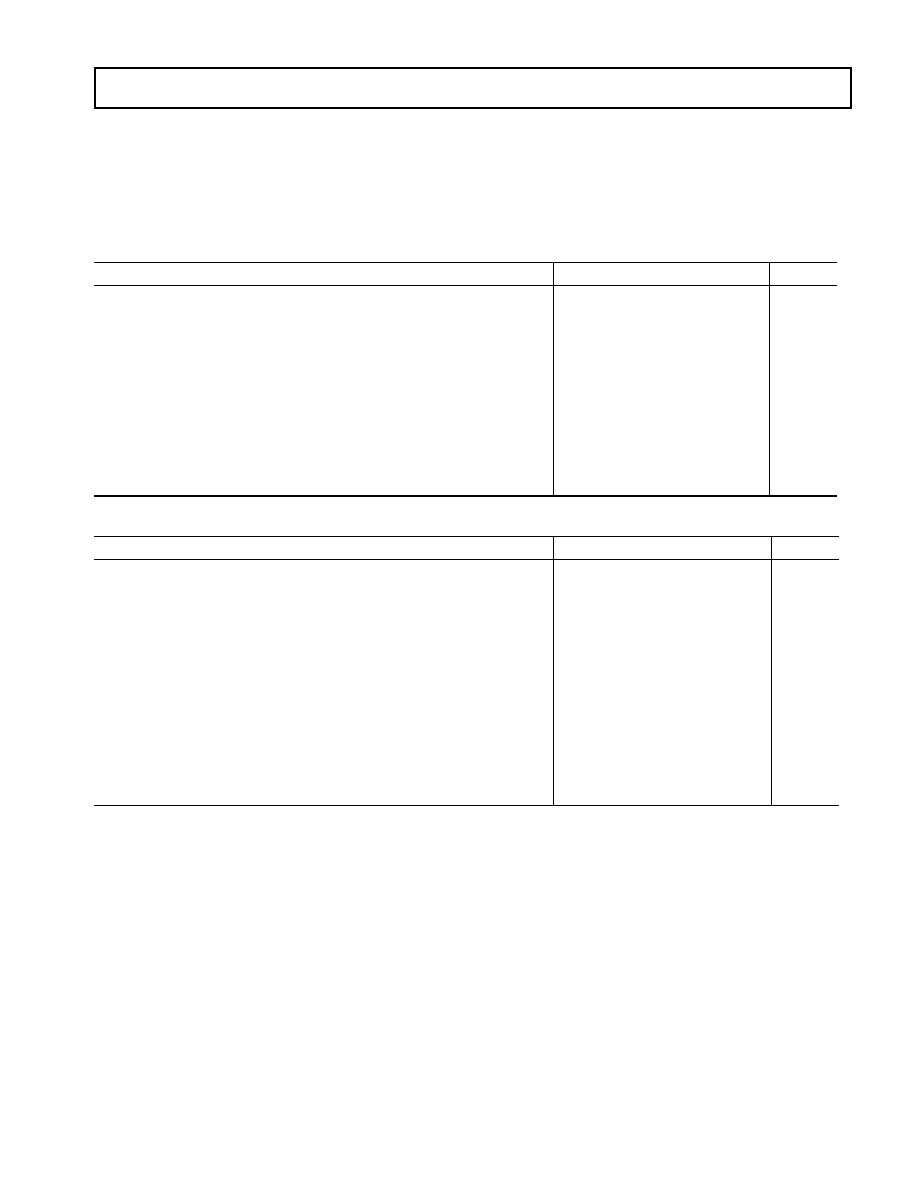

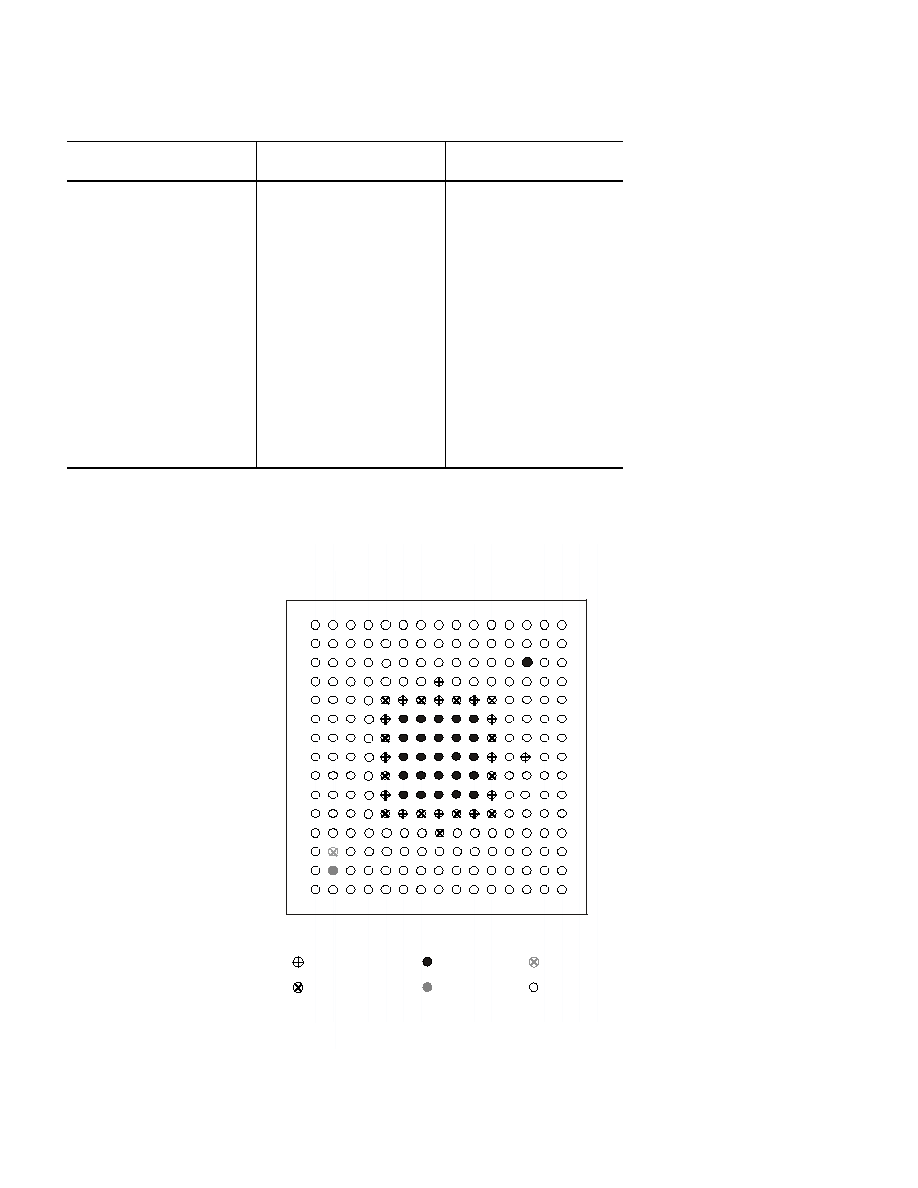

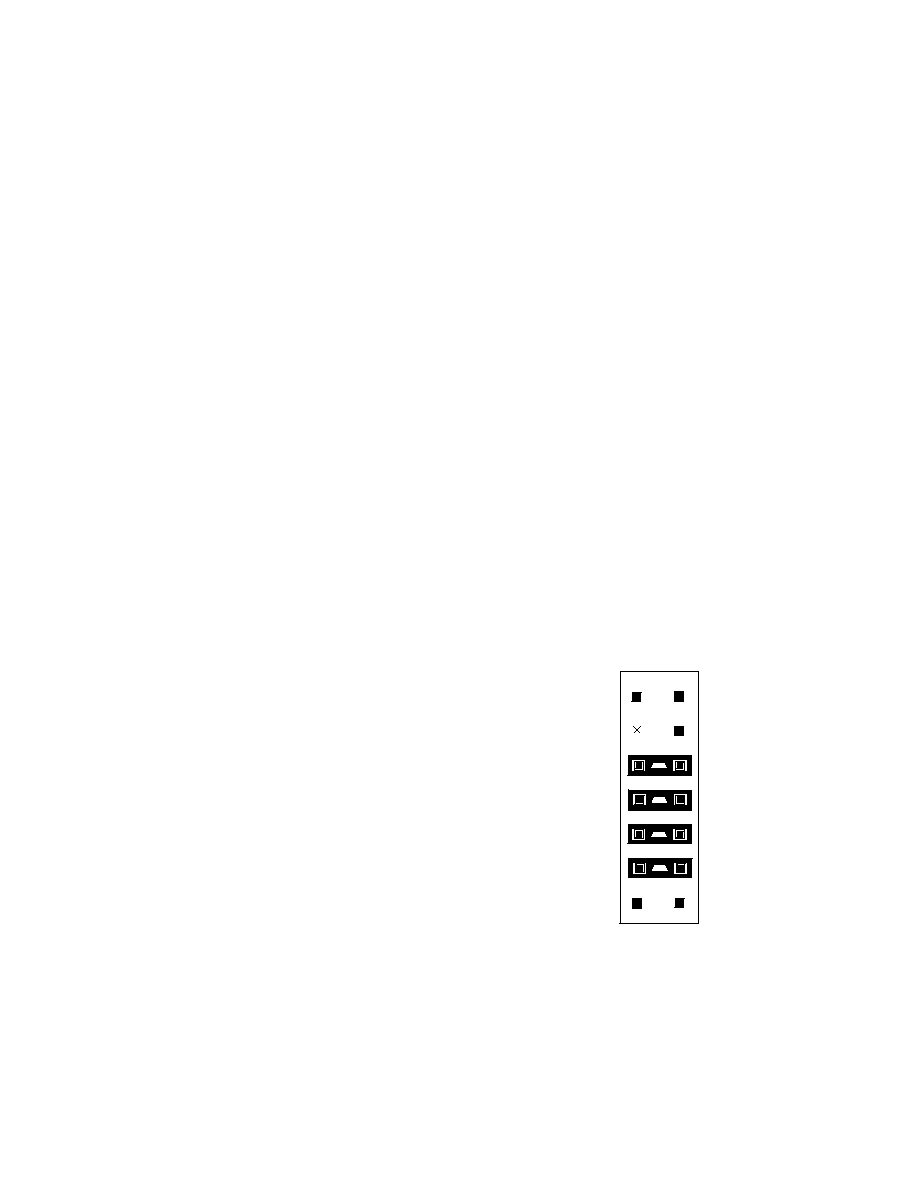

Target Board Header

The emulator interface to an Analog Devices JTAG DSP is a

14-pin header, as shown in

Figure 6

. The customer must supply

this header on the target board in order to communicate with the

emulator. The interface consists of a standard dual row 0.025"

square post header, set on 0.1"

×

0.1" spacing, with a minimum

post length of 0.235". Pin 3 is the key position used to prevent

the pod from being inserted backwards. This pin must be clipped

on the target board.

Also, the clearance (length, width, and height) around the header

must be considered. Leave a clearance of at least 0.15" and 0.10"

around the length and width of the header, and reserve a height

clearance to attach and detach the pod connector.

As can be seen in

Figure 6

, there are two sets of signals on the

header. There are the standard JTAG signals TMS, TCK, TDI,

TDO,

TRST, and EMU used for emulation purposes (via an

emulator). There are also secondary JTAG signals BTMS,

BTCK, BTDI, and

BTRST that are optionally used for board-

level (boundary scan) testing.

When the emulator is not connected to this header, place jumpers

across BTMS, BTCK,

BTRST, and BTDI as shown in

Figure 7

.

This holds the JTAG signals in the correct state to allow the DSP

to run free. Remove all the jumpers when connecting the

emulator to the JTAG header.

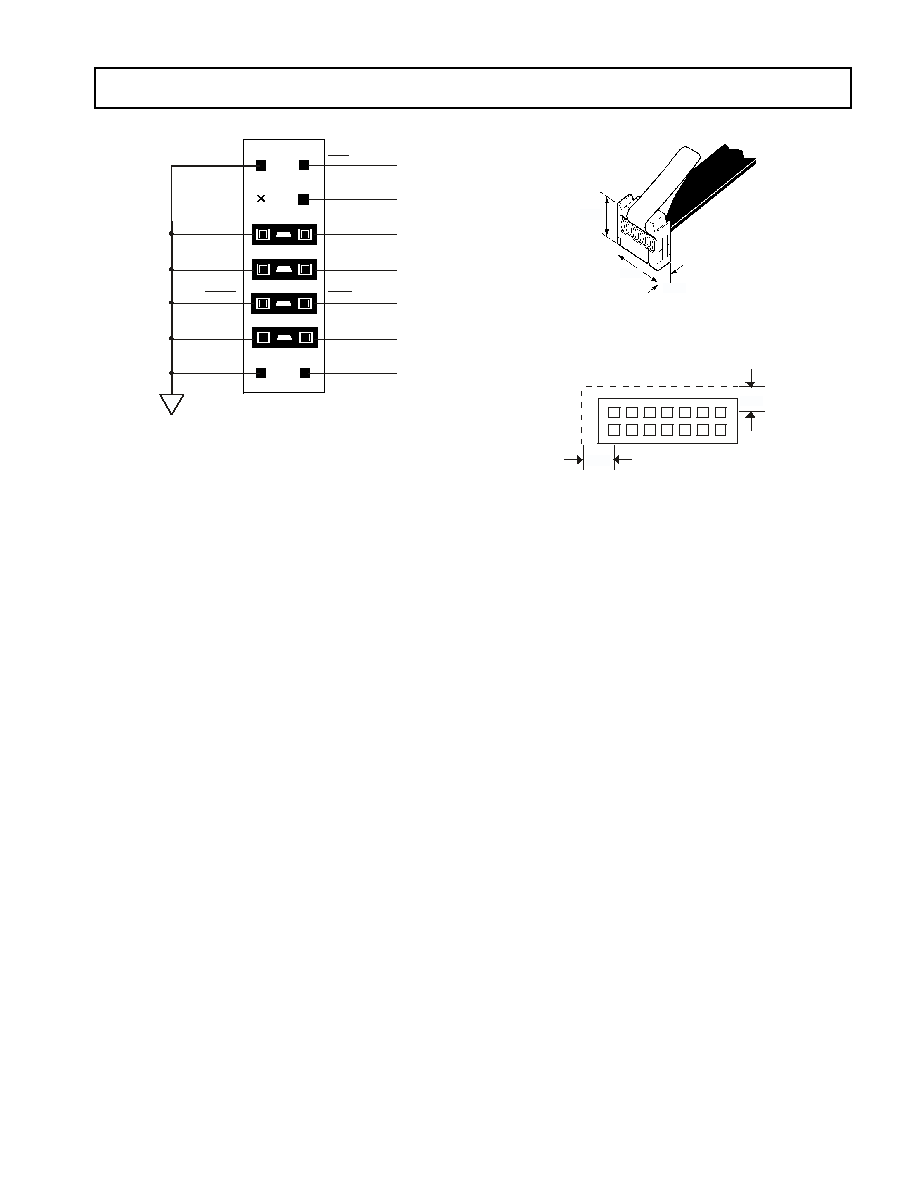

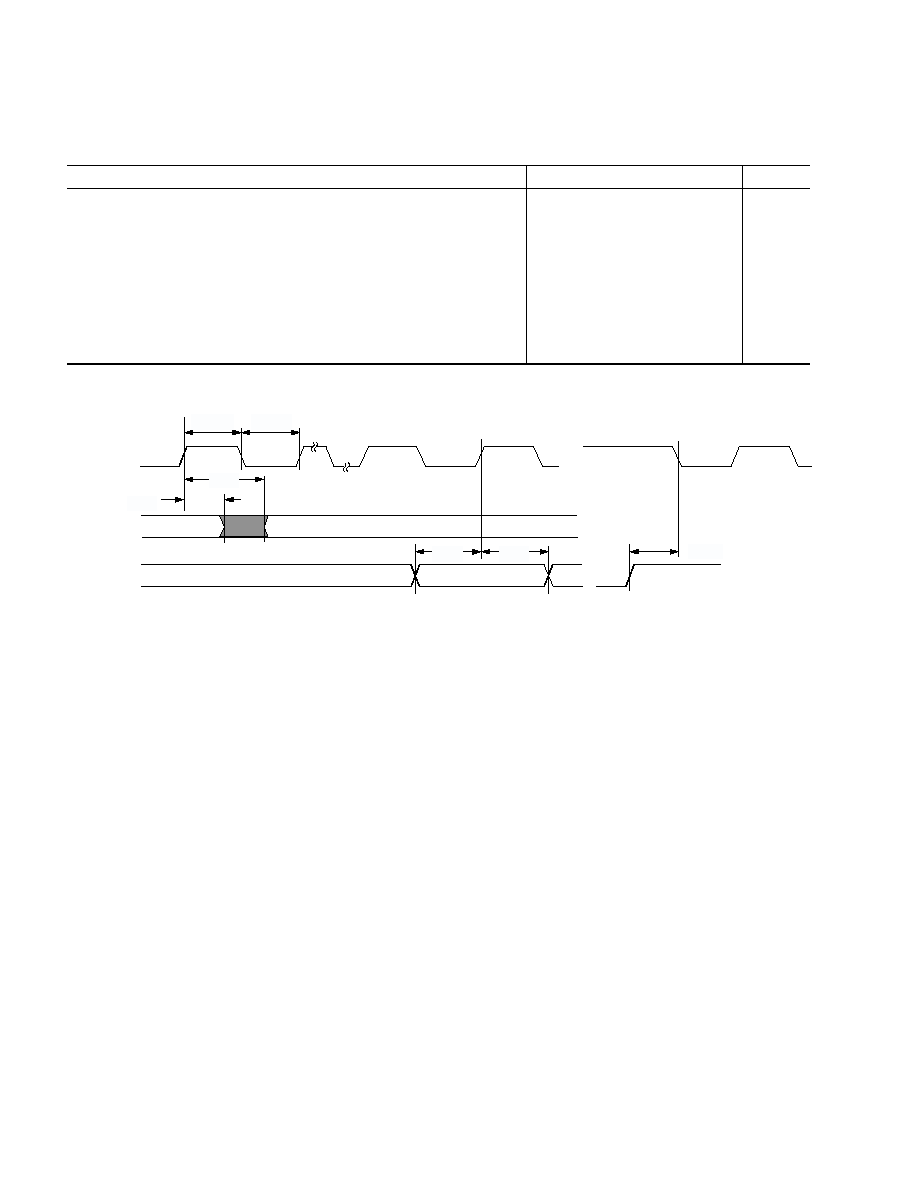

Figure 6. JTAG Target Board Connector for JTAG

Equipped Analog Devices DSP (Jumpers in Place)

TOP VIEW

13

14

11

12

9

10

7

8

5

6

3

4

1

2

GND

TMS

TCK

TDI

TDO

GND

KEY (NO PIN)

BTMS

BTCK

BTDI

GND

BTRST

TRST

EMU

11

REV. A

ADSP-21161N

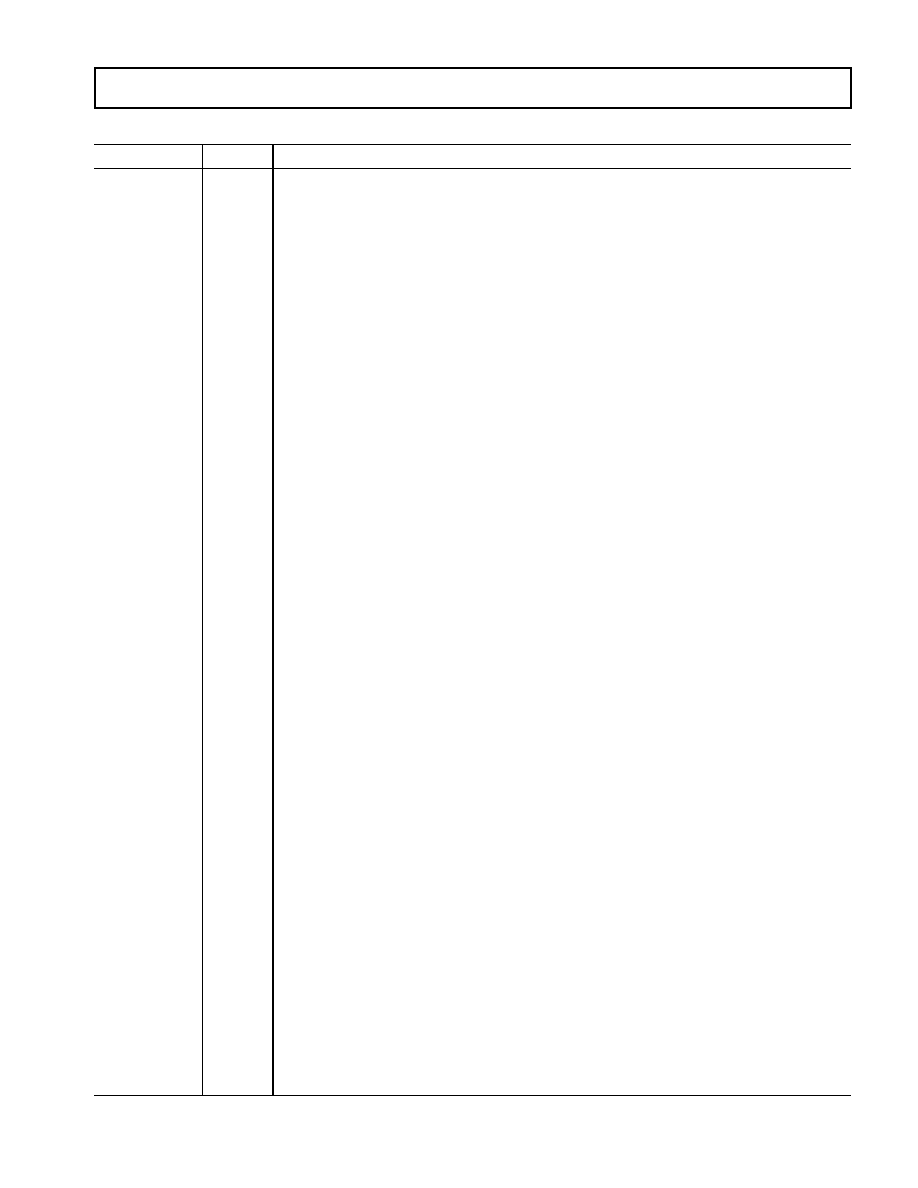

JTAG Emulator Pod Connector

Figure 8

details the dimensions of the JTAG pod connector at the

14-pin target end.

Figure 9

displays the keep-out area for a target

board header. The keep-out area enables the pod connector to

properly seat onto the target board header. This board area

should contain no components (chips, resistors, capacitors, etc.).

The dimensions are referenced to the center of the 0.025" square

post pin.

Design-for-Emulation Circuit Information

For details on target board design issues including mechanical

layout, single processor connections, multiprocessor scan chains,

signal buffering, signal termination, and emulator pod logic, see

the EE-68: Analog Devices

JTAG Emulation Technical Reference on

the Analog Devices website (

www.analog.com

)--use site search

on "EE-68". This document is updated regularly to keep pace

with improvements to emulator support.

Additional Information

This data sheet provides a general overview of the ADSP-21161N

architecture and functionality. For detailed information on the

ADSP-2116x Family core architecture and instruction set, refer

to the ADSP-21161 SHARC DSP Hardware Reference and the

ADSP-21160 SHARC DSP Instruction Set Reference.

Figure 7. JTAG Target Board Connector with No

Local Boundary Scan

TOP VIEW

13

14

11

12

9

10

9

7

8

5

6

3

4

1

2

EMU

GND

TMS

TCK

TRST

TDI

TDO

GND

KEY (NO PIN)

BTMS

BTCK

BTRST

BTDI

GND

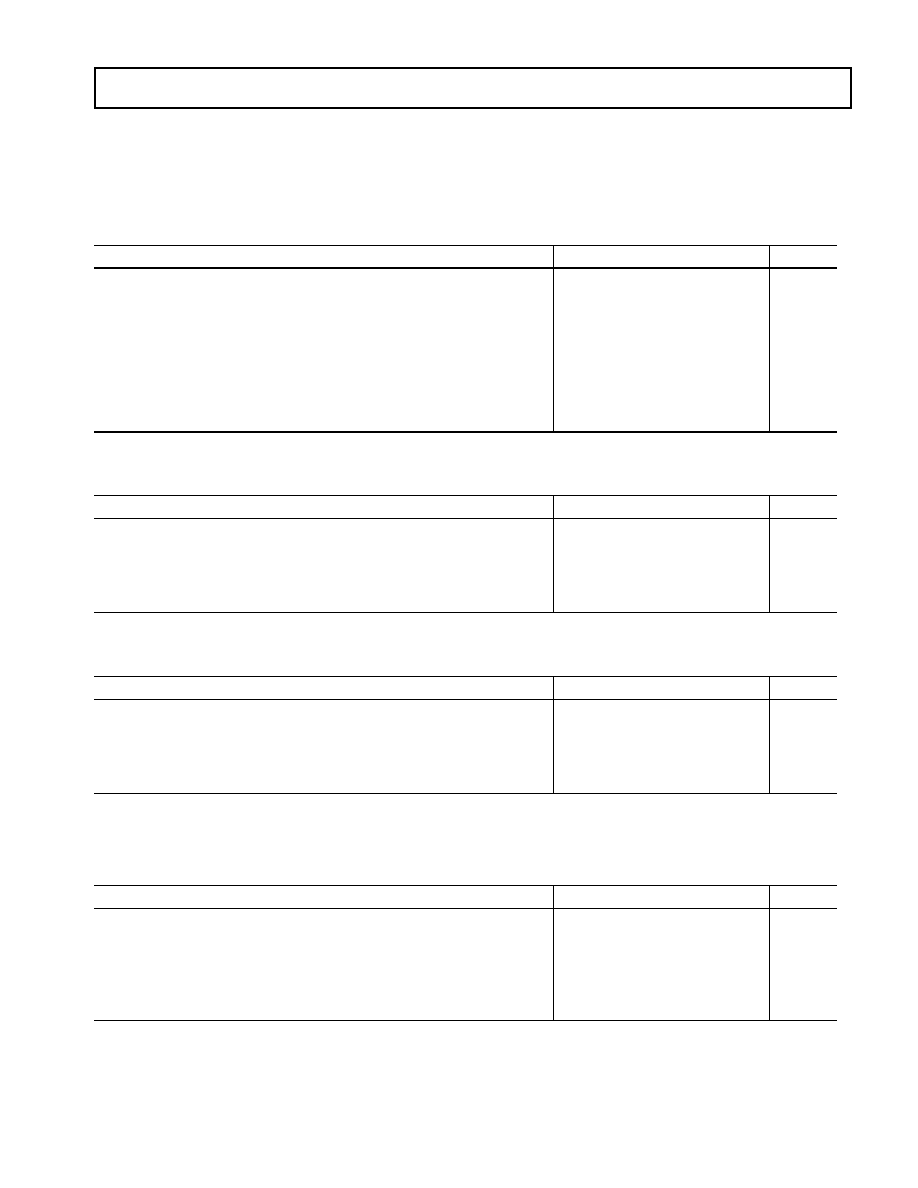

Figure 8. JTAG Pod Connector Dimensions

Figure 9. JTAG Pod Connector Keep-Out Area

0.64"

0.88"

0.24"

0.10"

0.15"

ADSP-21161N

12

REV. A

PIN FUNCTION DESCRIPTIONS

ADSP-21161N pin definitions are listed below. Inputs identified

as synchronous (S) must meet timing requirements with respect

to CLKIN (or with respect to TCK for TMS, TDI). Inputs

identified as asynchronous (A) can be asserted asynchronously

to CLKIN (or to TCK for

TRST).Tie or pull unused inputs to

V

DDEXT

or GND, except for the following:

·

ADDR23 0, DATA47 0, BRST, CLKOUT (Note:

These pins have a logic-level hold circuit enabled on the

ADSP-21161N DSP with ID2 0 = 00x.)

·

PA, ACK, RD, WR, DMARx, DMAGx, (ID20 = 00x)

(Note: These pins have a pull-up enabled on the ADSP-

21161N DSP with ID2 0 = 00x.)

·

LxCLK, LxACK, LxDAT7 0 (LxPDRDE = 0) (Note:

See Link Port Buffer Control Register Bit definitions in

the ADSP-21161N SHARC DSP Hardware Reference.)

·

DxA, DxB, SCLKx, SPICLK, MISO, MOSI,

EMU,

TMS,

TRST, TDI (Note: These pins have a pull-up.)

The following symbols appear in the Type column of

Table 2

:

A = Asynchronous, G = Ground, I = Input, O = Output,

P = Power Supply, S = Synchronous, (A/D) = Active Drive,

(O/D) = Open Drain, and T = Three-State (when

SBTS is

asserted or when the ADSP-21161N is a bus slave).

Unlike previous SHARC processors, the ADSP-21161N

contains internal series resistance equivalent to 50

on all

input/output drivers except the CLKIN and XTAL pins.

Therefore, for traces longer than six inches, external series

resistors on control, data, clock, or frame sync pins are not

required to dampen reflections from transmission line effects for

point-to-point connections. However, for more complex

networks such as a star configuration, series termination is still

recommended.

Table 2. Pin Function Descriptions

Pin Type

Function

ADDR23

0

I/O/T

External Bus Address. The ADSP-21161N outputs addresses for external memory and

peripherals on these pins. In a multiprocessor system the bus master outputs addresses for

read/writes of the IOP registers of other ADSP-21161Ns while all other internal memory

resources can be accessed indirectly via DMA control (that is, accessing IOP DMA parameter

registers). The ADSP-21161N inputs addresses when a host processor or multiprocessing

bus master is reading or writing its IOP registers. A keeper latch on the DSP's ADDR23-0

pins maintains the input at the level it was last driven. This latch is only enabled on the

ADSP-21161N with ID2

0 = 00x.

DATA47

16

I/O/T

External Bus Data. The ADSP-21161N inputs and outputs data and instructions on these

pins. Pull-up resistors on unused data pins are not necessary. A keeper latch on the DSP's

DATA47

16 pins maintains the input at the level it was last driven. This latch is only enabled

on the ADSP-21161N with ID2

0 = 00x.

Note: DATA15

8 pins (multiplexed with L1DAT7

0) can also be used to extend the data bus if

the link ports are disabled and will not be used. In addition, DATA7

0 pins (multiplexed with

L0DAT7

0) can also be used to extend the data bus if the link ports are not used. This enables

execution of 48-bit instructions from external SBSRAM (system clock speed-external port), SRAM

(system clock speed-external port) and SDRAM (core clock or one-half the core clock speed). The

IPACKx Instruction Packing Mode Bits in SYSCON should be set correctly (IPACK1

0 = 0x1)

to enable this full instruction Width/No-packing Mode of operation.

MS30

I/O/T

Memory Select Lines. These outputs are asserted (low) as chip selects for the corre-

sponding banks of external memory. Memory bank sizes are fixed to 16 M words for non-

SDRAM and 64 M words for SDRAM. The

MS30 outputs are decoded memory address

lines. In asynchronous access mode, the

MS30 outputs transition with the other address

outputs. In synchronous access modes, the

MS30 outputs assert with the other address

lines; however, they deassert after the first CLKIN cycle in which ACK is sampled asserted.

In a multiprocessor system, the

MSx signals are tracked by slave SHARCs. The internal

addresses 24 and 25 are zeros and 26 and 27 are decoded into

MS30.

RD

I/O/T

Memory Read Strobe.

RD is asserted whenever ADSP-21161N reads a word from external

memory or from the IOP registers of other ADSP-21161Ns. External devices, including

other ADSP-21161Ns, must assert

RD for reading from a word of the ADSP-21161N IOP

register memory. In a multiprocessing system,

RD is driven by the bus master. RD has a

20 k

internal pull-up resistor that is enabled for DSPs with ID2

0 = 00x.

13

REV. A

ADSP-21161N

WR

I/O/T

Memory Write Low Strobe.

WR is asserted when ADSP-21161N writes a word to external

memory or IOP registers of other ADSP-21161Ns. External devices must assert

WR for

writing to ADSP-21161N IOP registers. In a multiprocessing system, the bus master drives

WR. WR has a 20 k

internal pull-up resistor that is enabled for DSPs with ID2

0 = 00x.

BRST

I/O/T

Sequential Burst Access. BRST is asserted by ADSP-21161N to indicate that data

associated with consecutive addresses is being read or written. A slave device samples the

initial address and increments an internal address counter after each transfer. The incre-

mented address is not pipelined on the bus. A master ADSP-21161N in a multiprocessor

environment can read slave external port buffers (EPBx) using the burst protocol. BRST is

asserted after the initial access of a burst transfer. It is asserted for every cycle after that,

except for the last data request cycle (denoted by

RD or WR asserted and BRST negated).

A keeper latch on the DSP's BRST pin maintains the input at the level it was last driven.

This latch is only enabled on the ADSP-21161N with ID2

0 = 00x.

ACK

I/O/S

Memory Acknowledge. External devices can de-assert ACK (low) to add wait states to an

external memory access. ACK is used by I/O devices, memory controllers, or other periph-

erals to hold off completion of an external memory access. The ADSP-21161N deasserts

ACK as an output to add wait states to a synchronous access of its IOP registers. ACK has

a 20 k

internal pull-up resistor that is enabled during reset or on DSPs with ID2

0 = 00x.

SBTS

I/S

Suspend Bus and Three-State. External devices can assert

SBTS (low) to place the

external bus address, data, selects, and strobes in a high impedance state for the following

cycle. If the ADSP-21161N attempts to access external memory while

SBTS is asserted, the

processor will halt and the memory access will not be completed until

SBTS is deasserted.

SBTS should only be used to recover from host processor/ADSP-21161N deadlock.

CAS

I/O/T

SDRAM Column Access Strobe. In conjunction with

RAS, MSx, SDWE, SDCLKx,

and sometimes SDA10, defines the operation for the SDRAM to perform.

RAS

I/O/T

SDRAM Row Access Strobe. In conjunction with

CAS, MSx, SDWE, SDCLKx, and

sometimes SDA10, defines the operation for the SDRAM to perform.

SDWE

I/O/T

SDRAM Write Enable. In conjunction with

CAS, RAS, MSx, SDCLKx, and sometimes

SDA10, defines the operation for the SDRAM to perform.

DQM

O/T

SDRAM Data Mask. In write mode, DQM has a latency of zero and is used during a

precharge command and during SDRAM power-up initialization.

SDCLK0

I/O/S/T

SDRAM Clock Output 0. Clock for SDRAM devices.

SDCLK1

O/S/T

SDRAM Clock Output 1. Additional clock for SDRAM devices. For systems with multiple

SDRAM devices, handles the increased clock load requirements, eliminating need of off-

chip clock buffers. Either SDCLK1 or both SDCLKx pins can be three-stated.

SDCKE

I/O/T

SDRAM Clock Enable. Enables and disables the CLK signal. For details, see the data

sheet supplied with the SDRAM device.

SDA10

O/T

SDRAM A10 Pin. Enables applications to refresh an SDRAM in parallel with a non-

SDRAM accesses or host accesses. This pin replaces the DSP's A10 pin only during SDRAM

accesses.

IRQ20

I/A

Interrupt Request Lines. These are sampled on the rising edge of CLKIN and may be

either edge-triggered or level-sensitive.

FLAG11

0

I/O/A

Flag Pins. Each is configured via control bits as either an input or output. As an input, it

can be tested as a condition. As an output, it can be used to signal external peripherals.

TIMEXP

O

Timer Expired. Asserted for four core clock cycles when the timer is enabled and

TCOUNT decrements to zero.

HBR

I/A

Host Bus Request. Must be asserted by a host processor to request control of the ADSP-

21161N's external bus. When

HBR is asserted in a multiprocessing system, the ADSP-

21161N that is bus master will relinquish the bus and assert

HBG. To relinquish the bus,

the ADSP-21161N places the address, data, select, and strobe lines in a high impedance

state.

HBR has priority over all ADSP-21161N bus requests (BR61) in a multiprocessing

system.

Table 2. Pin Function Descriptions (continued)

Pin Type

Function

ADSP-21161N

14

REV. A

HBG

I/O

Host Bus Grant. Acknowledges an

HBR bus request, indicating that the host processor

may take control of the external bus.

HBG is asserted (held low) by the ADSP-21161N until

HBR is released. In a multiprocessing system, HBG is output by the ADSP-21161N bus

master and is monitored by all others.

After

HBR is asserted, and before HBG is given, HBG will float for 1 t

CK

(1 CLKIN cycle).

To avoid erroneous grants,

HBG should be pulled up with a 20k

to 50k

external resistor.

CS

I/A

Chip Select. Asserted by host processor to select the ADSP-21161N.

REDY O

(O/D)

Host Bus Acknowledge. The ADSP-21161N deasserts REDY (low) to add wait states to

a host access of its IOP registers when

CS and HBR inputs are asserted.

DMAR1

I/A

DMA Request 1 (DMA Channel 11). Asserted by external port devices to request DMA

services.

DMAR1 has a 20 k

internal pull-up resistor that is enabled for DSPs with

ID2

0 = 00x.

DMAR2

I/A

DMA Request 2 (DMA Channel 12). Asserted by external port devices to request DMA

services.

DMAR2 has a 20 k

internal pull-up resistor that is enabled for DSPs with

ID2

0 = 00x.

DMAG1

O/T

DMA Grant 1 (DMA Channel 11). Asserted by ADSP-21161N to indicate that the

requested DMA starts on the next cycle. Driven by bus master only.

DMAG1 has a 20 k

internal pull-up resistor that is enabled for DSPs with ID2

0 = 00x.

DMAG2

O/T

DMA Grant 2 (DMA Channel 12). Asserted by ADSP-21161N to indicate that the

requested DMA starts on the next cycle. Driven by bus master only.

DMAG2 has a 20 k

internal pull-up resistor that is enabled for DSPs with ID2

0 = 00x.

BR61

I/O/S

Multiprocessing Bus Requests. Used by multiprocessing ADSP-21161Ns to arbitrate for

bus mastership. An ADSP-21161N only drives its own

BRx line (corresponding to the value

of its ID2

0 inputs) and monitors all others. In a multiprocessor system with less than six

ADSP-21161Ns, the unused

BRx pins should be pulled high; the processor's own BRx line

must not be pulled high or low because it is an output.

BMSTR

O

Bus Master Output. In a multiprocessor system, indicates whether the ADSP-21161N is

current bus master of the shared external bus. The ADSP-21161N drives BMSTR high only

while it is the bus master. In a single-processor system (ID = 000), the processor drives this

pin high. This pin is used for debugging purposes.

ID2

0

I

Multiprocessing ID. Determines which multiprocessing bus request (

BR6

BR1) is used

by ADSP-21161N. ID = 001 corresponds to

BR1, ID=010 corresponds to BR2, and so on.

Use ID = 000 or ID = 001 in single-processor systems. These lines are a system configuration

selection that should be hardwired or only changed at reset.

RPBA

I/S

Rotating Priority Bus Arbitration Select. When RPBA is high, rotating priority for

multiprocessor bus arbitration is selected. When RPBA is low, fixed priority is selected. This

signal is a system configuration selection that must be set to the same value on every ADSP-

21161N. If the value of RPBA is changed during system operation, it must be changed in

the same CLKIN cycle on every ADSP-21161N.

PA

I/O/T

Priority Access. Asserting its

PA pin enables an ADSP-21161N bus slave to interrupt

background DMA transfers and gain access to the external bus.

PA is connected to all ADSP-

21161Ns in the system. If access priority is not required in a system, the

PA pin should be

left unconnected.

PA has a 20 k

internal pull-up resistor that is enabled for DSPs with

ID2

0 = 00x.

DxA

I/O

Data Transmit or Receive Channel A (Serial Ports 0, 1, 2, 3). Each DxA pin has an

internal pull-up resistor. Bidirectional data pin. This signal can be configured as an output

to transmit serial data, or as an input to receive serial data.

DxB

I/O

Data Transmit or Receive Channel B (Serial Ports 0, 1, 2, 3). Each DxB pin has an

internal pull-up resistor. Bidirectional data pin. This signal can be configured as an output

to transmit serial data, or as an input to receive serial data.

SCLKx

I/O

Transmit/Receive Serial Clock (Serial Ports 0, 1, 2, 3). Each SCLK pin has an internal

pull-up resistor. This signal can be either internally or externally generated.

Table 2. Pin Function Descriptions (continued)

Pin Type

Function

15

REV. A

ADSP-21161N

FSx

I/O

Transmit or Receive Frame Sync (Serial Ports 0, 1, 2, 3). The frame sync pulse initiates

shifting of serial data. This signal is either generated internally or externally. It can be active

high or low or an early or a late frame sync, in reference to the shifting of serial data.

SPICLK

I/O

Serial Peripheral Interface Clock Signal. Driven by the master, this signal controls the

rate at which data is transferred. The master may transmit data at a variety of baud rates.

SPICLK cycles once for each bit transmitted. SPICLK is a gated clock that is active during

data transfers, only for the length of the transferred word. Slave devices ignore the serial

clock if the slave select input is driven inactive (HIGH). SPICLK is used to shift out and

shift in the data driven on the MISO and MOSI lines. The data is always shifted out on one

clock edge of the clock and sampled on the opposite edge of the clock. Clock polarity and

clock phase relative to data are programmable into the SPICTL control register and define

the transfer format. SPICLK has a 50 k

internal pull-up resistor.

SPIDS

I

Serial Peripheral Interface Slave Device Select. An active low signal used to enable

slave devices. This input signal behaves like a chip select, and is provided by the master device

for the slave devices. In multimaster mode

SPIDS signal can be asserted to a master device

to signal that an error has occurred, as some other device is also trying to be the master

device. If asserted low when the device is in master mode, it is considered a multimaster

error. For a single-master, multiple-slave configuration where FLAG3

0 are used, this pin

must be tied or pulled high to V

DDEXT

on the master device. For ADSP-21161N to ADSP-

21161N SPI interaction, any of the master ADSP-21161N's FLAG3

0 pins can be used to

drive the

SPIDS signal on the ADSP-21161N SPI slave device.

MOSI

I/O (o/d)

SPI Master Out Slave. If the ADSP-21161N is configured as a master, the MOSI pin

becomes a data transmit (output) pin, transmitting output data. If the ADSP-21161N is

configured as a slave, the MOSI pin becomes a data receive (input) pin, receiving input data.

In an ADSP-21161N SPI interconnection, the data is shifted out from the MOSI output pin

of the master and shifted into the MOSI input(s) of the slave(s). MOSI has an internal pull-

up resistor.

MISO

I/O (o/d)

SPI Master In Slave Out. If the ADSP-21161N is configured as a master, the MISO pin

becomes a data receive (input) pin, receiving input data. If the ADSP-21161N is configured

as a slave, the MISO pin becomes a data transmit (output) pin, transmitting output data. In

an ADSP-21161N SPI interconnection, the data is shifted out from the MISO output pin

of the slave and shifted into the MISO input pin of the master. MISO has an internal pull-

up resistor. MISO can be configured as o/d by setting the OPD bit in the SPICTL register.

Note: Only one slave is allowed to transmit data at any given time.

LxDAT7

0

[DATA15

0]

I/O

[I/O/T]

Link Port Data (Link Ports 0

1).

For silicon revisions 1.2 and higher, each LxDAT pin has a keeper latch that is enabled when

used as a data pin; or a 20 k

internal pull-down resistor that is enabled or disabled by the

LxPDRDE bit of the LCTL register.

For silicon revisions 0.3, 1.0, and 1.1 each LxDAT pin has a 50 k

internal pull-down resistor

that is enabled or disabled by the LxPDRDE bit of the LCTL register.

Note: L1DAT7

0 are multiplexed with the DATA15

8 pins L0DAT7

0 are multiplexed with the

DATA7

0 pins. If link ports are disabled and are not used, these pins can be used as additional

data lines for executing instructions at up to the full clock rate from external memory. See

DATA47

16 for more information.

LxCLK

I/O

Link Port Clock (Link Ports 0

1). Each LxCLK pin has an internal pull-down 50 k

resistor that is enabled or disabled by the LxPDRDE bit of the LCTL register.

LxACK

I/O

Link Port Acknowledge (Link Ports 0

1). Each LxACK pin has an internal pull-down

50 k

resistor that is enabled or disabled by the LxPDRDE bit of the LCTL register.

EBOOT

I

EPROM Boot Select. For a description of how this pin operates, see the table in the

BMS

pin description. This signal is a system configuration selection that should be hardwired.

LBOOT

I

Link Boot. For a description of how this pin operates, see the table in the

BMS pin

description. This signal is a system configuration selection that should be hardwired.

Table 2. Pin Function Descriptions (continued)

Pin Type

Function

ADSP-21161N

16

REV. A

BMS

I/O/T

Boot Memory Select. Serves as an output or input as selected with the EBOOT and

LBOOT pins (see

Table 4

). This input is a system configuration selection that should be

hardwired. For Host and PROM boot, DMA channel 10 (EPB0) is used. For Link boot and

SPI boot, DMA channel 8 is used.

Three-state only in EPROM boot mode (when

BMS is an output).

CLKIN

I

Local Clock In. Used in conjunction with XTAL. CLKIN is the ADSP-21161N clock input.

It configures the ADSP-21161N to use either its internal clock generator or an external clock

source. Connecting the necessary components to CLKIN and XTAL enables the internal

clock generator. Connecting the external clock to CLKIN while leaving XTAL unconnected

configures the ADSP-21161N to use the external clock source such as an external clock

oscillator.The ADSP-21161N external port cycles at the frequency of CLKIN. The

instruction cycle rate is a multiple of the CLKIN frequency; it is programmable at power-

up via the CLK_CFG1

0 pins. CLKIN may not be halted, changed, or operated below the

specified frequency.

XTAL

O

Crystal Oscillator Terminal 2. Used in conjunction with CLKIN to enable the ADSP-

21161N's internal clock oscillator or to disable it to use an external clock source. See CLKIN.

CLK_CFG1-0 I

Core/CLKIN Ratio Control. ADSP-21161N core clock (instruction cycle) rate is equal

to n

×

PLLICLK where n is user selectable to 2, 3, or 4, using the CLK_CFG1

0 inputs.

These pins can also be used in combination with the

CLKDBL pin to generate additional

core clock rates of 6

×

CLKIN and 8

×

CLKIN (see the Clock Rate Ratios table in the

CLKDBL description).

CLKDBL

I

Crystal Double Mode Enable. This pin is used to enable the 2

×

clock double circuitry,

where CLKOUT can be configured as either 1

×

or 2

×

the rate of CLKIN. This CLKIN

double circuit is primarily intended to be used for an external crystal in conjunction with

the internal clock generator and the XTAL pin. The internal clock generator when used in

conjunction with the XTAL pin and an external crystal is designed to support up to a

maximum of 25 MHz external crystal frequency.

CLKDBL can be used in XTAL mode to

generate a 50 MHz input into the PLL. The 2

×

clock mode is enabled (during

RESET low)

by tying

CLKDBL to GND, otherwise it is connected to V

DDEXT

for 1

×

clock mode. For

example, this enables the use of a 25 MHz crystal to enable 100 MHz core clock rates and

a 50 MHz CLKOUT operation when CLK_CFG0 = 0, CLK_CFG1 = 0 and

CLKDBL=0.

This pin can also be used to generate different clock rate ratios for external clock oscillators

as well. The possible clock rate ratio options (up to 100 MHz) for either CLKIN (external

clock oscillator) or XTAL (crystal input) are shown in

Table 3 on Page 17

. An 8:1 ratio

enables the use of a 12.5 MHz crystal to generate a 100 MHz core (instruction clock) rate

and a 25 MHz CLKOUT (external port) clock rate. See also

Figure 10 on Page 20

.

Note: When using an external crystal, the maximum crystal frequency cannot exceed 25 MHz.

For all other external clock sources, the maximum CLKIN frequency is 50 MHz.

CLKOUT

O/T

Local Clock Out. CLKOUT is 1

×

or 2

×

and is driven at either 1

×

or 2

×

the frequency of

CLKIN frequency by the current bus master. The frequency is determined by the

CLKDBL

pin. This output is three-stated when the ADSP-21161N is not the bus master or when the

host controls the bus (

HBG asserted). A keeper latch on the DSP's CLKOUT pin maintains

the output at the level it was last driven. This latch is only enabled on the ADSP-21161N

with ID2

0 = 00x.

If

CLKDBL enabled, CLKOUT=2

×

CLKIN

If

CLKDBL disabled, CLKOUT=1

×

CLKIN

Note: CLKOUT is only controlled by the

CLKDBL pin and operates at either 1

×

CLKIN or

2

×

CLKIN.

Do not use CLKOUT in multiprocessing systems. Use CLKIN instead.

RESET

I/A

Processor Reset. Resets the ADSP-21161N to a known state and begins execution at the

program memory location specified by the hardware reset vector address. The

RESET input

must be asserted (low) at power-up.

Table 2. Pin Function Descriptions (continued)

Pin Type

Function

17

REV. A

ADSP-21161N

BOOT MODES

RSTOUT

1

O

Reset Out. When

RSTOUT is asserted (low), this pin indicates that the core blocks are in

reset. It is deasserted 4080 cycles after

RESET is deasserted indicating that the PLL is stable

and locked.

TCK

I

Test Clock (JTAG). Provides a clock for JTAG boundary scan.

TMS

I/S

Test Mode Select (JTAG). Used to control the test state machine. TMS has a 20 k

internal

pull-up resistor.

TDI

I/S

Test Data Input (JTAG). Provides serial data for the boundary scan logic. TDI has a 20 k

internal pull-up resistor.

TDO

O

Test Data Output (JTAG). Serial scan output of the boundary scan path.

TRST

I/A

Test Reset (JTAG). Resets the test state machine.

TRST must be asserted (pulsed low)

after power-up or held low for proper operation of the ADSP-21161N.

TRST has a 20 k

internal pull-up resistor.

EMU

O (O/D)

Emulation Status. Must be connected to the ADSP-21161N Analog Devices DSP Tools

product line of JTAG emulators target board connector only.

EMU has a 50 k

internal

pull-up resistor.

V

DDINT

P

Core Power Supply. Nominally +1.8 V dc and supplies the DSP's core processor (14 pins).

V

DDEXT

P

I/O Power Supply. Nominally +3.3 V dc. (13 pins).

AVDD

P

Analog Power Supply. Nominally +1.8 V dc and supplies the DSP's internal PLL (clock

generator). This pin has the same specifications as V

DDINT

, except that added filtering

circuitry is required.

See Power Supplies on Page 9.

AGND

G

Analog Power Supply Return.

GND

G

Power Supply Return. (26 pins).

NC

Do Not Connect. Reserved pins that must be left open and unconnected. (5 pins

2

).

1

RSTOUT exists only for silicon revision 1.2.

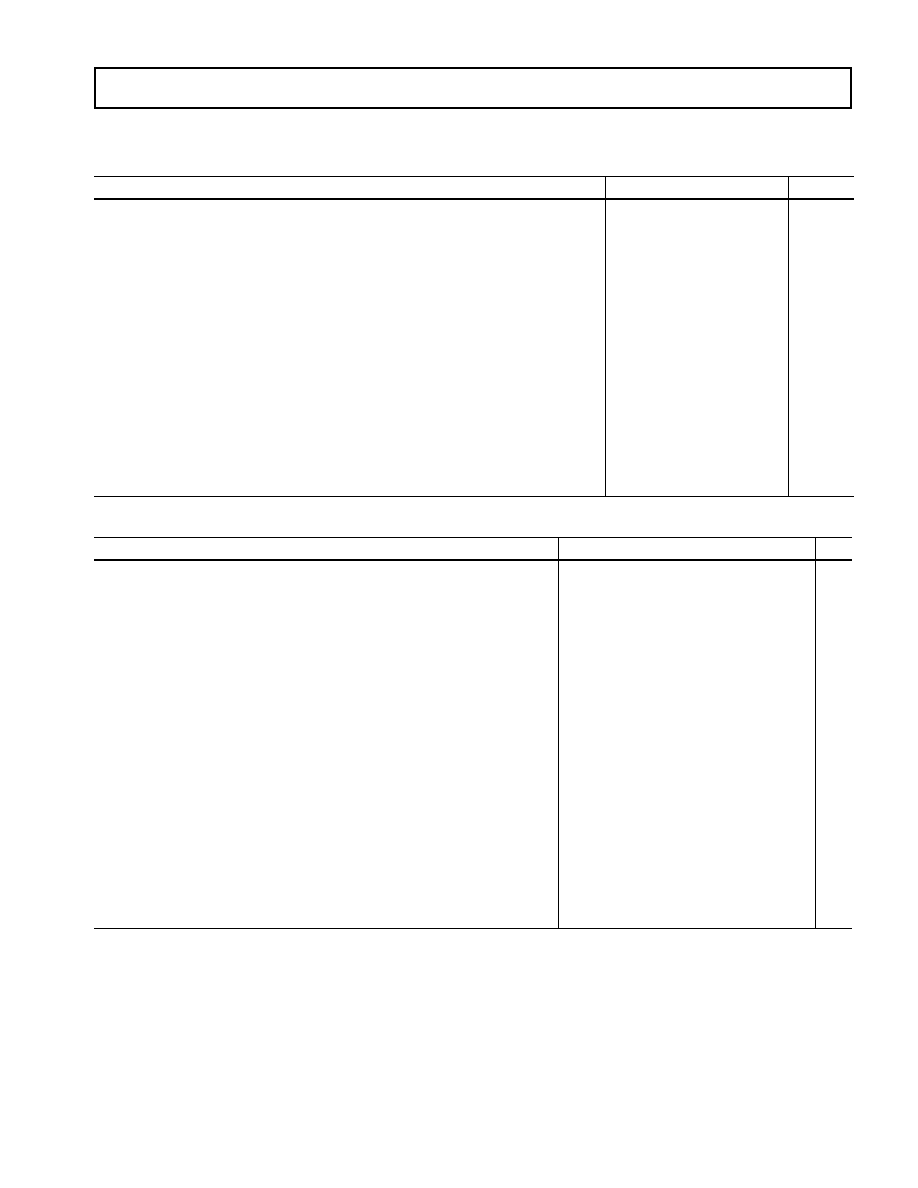

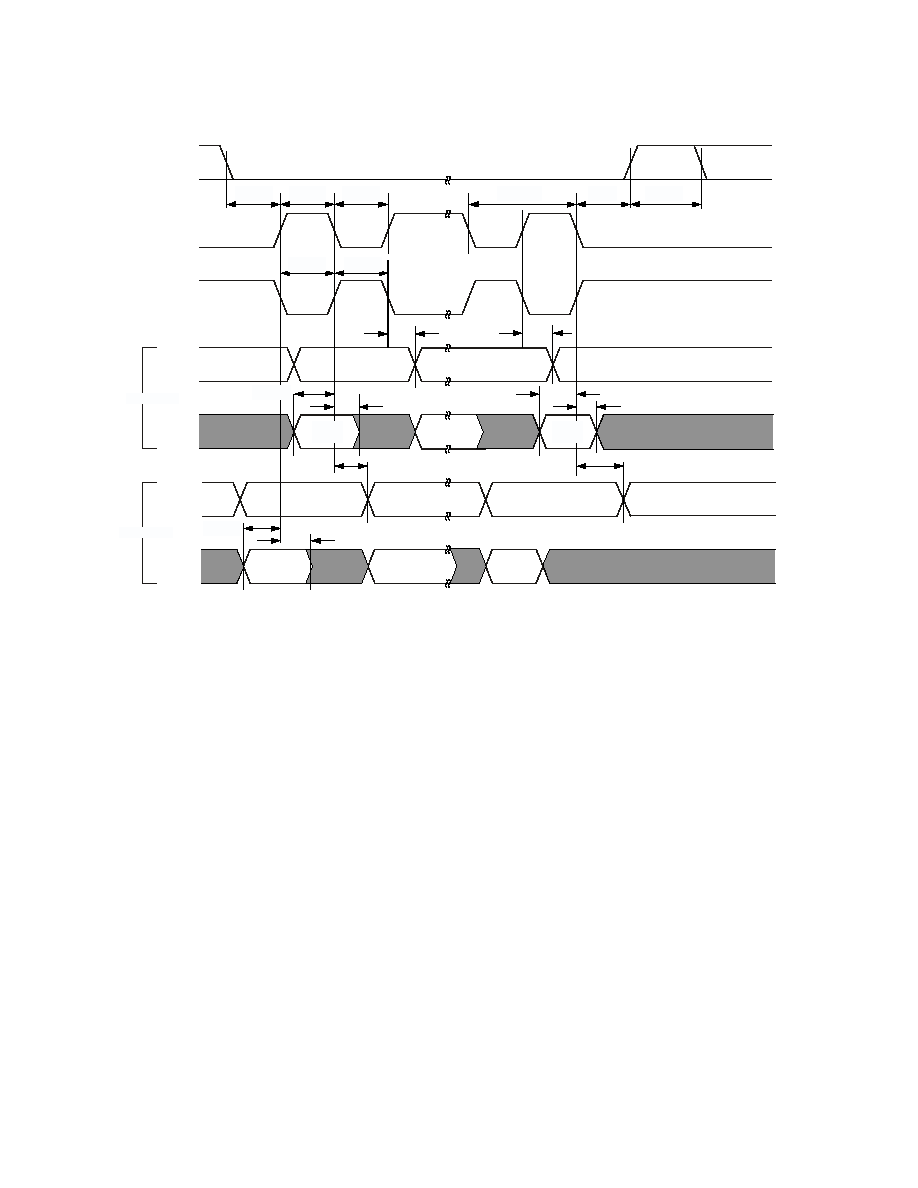

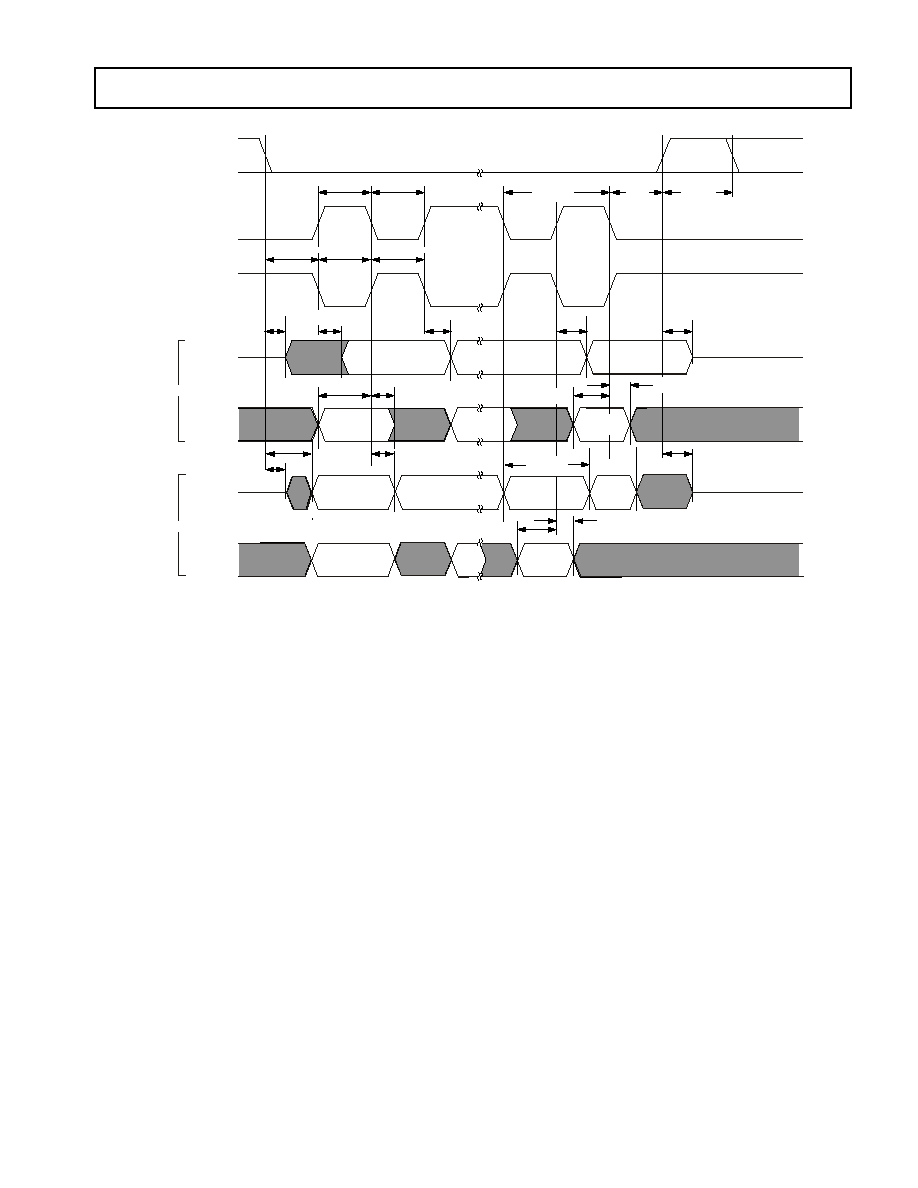

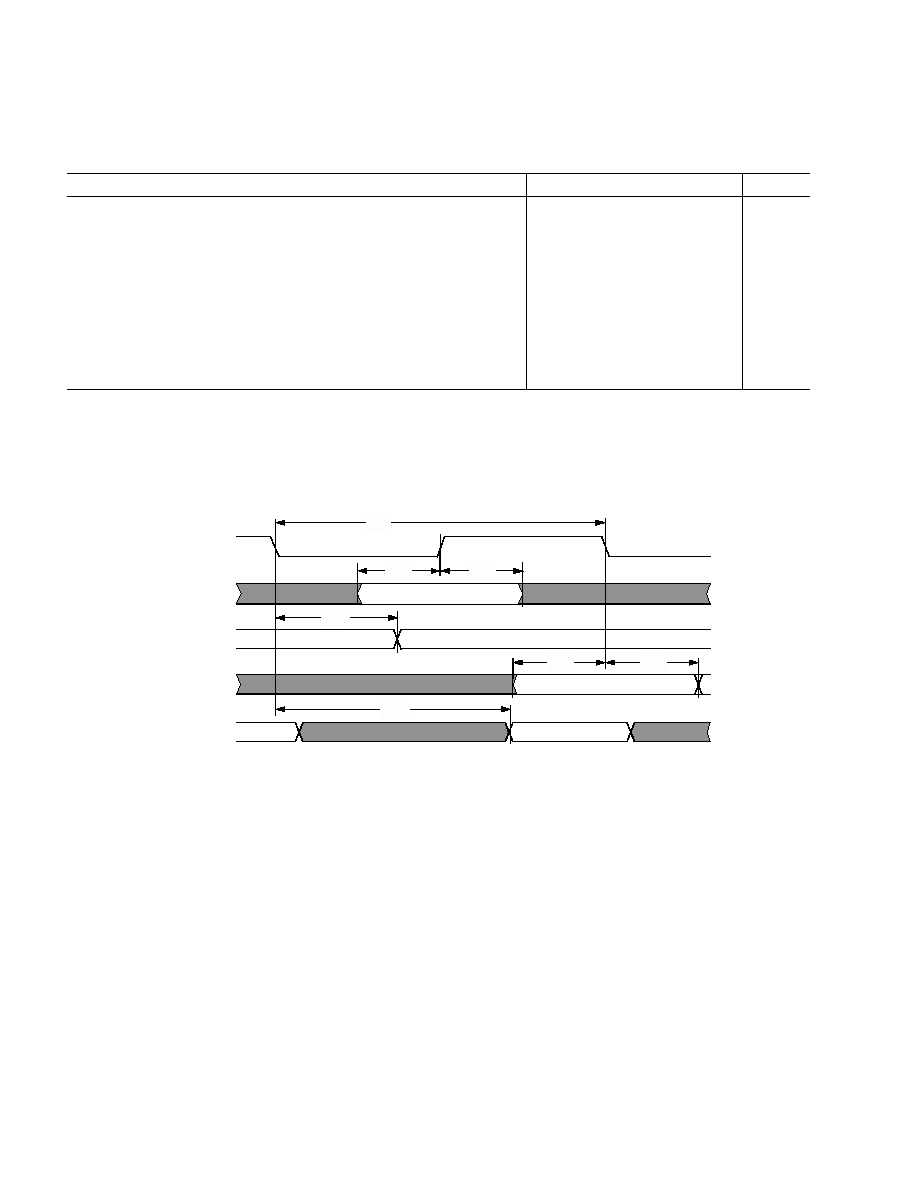

2