Document Outline

- Specifications

- Pinout

- Package drawings

- Ordering Guide

- Features

- Applications

- Product Description

- Absolute Maximum Ratings

- Functional Block Diagram

- Pin Function Description

- Typical Characteristics

- THERMAL CHARACTERISTICS

- GENERAL DESCRIPTION

- INTERNAL REGISTERS OF THE ADM1030

- SERIAL BUS INTERFACE

- ALERT RESPONSE ADDRESS

- TEMPERATURE MEASUREMENT SYSTEM

- ADDRESSING THE DEVICE

- LAYOUT CONSIDERATIONS

- THE ADM1030 INTERRUPT SYSTEM

- USING AS AN INPUT

- MODES OF OPERATION

- STATUS REGISTERS

- AUTOMATIC FAN SPEED CONTROL

- HOW DOES THE CONTROL LOOP WORK?

- FAN SPIN-UP

- PROGRAMMING THE AUTOMATIC FAN SPEED

- CONTROL LOOP

- OTHER CONTROL LOOP PARAMETERS

- CONTROL MODE

- FILTERED CONTROL MODE

- SPEED CONTROL LOOP

- RPM FEEDBACK MODE

- FAN SPEED MEASUREMENT EQUATIONS

- FAN DRIVE USING PWM CONTROL

- FAN SPEED MEASUREMENT

- FAN FAULTS

- DIAGRAMS

- Diagram for Serial Bus Timing

- Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

- Writing to the Address Pointer Register Only

- Reading Data from a Previously Selected Register

- Signal Conditioning

- Operation of THERM and INT Signals

- Automatic Fan Speed Control

- 33% PWM Duty Cycle Represented in Time Slots

- Filtered Mode Algorithm

- Interfacing the ADM1030 to a 3-Wire Fan

- Interfacing the ADM1030 to a 2-Wire Fan

- Fan Speed Measurement

- Operation of FAN_FAULT and Interrupt Pins

- Typical Application Circuit

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

ADM1030*

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 2001

Intelligent Temperature

Monitor and PWM Fan Controller

FUNCTIONAL BLOCK DIAGRAM

SERIAL BUS

INTERFACE

INTERRUPT

STATUS

REGISTER

VALUE AND LIMIT

REGISTERS

OFFSET

REGISTERS

CONFIGURATION

REGISTER

LIMIT

COMPARATOR

2.5V

BANDGAP

REFERENCE

ANALOG

MULTIPLEXER

BANDGAP

TEMPERATURE

SENSOR

SLAVE

ADDRESS

REGISTER

ADD

SDA

SCL

GND

ADM1030

FAN

CHARACTERISTICS

REGISTER

FAN SPEED

CONFIG

REGISTER

T

MIN

/T

RANGE

REGISTER

FAN

SPEED

COUNTER

ADDRESS

POINTER

REGISTER

PWM

CONTROLLER

TACH SIGNAL

CONDITIONING

NC

INT

THERM

FAN_FAULT

NC

NC

NC

PWM_OUT

TACH/AIN

D+

D

V

CC

ADC

NC = NO CONNECT

FEATURES

Optimized for Pentium

®

III: Allows Reduced Guardbanding

Software and Automatic Fan Speed Control

Automatic Fan Speed Control Allows Control Indepen-

dent of CPU Intervention after Initial Setup

Control Loop Minimizes Acoustic Noise and Battery

Consumption

Remote Temperature Measurement Accurate to 1 C

Using Remote Diode

0.125 C Resolution on Remote Temperature Channel

Local Temperature Sensor with 0.25 C Resolution

Pulsewidth Modulation Fan Control (PWM)

Programmable PWM Frequency

Programmable PWM Duty Cycle

Tach Fan Speed Measurement

Analog Input To Measure Fan Speed of 2-Wire Fans

(Using Sense Resistor)

2-Wire System Management Bus (SMBus) with ARA

Support

Overtemperature

THERM Output Pin

Programmable

INT Output Pin

Configurable Offset for All Temperature Channels

3 V to 5.5 V Supply Range

Shutdown Mode to Minimize Power Consumption

APPLICATIONS

Notebook PCs, Network Servers and Personal Computers

Telecommunications Equipment

PRODUCT DESCRIPTION

The ADM1030 is an ACPI-compliant two-channel digital ther-

mometer and under/over temperature alarm, for use in computers

and thermal management systems. Optimized for the Pentium

III, the higher 1

°C accuracy offered allows systems designers to

safely reduce temperature guardbanding and increase system

performance. A Pulsewidth Modulated (PWM) Fan Control out-

put controls the speed of a cooling fan by varying output duty

cycle. Duty cycle values between 33%100% allow smooth

control of the fan. The speed of the fan can be monitored via a

TACH input for a fan with a tach output. The TACH input can

be programmed as an analog input, allowing the speed of a 2-wire

fan to be determined via a sense resistor. The device will also

detect a stalled fan. A dedicated Fan Speed Control Loop pro-

vides control even without the intervention of CPU software. It

also ensures that if the CPU or system locks up, the fan can still

be controlled based on temperature measurements, and the fan

speed adjusted to correct any changes in system temperature.

Fan Speed may also be controlled using existing ACPI software.

One input (two pins) is dedicated to a remote temperature-

sensing diode with an accuracy of

±1°C, and a local temperature

sensor allows ambient temperature to be monitored. The device

has a programmable

INT output to indicate error conditions.

There is a dedicated

FAN_FAULT output to signal fan failure.

The

THERM pin is a fail-safe output for over-temperature

conditions that can be used to throttle a CPU clock.

*Patents pending.

Pentium is a registered

trademark of Intel Corporation.

REV. 0

2

ADM1030SPECIFICATIONS

1

(T

A

= T

MIN

to T

MAX

, V

CC

= V

MIN

to V

MAX

, unless otherwise noted.)

Parameter

Min

Typ

Max

Unit

Test Conditions/Comments

POWER SUPPLY

Supply Voltage, V

CC

3.0

3.30

5.5

V

Supply Current, I

CC

1.4

3

mA

Interface Inactive, ADC Active

32

50

µA

Standby Mode

TEMPERATURE-TO-DIGITAL CONVERTER

Internal Sensor Accuracy

±1

±3

°C

Resolution

0.25

°C

External Diode Sensor Accuracy

±1

°C

60

°C T

D

100°C

Resolution

0.125

°C

Remote Sensor Source Current

180

µA

High Level

11

µA

Low Level

OPEN-DRAIN DIGITAL OUTPUTS

(

THERM, INT, FAN_FAULT, PWM_OUT)

Output Low Voltage, V

OL

0.4

V

I

OUT

= 6.0 mA; V

CC

= 3 V

High-Level Output Leakage Current, I

OH

0.1

1

µA

V

OUT

= V

CC

; V

CC

= 3 V

DIGITAL INPUT LEAKAGE CURRENT

Input High Current, I

IH

1

µA

V

IN

= V

CC

Input Low Current, I

IL

1

µA

V

IN

= 0

Input Capacitance, C

IN

5

pF

DIGITAL INPUT LOGIC LEVELS

2

(ADD,

THERM, TACH)

Input High Voltage, V

IH

2.1

V

Input Low Voltage, V

IL

0.8

V

OPEN-DRAIN SERIAL DATA

BUS OUTPUT (SDA)

Output Low Voltage, V

OL

0.4

V

I

OUT

= 6.0 mA; V

CC

= 3 V

High-Level Output Leakage Current, I

OH

0.1

1

µA

V

OUT

= V

CC

SERIAL BUS DIGITAL INPUTS

(SCL, SDA)

Input High Voltage, V

IH

2.1

V

Input Low Voltage, V

IL

0.8

V

Hysteresis

500

mV

FAN RPM-TO-DIGITAL CONVERTER

Accuracy

±6

%

60

°C T

A

100°C

Resolution

8

Bits

TACH Nominal Input RPM

4400

RPM

Divisor N = 1, Fan Count = 153

2200

RPM

Divisor N = 2, Fan Count = 153

1100

RPM

Divisor N = 4, Fan Count = 153

550

RPM

Divisor N = 8, Fan Count = 153

Conversion Cycle Time

637

ms

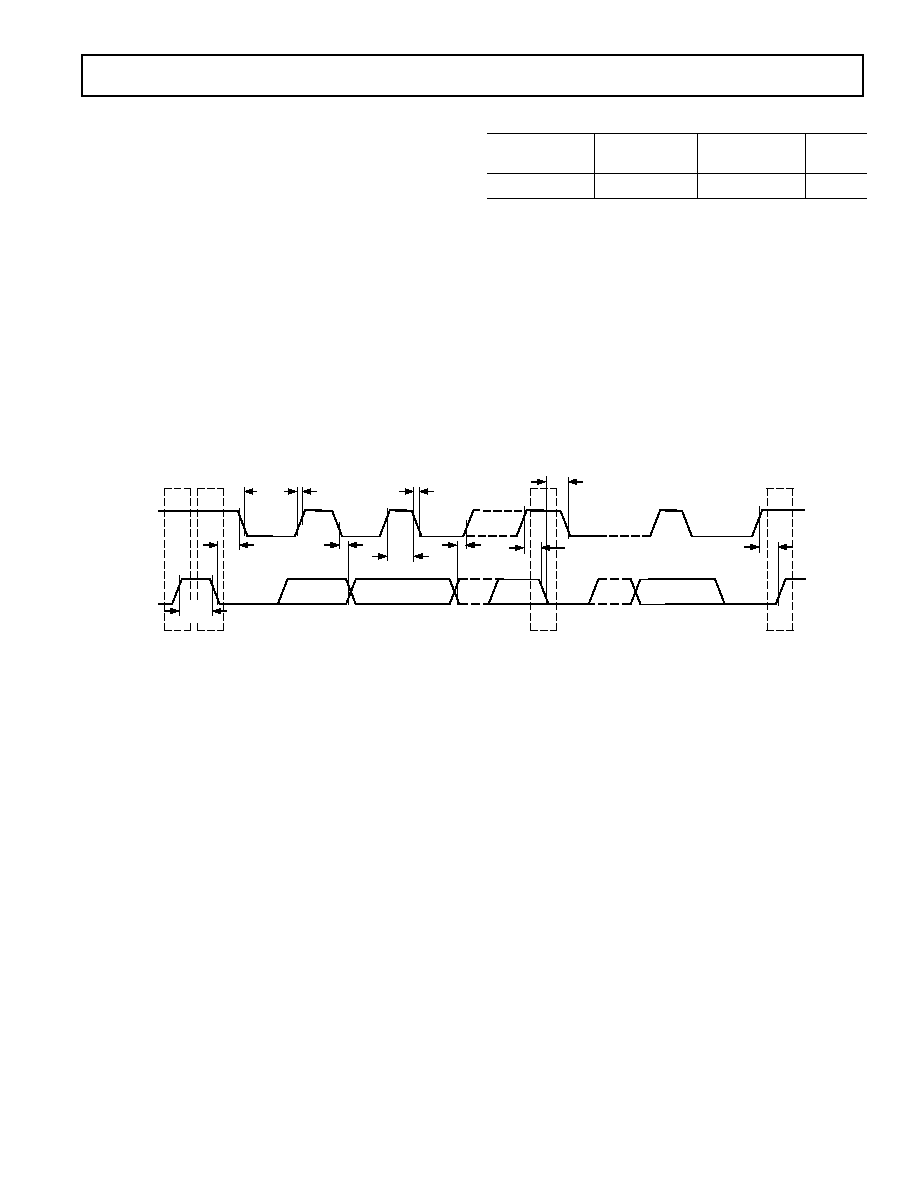

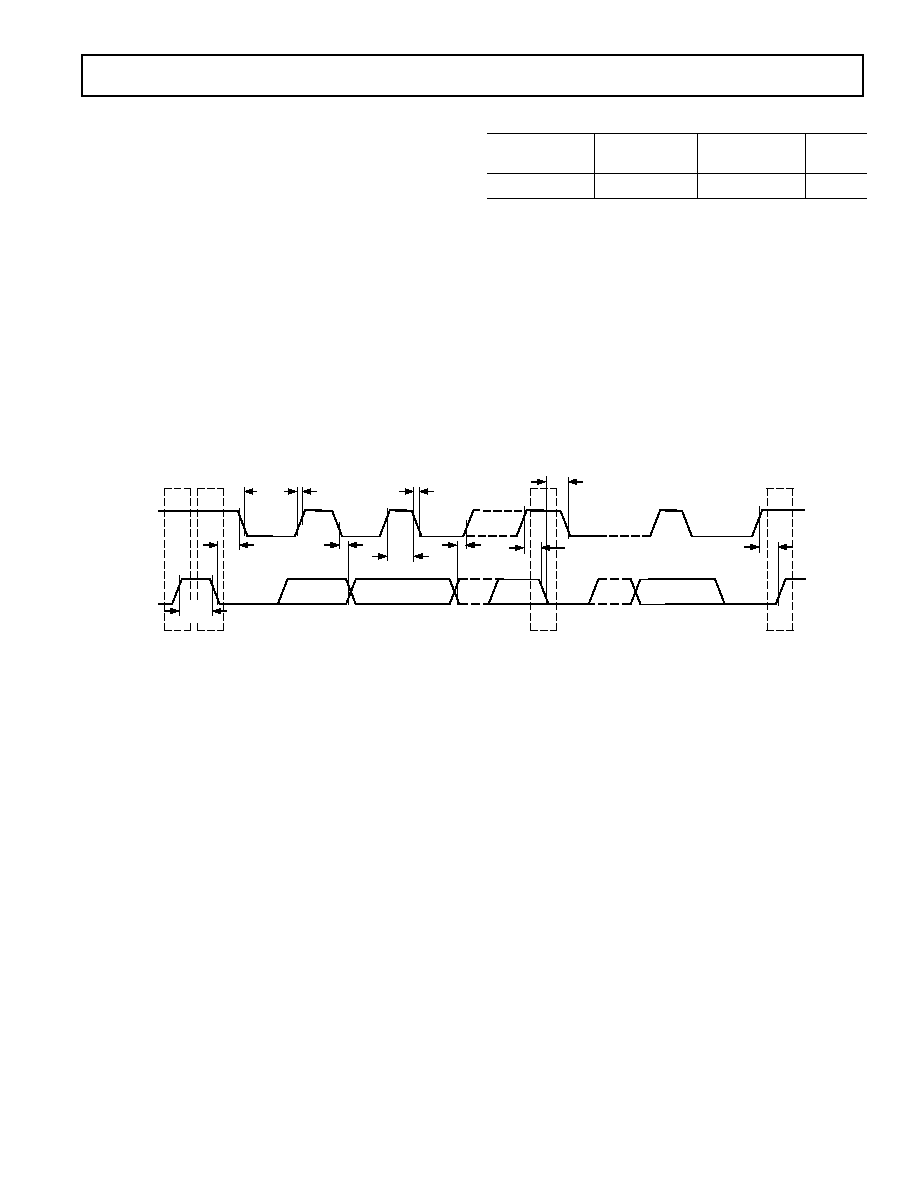

SERIAL BUS TIMING

3

Clock Frequency, f

SCLK

10

100

kHz

See Figure 1

Glitch Immunity, t

SW

50

ns

See Figure 1

Bus Free Time, t

BUF

4.7

µs

See Figure 1

Start Setup Time, t

SU;STA

4.7

µs

See Figure 1

Start Hold Time, t

HD;STA

4

µs

See Figure 1

Stop Condition Setup Time t

SU;STO

4

µs

See Figure 1

SCL Low Time, t

LOW

1.3

µs

See Figure 1

SCL High Time, t

HIGH

4

50

µs

See Figure 1

SCL, SDA Rise Time, t

R

1000

ns

See Figure 1

SCL, SDA Fall Time, t

F

300

ns

See Figure 1

Data Setup Time, t

SU;DAT

250

ns

See Figure 1

Data Hold Time, t

HD;DAT

300

ns

See Figure 1

NOTES

1

Typicals are at T

A

= 25

°C and represent most likely parametric norm. Shutdown current typ is measured with V

CC

= 3.3 V.

2

ADD is a three-state input that may be pulled high, low or left open-circuit.

3

Timing specifications are tested at logic levels of V

IL

= 0.8 V for a falling edge and V

IH

= 2.2 V for a rising edge.

Specifications subject to change without notice.

REV. 0

ADM1030

3

ABSOLUTE MAXIMUM RATINGS

*

Positive Supply Voltage (V

CC

) . . . . . . . . . . . . . . . . . . . . 6.5 V

Voltage on Any Input or Output Pin . . . . . . . . 0.3 V to +6.5 V

Input Current at Any Pin . . . . . . . . . . . . . . . . . . . . . . .

±5 mA

Package Input Current . . . . . . . . . . . . . . . . . . . . . . .

±20 mA

Maximum Junction Temperature (T

JMAX

) . . . . . . . . . . 150

°C

Storage Temperature Range . . . . . . . . . . . . 65

°C to +150°C

Lead Temperature, Soldering

Vapor Phase 60 sec . . . . . . . . . . . . . . . . . . . . . . . . . 215

°C

Infrared 15 sec . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

°C

ESD Rating All Pins . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 V

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

THERMAL CHARACTERISTICS

16-Lead QSOP Package

JA

= 105

°C/W,

JC

= 39

°C/W

ORDERING GUIDE

Temperature

Package

Package

Model

Range

Description

Option

ADM1030ARQ

0

°C to 100°C

16-Lead QSOP RQ-16

t

SU:STO

P

S

P

t

HD:STA

t

SU:STA

t

SU:DAT

t

HIGH

t

F

t

HD:DAT

t

R

t

LOW

t

HD:STA

t

BUF

S

SCL

SDA

Figure 1. Diagram for Serial Bus Timing

REV. 0

ADM1030

4

PIN FUNCTION DESCRIPTIONS

Pin No.

Mnemonic

Description

1

PWM_OUT

Digital Output (Open-Drain). Pulsewidth modulated output to control fan speed. Requires pull-

up resistor (10 k

typical).

2

TACH/AIN

Digital/Analog Input. Fan tachometer input to measure fan speed. May be reprogrammed as an

analog input to measure speed of a 2-wire fan via a sense resistor (2

typical)

3, 4, 11, 12

NC

Not Connected.

5

GND

System Ground.

6

V

CC

Power. Can be powered by 3.3 V Standby power if monitoring in low power states is required.

7

THERM

Digital I/O (Open-Drain). An active low thermal overload output that indicates a violation of a

temperature set point (overtemperature). Also acts as an input to provide external fan control.

When this pin is pulled low by an external signal, a status bit is set, and the fan speed is set to

full-on. Requires pull-up resistor (10 k

).

8

FAN_FAULT

Digital Output (Open-Drain). Can be used to signal a fan failure. Requires pull-up resistor

(typically 10 k

).

9

D

Analog Input. Connected to cathode of an external temperature-sensing diode. The temperature-

sensing element is either a Pentium III substrate transistor or a general-purpose 2N3904.

10

D+

Analog Input. Connected to anode of the external temperature-sensing diode.

13

ADD

Three-state Logic Input. Sets two lower bits of device SMBus address.

14

INT

Digital Output (Open-Drain). Can be programmed as an interrupt output for temperature/fan

speed interrupts. Requires pull-up resistor (10 k

typical).

15

SDA

Digital I/O. Serial Bus Bidirectional Data. Open-drain output. Requires pull-up resistor

(2.2 k

typical).

16

SCL

Digital Input. Serial Bus Clock. Requires pull-up resistor (2.2 k

typ).

PIN CONFIGURATION

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

PWM_OUT

SCL

ADM1030

TACH/AIN

SDA

NC

INT

NC

ADD

GND

NC

V

CC

NC

THERM

D+

FAN_FAULT

D

NC = NO CONNECT

REV. 0

5

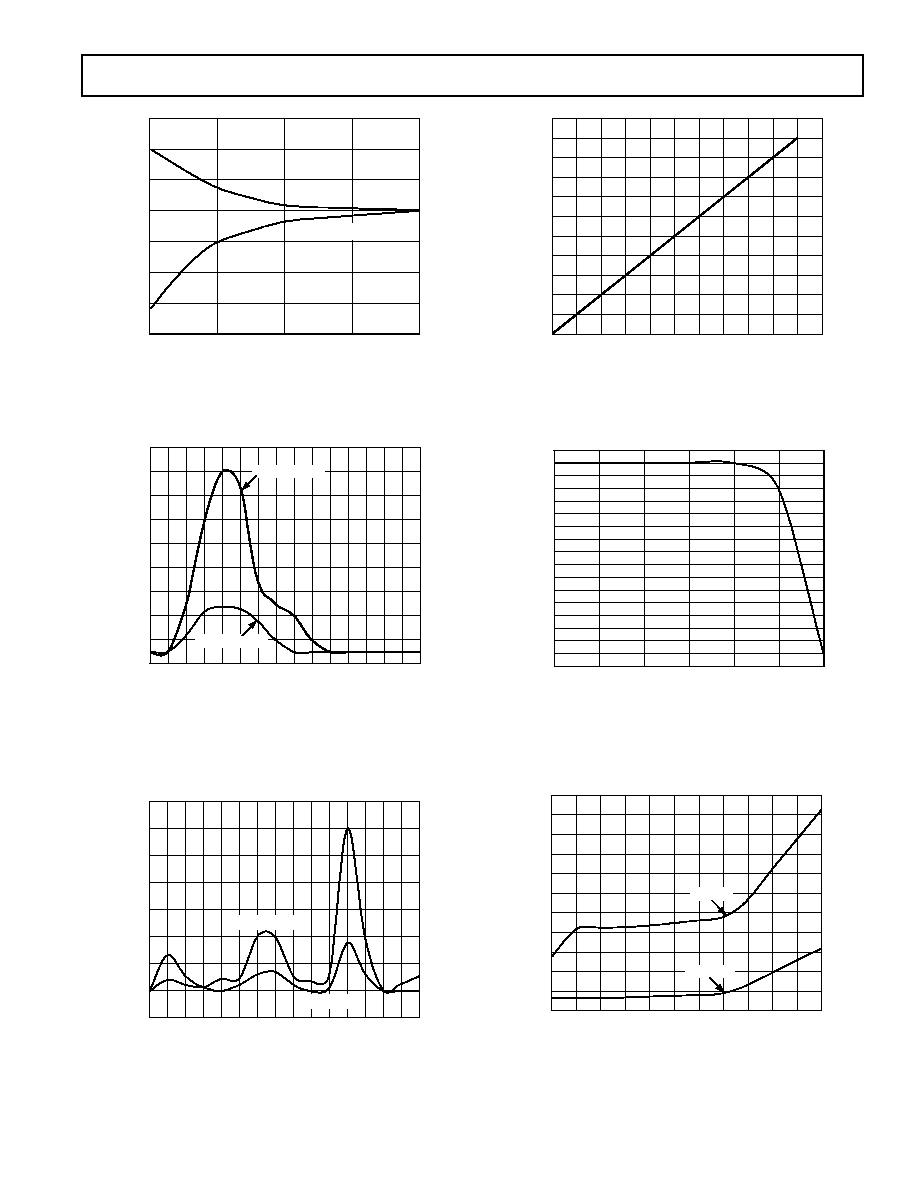

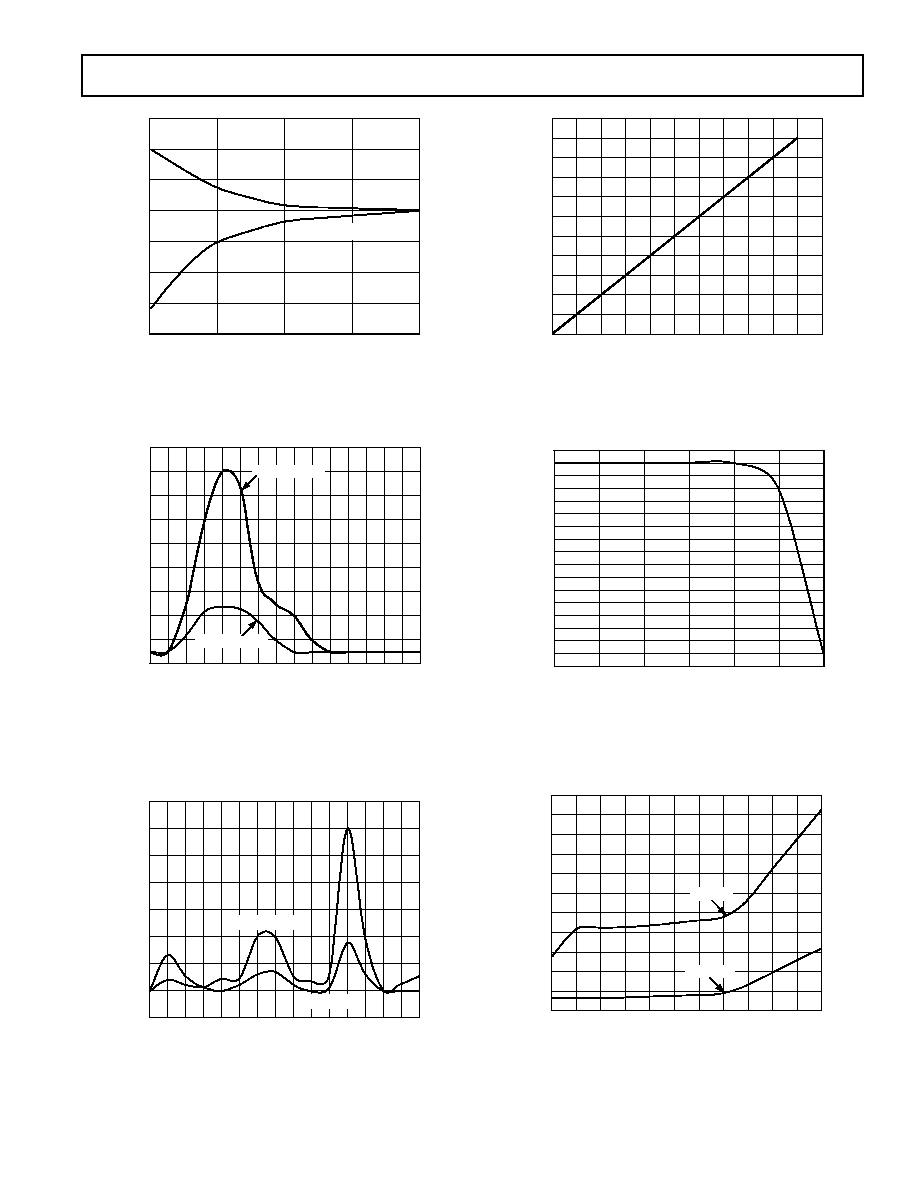

Typical Performance CharacteristicsADM1030

LEAKAGE RESISTANCE M

15

10

1

100

3.3

REMO

TE TEMPERA

T

URE

ERR

OR

C

10

30

5

20

5

0

10

15

DXP TO GND

DXP TO V

CC

(3.3V)

TPC 1. Temperature Error vs. PCB Track Resistance

FREQUENCY Hz

17

0

REMO

TE TEMPERA

T

URE

ERR

OR

C

15

13

11

9

7

5

3

1

1

500k

2M

4M

6M

10M

100M

400M

V

IN

= 100mV p-p

V

IN

= 200mV p-p

TPC 2. Temperature Error vs. Power Supply Noise

Frequency

FREQUENCY Hz

1

0

400M

100k

1M

100M

200M

300M

2

0

3

1

500M

REMO

TE TEMPERA

T

URE

ERR

OR

C

7

6

5

4

V

IN

= 40mV p-p

V

IN

= 20mV p-p

TPC 3. Temperature Error vs. Common-Mode Noise

Frequency

PIII TEMPERATURE C

80

0

0

60

10

READING

C

20

30

40

50

70

60

50

30

10

40

20

70

80

90

100

110

90

110

100

TPC 4. Pentium III Temperature Measurement vs.

ADM1030 Reading

DXP DXN CAPACITANCE nF

2

10

1

47

2.2

REMO

TE TEMPERA

T

URE

ERR

OR

C

3.3

4.7

10

22

3

5

7

9

6

1

11

12

13

14

15

16

0

1

4

8

TPC 5. Temperature Error vs. Capacitance between

D+ and D

SCLK FREQUENCY kHz

80

0

0

75

1

SUPPL

Y CURRENT

A

5

10

25

50

70

60

50

30

10

40

20

100

250

500

750 1000

90

100

110

V

CC

= 5V

V

CC

= 3.3V

TPC 6. Standby Current vs. Clock Frequency

REV. 0

ADM1030

6

TPC 7. Temperature Error vs. Differential-Mode Noise

Frequency

TPC 8. Standby Supply Current vs. Supply Voltage

TPC 9. Local Sensor Error

TPC 10. Remote Sensor Error

TPC 11. Supply Current vs. Supply Voltage

FREQUENCY Hz

7

1

0

400M

100k

REMO

TE TEMPERA

T

URE

ERR

OR

C

1M

100M

200M

300M

6

5

4

2

0

3

1

500M

V

IN

= 30mV p-p

V

IN

= 20mV p-p

SUPPLY VOLTAGE V

200

SUPPL

Y CURRENT

A

180

160

140

60

120

80

40

20

0

100

20

0

1.1

1.3

1.5

1.7

1.9

2.1

2.5

2.9

4.5

ADD = Hi-Z

ADD = GND

ADD = V

CC

TEMPERATURE C

0.08

0

ERR

OR

C

0

0.08

0.16

0.24

0.32

0.40

0.48

0.56

0.64

0.72

0.80

20

40

60

80

85

100

105

120

SUPPLY VOLTAGE V

1.30

0.80

2.0

SUPPL

Y CURRENT

mA

2.4

1.25

1.20

1.15

1.05

0.95

1.10

1.00

0.90

0.85

2.8

3.2

3.6

4.0

4.4

4.8

2.2

2.6

3.0

3.4

3.8

4.2

4.6

5.0

TIME Sec

120

20

0

TEMPERA

T

URE

C

2

110

100

90

70

50

80

60

40

30

4

6

8

10

1

3

5

7

9

10

0

TPC 12. Response to Thermal Shock

TEMPERATURE C

0.16

0

ERR

OR

C

0.08

0

0.08

0.16

0.24

0.32

0.40

0.48

0.56

0.64

0.72

0.80

0.88

20

40

60

80

85

100

105

120

REV. 0

ADM1030

7

GENERAL DESCRIPTION

The ADM1030 is a temperature monitor and PWM fan control-

ler for microprocessor-based systems. The device communicates

with the system via a serial System Management Bus. The serial

bus controller has a hardwired address pin for device selection

(Pin 13), a serial data line for reading and writing addresses and

data (Pin 15), and an input line for the serial clock (Pin 16). All

control and programming functions of the ADM1030 are per-

formed over the serial bus. The device also supports the SMBus

Alert Response Address (ARA) function.

INTERNAL REGISTERS OF THE ADM1030

A brief description of the ADM1030's principal internal regis-

ters is given below. More detailed information on the function of

each register is given in Table XII to Table XXVI.

Configuration Register

Provides control and configuration of various functions on

the device.

Address Pointer Register

This register contains the address that selects one of the other

internal registers. When writing to the ADM1030, the first byte

of data is always a register address, which is written to the

Address Pointer Register.

Status Registers

These registers provide status of each limit comparison.

Value and Limit Registers

The results of temperature and fan speed measurements are

stored in these registers, along with their limit values.

Fan Speed Config Register

This register is used to program the PWM duty cycle for the fan.

Offset Registers

Allows the temperature channel readings to be offset by a 5-bit

two's complement value written to these registers. These values

will automatically be added to the temperature values (or sub-

tracted from if negative). This allows the systems designer to

optimize the system if required, by adding or subtracting up to

15

°C from a temperature reading.

Fan Characteristics Register

This register is used to select the spin-up time, PWM frequency,

and speed range for the fan used.

THERM Limit Registers

These registers contain the temperature values at which

THERM

will be asserted.

T

MIN

/T

RANGE

Registers

These registers are read/write registers that hold the minimum

temperature value below which the fan will not run when the

device is in Automatic Fan Speed Control Mode. These regis-

ters also hold the values defining the range over that auto fan

control will be provided, and hence determines the temperature

at which the fan will run at full speed.

SERIAL BUS INTERFACE

Control of the ADM1030 is carried out via the SMBus. The

ADM1030 is connected to this bus as a slave device, under the

control of a master device, e.g., the 810 chipset.

The ADM1030 has a 7-bit serial bus address. When the device

is powered up, it will do so with a default serial bus address.

The five MSBs of the address are set to 01011, the two LSBs

are determined by the logical state of Pin 13 (ADD). This is a

three-state input that can be grounded, connected to V

CC

, or

left open-circuit to give three different addresses. The state of

the ADD pin is only sampled at power-up, so changing ADD

with power on will have no effect until the device is powered off,

then on again.

Table I. ADD Pin Truth Table

ADD Pin

A1

A0

GND

0

0

No Connect

1

0

V

CC

0

1

If ADD is left open-circuit, the default address will be 0101110.

The facility to make hardwired changes at the ADD pin allows

the user to avoid conflicts with other devices sharing the same

serial bus, for example, if more than one ADM1030 is used in

a system.

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START

condition, defined as a high-to-low transition on the serial

data line SDA while the serial clock line SCL remains high.

This indicates that an address/data stream will follow. All

slave peripherals connected to the serial bus respond to the

START condition, and shift in the next 8 bits, consisting of a

7-bit address (MSB first) plus an R/

W bit that determines the

direction of the data transfer, i.e., whether data will be

written to or read from the slave device.

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the low

period before the ninth clock pulse, known as the Acknowl-

edge Bit. All other devices on the bus now remain idle while

the selected device waits for data to be read from or written

to it. If the R/

W bit is a 0, the master will write to the slave

device. If the R/

W bit is a 1, the master will read from the

slave device.

2. Data is sent over the serial bus in sequences of nine clock

pulses, eight bits of data followed by an Acknowledge Bit

from the slave device. Transitions on the data line must

occur during the low period of the clock signal and remain

stable during the high period, as a low-to-high transition

when the clock is high may be interpreted as a STOP signal.

The number of data bytes that can be transmitted over the

serial bus in a single READ or WRITE operation is limited

only by what the master and slave devices can handle.

3. When all data bytes have been read or written, stop condi-

tions are established. In WRITE mode, the master will pull

the data line high during the tenth clock pulse to assert a

STOP condition. In READ mode, the master device will

override the acknowledge bit by pulling the data line high

during the low period before the ninth clock pulse. This is

known as No Acknowledge. The master will then take the

data line low during the low period before the tenth clock

pulse, then high during the tenth clock pulse to assert a

STOP condition.

Any number of bytes of data may be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined at

the beginning and cannot subsequently be changed without

starting a new operation.

REV. 0

ADM1030

8

In the case of the ADM1030, write operations contain either

one or two bytes, and read operations contain one byte, and

perform the following functions.

To write data to one of the device data registers or read data

from it, the Address Pointer Register must be set so that the

correct data register is addressed; data can then be written into

that register or read from it. The first byte of a write operation

always contains an address that is stored in the Address Pointer

Register. If data is to be written to the device, then the write

operation contains a second data byte that is written to the

register selected by the address pointer register.

This is illustrated in Figure 2a. The device address is sent over

the bus followed by R/

W set to 0. This is followed by two data

bytes. The first data byte is the address of the internal data

register to be written to, which is stored in the Address Pointer

Register. The second data byte is the data to be written to the

internal data register.

When reading data from a register there are two possibilities:

1. If the ADM1030's Address Pointer Register value is unknown

or not the desired value, it is first necessary to set it to the

correct value before data can be read from the desired data

register. This is done by performing a write to the ADM1030

as before, but only the data byte containing the register address

is sent, as data is not to be written to the register. This is

shown in Figure 2b.

A read operation is then performed consisting of the serial bus

address, R/

W bit set to 1, followed by the data byte read from

the data register. This is shown in Figure 2c.

2. If the Address Pointer Register is known to be already at the

desired address, data can be read from the corresponding

data register without first writing to the Address Pointer

Register, so Figure 2b can be omitted.

NOTES

1. Although it is possible to read a data byte from a data register

without first writing to the Address Pointer Register, if the

Address Pointer Register is already at the correct value, it is

not possible to write data to a register without writing to the

Address Pointer Register, because the first data byte of a

write is always written to the Address Pointer Register.

2. In Figures 2a to 2c, the serial bus address is shown as the

default value 01011(A1)(A0), where A1 and A0 are set by

the three-state ADD pin.

3. The ADM1030 also supports the Read Byte protocol, as

described in the System Management Bus specification.

R/W

0

SCL

SDA

1

0

1

1

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADM1030

START BY

MASTER

1

9

1

ACK. BY

ADM1030

9

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADM1030

STOP BY

MASTER

1

9

SCL (CONTINUED)

SDA (CONTINUED)

FRAME 1

SERIAL BUS ADDRESS BYTE

FRAME 2

ADDRESS POINTER REGISTER BYTE

FRAME 3

DATA BYTE

Figure 2a. Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

R/W

0

SCL

SDA

1

0

1

1

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADM1030

START BY

MASTER

1

9

1

ACK. BY

ADM1030

9

FRAME 1

SERIAL BUS ADDRESS BYTE

FRAME 2

ADDRESS POINTER REGISTER BYTE

STOP BY

MASTER

Figure 2b. Writing to the Address Pointer Register Only

R/

W

0

SCL

SDA

1

0

1

1

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

NO ACK.

BY MASTER

START BY

MASTER

1

9

1

ACK. BY

ADM1030

9

FRAME 1

SERIAL BUS ADDRESS BYTE

FRAME 2

DATA BYTE FROM ADM1030

STOP BY

MASTER

Figure 2c. Reading Data from a Previously Selected Register

REV. 0

ADM1030

9

ALERT RESPONSE ADDRESS

Alert Response Address (ARA) is a feature of SMBus devices

that allows an interrupting device to identify itself to the host

when multiple devices exist on the same bus.

The

INT output can be used as an interrupt output or can be used

as an

SMBALERT. One or more INT outputs can be connected

to a common

SMBALERT line connected to the master. If a

device's

INT line goes low, the following procedure occurs:

1.

SMBALERT pulled low.

2. Master initiates a read operation and sends the Alert

Response Address (ARA = 0001 100). This is a general call

address that must not be used as a specific device address.

3. The device whose

INT output is low responds to the Alert

Response Address, and the master reads its device address.

The address of the device is now known and can be interro-

gated in the usual way.

4. If more than one device's

INT output is low, the one with

the lowest device address will have priority, in accordance

with normal SMBus arbitration.

5. Once the ADM1030 has responded to the Alert Response

Address, it will reset its

INT output; however, if the error

condition that caused the interrupt persists,

INT will be

reasserted on the next monitoring cycle.

TEMPERATURE MEASUREMENT SYSTEM

Internal Temperature Measurement

The ADM1030 contains an on-chip bandgap temperature sen-

sor. The on-chip ADC performs conversions on the output of

this sensor and outputs the temperature data in 10-bit two's

complement format. The resolution of the local temperature

sensor is 0.25

°C. The format of the temperature data is shown

in Table II.

External Temperature Measurement

The ADM1030 can measure the temperature of an external

diode sensor or diode-connected transistor, connected to Pins

9 and 10.

These pins are a dedicated temperature input channel. The

function of Pin 7 is as a

THERM input/output and is used to

flag overtemperature conditions.

The forward voltage of a diode or diode-connected transistor,

operated at a constant current, exhibits a negative temperature

coefficient of about 2 mV/

°C. Unfortunately, the absolute

value of V

BE

, varies from device to device, and individual

calibration is required to null this out, so the technique is

unsuitable for mass production.

The technique used in the ADM1030 is to measure the change

in V

BE

when the device is operated at two different currents.

This is given by:

V

BE

= KT/q

× ln (N)

where:

K is Boltzmann's constant.

q is charge on the carrier.

T is absolute temperature in Kelvins.

N is ratio of the two currents.

Figure 3 shows the input signal conditioning used to measure

the output of an external temperature sensor. This figure shows

the external sensor as a substrate transistor, provided for tempera-

ture monitoring on some microprocessors, but it could equally

well be a discrete transistor.

LOW-PASS

FILTER

f

C

= 65kHz

BIAS

DIODE

REMOTE

SENSING

TRANSISTOR

I

N

I

I

BIAS

D+

D

V

OUT+

V

OUT

TO

ADC

V

DD

Figure 3. Signal Conditioning

If a discrete transistor is used, the collector will not be grounded,

and should be linked to the base. If a PNP transistor is used, the

base is connected to the D input and the emitter to the D+

input. If an NPN transistor is used, the emitter is connected to

the D input and the base to the D+ input.

One LSB of the ADC corresponds to 0.125

°C, so the ADM1030

can theoretically measure temperatures from 127

°C to +127.75°C,

although 127

°C is outside the operating range for the device.

The extended temperature resolution data format is shown in

Tables III and IV.

Table II. Temperature Data Format (Local Temperature and

Remote Temperature High Bytes)

Temperature ( C)

Digital Output

128

°C

1000 0000

125

°C

1000 0011

100

°C

1001 1100

75

°C

1011 0101

50

°C

1100 1110

25

°C

1110 0111

1

°C

1111 1111

0

°C

0000 0000

+1

°C

0000 0001

+10

°C

0000 1010

+25

°C

0001 1001

+50

°C

0011 0010

+75

°C

0100 1011

+100

°C

0110 0100

+125

°C

0111 1101

+127

°C

0111 1111

REV. 0

ADM1030

10

Table III. Remote Sensor Extended Temperature Resolution

Extended

Remote Temperature

Resolution ( C)

Low Bits

0.000

000

0.125

001

0.250

010

0.375

011

0.500

100

0.625

101

0.750

110

0.875

111

The extended temperature resolution for the local and remote

channels is stored in the Extended Temperature Resolution

Register (Register 0x06), and is outlined in Table XVIII.

Table IV. Local Sensor Extended Temperature Resolution

Extended

Local Temperature

Resolution ( C)

Low Bits

0.00

00

0.25

01

0.50

10

0.75

11

To prevent ground noise interfering with the measurement, the

more negative terminal of the sensor is not referenced to ground,

but is biased above ground by an internal diode at the D input.

If the sensor is used in a very noisy environment, a capacitor of

value up to 1000 pF may be placed between the D+ and D

inputs to filter the noise.

To measure

V

, the sensor is switched between operating

currents of I and N

× I. The resulting waveform is passed through

a 65 kHz low-pass filter to remove noise, then to a chopper-

stabilized amplifier that performs the functions of amplification

and rectification of the waveform to produce a dc voltage pro-

portional to

V

BE

. This voltage is measured by the ADC to give

a temperature output in 11-bit two's complement format. To

further reduce the effects of noise, digital filtering is performed

by averaging the results of 16 measurement cycles. An external

temperature measurement nominally takes 9.6 ms.

LAYOUT CONSIDERATIONS

Digital boards can be electrically noisy environments and care

must be taken to protect the analog inputs from noise, particu-

larly when measuring the very small voltages from a remote

diode sensor. The following precautions should be taken:

1. Place the ADM1030 as close as possible to the remote sens-

ing diode. Provided that the worst noise sources such as clock

generators, data/address buses, and CRTs are avoided, this

distance can be 4 to 8 inches.

2. Route the D+ and D tracks close together, in parallel, with

grounded guard tracks on each side. Provide a ground plane

under the tracks if possible.

3. Use wide tracks to minimize inductance and reduce noise pick-

up. 10 mil track minimum width and spacing is recommended.

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

GND

D+

D

GND

Figure 4. Arrangement of Signal Tracks

4. Try to minimize the number of copper/solder joints, which

can cause thermocouple effects. Where copper/solder joints

are used, make sure that they are in both the D+ and D

path and at the same temperature.

Thermocouple effects should not be a major problem as 1

°C

corresponds to about 200

µV, and thermocouple voltages are

about 3

µV/°C of temperature difference. Unless there are two

thermocouples with a big temperature differential between

them, thermocouple voltages should be much less than 200

µV.

5. Place a 0.1

µF bypass capacitor close to the ADM1030.

6. If the distance to the remote sensor is more than 8 inches, the

use of twisted pair cable is recommended. This will work up

to about 6 to 12 feet.

7. For really long distances (up to 100 feet) use shielded twisted

pair such as Belden #8451 microphone cable. Connect the

twisted pair to D+ and D and the shield to GND close to

the ADM1030. Leave the remote end of the shield uncon-

nected to avoid ground loops.

Because the measurement technique uses switched current

sources, excessive cable and/or filter capacitance can affect the

measurement. When using long cables, the filter capacitor C1

may be reduced or removed. In any case the total shunt capaci-

tance should not exceed 1000 pF.

Cable resistance can also introduce errors. 1

series resistance

introduces about 0.5

°C error.

ADDRESSING THE DEVICE

ADD (Pin 13) is a three-state input. It is sampled, on power-up

to set the lowest two bits of the serial bus address. Up to three

addresses are available to the systems designer via this address

pin. This reduces the likelihood of conflicts with other devices

attached to the System Management Bus.

THE ADM1030 INTERRUPT SYSTEM

The ADM1030 has two interrupt outputs,

INT and THERM.

These have different functions.

INT responds to violations of

software programmed temperature limits and is maskable

(described in more detail later).

THERM is intended as a "fail-safe" interrupt output that can-

not be masked. If the temperature is below the low temperature

limit, the

INT pin will be asserted low to indicate an out-of-limit

condition. If the temperature exceeds the high temperature limit,

the

INT pin will also be asserted low. A third limit; THERM

limit, may be programmed into the device to set the temperature

limit above which the overtemperature

THERM pin will be

REV. 0

ADM1030

11

asserted low. The behavior of the high limit and

THERM limit

is as follows:

1. Whenever the temperature measured exceeds the high tem-

perature limit, the

INT pin is asserted low.

2. If the temperature exceeds the

THERM limit, the THERM

output asserts low. This can be used to throttle the CPU

clock. If the

THERM-to-Fan Enable bit (Bit 7 of THERM

behavior/revision register) is cleared to 0, the fan will not run

full-speed. The

THERM limit may be programmed at a

lower temperature than the high temperature limit. This

allows the system to run in silent mode, where the CPU can

be throttled while the cooling fan is off. If the temperature

continues to increase, and exceeds the high temperature limit,

an

INT is generated. Software may then decide whether the

fan should run to cool the CPU. This allows the system to

run in SILENT MODE.

3. If the

THERM-to-Fan Enable bit is set to 1, the fan will run

full-speed whenever

THERM is asserted low. In this case,

both throttling and active cooling take place. If the high

temperature limit is programmed to a lower value than the

THERM limit, exceeding the high temperature limit will

assert

INT low. Software could change the speed of the fan

depending on temperature readings. If the temperature con-

tinues to increase and exceeds the

THERM limit, THERM

asserts low to throttle the CPU and the fan runs full-speed.

This allows the system to run in PERFORMANCE MODE,

where active cooling takes place and the CPU is only throttled

at high temperature.

Using the high temperature limit and the

THERM limit in this

way allows the user to gain maximum performance from the system

by only slowing it down, should it be at a critical temperature.

Although the ADM1030 does not have a dedicated Interrupt

Mask Register, clearing the appropriate enable bits in Configu-

ration Register 2 will clear the appropriate interrupts and mask

out future interrupts on that channel. Disabling interrupt bits

will prevent out-of-limit conditions from generating an interrupt

or setting a bit in the Status Registers.

USING

THERM AS AN INPUT

The

THERM pin is an open-drain input/output pin. When used

as an output, it signals over-temperature conditions. When

asserted low as an output, the fan will be driven full-speed if the

THERM-to-Fan Enable bit is set to 1 (Bit 7 of Register 0x3F).

When

THERM is pulled low as an input, the THERM bit (Bit

7) of Status Register 2 is set to 1, and the fan is driven full-speed.

Note that the

THERM-to-Fan Enable bit has no effect when-

ever

THERM is used as an input. If THERM is pulled low as

an input, and the

THERM-to-Fan Enable bit = 0, the fan will

still be driven full-speed. The

THERM-to-Fan Enable bit only

affects the behavior of

THERM when used as an output.

STATUS REGISTERS

All out-of-limit conditions are flagged by status bits in Status

Registers 1 and 2 (0x02, 0x03). Bits 0 and 1 (Alarm Speed, Fan

Fault) of Status Register 1, once set, may be cleared by reading

Status Register 1. Once the Alarm Speed bit is cleared, this bit

will not be reasserted on the next monitoring cycle even if the

condition still persists. This bit may be reasserted only if the

fan is no longer at Alarm Speed. Bit 1 (Fan Fault) is set when-

ever a fan tach failure is detected.

Once cleared, it will reassert on subsequent fan tach failures.

Bits 2 and 3 of Status Register 1 are the Remote Temperature

High and Low status bits. Exceeding the high or low tempera-

ture limits for the external channel sets these status bits. Reading

the status register clears these bits. However, these bits will be

reasserted if the out-of limit condition still exists on the next

monitoring cycle. Bits 6 and 7 are the Local Temperature High

and Low status bits. These behave exactly the same as the Remote

Temperature High and Low status bits. Bit 4 of Status Register

1 indicates that the Remote Temperature THERM limit has

been exceeded. This bit gets cleared on a read of Status Register

1 (see Figure 5). Bit 5 indicates a Remote Diode Error. This

bit will be a 1 if a short or open is detected on the Remote

Temperature channel on power-up. If this bit is set to 1 on

power-up, it cannot be cleared. Bit 6 of Status Register 2 (0x03)

indicates that the Local THERM limit has been exceeded. This bit

is cleared on a read of Status Register 2. Bit 7 indicates that

THERM has been pulled low as an input. This bit can also be

cleared on a read of Status Register 2.

5

INT REARMED

STATUS REG. READ

TEMP

THERM LIMIT

THERM

INT

Figure 5. Operation of

THERM and INT Signals

Figure 5 shows the interaction between

INT and THERM.

Once a critical temperature THERM limit is exceeded, both

INT and THERM assert low. Reading the Status Registers

clears the interrupt and the

INT pin goes high. However, the

THERM pin remains asserted until the measured temperature

falls 5

°C below the exceeded THERM limit. This feature can be

used to CPU throttle or drive a fan full-speed for maximum

cooling. Note, that the

INT pin for that interrupt source is not

rearmed until the temperature has fallen below the THERM

limit 5

°C. This prevents unnecessary interrupts from tying up

valuable CPU resources.

MODES OF OPERATION

The ADM1030 has four different modes of operation. These

modes determine the behavior of the system.

1. Automatic Fan Speed Control Mode.

2. Filtered Automatic Fan Speed Control Mode.

3. PWM Duty Cycle Select Mode (directly sets fan speed under

software control).

4. RPM Feedback Mode.

REV. 0

ADM1030

12

AUTOMATIC FAN SPEED CONTROL

The ADM1030 has a local temperature channel and a remote

temperature channel, which may be connected to an on-chip

diode-connected transistor on a CPU. These two temperature

channels may be used as the basis for an automatic fan speed

control loop to drive a fan using Pulsewidth Modulation (PWM).

HOW DOES THE CONTROL LOOP WORK?

The Automatic Fan Speed Control Loop is shown in Fig-

ure 6 below.

FAN

SPEED

MAX

MIN

TEMPERATURE

T

MIN

T

MAX

= T

MIN

+ T

RANGE

SPIN UP FOR 2 SECONDS

Figure 6. Automatic Fan Speed Control

In order for the fan speed control loop to work, certain loop

parameters need to be programmed into the device.

1. T

MIN

. The temperature at which the fan should switch on

and run at minimum speed. The fan will only turn on once

the temperature being measured rises above the T

MIN

value

programmed. The fan will spin up for a predetermined time

(default = 2 secs). See Fan Spin-Up section for more details.

2. T

RANGE

. The temperature range over which the ADM1030

will automatically adjust the fan speed. As the temperature

increases beyond T

MIN

, the PWM_OUT duty cycle will be

increased accordingly. The T

RANGE

parameter actually defines

the fan speed versus temperature slope of the control loop.

3. T

MAX

. The temperature at which the fan will be at its maxi-

mum speed. At this temperature, the PWM duty cycle

driving the fan will be 100%. T

MAX

is given by T

MIN

+

T

RANGE

. Since this parameter is the sum of the T

MIN

and

T

RANGE

parameters, it does not need to be programmed into

a register on-chip.

4. A hysteresis value of 5

°

C is included in the control loop to

prevent the fan continuously switching on and off if the tem-

perature is close to T

MIN

. The fan will continue to run until

such time as the temperature drops 5

°

C below T

MIN

.

Figure 7 shows the different control slopes determined by the

T

RANGE

value chosen, and programmed into the ADM1030.

T

MIN

was set to 0

°

C to start all slopes from the same point. It

can be seen how changing the T

RANGE

value affects the PWM

duty cycle versus temperature slope.

TEMPERATURE C

PWM DUTY CYCLE

%

0

100

93

87

80

73

66

60

53

47

40

33

T

MIN

T

MAX

= T

MIN

+ T

RANGE

5

10

20

40

60

80

T

RANGE

= 80

C

T

RANGE

= 40

C

T

RANGE

= 20

C

T

RANGE

= 10

C

T

RANGE

= 5

C

Figure 7. PWM Duty Cycle vs. Temperature Slopes (T

RANGE

)

Figure 8 shows how, for a given T

RANGE

, changing the T

MIN

value affects the loop. Increasing the T

MIN

value will increase

the T

MAX

(temperature at which the fan runs full speed) value,

since T

MAX

= T

MIN

+ T

RANGE

. Note, however, that the PWM

Duty Cycle vs Temperature slope remains exactly the same.

Changing the T

MIN

value merely shifts the control slope. The

T

MIN

may be changed in increments of 4

°

C.

TEMPERATURE C

PWM DUTY CYCLE

%

0

100

93

87

80

73

66

60

53

47

40

33

T

MIN

T

MAX

= T

MIN

+ T

RANGE

20

40

60

80

T

RANGE

= 40

C

T

RANGE

= 40

C

T

RANGE

= 40

C

Figure 8. Effect of Increasing T

MIN

Value on Control Loop

FAN SPIN-UP

As was previously mentioned, once the temperature being mea-

sured exceeds the T

MIN

value programmed, the fan will turn on

at minimum speed (default = 33% duty cycle). However, the

problem with fans being driven by PWM is that 33% duty cycle

is not enough to reliably start the fan spinning. The solution is

to spin the fan up for a predetermined time, and once the fan

has spun up, its running speed may be reduced in line with the

temperature being measured.

The ADM1030 allows fan spin-up times between 200 ms and

8 seconds. Bits <2:0> of Fan Characteristics Register 1 (Register

0x20) program the fan spin-up time.

REV. 0

ADM1030

13

Table V. Fan Spin-Up Times

Spin-Up Time

Bits 2:0

(Fan Characteristics Register 1)

000

200 ms

001

400 ms

010

600 ms

011

800 ms

100

1 sec

101

2 secs (Default)

110

4 secs

111

8 secs

Once the Automatic Fan Speed Control Loop parameters have

been chosen, the ADM1030 device may be programmed. The

ADM1030 is placed into Automatic Fan Speed Control Mode

by setting Bit 7 of Configuration Register 1 (Register 0x00).

The device powers up into Automatic Fan Speed Control

Mode by default. The control mode offers further flexibility

in that the user can decide which temperature channel/chan-

nels control the fan.

Table VI. Auto Mode Fan Behavior

Bits 6, 5

Control Operation (Config Register 1)

00

Remote Temperature Controls the Fan.

11

Maximum Speed Calculated by Local and Remote

Temperature Channels Control the Fan.

When Bits 5 and 6 of Config Register 1 are both set to 1, it

offers increased flexibility. The local and remote temperature

channels can have independently programmed control loops

with different control parameters. Whichever control loop

calculates the fastest fan speed based on the temperature being

measured, drives the fan.

Figure 9 shows how the fan's PWM duty cycle is determined by

two independent control loops. This is the type of Auto Mode

Fan Behavior seen when Bits 5 and 6 of Config Register 1 are

set to 11. Figure 9a shows the control loop for the Local Tem-

perature channel. Its T

MIN

value has been programmed to 20

°C,

and its T

RANGE

value is 40

°C. The local temperature's T

MAX

will

thus be 60

°C. Figure 9b shows the control loop for the Remote

Temperature channel. Its T

MIN

value has been set to 0

°C, while its

T

RANGE

= 80

°C. Therefore, the Remote Temperature's T

MAX

value will be 80

°C.

Consider if both temperature channels measure 40

°C. Both

control loops will calculate a PWM duty cycle of 66%. There-

fore, the fan will be driven at 66% duty cycle.

If both temperature channels measure 20

°C, the local channel

will calculate 33% PWM duty cycle, while the remote channel

will calculate 50% PWM duty cycle. Thus, the fan will be

driven at 50% PWM duty cycle. Consider the local temperature

measuring 60

°C while the remote temperature is measuring

70

°C. The PWM duty cycle calculated by the local temperature

control loop will be 100% (since the temperature = T

MAX

). The

PWM duty cycle calculated by the remote temperature control

loop at 70

°C will be approximately 90%. So the fan will run

full-speed (100% duty cycle). Remember, that the fan speed will

be based on the fastest speed calculated, and is not necessarily

based on the highest temperature measured. Depending on the

control loop parameters programmed, a lower temperature on

one channel, may actually calculate a faster speed, than a higher

temperature on the other channel.

LOCAL TEMPERATURE C

PWM DUTY CYCLE

%

0

100

93

87

80

73

66

60

53

47

40

33

T

MIN

T

MAX

= T

MIN

+ T

RANGE

20

40

60

T

RANGE

= 40

C

a.

REMOTE TEMPERATURE C

PWM DUTY CYCLE

%

0

100

93

87

80

73

66

60

53

47

40

33

T

MIN

T

MAX

= T

MIN

+ T

RANGE

20

40

80

70

T

RANGE

= 80

C

b.

Figure 9. Max Speed Calculated by Local and Remote

Temperature Control Loops Drives Fan

PROGRAMMING THE AUTOMATIC FAN SPEED

CONTROL LOOP

1. Program a value for T

MIN

.

2. Program a value for the slope T

RANGE

.

3. T

MAX

= T

MIN

+ T

RANGE

.

4. Program a value for Fan Spin-up Time.

5. Program the desired Automatic Fan Speed Control Mode

Behavior, i.e., which temperature channel controls the fan.

6. Select Automatic Fan Speed Control Mode by setting Bit 7

of Configuration Register 1.

OTHER CONTROL LOOP PARAMETERS

Having programmed all the above loop parameters, are there

any other parameters to worry about?

T

MIN

was defined as being the temperature at which the fan switched

on and ran at minimum speed. This minimum speed is 33% duty

cycle by default. If the minimum PWM duty cycle is programmed

to 33%, the fan control loops will operate as previously described.

REV. 0

ADM1030

14

It should be noted however, that changing the minimum PWM

duty cycle affects the control loop behavior.

Slope 1 of Figure 10 shows T

MIN

set to 0

°C and the T

RANGE

chosen is 40

°C. In this case, the fan's PWM duty cycle will vary

over the range 33% to 100%. The fan will run full-speed at

40

°C. If the minimum PWM duty cycle at which the fan runs at

T

MIN

is changed, its effect can be seen on Slopes 2 and 3. Take

Case 2, where the minimum PWM duty cycle is reprogrammed

from 33% (default) to 53%.

TEMPERATURE C

100

93

87

80

73

66

60

47

40

33

T

MIN

16

28

40

60

0

PWM DUTY CYCLE

%

53

T

RANGE

= 40

C

Figure 10. Effect of Changing Minimum Duty Cycle on

Control Loop with Fixed T

MIN

and T

RANGE

Values

The fan will actually reach full-speed at a much lower tempera-

ture, 28

°C. Case 3 shows that when the minimum PWM duty

cycle was increased to 73%, the temperature at which the fan

ran full-speed was 16

°C. So the effect of increasing the mini-

mum PWM duty cycle, with a fixed T

MIN

and fixed T

RANGE

, is

that the fan will actually reach full-speed (T

MAX

) at a lower

temperature than T

MIN

+ T

RANGE

. How can T

MAX

be calculated?

In Automatic Fan Speed Control Mode, the register that

holds the minimum PWM duty cycle at T

MIN

, is the Fan Speed

Config Register (Register 0x22). Table VII shows the relation-

ship between the decimal values written to the Fan Speed Config

Register and PWM duty cycle obtained.

Table VII. Programming PWM Duty Cycle

Decimal Value

PWM Duty Cycle

00

0%

01

7%

02

14%

03

20%

04

27%

05

33% (Default)

06

40%

07

47%

08

53%

09

60%

10 (0x0A)

67%

11 (0x0B)

73%

12 (0x0C)

80%

13 (0x0D)

87%

14 (0x0E)

93%

15 (0x0F)

100%

The temperature at which the fan will run full-speed (100%

duty cycle) is given by:

T

MAX

= T

MIN

+ ((Max DC Min DC)

× T

RANGE

/10)

where,

T

MAX

= Temperature at which fan runs full-speed.

T

MIN

= Temperature at which fan will turn on.

Max DC = Maximum Duty Cycle (100%) = 15 decimal.

Min DC = Duty Cycle at T

MIN

, programmed into Fan Speed

Config Register (default = 33% = 5 decimal).

T

RANGE

= PWM Duty Cycle versus Temperature Slope.

Example 1

T

MIN

= 0

°

C, T

RANGE

= 40

°

C

Min DC = 53% = 8 decimal (Table VII)

Calculate T

MAX

.

T

MAX

= T

MIN

+ ((Max DC Min DC)

× T

RANGE

/10)

T

MAX

= 0 + ((100% DC 53% DC)

× 40/10)

T

MAX

= 0 + ((15 8)

× 4) = 28

T

MAX

= 28 C (As seen on Slope 2 of Figure 10)

Example 2

T

MIN

= 0

°

C, T

RANGE

= 40

°

C

Min DC = 73% = 11 Decimal (Table VII)

Calculate T

MAX

.

T

MAX

= T

MIN

+ ((Max DC Min DC)

× T

RANGE

/10)

T

MAX

= 0 + ((100% DC 73% DC)

× 40/10)

T

MAX

= 0 + ((15 11)

× 4) = 16

T

MAX

= 16 C (As seen on Slope 3 of Figure 10)

Example 3

T

MIN

= 0

°C, T

RANGE

= 40

°C

Min DC = 33% = 5 Decimal (Table VII)

Calculate T

MAX

.

T

MAX

= T

MIN

+ ((Max DC Min DC)

× T

RANGE

/10)

T

MAX

= 0 + ((100% DC 33% DC)

× 40/10)

T

MAX

= 0 + ((15 5)

× 4) = 40

T

MAX

= 40 C (As seen on Slope 1 of Figure 10)

In this case, since the Minimum Duty Cycle is the default 33%,

the equation for T

MAX

reduces to:

T

MAX

= T

MIN

+ ((Max DC Min DC)

× T

RANGE

/10)

T

MAX

= T

MIN

+ ((15 5)

× T

RANGE

/10)

T

MAX

= T

MIN

+ (10

× T

RANGE

/10)

T

MAX

= T

MIN

+ T

RANGE

REV. 0

ADM1030

15

RELEVANT REGISTERS FOR AUTOMATIC FAN SPEED

CONTROL MODE

Register 0x00 Configuration Register 1

<7>

Logic 1 selects Automatic Fan Speed Control, Logic 0

selects software control (Default = 1).

<6:5> 00 = Remote Temperature controls Fan

11 = Fastest Calculated Speed controls the fan when

Bit 7 = Logic 1.

Register 0x20 Fan Characteristics Register 1

<2:0> Fan 1 Spin-Up Time

000 = 200 ms

001 = 400 ms

010 = 600 ms

011 = 800 ms

100 = 1 sec

101 = 2 secs (Default)

110 = 4 secs

111 = 8 secs

<5:3> PWM Frequency Driving the Fan

000 = 11.7 Hz

001 = 15.6 Hz

010 = 23.4 Hz

011 = 31.25 Hz (Default)

100 = 37.5 Hz

101 = 46.9 Hz

110 = 62.5 Hz

111 = 93.5 Hz

<7:6> Speed Range N; defines the lowest fan speed that can be

measured by the device.

00 = 1: Lowest Speed = 2647 RPM

01 = 2: Lowest Speed = 1324 RPM

10 = 4: Lowest Speed = 662 RPM

11 = 8: Lowest Speed = 331 RPM

Register 0x22 Fan Speed Configuration Register

<3:0> Min Speed: This nibble contains the speed at which the

fan will run when the temperature is at T

MIN

. The default

is 0x05, meaning that the fan will run at 33% duty cycle

when the temperature is at T

MIN

.

Register 0x24 Local Temp T

MIN

/T

RANGE

<7:3> Local Temp T

MIN

. These bits set the temperature at

which the fan will turn on when under Auto Fan Speed

Control. T

MIN

can be programmed in 4

°C increments.

00000 = 0

°C

00001 = 4

°C

00010 = 8

°C

00011 = 12

°C

|

|

01000 = 32

°C (Default)

|

|

11110 = 120

°C

11111 = 124

°C

<2:0> Local Temperature T

RANGE

. This nibble sets the tem-

perature range over which Automatic Fan Speed Control

takes place.

000 = 5

°C

001 = 10

°C

010 = 20

°C

011 = 40

°C

100 = 80

°C

Register 0x25 Remote Temperature T

MIN

/T

RANGE

<7:3> Remote Temperature T

MIN

. Sets the temperature at

which the fan will switch on based on Remote Tempera-

ture Readings.

00000 = 0

°C

00001 = 4

°C

00010 = 8

°C

00011 = 12

°C

|

|

01100 = 48

°C

|

|

11110 = 120

°

C

11111 = 124

°

C

<2:0> Remote Temperature T

RANGE

. This nibble sets the tem-

perature range over which the fan will be controlled based

on Remote Temperature readings.

000 = 5

°C

001 = 10

°C

010 = 20

°C

011 = 40

°C

100 = 80

°C

REV. 0

ADM1030

16

FILTERED CONTROL MODE

The Automatic Fan Speed Control Loop reacts instantaneously

to changes in temperature, i.e., the PWM duty cycle will respond

immediately to temperature change. In certain circumstances,

we may not want the PWM output to react instantaneously to

temperature changes. If significant variations in temperature

were found in a system, it would have the effect of changing the

fan speed, which could be obvious to someone in close proxim-

ity. One way to improve the system's acoustics would be to

slow down the loop so that the fan ramps slowly to its newly

calculated fan speed. This also ensures that temperature transients

will effectively be ignored, and the fan's operation will be smooth.

There are two means by which to apply filtering to the Auto-

matic Fan Speed Control Loop. The first method is to ramp the

fan speed at a predetermined rate, to its newly calculated value

instead of jumping directly to the new fan speed. The second

approach involves changing the on-chip ADC sample rate, to

change the number of temperature readings taken per second.

The filtered mode on the ADM1030 is invoked by setting Bit 0

of the Fan Filter Register (Register 0x23). Once the Fan Filter

Register has been written to, and all other control loop param-

eters (T

MIN

, T

RANGE

, etc.) have been programmed, the device

may be placed into Automatic Fan Speed Control Mode by

setting Bit 7 of Configuration Register 1 (Register 0x00) to 1.

Effect of Ramp Rate on Filtered Mode

Bits <6:5> of the Fan Filter Register determine the ramp rate in

Filtered Mode. The PWM_OUT signal driving the fan will have

a period, T, given by the PWM_OUT drive frequency, f, since

T = 1/f. For a given PWM period, T, the PWM period is subdi-

vided into 240 equal time slots. One time slot corresponds to

the smallest possible increment in PWM duty cycle. A PWM

signal of 33% duty cycle will thus be high for 1/3

× 240 time

slots and low for 2/3

× 240 time slots. Therefore, 33% PWM

duty cycle corresponds to a signal which is high for 80 time slots

and low for 160 time slots.

PWM_OUT

33% DUTY

CYCLE

160 TIME

SLOTS

80 TIME

SLOTS

PWM OUTPUT

(ONE PERIOD) =

240 TIME SLOTS

Figure 11. 33% PWM Duty Cycle Represented in Time

Slots

The ramp rates in Filtered Mode are selectable between 1, 2, 4,

and 8. The ramp rates are actually discrete time slots. For

example, if the ramp rate = 8, then eight time slots will be added

to the PWM_OUT high duty cycle each time the PWM_OUT

duty cycle needs to be increased. Figure 12 shows how the

Filtered Mode algorithm operates.

INCREMENT

PREVIOUS PWM

VALUE BY RAMP

RATE

READ

TEMPERATURE

CALCULATE

NEW PWM

DUTY CYCLE

IS NEW

PWM VALUE >

PREVIOUS

VALUE?

DECREMENT

PREVIOUS

PWM VALUE

BY RAMP

RATE

YES

NO

Figure 12. Filtered Mode Algorithm

The Filtered Mode algorithm calculates a new PWM duty cycle

based on the temperature measured. If the new PWM duty cycle

value is greater than the previous PWM value, the previous PWM

duty cycle value is incremented by either 1, 2, 4, or 8 time slots

(depending on the setting of bits <6:5> of the Fan Filter Regis-

ter). If the new PWM duty cycle value is less than the previous

PWM value, the previous PWM duty cycle is decremented by 1,

2, 4, or 8 time slots. Each time the PWM duty cycle is incremented

or decremented, it is stored as the previous PWM duty cycle for

the next comparison.

So what does an increase of 1, 2, 4, or 8 time slots actually mean

in terms of PWM duty cycle?

A Ramp Rate of 1 corresponds to one time slot, which is 1/240

of the PWM period. In Filtered Auto Fan Speed Control Mode,

incrementing or decrementing by 1 changes the PWM output

duty cycle by 0.416%.

Table VIII. Effect of Ramp Rates on PWM_OUT

Ramp Rate

PWM Duty Cycle Change

1

0.416%

2

0.833%

4

1.66%

8

3.33%

So programming a ramp rate of 1, 2, 4, or 8 simply increases

or decreases the PWM duty cycle by the amounts shown in

Table V, depending on whether the temperature is increasing

or decreasing.

Figure 13 shows remote temperature plotted against PWM duty

cycle for Filtered Mode. The ADC sample rate is the highest

sample rate; 11.25 kHz. The ramp rate is set to 8 which would

correspond to the fastest ramp rate. With these settings it took

approximately 12 seconds to go from 0% duty cycle to 100%

duty cycle (full-speed). The T

MIN

value = 32

°C and the T

RANGE

= 80

°C. It can be seen that even though the temperature increased

very rapidly, the fan gradually ramps up to full speed.

REV. 0

ADM1030

17

TIME s

0

12

140

80

40

60

20

0

80

60

40

20

0

120

120

100

PWM DUTY CYCLE

%

R

TEMP

C

100

R

TEMP

PWM DUTY CYCLE

Figure 13. Filtered Mode with Ramp Rate = 8

Figure 14 shows how changing the ramp rate from 8 to 4 affects

the control loop. The overall response of the fan is slower. Since

the ramp rate is reduced, it takes longer for the fan to achieve full

running speed. In this case, it took approximately 22 seconds for

the fan to reach full speed.

TIME s

0

22

120

80

40

60

20

0

140

80

60

40

20

0

110

120

100

PWM DUTY CYCLE

%

R

TEMP

C

R

TEMP

PWM DUTY CYCLE

Figure 14. Filtered Mode with Ramp Rate = 4

Figure 15 shows the PWM output response for a ramp rate of 2.

In this instance the fan took about 54 seconds to reach full

running speed.

80

60

40

20

0

120

100

R

TEMP

C

TIME s

0

54

140

80

40

60

20

0

120

PWM DUTY CYCLE

%

100

R

TEMP

PWM DUTY CYCLE

Figure 15. Filtered Mode with Ramp Rate = 2

Finally, Figure 16 shows how the control loop reacts to tem-

perature with the slowest ramp rate. The ramp rate is set to 1,

while all other control parameters remain the same. With the

slowest ramp rate selected it took 112 seconds for the fan to

reach full speed.

TIME s

0

112

120

80

40

60

20

0

140

80

60

40

20

0

110

120

100

PWM DUTY CYCLE

%

R

TEMP

C

R

TEMP

PWM DUTY CYCLE

Figure 16. Filtered Mode with Ramp Rate = 1

As can be seen from Figures 13 through 16, the rate at which

the fan will react to temperature change is dependent on the

ramp rate selected in the Fan Filter Register. The higher the

ramp rate, the faster the fan will reach the newly calculated

fan speed.

Figure 17 shows the behavior of the PWM output as tempera-

ture varies. As the temperature is rising, the fan speed will ramp

up. Small drops in temperature will not affect the ramp-up func-

tion since the newly calculated fan speed will still be higher than

the previous PWM value. The Filtered Mode allows the PWM

output to be made less sensitive to temperature variations. This

will be dependent on the ramp rate selected and the ADC sample

rate programmed into the Fan Filter Register.

90

90

TIME s

80

80

70

70

60

60

50

50

40

40

30

30

20

20

10

10

0

0

PWM DUTY CYCLE

%

R

TEMP

C

R

TEMP

PWM DUTY CYCLE

Figure 17. How Fan Reacts to Temperature Variation in

Filtered Mode

REV. 0

ADM1030

18

Effect of ADC Sample Rate on Filtered Mode

The second means by which to change the Filtered Mode char-

acteristics is to adjust the ADC sample rate. The faster the ADC

sample rate, the more temperature samples are obtained per

second. One way to apply filtering to the control loop is to

slow down the ADC sampling rate. This means that the num-

ber of iterations of the Filtered Mode algorithm per second

are effectively reduced. If the number of temperature measure-

ments per second are reduced, how often the PWM_OUT

signal controlling the fan is updated is also reduced.

Bits <4:2> of the Fan Filter Register (Reg 0x23) set the ADC

sample rate. The default ADC sample rate is 1.4 kHz. The

ADC sample rate is selectable from 87.5 Hz to 11.2 kHz.

Table IX shows how many temperature samples are obtained

per second, for each of the ADC sample rates.

Table IX. Temperature Updates per Second

ADC Sample Rate

Temperature Updates/Sec

87.5 Hz

0.0625

175 Hz

0.125

350 Hz

0.25

700 Hz

0.5

1.4 kHz

1 (Default)

2.8 kHz

2

5.6 kHz

4

11.2 kHz

8

RELEVANT REGISTERS FOR FILTERED AUTOMATIC

FAN SPEED CONTROL MODE

In addition to the registers used to program the normal Auto-

matic Fan Speed Control Mode, the following register needs to

be programmed.

Register 0x23 Fan Filter Register

<7>

Spin-up Disable :- when this bit is set to 1, fan spin-up

is disabled. (Default = 0)

<6:5> Ramp Rate: these bits set the ramp rate for filtered mode.

00 = 1 (0.416% Duty Cycle Change)

01 = 2 (0.833% Duty Cycle Change)

10 = 4 (1.66% Duty Cycle Change)

11 = 8 (3.33% Duty Cycle Change)

<4:2> ADC Sample Rate

000 = 87.5 Hz

001 = 175 Hz

010 = 350 Hz

011 = 700 Hz

100 = 1.4 kHz (Default)

101 = 2.8 kHz

110 = 5.6 kHz

111 = 11.2 kHz

<1>

Unused. Default = 0

<0>

Fan 1 Filter Enable: when this bit is set to 1, it enables

filtering on Fan 1. Default = 0.

PROGRAMMING THE FILTERED AUTOMATIC FAN

SPEED CONTROL LOOP

1. Program a value for T

MIN

.

2. Program a value for the slope T

RANGE

.

3. T

MAX

= T

MIN

+ T

RANGE

.

4. Program a value for Fan Spin-up Time.

5. Program the desired Automatic Fan Speed Control Mode

Behavior, i.e., which temperature channel controls the fan.

6. Program a ramp rate for the filtered mode.

7. Program the ADC sample rate in the Fan Filter Register.

8. Set Bit 0 to enable fan filtered mode for the fan.

9. Select Automatic Fan Speed Control Mode by setting Bit 7 of

Configuration Register 1.

PWM DUTY CYCLE SELECT MODE

The ADM1030 may be operated under software control by clear-

ing Bit 7 of Configuration Register 1 (Register 0x00). This

allows the user to directly control PWM Duty Cycle.

Clearing Bit 5 of Configuration Register 1 allows fan control by

varying PWM duty cycle. Values of duty cycle between 0% to

100% may be written to the Fan Speed Config Register (0x22)

to control the speed of the fan. Table X shows the relationship

between hex values written to the Fan Speed Configuration

Register and PWM duty cycle obtained.

Table X. PWM Duty Cycle Select Mode

Hex Value

PWM Duty Cycle

00

0%

01

7%

02

14%

03

20%

04

27%

05

33%

06

40%

07

47%

08

53%

09

60%

0A

67%

0B

73%

0C

80%

0D

87%

0E

93%

0F

100%

REV. 0

ADM1030

19

RPM FEEDBACK MODE

The second method of fan speed control under software is RPM

Feedback Mode. This involves programming the desired fan

RPM value to the device to set fan speed. The advantages include

a very tightly maintained fan RPM over the fan's life, and virtu-

ally no acoustic pollution due to fan speed variation.

Fans typically have manufacturing tolerances of

±20%, meaning

a wide variation in speed for a typical batch of identical fan

models. If it is required that all fans run at exactly 5000 RPM,

it may be necessary to specify fans with a nominal fan speed of

6250 RPM. However, many of these fans will run too fast and

make excess noise. A fan with nominal speed of 6250 RPM

could run as fast as 7000 RPM at 100% PWM duty cycle. RPM

Mode will allow all of these fans to be programmed to run at the