Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

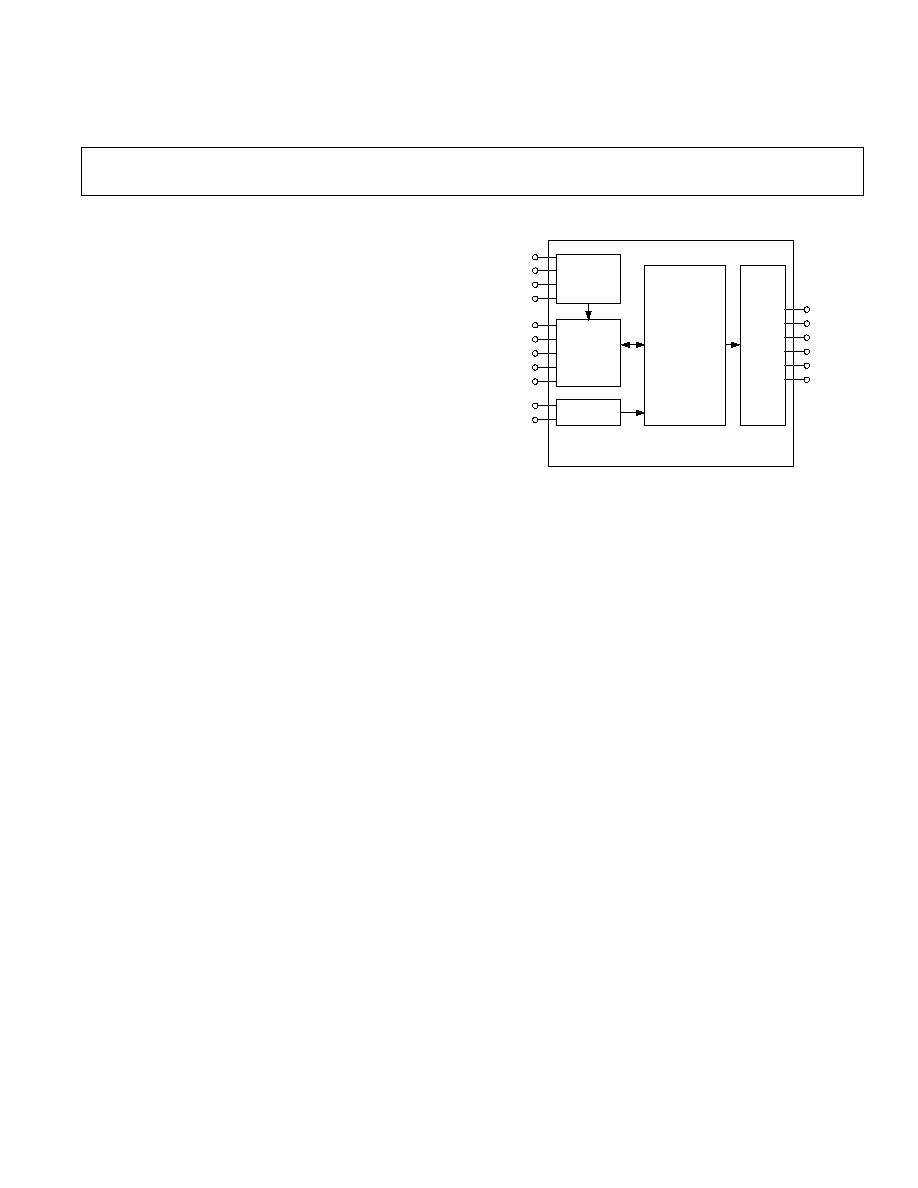

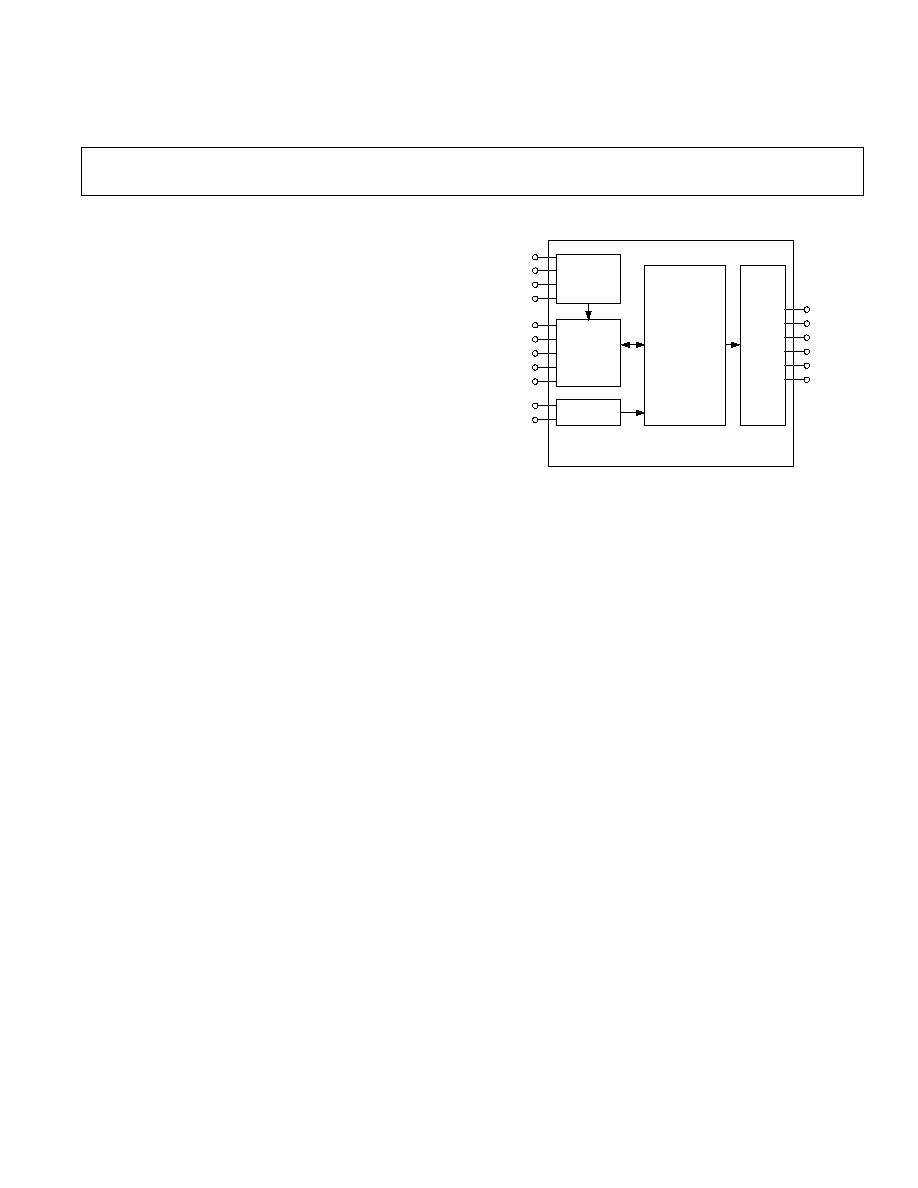

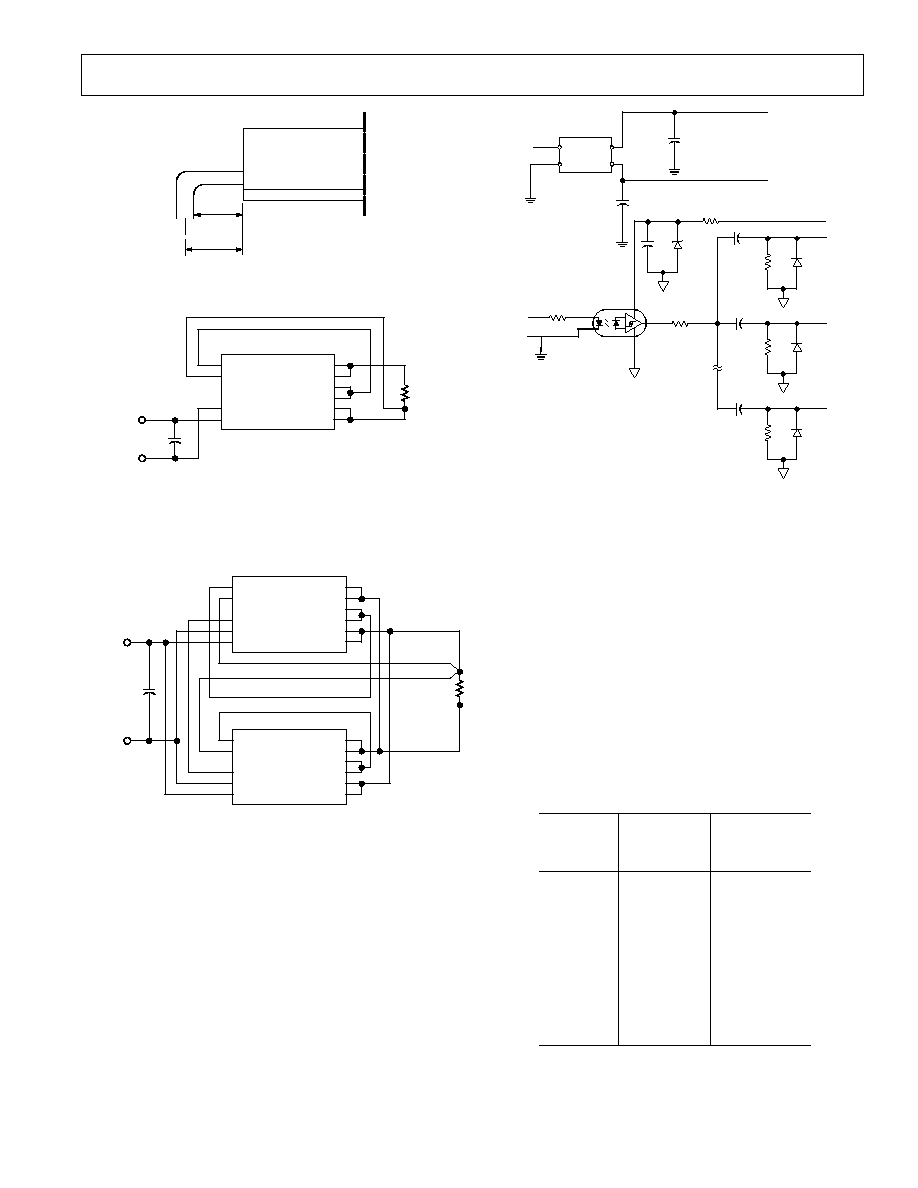

FUNCTIONAL BLOCK DIAGRAM

OUTPUT SIDE

CONTROL

CIRCUIT

INPUT SIDE

CONTROL

CIRCUIT

EMI FILTER

OUTPUT

FILTER

SENSE

REF

+ SENSE

ADJUST

STATUS

V

AUX

INHIBIT

SYNC

I

SHARE

TEMP

V

IN

+V

IN

FIXED

FREQUENCY

DUAL

INTERLEAVED

POWER TRAIN

SENSE

RETURN

RETURN

+V

OUT

+V

OUT

SENSE

REF

ADDC02828SA

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

ADDC02828SA

FEATURES

28 V dc Input, 28 V dc @ 3.6 A, 100 W Output

Integral EMI Filter Designed to Meet MIL-STD-461D

Low Weight: 80 Grams

NAVMAT Derated

Many Protection and System Features

APPLICATIONS

Commercial and Military Airborne Electronics

Missile Electronics

Space-Based Antennae and Vehicles

Mobile/Portable Ground Equipment

Distributed Power Architecture for Active Array Radar

GENERAL DESCRIPTION

The ADDC02828SA hybrid dc/dc converter with integral EMI

filter offers the highest power density of any dc/dc converter

available today with its features and in its power range. The

converter with integral EMI filter is a fixed frequency, 1 MHz,

square wave switching dc/dc power supply. It is not a variable

frequency resonant converter. In addition to many protection

features, this converter has system level features that allow it to

be used as a component in larger systems as well as a stand-

alone power supply. The unit is designed for high reliability and

high performance applications where saving space and/or weight

is critical.

The ADDC02828SA is available in three screening grades; all

grades use a hermetically sealed, molybdenum based hybrid

package. Contact factory for MIL-STD-883 device availability.

28 V/100 W DC/DC Converter

with Integral EMI Filter

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700

World Wide Web Site: http://www.analog.com

Fax: 617/326-8703

© Analog Devices, Inc., 1997

PRODUCT HIGHLIGHTS

1. 60 W/cubic inch power density with an integral EMI filter

designed to meet all applicable requirements in MIL-STD-

461D when installed in a typical system setup.

2. Light weight: 80 grams

3. Operational and survivable over a wide range of input condi-

tions: 16 V50 V dc; survives low line, high line and positive

and negative transients. See Input Voltage Range section.

4. High reliability; NAVMAT derated

5. Protection Features Include:

Output Overvoltage Protection

Output Short Circuit Current Protection

Thermal Monitor/Shutdown

Input Overvoltage Shutdown

Input Transient Protection

6. System Level Features Include:

Current Sharing for Parallel Operation

Inhibit Control

Output Status Signal

Synchronization for Multiple Units

Input Referenced Auxiliary Voltage Supply

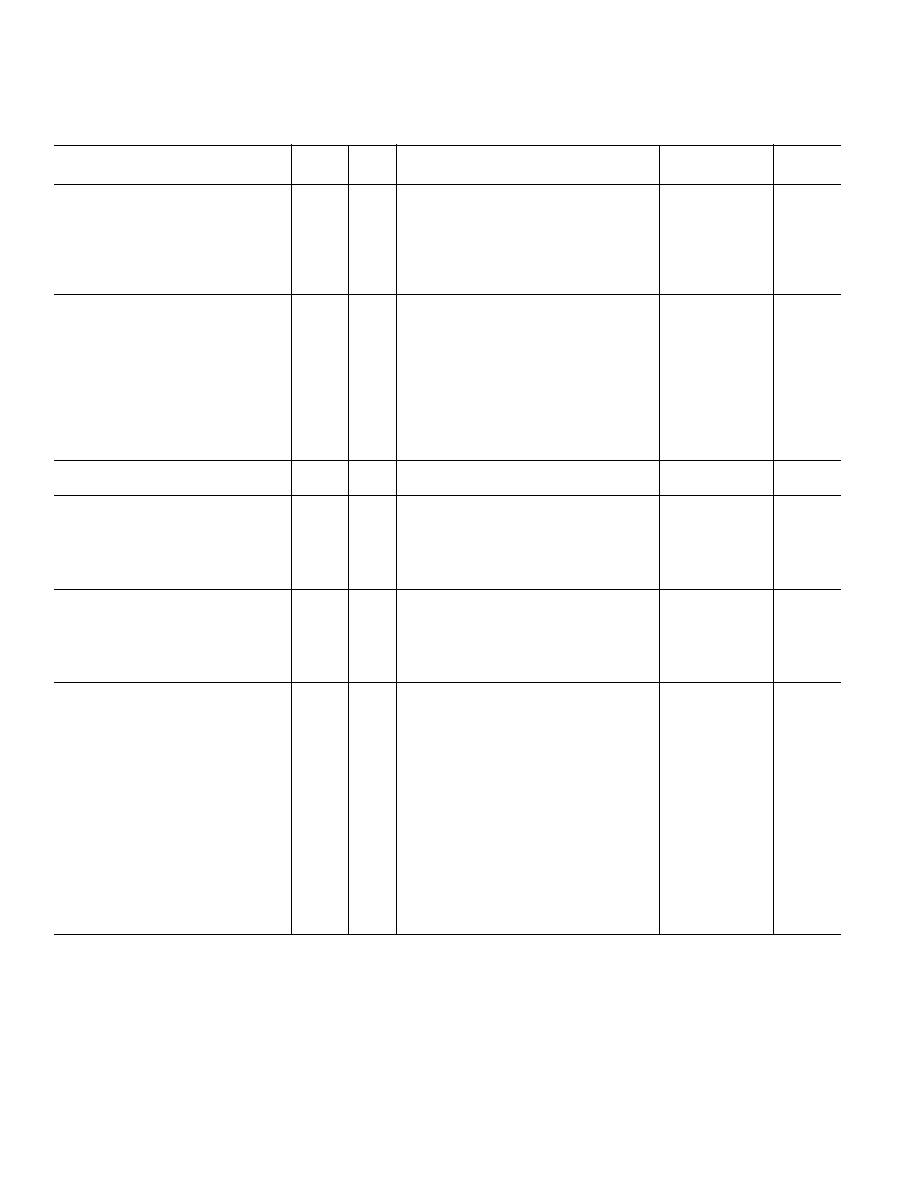

ADDC02828SASPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Case

Test

ADDC02828SA

Parameter

Temp

Level

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Steady State Operating Input Voltage Range

1

Full

VI

I

O

= 0.36 A to 3.6 A

18

28

40

V

Abnormal Operating Input Voltage Range

(Per MIL-STD-704D)

1

Full

VI

I

O

= 0.36 A to 2.9 A

16

50

V

Input Overvoltage Shutdown

+25

°

C

I

50

52.5

55

V

No Load Input Current

+25

°

C

VI

85

100

mA

Disabled Input Current

+25

°

C

VI

1

5

mA

OUTPUT CHARACTERISTICS

2, 3

Output Voltage (V

O

)

+25

°

C

I

I

O

= 0.36 A to 3.6 A, V

IN

= 18 V to 40 V dc

27.44 28.00

28.56 V

Full

VI

I

O

= 0.36 A to 3.6 A, V

IN

= 18 V to 40 V dc

26.88

29.12 V

Full

VI

I

O

= 0.36 A to 2.9 A, V

IN

= 16 V to 50 V dc

26.88

29.12 V

Line Regulation

+25

°

C

VI

I

O

= 3.6 A, V

IN

= 18 V to 40 V dc

10

60

mV

Load Regulation

+25

°

C

VI

V

IN

= 28 V dc, I

O

= 0.36 A to 3.6 A

15

45

mV

Output Ripple/Noise

4

+25

°

C

I

I

O

= 3.6 A, 5 kHz 2 MHz BW

50

100

mV p-p

Output Current (I

O

)

Full

VI

V

IN

= 18 V to 40 V dc

0.36

3.6

A

Output Overvoltage Protection

+25

°

C

V

I

O

= 3.6 A, Open Remote Sense Connection

125

% V

O

Nom

Output Current Limit

+25

°

C

V

V

O

= 90% V

OUT

Nom

130

% I

O

max

Output Short Circuit Current

+25

°

C

I

11

A

ISOLATION CHARACTERISTICS

Isolation Resistance

+25

°

C

I

Input to Output or Any Pin to Case at 500 V dc

100

M

DYNAMIC CHARACTERISTICS

4

Maximum Output Voltage Deviation Due to

Step Change in Load

+25

°

C

I

I

O

= 1.8 A to 3.6 A or 3.6 A to 1.8 A, di/dt = 0.5 A/

µ

s

1.8

V

Response Time Due to Step Change in Load

+25

°

C

I

I

O

= 1.8 A to 3.6 A or 3.6 A to 1.8 A, di/dt = 0.5 A/

µ

s

150

µ

s

Time for V

OUT

to Return within 2% of Final Value

Soft Start Turn-On Time

5

+25

°

C

I

I

O

= 3.6 A, From Inhibit High to Status High

15

20

ms

THERMAL CHARACTERISTICS

Efficiency

+25

°

C

I

I

O

= 2.2 A

81

85

%

Full

VI

I

O

= 2.2 A

80

%

+25

°

C

I

I

O

= 3.6 A

81

85

%

Full

VI

I

O

= 3.6 A

80

%

Hottest Junction Temperature

6

+90

°

C

V

I

O

= 3.6 A

110

°

C

CONTROL CHARACTERISTICS

Clock Frequency

Full

VI

I

O

= 0.36 A

0.85

0.99

MHz

ADJUST (Pin 3) V ADJ

+25

°

C

I

5.5

5.6

5.7

V

STATUS (Pin 4)

V

OH

+25

°

C

I

I

OH

= 400

µ

A

2.4

4.0

V

V

OL

+25

°

C

I

I

OL

= 1 mA

0.15

0.7

V

V

AUX

(Pin 5)

V

O

(nom)

+25

°

C

I

I

AUX

= 5 mA, Load Current = 3.6 A

12.85 13.1

13.35 V

INHIBIT (Pin 6)

V

IL

+25

°

C

I

0.5

V

I

IL

+25

°

C

I

V

IL

= 0.5 V

1.2

mA

V

I

(Open Circuit)

+25

°

C

I

15

V

SYNC (Pin 7)

7

V

IH

+25

°

C

I

4.0

V

I

IH

+25

°

C

I

V

IH

= 7.0 V

150

µ

A

I

SHARE

(Pin 8)

+25

°

C

I

I

O

= 3.6 A

2.70

2.80

2.90

V

TEMP (Pin 9)

+25

°

C

V

3.90

V

NOTES

1

50 V dc upper limit rated for transient condition of up to 50 ms. 16 V dc lower limit rated for continuous operation during emergency condition. Steady state and

abnormal input voltage range require source impedance sufficient to ensure input stability at low line. See sections entitled System Instability Considerations and

Input Voltage Range.

2

Measured at the remote sense points.

3

Unit regulates output voltage to zero load.

4

C

LOAD

= 0.

5

Output is fully loaded into a constant resistive load.

6

Refer to Thermal Characteristics section for more information.

7

Unit has internal pull-down; refer to section entitled Pin 7 (SYNC).

Specifications subject to change without notice.

REV. 0

2

(T

C

= +25 C, V

IN

= 28 V dc 0.5 V dc, unless otherwise noted; full temperature range is

55 C to +90 C; all temperatures are case and T

C

is the temperature measured at the center of the package bottom.)

ADDC02828SA

REV. 0

3

ABSOLUTE MAXIMUM RATINGS*

INHIBIT . . . . . . . . . . . . . . . . . . . . . . . . . . 50 V dc, 0.5 V dc

SYNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 V dc, 0.5 V dc

I

SHARE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 V dc, 0.5 V dc

TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 V dc, 0.3 V dc

Common-Mode Voltage, Input to Output . . . . . . . . . 500 V dc

Lead Soldering Temp (10 sec) . . . . . . . . . . . . . . . . . . . +300

°

C

Storage Temperature . . . . . . . . . . . . . . . . . . 65

°

C to +150

°

C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . +150

°

C

Maximum Case Operating Temperature . . . . . . . . . . . +125

°

C

*Absolute maximum ratings are limiting values, to be applied individually, and

beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied. Exposure of

absolute maximum rating conditions for extended periods of time may affect

device reliability.

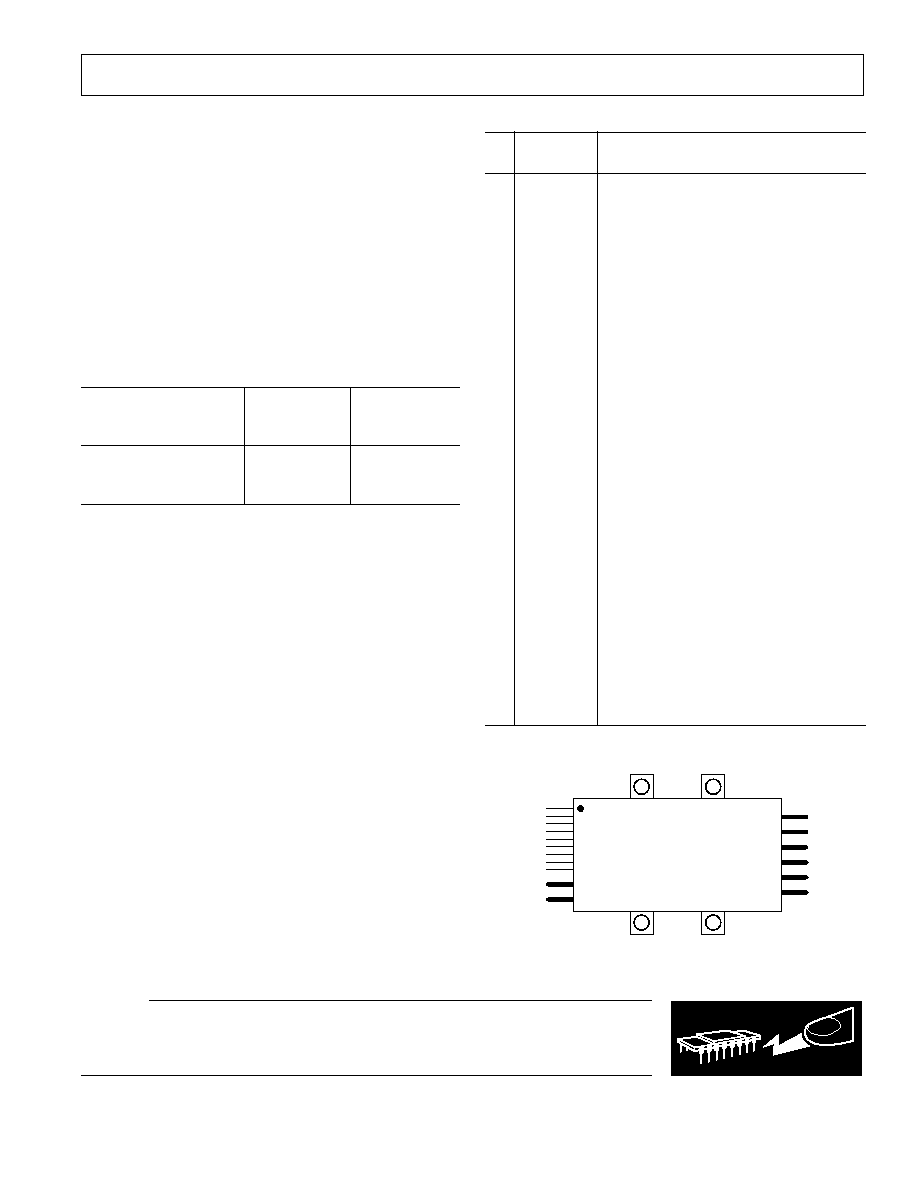

ORDERING GUIDE

Operating

Temperature

Device

Range (Case)

Description

ADDC02828SAKV

40

°

C to +85

°

C

Hermetic Package

ADDC02828SATV

55

°

C to +90

°

C

Hermetic Package

ADDC02828SATV/883B*

55

°

C to +125

°

C Hermetic Package

*Contact factory.

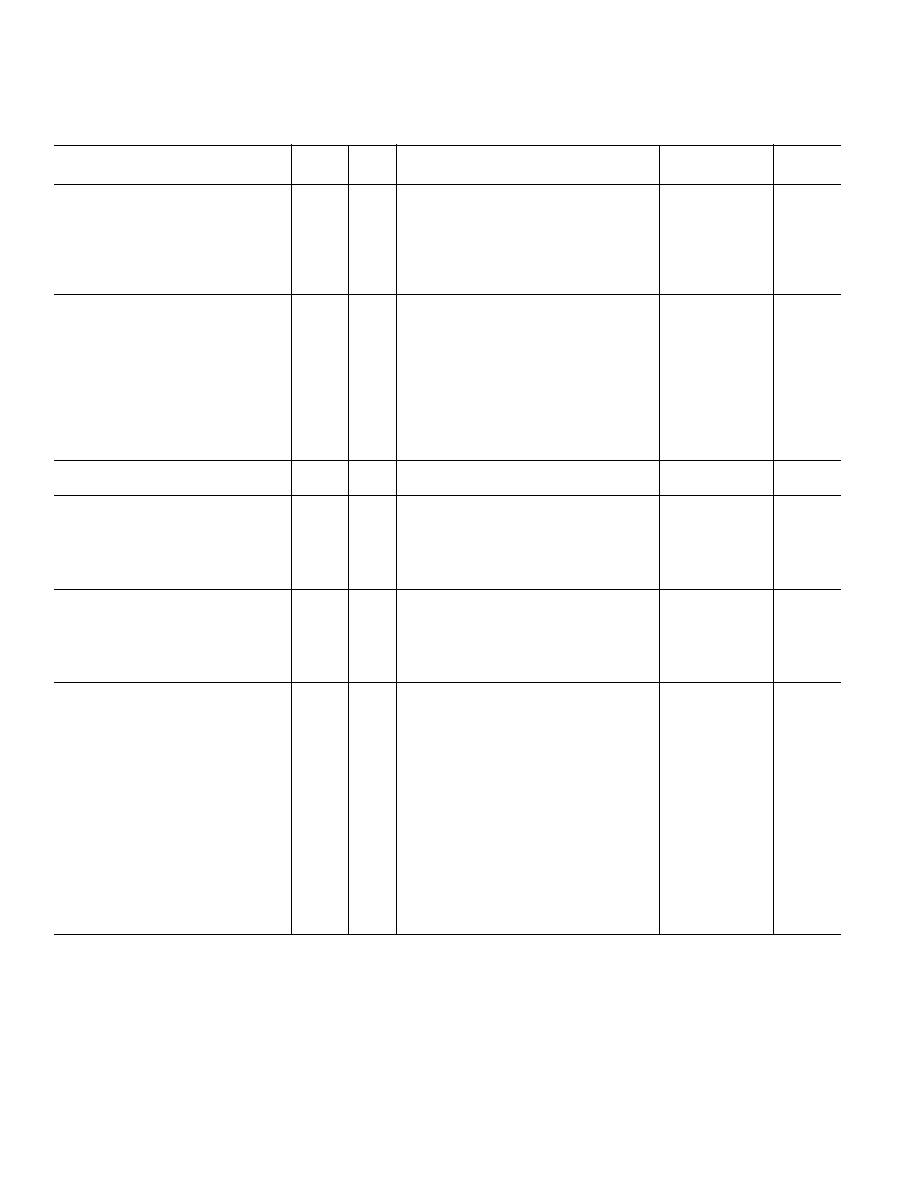

EXPLANATION OF TEST LEVELS

Test Level

I

100% production tested.

II

100% production tested at +25

°

C, and sample tested at

specified temperatures.

III

Sample tested only.

IV

Parameter is guaranteed by design and characterization

testing.

V

Parameter is a typical value only.

VI

All devices are 100% production tested at +25

°

C. 100%

production tested at temperature extremes for military

temperature devices; guaranteed by design and charac-

terization testing for industrial devices.

PIN FUNCTION DESCRIPTIONS

Pin

No.

Name

Function

1

SENSE

Feedback loop connection for remote sensing

output voltage. Must always be connected to

output return for proper operation.

2

+SENSE

Feedback loop connection for remote sensing

output voltage. Must always be connected to

+V

OUT

for proper operation.

3

ADJUST

Adjusts output voltage setpoint.

4

STATUS

Indicates output voltage is within

±

5% of

nominal. Active high referenced to SENSE

(Pin 1).

5

V

AUX

Low level dc auxiliary voltage supply refer-

enced to input return (Pin 10).

6

INHIBIT

Power Supply Inhibit. Active low and refer-

enced to input return (Pin 10).

7

SYNC

Clock synchronization input for multiple units;

referenced to input return (Pin 10).

8

I

SHARE

Current share pin that allows paralleled units

to share current typically within

±

5% at full

load; referenced to input return (Pin 10).

9

TEMP

Case temperature indicator and temperature

shutdown override; referenced to input return

(Pin 10).

10

V

IN

Input Return.

11

+V

IN

+28 V Nominal Input Bus.

12

+V

OUT

+28 V dc Output.

13

+V

OUT

+28 V dc Output.

14

SENSE

REF

Output Sense Reference.

15

SENSE

REF

Output Sense Reference.

16

RETURN

Output Return.

17

RETURN

Output Return.

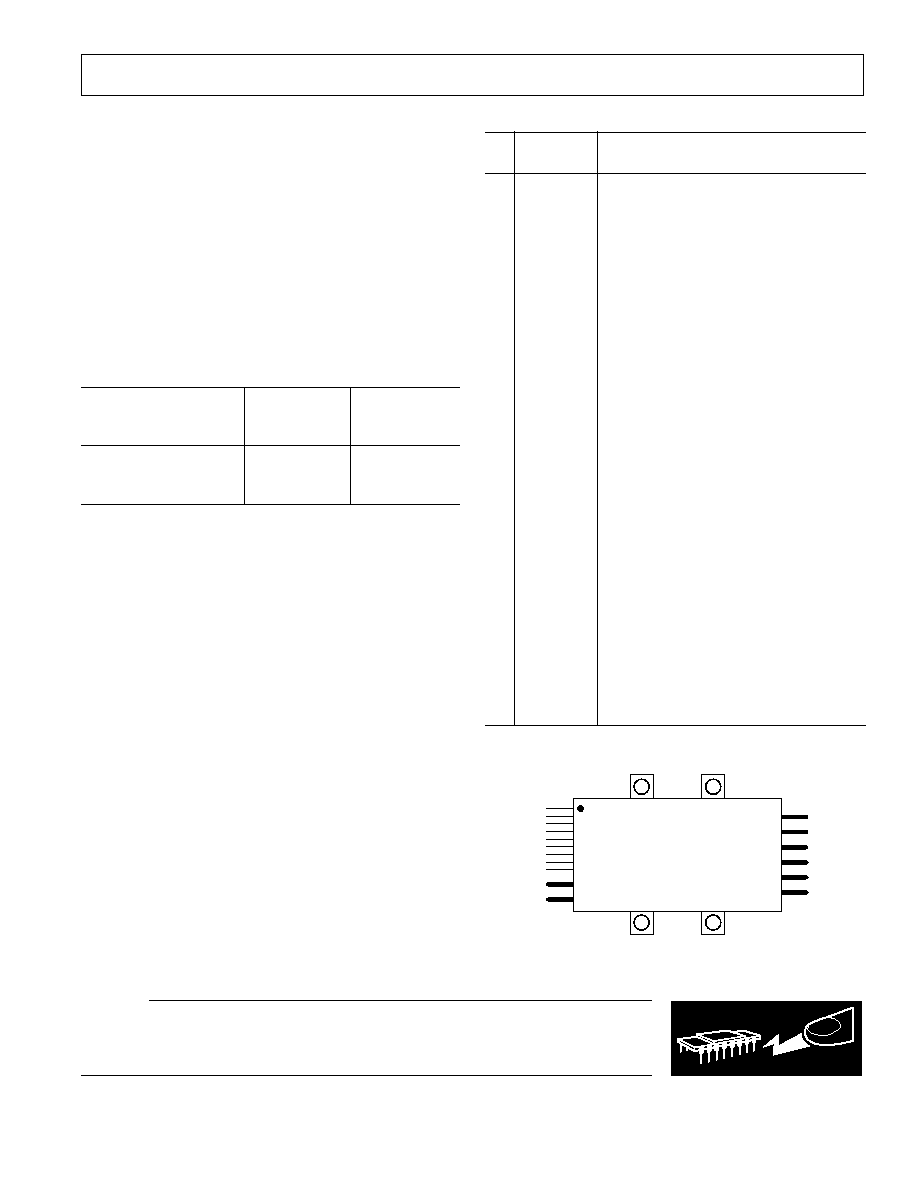

PIN CONFIGURATION

1

11

12

17

TOP

VIEW

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Therefore, proper ESD precautions are recommended to avoid performance degradation or loss

of functionality.

WARNING!

ESD SENSITIVE DEVICE

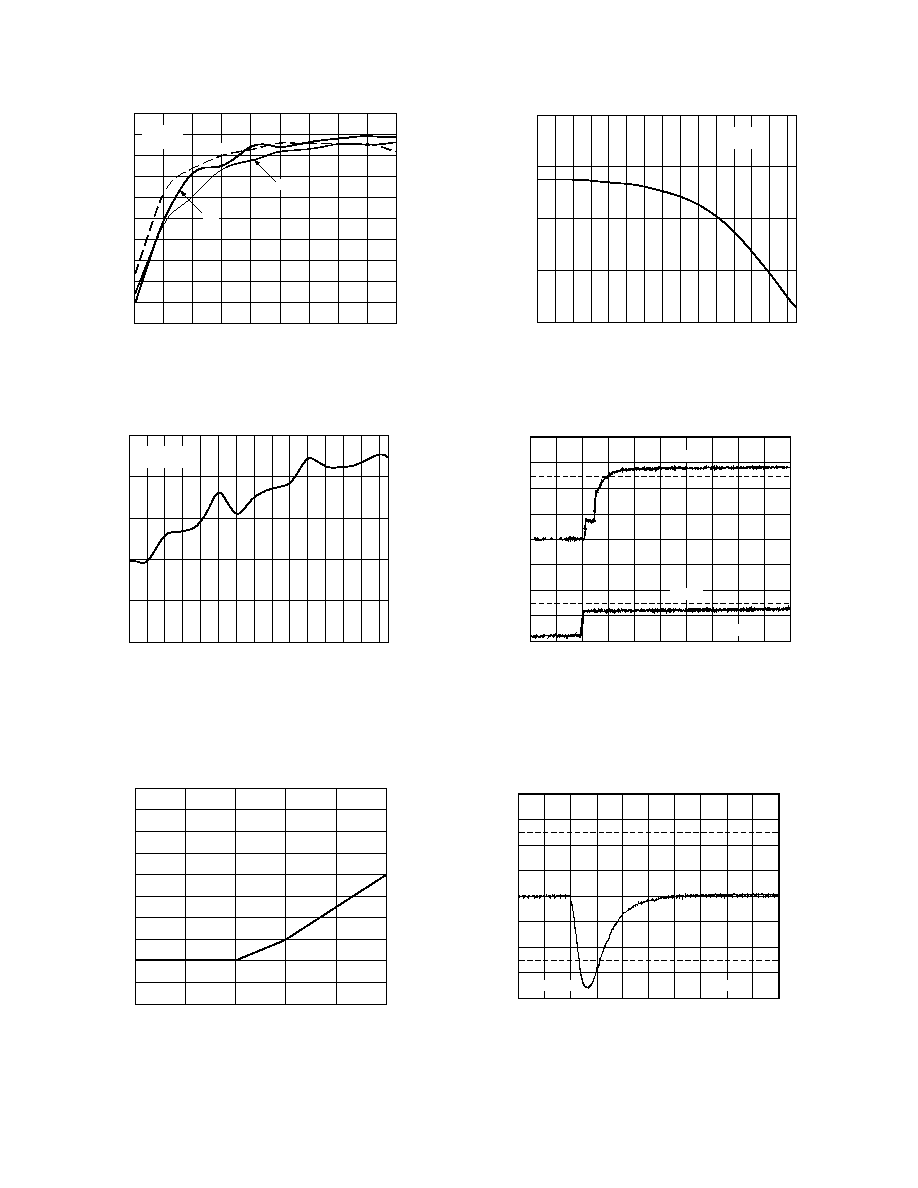

ADDC02828SATypical Performance Curves

REV. 0

4

OUTPUT POWER Volts

88

10

20

30

40

60

70

80

90

86

84

82

80

78

76

74

72

70

68

50

100

V

O

= 28V

T = +25 C

40V

28V

18V

EFFICIENCY %

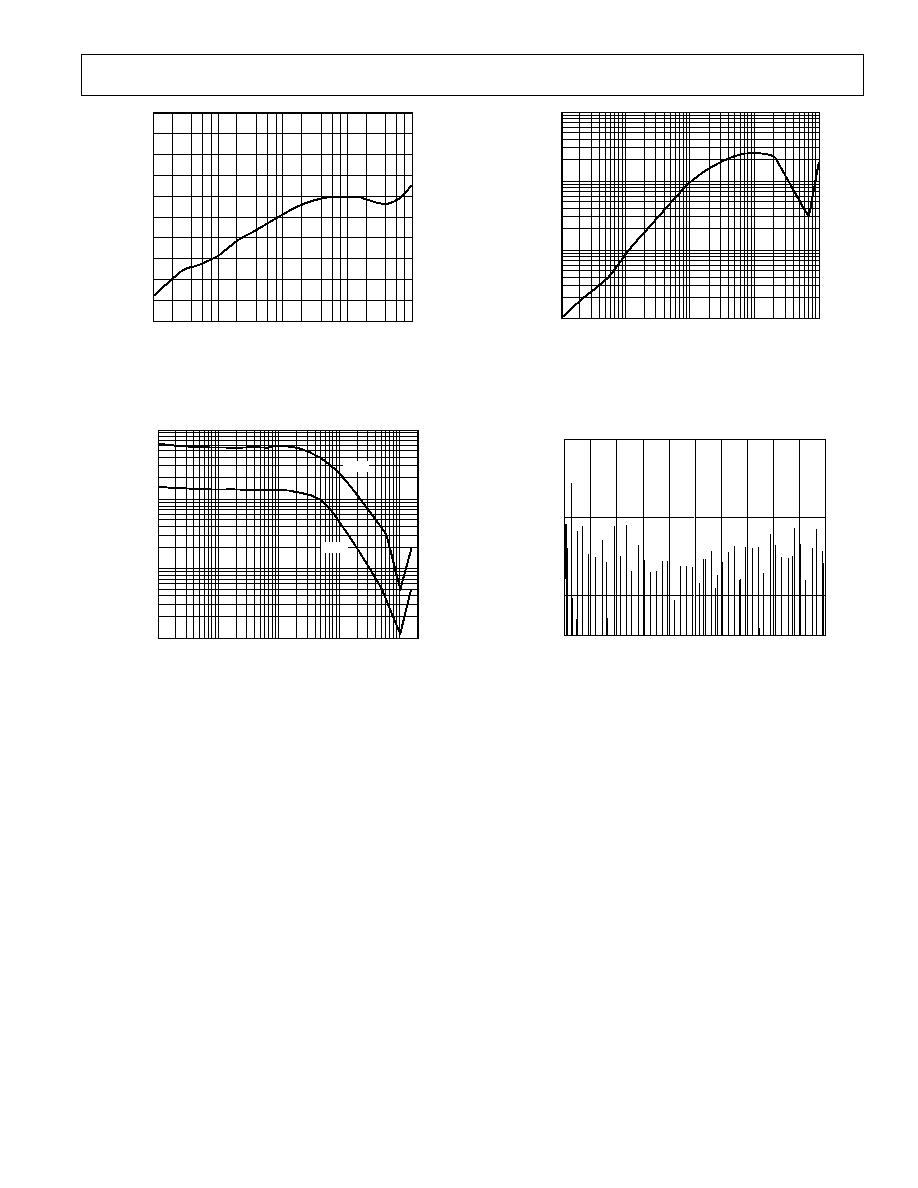

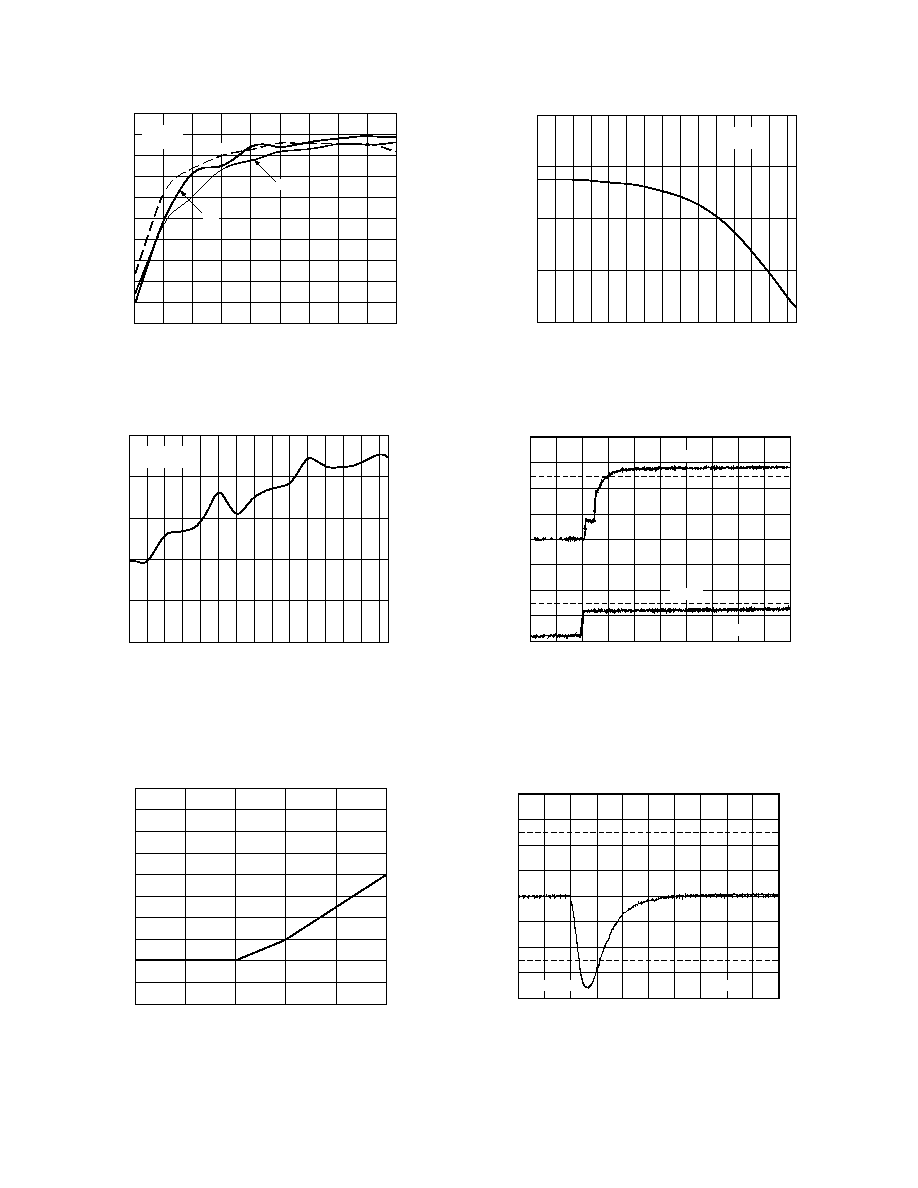

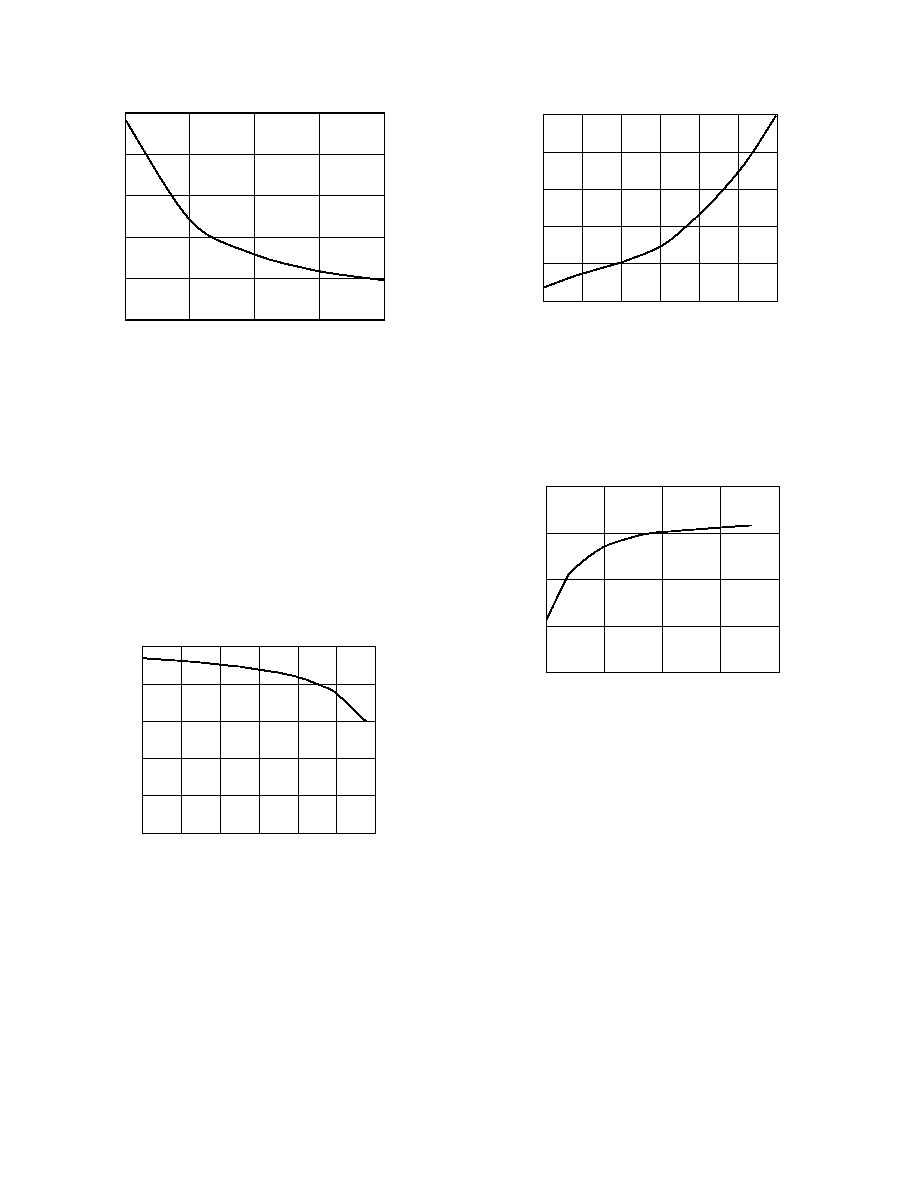

Figure 1. Efficiency vs. Line and Load at +25

°

C

T

CASE

°

C

87

86

82

55

75

45

EFFICIENCY %

35 25 15 5

5

15

25

35

45

55

65

85

84

83

85

28V

IN

75W PEAK

Figure 2. Efficiency vs. Case Temperature (

°

C)

(at Nominal V

IN

, 75% Max Load)

OUTPUT POWER Watts

14.0

80

75

85

90

95

100

13.9

13.8

13.7

13.6

13.5

13.4

13.3

13.2

13.1

13.0

INPUT VOLTAGE Volts

Figure 3. Low Line Dropout vs. Load at 90

°

C Case

Temperature

T

CASE

°

C

1.00

0.50

1.00

55

75

45 35 25 15 5

5

15

25

35

45

55

65

0.00

0.50

85

28V

IN

75WATTS

V

OUT

DEVIATION %

Figure 4. Output Voltage vs. Case Temperature (

°

C)

10V

10V

V

OUT

V

INHIBIT

5ms

Figure 5. Output Voltage Transient During Turn-On with

Minimum Load Displaying Soft Start When Supply Is

Enabled

50µs

500mV/Div

Figure 6. Output Voltage Transient Response to

a 1.8 A to 3.6 A Step Change in Load with Zero Load

Capacitance

ADDC02828SA

REV. 0

5

FREQUENCY Hz

1.0

10

.001

.01

0.1

100

10k

100k

1k

|Z

OUT

|

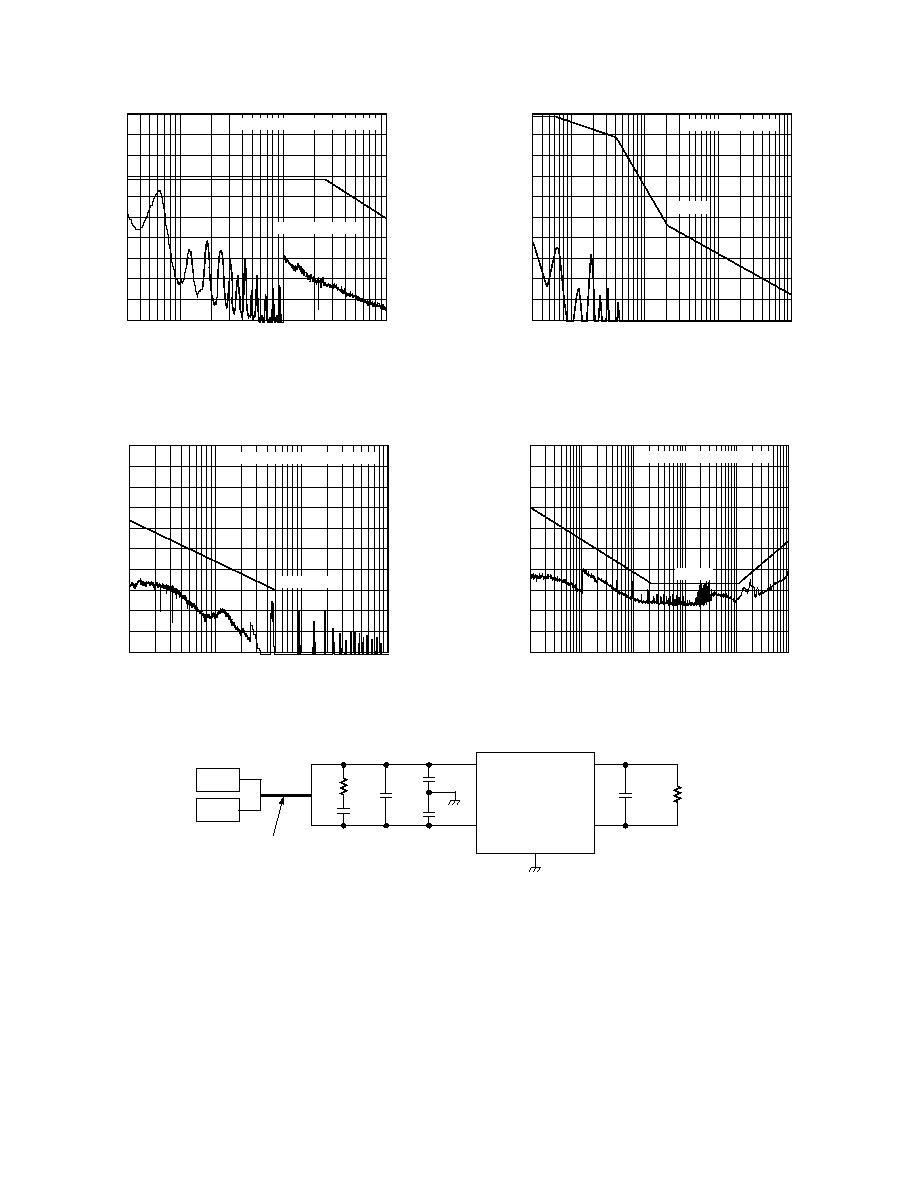

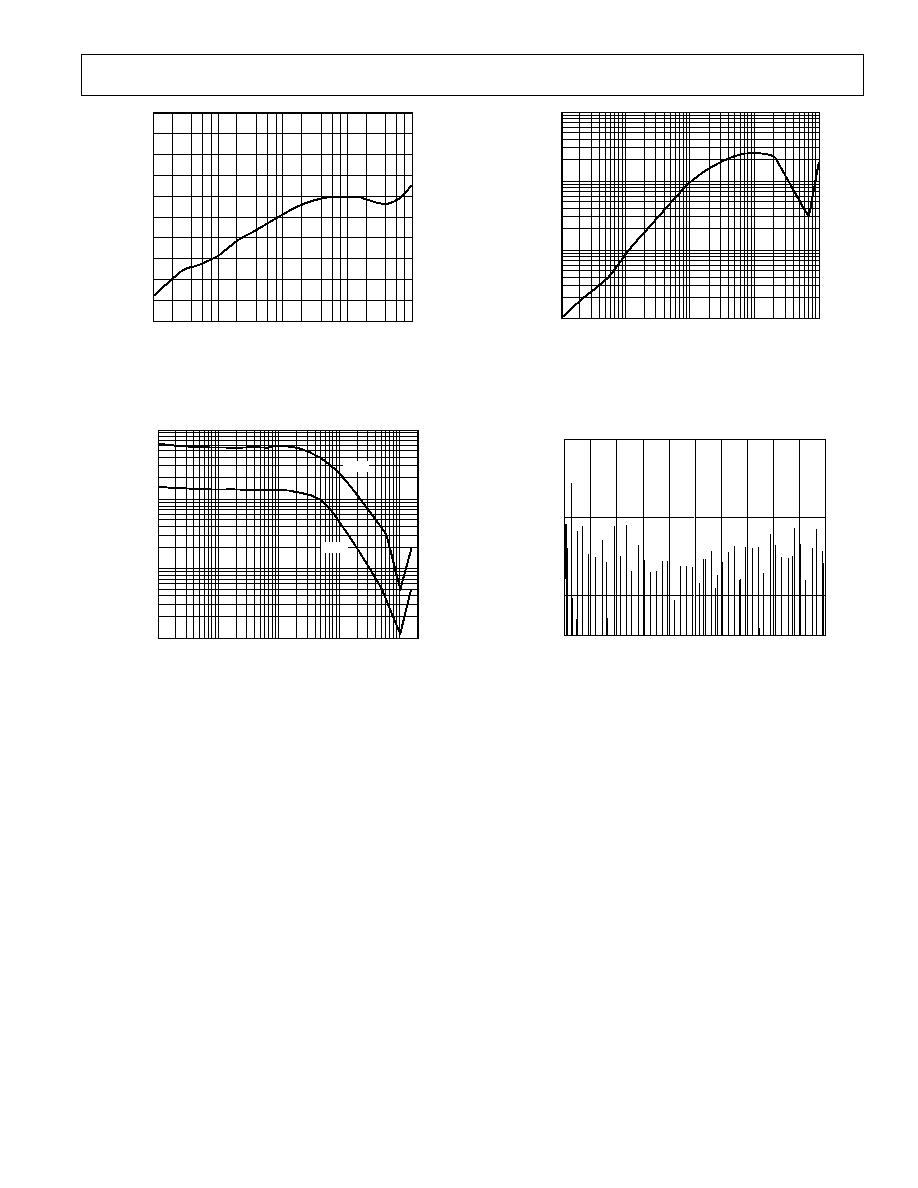

Figure 9. Incremental Output Impedance (Magnitude)

1mV

100µV

VOLTS

2.00 MHz/Div

Figure 10. Output Voltage Ripple Spectrum

10

50k

100

1k

0

10

100

20

30

40

50

60

70

80

90

10k

FREQUENCY Hz

|A

S

| dB

Figure 7. Audio Susceptibility (Magnitude of V

OUT

/V

IN

)

FREQUENCY Hz

10.0

10

0.01

0.1

|Z

IN

|

1.0

100

10k

100k

1k

18Vdc

28Vdc

Figure 8. Incremental Input Impedance (Magnitude)

ADDC02828SATypical EMI Curves and Test Setup

REV. 0

6

+V

IN

V

IN

+V

OUT

RETURN

CASE

LISN

1/4

0.1µF

GROUND PLANE

82nF

82nF

2µF

1

100µF

TWO METERS OF

TWISTED CABLE

NOTE: 100µF CAPACITOR AND 1

RESISTOR PROVIDE STABILIZATION FOR 100µH DIFFERENTIAL SOURCE INDUCTANCE

INTRODUCED BY THE LISNs. REFER TO SECTION ON EMI CONSIDERATIONS FOR MORE INFORMATION.

LISN

Figure 15. Schematic of Test Setup for EMI Measurements

FREQUENCY MHz

130

0.01

0.0001

0.001

70

90

30

EMISSION LEVEL dB µV

110

50

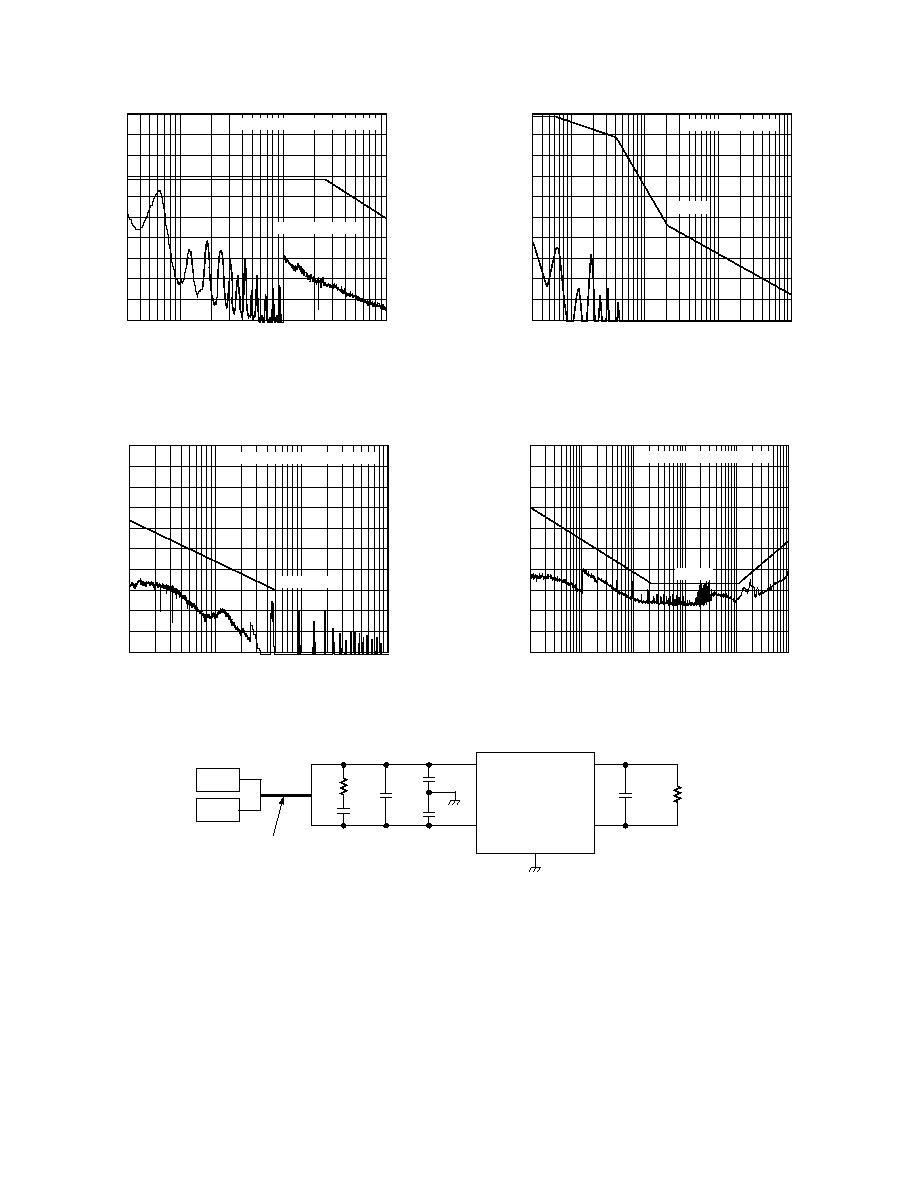

CONDUCTED EMISSIONS CE101

CE1011 4.5 AMPS

Figure 11. Conducted Emissions, MIL-STD-461D, CE101,

+28 V Hot Line 100 W Load

FREQUENCY MHz

130

10

0.01

0.1

70

90

30

EMISSION LEVEL dB µV

110

50

1

CONDUCTED EMISSIONS CE102

LIMIT 28VDC

Figure 12. Conducted Emissions, MIL-STD-461D, CE102,

+28 V Hot Line 100 W Load

FREQUENCY MHz

166

0.1

0.0001

0.001

106

126

66

EMISSION LEVEL dB/pT

146

86

0.01

RE101 MILSTD461D

RE1011

Figure 13. Radiated Emissions, MIL-STD-461D, RE101,

100 W Load

FREQUENCY MHz

90

10

0.01

0.1

30

50

30

EMISSION LEVEL dB µV/m

70

10

1

100

1000

RADIATED EMISSIONS RE102

RE1022

Figure 14. Radiated Emissions, MIL-STD-461D, RE102,

Vertical Polarity, 100 W Load

Note: Figures 1115 were obtained from measurements on the ADDC02805SA, a single 5 V dc output converter. Since the con-

struction and topology of the ADDC02828SA is almost identical to the ADDC02805SA, and the component values of the EMI

differential and common-mode filter in the ADDC02828SA are identical to the ADDC02805SA, the subject figures are shown here

as typical of the ADDC02828SA.

ADDC02828SA

REV. 0

7

BASIC OPERATION

The ADDC02828SA converter uses a flyback topology with

dual interleaved power trains operating 180

°

out of phase. Each

power train switches at a fixed frequency of 500 kHz, resulting

in a 1 MHz fixed switching frequency as seen at the input and

output of the converter. In a flyback topology, energy is stored

in the inductor during one half portion of the switching cycle

and is then transferred to the output filter during the next half

portion. With two interleaved power trains, energy is transferred

to the output filter during both halves of the switching cycle,

resulting in smaller filters to meet the required ripple.

A five pole differential input EMI filter, along with a common-

mode EMI capacitor and careful attention to layout parasitics, is

designed to meet all applicable requirements in MIL-STD-461D

when installed in a typical system setup. A more detailed dis-

cussion of CE102 and other EMI issues is included in the sec-

tion entitled EMI Considerations.

The converter uses current mode control and employs a high

performance opto-isolator in its feedback path to maintain isola-

tion between input and output. The control circuit is designed

to give a nearly constant output current as the output voltage

drops from V

O

nom to V

SC

during a short circuit condition. It

does not let the current fold back below the maximum rated

output current. The output overvoltage protection circuitry,

which is independent from the normal feedback loop, protects

the load against a break in the remote sense leads. Remote

sense connections, which can be made at the load, can adjust

for voltage drops of as much as 0.25 V dc between the converter

and the load, thereby maintaining an accurate voltage level at

the load.

An input overvoltage protection feature shuts down the con-

verter when the input voltage exceeds (nominally) 52.5 V dc.

An internal temperature sensor shuts down the unit and pre-

vents it from becoming too hot if the heat removal system fails.

The temperature sensed is the case temperature and is factory

set to trip at a nominal case temperature of 110

°

C to 115

°

C.

The shut-down temperature setting can be raised externally or

disabled by the user.

Each unit has an INHIBIT pin that can be used to turn off the

converter. This feature can be used to sequence the turn-on of

multiple converters and to reduce input power draw during

extended time in a no load condition.

A SYNC pin, referenced to the input return line (Pin 10), is

available to synchronize multiple units to one switching fre-

quency. This feature is particularly useful in eliminating beat

frequencies that may cause increased output ripple on paralleled

units. A current share pin (I

SHARE

) is available that permits

paralleled units to share current, typically within 5% at full load.

A low level dc auxiliary voltage supply referenced to the input

return line is provided for miscellaneous system use.

PIN CONNECTIONS

Pins 1 and 2 ( SENSE)

Pins 1 and 2 must always be connected for proper operation,

although failure to make these connections will not be catastrophic

to the converter under normal operating conditions. If no load

is present on the converter, failure to make these connections

could result in damage to the device. If the ADDC02828SA is

used to provide a +28 V dc output, Pin 1 must always be con-

nected to the output sense reference (Pins 14 and 15) and Pin 2

must always be connected to +V

OUT

(Pins 12 and 13). If the

ADDC02828SA is used to provide a 28 V dc output, Pin 1

must always be connected to RETURN (Pins 16 and 17) and

Pin 2 must always be connected to the output sense reference

(Pins 14 and 15). The connections to +V

OUT

(for a +28 V dc

output) and RETURN (for a 28 V dc output) can be made at

any one of the output pins of the converter, or remotely at the

load. A remote connection at the load can adjust for voltage

drops of as much as 0.25 V dc between the converter and the

load.

Long remote sense leads can affect converter stability, although

this condition is rare. The impedance of the long power leads

between the converter and the remote sense point could affect

the converter's unity gain crossover frequency and phase mar-

gin. Consult factory if long remote sense leads are to be used.

Pin 3 (ADJUST)

An adjustment pin is provided so the user can change the nomi-

nal output voltage during the prototype stage. Since very low

temperature coefficient resistors are used to set the output volt-

age and maintain tight regulation over temperature, using stan-

dard external resistors to adjust the output voltage will loosen

output regulation over temperature. Furthermore, since the

status trip point is not changed when the output voltage is ad-

justed using external resistors, the status line will no longer trip

at the standard levels of the newly adjusted output voltage. If

necessary, modified standard units can be ordered with the

necessary changes made inside the package at the factory. The

ADJUST function is sensitive to noise, and care should be taken

in the routing of connections.

To make the output voltage higher, place a resistor from ADJUST

(Pin 3) to SENSE (Pin 1). To make the output voltage lower,

place a resistor from ADJUST (Pin 3) to +SENSE (Pin 2).

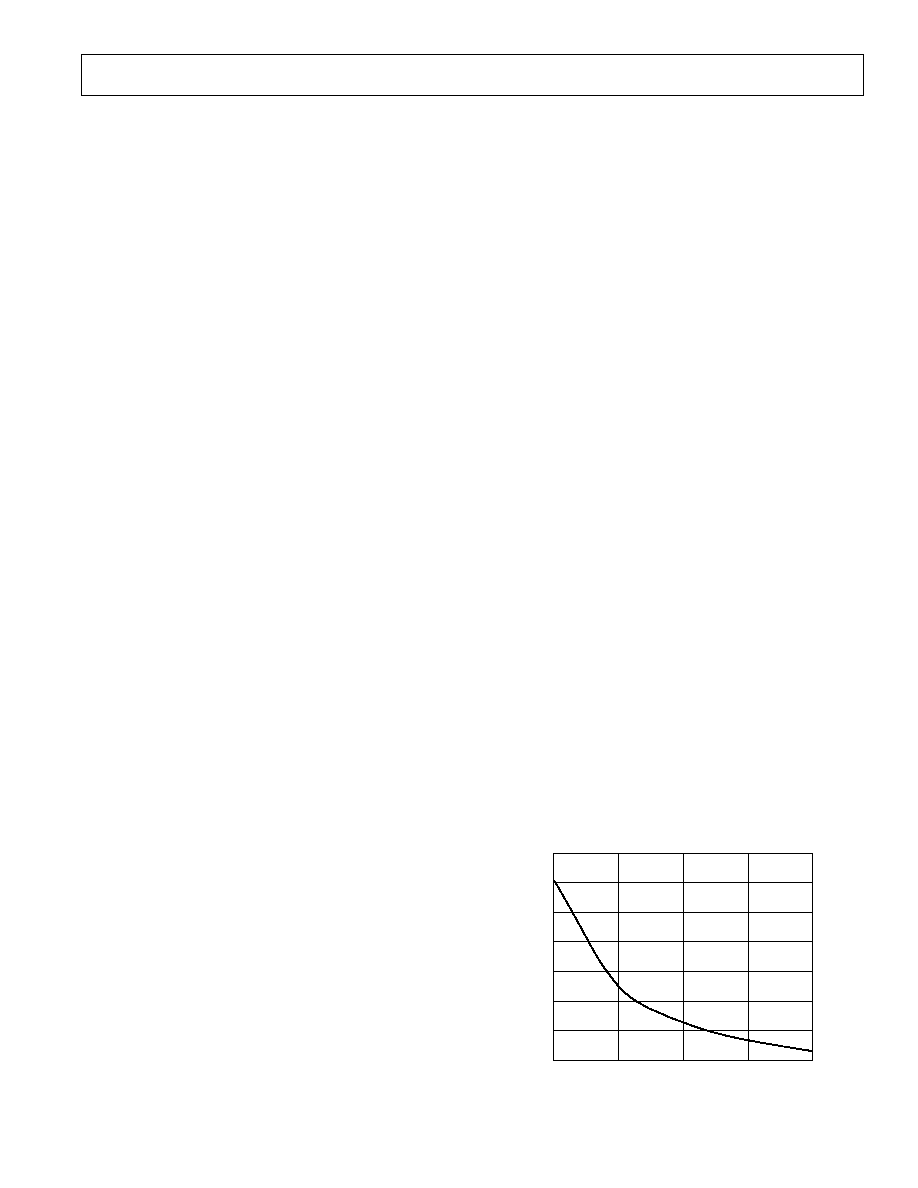

Figures 16 and 17 show resistor values for a

±

5% change in

output voltage:

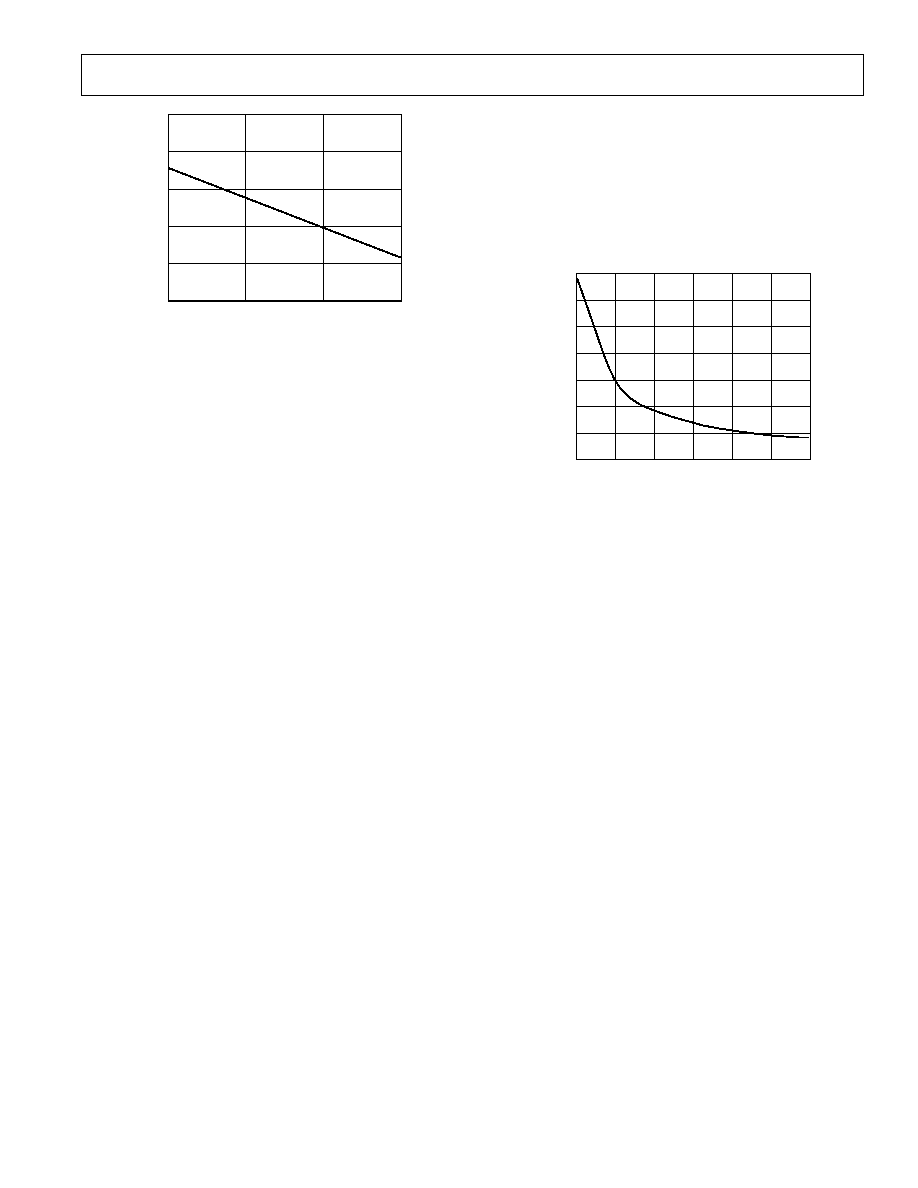

OUTPUT VOLTAGE %

8

7

RESISTANCE M

1

99

95

98

97

96

5

4

3

2

6

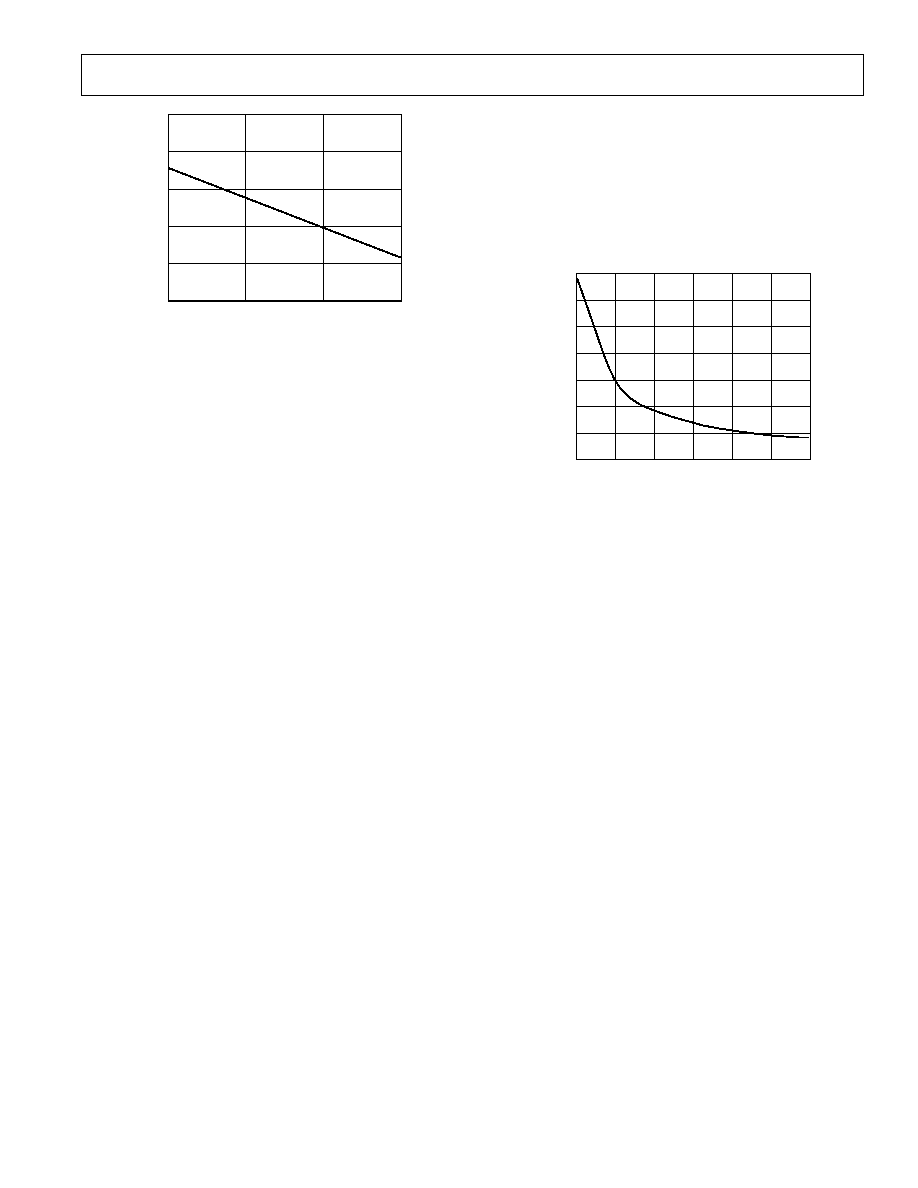

Figure 16. External Resistor Value for Reducing Output

Voltage

ADDC02828SA

REV. 0

8

OUTPUT VOLTAGE %

5

4

RESISTANCE M

0

101

105

102

103

104

3

2

1

Figure 17. External Resistor Value for Increasing Output

Voltage

With regard to the range that the output voltage can be adjusted

by the user, there are two concerns. As the output voltage is

raised it may become difficult to maintain regulation at full

power and low input voltage. As the output voltage is lowered,

it may become difficult to maintain regulation at minimum

power and high input line.

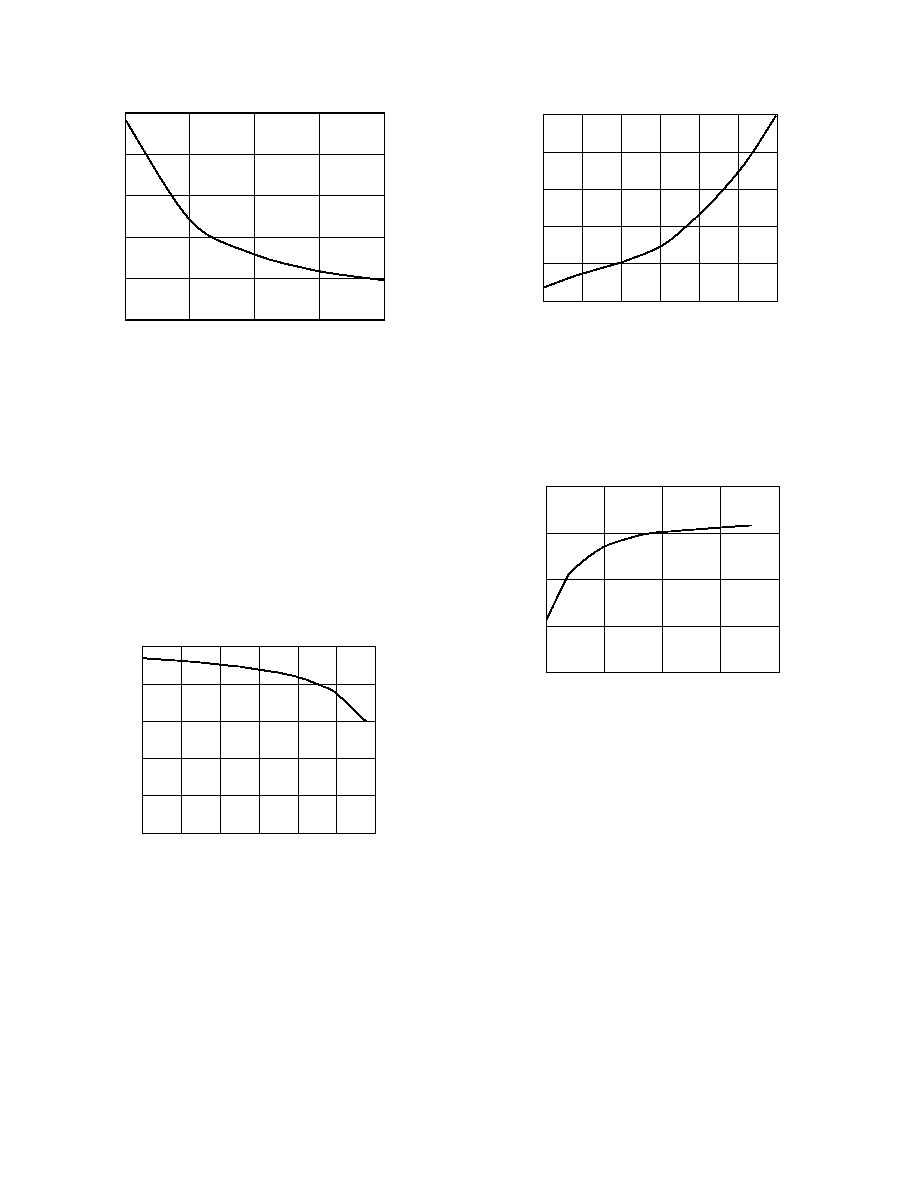

Pin 4 (STATUS)

Pin 4 is active high referenced to SENSE (Pin 1), indicating

that the output voltage is typically within

±

5%. The pin is

pulled both up and down by internal circuitry. Figures 18 and

19 show the typical source and sink capabilities of the status

output. Refer to the paragraphs describing Pin 3 (ADJUST) for

effect on status trip point.

I

OH

mA

5

4

0.2

0.4

0.6

0.8

1

1.2

1.4

3

2

0

1

V

OH

Volts

Figure 18. Source Capability of Status Output

I

OL

mA

1.0

0.8

0.0

1.0

19.0

4.0

7.0

V

OL

V

10.0

13.0

16.0

0.6

0.4

0.2

Figure 19. Sink Capability of Status Output

Pin 5 (V

AUX

)

Pin 5 is referenced to the input return and provides a semi-

regulated 11 V to 14 V dc voltage supply for miscellaneous

system use. The maximum permissible current draw is 5 mA

and the voltage varies with the output load of the converter as

shown in Figure 20.

CONVERTER OUTPUT CURRENT Amps

14

0

1

2

3

4

13

12

10

11

28V

IN

V

AUX

Volts

Figure 20. V

AUX

vs. Load

Pin 6 (INHIBIT)

Pin 6 is active low and is referenced to the input return of the

converter. Connecting it to the input return will turn the

converter off. For normal operation, the inhibit pin is inter-

nally pulled up to 12 V. Use of an open collector circuit is

recommended.

When Pin 6 is disconnected from input return, the converter

will restart in the soft-start mode. Pin 6 must be kept low for at

least 2 milliseconds to initiate a full soft start. Shorter off times

will result in a partial soft start. Figure 21 shows the input

characteristics of Pin 6.

ADDC02828SA

REV. 0

9

V

IL

V

1.2

1.1

0.7

0.5

2.0

1.0

I

IL

mA

1.5

1.0

0.9

0.8

Figure 21. Input Characteristics of Pin 6 When Pulled Low

Pin 7 (SYNC)

Pin 7 can be used for connecting multiple converters to a mas-

ter clock. This master clock can be either an externally user-

supplied clock or it can be a converter that has been modified

and designated as a master unit. Consult factory for availability

of these devices. Capacitive coupling of the clock signal will

ensure that if the master clock stops working the individual

units will continue to operate at their own internal clock fre-

quency, thereby eliminating a potential single point failure.

Capacitive coupling will also permit a wider duty cycle to be

used. The SYNC pin has an internal pull-down so it is not

necessary to sink any current when driving the pin low. Reference

Figure 28 for a fault tolerant, secondary side powered SYNC

drive circuit.

For user-supplied master clocks with no external circuitry, the

following specifications must be met:

a. Frequency: 1.00 MHz min

b. Duty cycle: 7% min, 14% max

c. High state voltage high level: 4 V min to 7 V max

d. Low state voltage low level: 0 V min to 3.0 V max

Users should note that the SYNC pin is referenced to the input

return of the converter. If the user-supplied master clock is

generated on the output side of the converter, the signal should

be isolated.

Users should be careful about the frequency selected for the

external master clock. Higher switching frequencies will reduce

efficiency and may reduce the amount of output power available at

minimum input line. Consult factory for modified standard switch-

ing frequency to accommodate system clock characteristics.

Pin 8 (I

SHARE

)

Pin 8 allows paralleled converters to share the total load cur-

rent, typically within

±

5% at full load. To use the current share

feature, connect all current share pins to each other and con-

nect the SENSE pins on each of the converters. The current

sharing function is sensitive to the differential voltage between the

input return pins of paralleled converters. The current sharing

function is also sensitive to noise, and care should be taken in

the routing of connections. Refer to Figure 27 for typical appli-

cation circuits using paralleled converters.

Pin 9 (TEMP)

Pin 9 can be used to indicate case temperature or to raise or

disable the temperature at which thermal shutdown occurs.

Typically, 3.90 V corresponds to +25

°

C, with a +13.1 mV/

°

C

change for every 1

°

C rise. The sensor IC (connected from Pin 9

to the input return [Pin 10]) has a 13.1 k

impedance.

The thermal shutdown feature has been set to shut down the

converter when the case temperature is nominally 110

°

C to

115

°

C. To raise the temperature at which shutdown occurs,

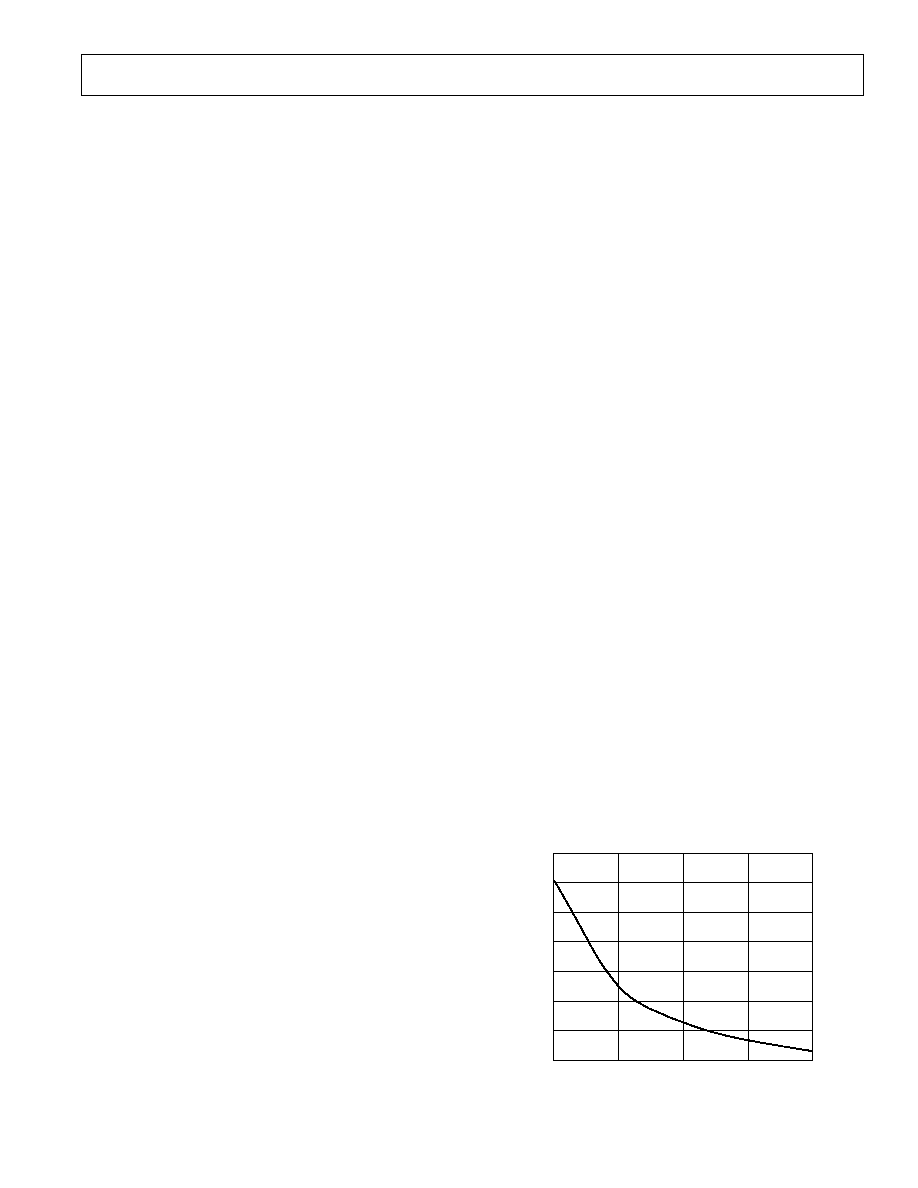

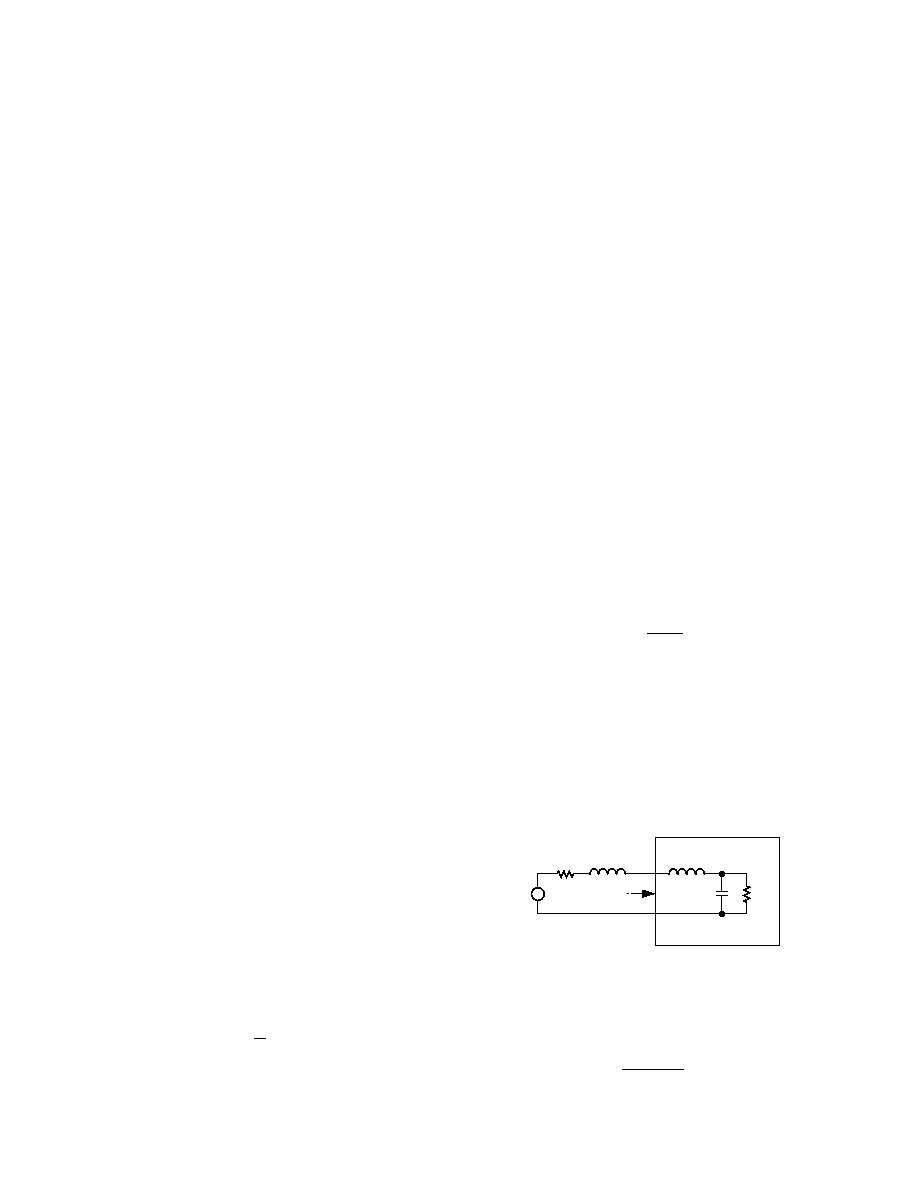

connect a resistor with the value shown in Figure 22 from Pin 9

to the input return (Pin 10). To completely disable the tem-

perature shutdown feature, connect a 50 k

resistor from Pin 9

to the input return (Pin 10).

SHUTDOWN CASE TEMPERATURE

°

C

1400

0

120

150

125

130

135

140

145

1200

1000

800

400

200

600

RESISTANCE k

Figure 22. External Resistor Value for Raising

Temperature Shutdown Point

INPUT VOLTAGE RANGE

The steady state operating input voltage range for the converter

is defined as 18 V to 40 V. The abnormal operating input volt-

age range is defined as 16 V to 50 V. In accordance with MIL-

STD-704D, the converter can operate up to 50 V dc input for

transient conditions as long as 50 milliseconds, and it can oper-

ate down to 16 V dc input for continuous operation during

emergency conditions. Figure 3 (typical low line dropout vs.

load) shows that the converter can work continuously down to

and below 16 V dc under reduced load conditions.

The ADDC02828SA can be modified to survive, but not work

through, the upper limit input voltages defined in MIL-STD-704A

(aircraft) and MIL-STD-1275A (military vehicles). MIL-STD-704A

defines an 80 V surge that lasts for 1 second before it falls below

50 V, while MIL-STD-1275A defines a 100 V surge that lasts

for 200 milliseconds before it falls below 50 V. In both cases,

the ADDC02828SA can be modified to operate to specification

up to the 50 V input voltage limit and to shut down and protect

itself during the time the input voltage exceeds 50 V. When the

input voltage falls below 50 V as the surge ends, the converter

will automatically initiate a soft start. In order to survive these

higher input voltage surges; the modified converter, however, will

no longer have input transient protection as described below.

Contact the factory for information on units surviving high input

voltage surges.

Input Voltage Transient Protection: The converter has a

transient voltage suppressor connected across its input leads to

protect the unit against high voltage pulses (both positive and

negative) of short duration. With the power supply connected

in the typical system setup shown in Figure 15, a transient

voltage pulse is created across the converter in the following

manner. A 20

µ

F capacitor is first charged to 400 V. It is then

connected directly across the converter's end of the two meter

power lead cable through a 2

on-state resistance MOSFET.

ADDC02828SA

REV. 0

10

The duration of this connection is 10

µ

s. The pulse is repeated

every second for 30 minutes. This test is repeated with the

connection of the 20

µ

F capacitor reversed to create a negative

pulse on the supply leads. (If continuous reverse voltage protec-

tion is required, a diode can be added externally in series at the

expense of lower efficiency for the power system.)

The converter responds to this input transient voltage test by

shutting down due to its input overvoltage protection feature.

Once the pulse is over, the converter initiates a soft-start, which

is completed before the next pulse. No degradation of converter

performance occurs.

THERMAL CHARACTERISTICS

Junction and Case Temperatures: It is important for the

user to know how hot the hottest semiconductor junctions

within the converter get and to understand the relationship

between junction, case and ambient temperatures. The hottest

semiconductors in the 100 W product line of Analog Devices'

high density power supplies are the switching MOSFETs and

the output rectifiers. There is an area inside the main power

transformers that is hotter than these semiconductors, but it is

within NAVMAT guidelines and well below the Curie tempera-

ture of the ferrite. (The Curie temperature is the point at which

the ferrite begins to lose its magnetic properties.)

Since NAVMAT guidelines require that the maximum junction

temperature be 110

°

C, the power supply manufacturer must

specify the temperature rise above the case for the hottest semi-

conductors so the user can determine what case temperature

is required to meet NAVMAT guidelines. The thermal charac-

teristics section of the specification table states the hottest junction

temperature for maximum output power at a specified case

temperature. The unit can operate to higher case temperatures

than 90

°

C, but 90

°

C is the maximum temperature that permits

NAVMAT guidelines to be met.

Case and Ambient Temperatures: It is the user's responsibility

to properly heat sink the power supply in order to maintain the

appropriate case temperature and, in turn, the maximum junction

temperature. Maintaining the appropriate case temperature is a

function of the ambient temperature and the mechanical heat

removal system. The static relationship of these variables is

established by the following formula:

T

C

=

T

A

+

( P

D

×

R

CA

)

where

T

C

= case temperature measured at the center of the pack-

age bottom,

T

A

= ambient temperature of the air available for cooling,

P

D

= the power, in watts, dissipated in the power supply,

R

CA

= the thermal resistance from the center of the package

to free air, or case to ambient.

The power dissipated in the power supply, P

D

, can be calcu-

lated from the efficiency, , given in the data sheets and the

actual output power, P

O

, in the user's application by the follow-

ing formula:

P

D

=

P

O

1

1

For example, at 80 W of output power and 80% efficiency, the

power dissipated in the power supply is 20 W. If, under these

conditions, the user wants to maintain NAVMAT deratings

(i.e., a case temperature of approximately 90

°

C) with an ambi-

ent temperature of 75

°

C, the required thermal resistance, case

to ambient, can be calculated as

90 = 75 + (20

×

R

CA

) or R

CA

= 0.75

°

C/W

This thermal resistance, case to ambient, will determine what

kind of heat sink and whether convection cooling or forced air

cooling is required to meet the constraints of the system.

SYSTEM INSTABILITY CONSIDERATIONS

In a distributed power supply architecture, a power source

provides power to many "point-of-load" (POL) converters. At

low frequencies, the POL converters appear incrementally as

negative resistance loads. This negative resistance could cause

system instability problems.

Incremental Negative Resistance: A POL converter is de-

signed to hold its output voltage constant no matter how its

input voltage varies. Given a constant load current, the power

drawn from the input bus is therefore also a constant. If the

input voltage increases by some factor, the input current must

decrease by the same factor to keep the power level constant.

In incremental terms, a positive incremental change in the

input voltage results in a negative incremental change in the

input current. The POL converter therefore looks, incremen-

tally, as a negative resistor.

The value of this negative resistor at a particular operating

point, V

IN

, I

IN

, is:

R

N

=

V

IN

I

IN

Note that this resistance is a function of the operating point. At

full load and low input line, the resistance is its smallest, while

at light load and high input line, it is its largest.

Potential System Instability: The preceding analysis assumes

dc voltages and currents. For ac waveforms the incremental

input model for the POL converter must also include the effects

of its input filter and control loop dynamics. When the POL

converter is connected to a power source, modeled as a voltage

source, V

S,

in series with an inductor, L

S

, and some positive

resistor, R

S

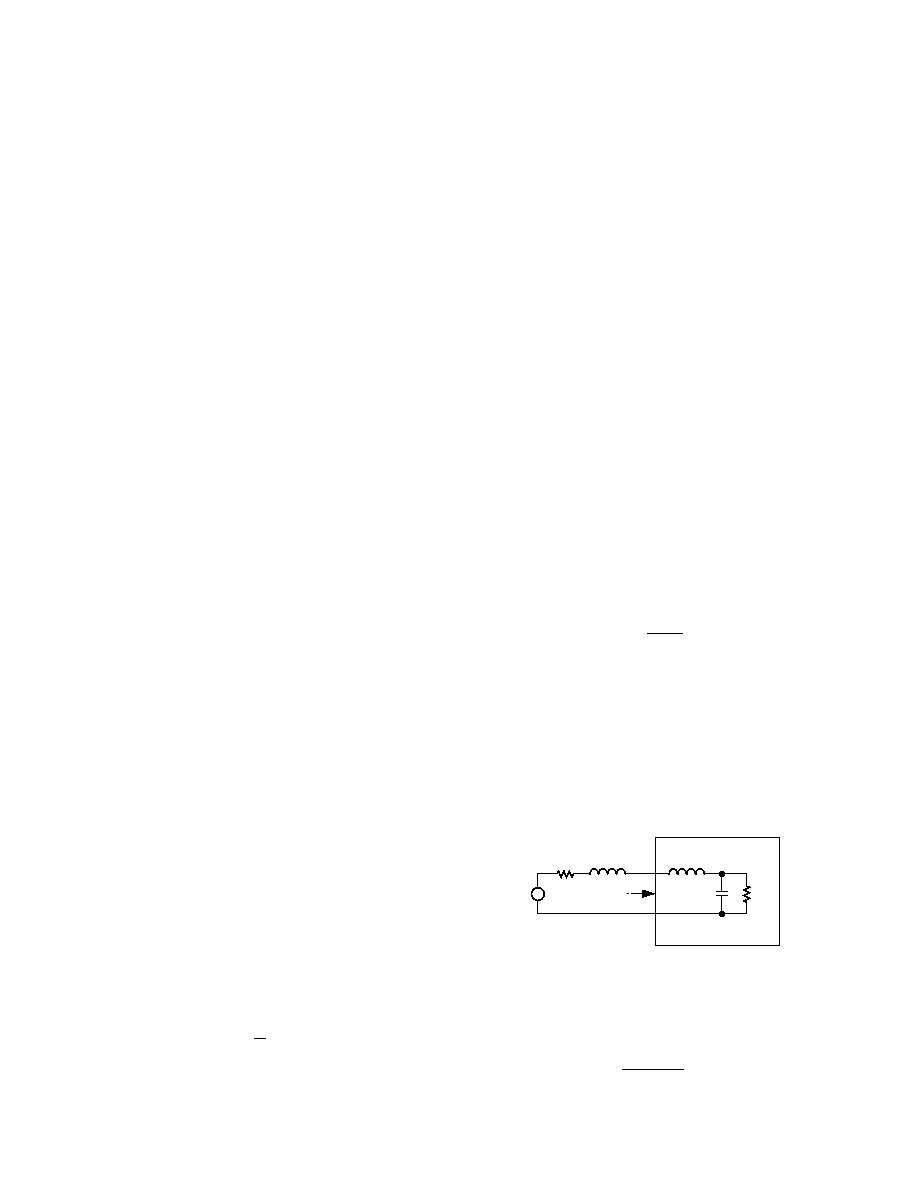

, the network of Figure 23 results.

L

P

C

P

|R

N

|

ADI DC/DC CONVERTER

L

S

R

S

V

S

INPUT

TERMINALS

Figure 23. Model of Power Source and POL Converter

Connection

The network shown in Figure 23 is second order and has the

following characteristic equation:

s

2

(L

S

+

L

P

)C

+

s

(L

S

+

L

P

)

|R

N

|

+

R

S

C

P

+

1

=

0

ADDC02828SA

REV. 0

11

For the power delivery to be efficient, it is required that R

S

<< R

N

.

For the system to be stable, however, the following relationship

must hold:

C

P

|R

N

|

>

(L

S

+

L

P

)

R

S

or R

S

>

(L

S

+

L

P

)

C

P

|R

N

|

Notice from this result that if (L

S

+ L

P

) is too large, or if R

S

is

too small, the system might be unstable. This condition would

first be observed at low input line and full load since the abso-

lute value of R

N

is smallest at this operating condition.

If an instability results, and it cannot be corrected by changing

L

S

or R

S

(such as during the MIL-STD-461D tests) due to the

LISN requirement, one possible solution is to place a capacitor

across the input of the POL converter. Another possibility is to

place a small resistor in series with this extra capacitor.

The analysis so far has assumed the source of power was a volt-

age source (e.g., a battery) with some source impedance. In

some cases, this source may be the output of a front-end (FE)

converter. Although each FE converter is different, a model for

a typical one would have an LC output filter driven by a voltage

source whose value was determined by the feedback loop. The

LC filter usually has a high Q, so the compensation of the

feedback loop is chosen to help dampen any oscillations that

result from load transients. In effect, the feedback loop adds

"positive resistance" to the LC network.

When the POL converter is connected to the output of this FE

converter, the POL's "negative resistance" counteracts the

effects of the FE's "positive resistance" offered by the feedback

loop. Depending on the specific details, this might simply mean

that the FE converter's transient response is slightly more oscil-

latory, or it may cause the entire system to be unstable.

For the ADDC02828SA, L

P

is approximately 1

µ

H and C

P

is

approximately 4

µ

F. Figure 8 shows a more accurate depiction

of the input impedance of the converter as a function of fre-

quency. The negative resistance is, itself, a very good incremen-

tal model for the power state of the converter for frequencies

into the several kHz range.

NAVMAT DERATING

NAVMAT is a Navy power supply reliability manual that is

frequently cited by specifiers of power supplies. A key section of

NAVMAT P4855-1A discusses guidelines for derating designs

and their components. The two key derating criteria are voltage

derating and power derating. Voltage derating is done to reduce

the possibility of electrical breakdown, whereas power derating

is done to maintain the component material below a specified

maximum temperature. While power deratings are typically

stated in terms of current limits (e.g., derate to x% of maximum

rating), NAVMAT also specifies a maximum junction tem-

perature of the semiconductor devices in a power supply. The

NAVMAT component deratings applicable to the ADDC02828SA

are as follows:

Resistors

80% voltage derating

50% power derating

Capacitors

50% voltage and ripple voltage derating

70% ripple current derating

Transformers and Inductors

60% continuous voltage and current derating

90% surge voltage and current derating

20

°

C less than rated core temperature

30

°

C below insulation rating for hot spot temperature

25% insulation breakdown voltage derating

40

°

C maximum temperature rise

Transistors

50% power derating

60% forward current (continuous) derating

75% voltage and transient peak voltage derating

110

°

C maximum junction temperature

Diodes (Switching, General Purpose, Rectifiers)

70% current (surge and continuous) derating

65% peak inverse voltage derating

110

°

C maximum junction temperature

Diodes (Zeners)

70% surge current derating

60% continuous current derating

50% power derating

110

°

C maximum junction temperature

Microcircuits (Linears)

70% continuous current derating

75% signal voltage derating

110

°

C maximum junction temperature

The ADDC02828SA can meet all the derating criteria listed

above. However, there are a few areas of the NAVMAT deratings

where meeting the guidelines unduly sacrifices performance of

the circuit. Therefore, the standard unit makes the following

exceptions.

Common-Mode EMI Filter Capacitors: The standard

supply uses 500 V capacitors to filter common-mode EMI.

NAVMAT guidelines would require 1000 V capacitors to meet

the 50% voltage derating (500 V dc input to output isolation),

resulting in less common-mode capacitance for the same space.

In typical electrical power supply systems, where the load

ground is eventually connected to the source ground, common-

mode voltages never get near the 500 V dc rating of the standard

supply. Therefore, a lower voltage rating capacitor (500 V)

was chosen to fit more capacitance in the same space in order

to better meet the conducted emissions requirement of MIL-

STD-461D (CE102). For those applications requiring 250 V

or less of isolation from input to output, the present designs

would meet NAVMAT guidelines.

Switching Transistors: 100 V MOSFETs are used in the

standard unit to switch the primary side of the transformers.

Their nominal off-state voltage meets the NAVMAT derating

guidelines. When the MOSFETs are turned off, however, mo-

mentary spikes occur that reach 100 V. The present generation

of MOSFETs are rated for repetitive avalanche, a condition that

was not considered by the NAVMAT deratings. In the worst

case condition, the energy dissipated during avalanche is 1% of

the device's rated repetitive avalanche energy. To meet the

NAVMAT derating, 200 V MOSFETs could be used. The

100 V MOSFETs are used instead for their lower on-state resis-

tance, resulting in higher efficiency for the power supply.

NAVMAT Junction Temperatures: The two types of power

deratings (current and temperature) can be independent of one

another. For instance, a switching diode can meet its derating

ADDC02828SA

REV. 0

12

ripple voltages will be smaller than if the load is grounded. The

test specifications do not state which procedure should be used.

However, in neither case (load grounded or floating) will the

typical EMI test setup described below be exactly representative

of the final system configuration EMI test. For the following

reasons, the same is true if separately packaged EMI filters are

used.

In almost all systems the output ground of the converter is ulti-

mately connected to the input ground of the system. The para-

sitic capacitances and inductances in this connection will affect

the common-mode voltage and the CE102 measurement. In

addition, the inductive impedance of this ground connection

can cause resonances, thereby affecting the performance of the

common-mode filter in the power supply.

In response to these ambiguities, the Analog Devices' converter

has been tested for CE102 under a constant load and with the

output ground floating. While these measurements are a good

indication of how the converter will operate in the final system

configuration, the user should confirm CE102 testing in the

final system configuration.

CE101: This test measures emissions on the input leads in the

frequency range between 30 Hz and 10 kHz. The intent of this

requirement is to ensure that the dc/dc converter does not cor-

rupt the power quality (allowable voltage distortion) on the

power buses present on the platform. There are several CE101

limit curves in MIL-STD-461D. The most stringent one app-

licable for the converter is that for submarine applications.

Figure 11 shows that the converter easily meets this requirement

(the return line measurement is similar). The components at

60 Hz and its harmonics are a result of ripple in the output of

the power source used to supply the converter.

CE102: This test measures emissions in the frequency range

between 10 kHz and 10 MHz. The measurements are made on

both of the input leads of the converter which are connected to

the power source through LISNs. The intent of this requirement

in the lower frequency portion of the requirement is to ensure

that the dc/dc converter does not corrupt the power quality

(allowable voltage distortion) on the power buses present on the

platform. At higher frequencies, the intent is to serve as a sepa-

rate control from RE102 on potential radiation from power

leads, which may couple into sensitive electronic equipment.

Figure 12 shows the CE102 limit and the measurement taken

from the +V

IN

line. While the measurement taken from the

input return line is slightly different, both comfortably meet the

MIL-STD-461D, CE102 limit. (Reference the last section of

EMI Considerations for how to adjust the external components

in the test setup circuit to increase the margin between the

specification limit and the measured results.)

CS101: This test measures the ability of the converter to reject

low frequency differential signals, 30 Hz to 50 kHz, injected on

the dc inputs. The measurement is taken on the output power

leads. The intent is to ensure that equipment performance is

not degraded from ripple voltages associated with allowable

distortion of power source voltage waveforms. Figure 7 shows a

typical audio susceptibility graph. Note that according to the

MIL-STD-461D test requirements, the injected signal between

30 Hz and 5 kHz has an amplitude of 2 V rms and from 5 kHz

to 50 kHz the amplitude decreases inversely with frequency to

0.2 V rms. The curve of the injected signal should be multiplied

by the audio susceptibility curve to determine the output ripple

of 70% of its maximum current, but its junction temperature

can be higher than 110

°

C if the case temperature of the con-

verter, which is not controlled by the manufacturer, is allowed

to go higher. Since some users may choose to operate the power

supply at a case temperature higher than 90

°

C, it then becomes

important to know the temperature rise of the hottest semicon-

ductors. This is covered in the specification table in the section

entitled Thermal Characteristics.

EMI CONSIDERATIONS

The ADDC02828SA has an integral differential- and common-

mode EMI filter that is designed to meet all applicable require-

ments in MIL-STD-461D when the power converter is installed

in a typical system setup (described below). The converter also

contains transient protection circuitry that permits the unit to

survive short, high voltage transients across its input power

leads. The purpose of this section is to describe the various

MIL-STD-461D tests and the converter's corresponding perfor-

mance. Consult factory for additional information.

The figures and tests referenced herein were obtained from

measurements on the ADDC02805SA, a single 5 V dc output

converter. Since the construction and topology of the 28 V dc

output converter is almost identical to the 5 V dc output converter,

and the component values of the EMI differential- and common-

mode filter in the 28 V dc output converter are identical to the

5 V output converter, the text references these figures and tests

as typical of the ADDC02828SA converter as well.

Electromagnetic interference (EMI) is governed by MIL-STD-461D,

which establishes design requirements, and MIL-STD-462D,

which defines test methods. EMI requirements are categorized

as follows (xxx designates a three digit number):

·

CExxx: Conducted Emissions (EMI produced internal to the

power supply, which is conducted externally through its input

power leads)

·

CSxxx: Conducted Susceptibility (EMI produced external to

the power supply, which is conducted internally through the

input power leads and may interfere with the supply's op-

eration)

·

RExxx: Radiated Emissions (EMI produced internal to the

power supply, which is radiated into the surrounding space)

·

RSxxx: Radiated Susceptibility (EMI produced external to

the power supply, which radiates into or through the power

supply and may interfere with its proper operation)

It should be noted that there are several areas of ambiguity, with

respect to CE102 measurements, that may concern the systems

engineer. One is the nature of the load. If it is constant, the

ripple voltage on the converter's input leads is due only to the

operation of the converter. If, on the other hand, the load is

changing over time, this variation causes an additional input

current and voltage ripple to be drawn at the same frequency. If

the frequency is high enough, the converter's filter will help

attenuate this second source of ripple, but if it is below approxi-

mately 100 kHz, it will not. The system may then not meet the

CE102 requirement, even though the converter is not the source

of the EMI. If this is the case, additional capacitance may be

needed across the load or across the input to the converter.

Another ambiguity in the CE102 measurement concerns common-

mode voltage. If the load is left unconnected from the ground

plane (even though the case is grounded), the common-mode

ADDC02828SA

REV. 0

13

at any frequency. When this is done, the worst case output

ripple at the frequency of the input ripple occurs at 5 kHz, at

which point there is typically a 25 mV peak-to-peak output

ripple.

It should be noted that MIL-STD-704 has a more relaxed require-

ment for rejection of low frequency differential signals injected on

the dc inputs than MIL-STD-461D. MIL-STD-704 calls for a

lower amplitude ripple to be injected on the input in a narrower

frequency band, 10 Hz to 20 kHz.

CS114: This test measures the ability of the converter to oper-

ate correctly during and after being subjected to currents in-

jected into bulk cables in the 10 kHz to 400 MHz range. Its

purpose is to simulate currents that would be developed in these

cables due to electromagnetic fields generated by antenna trans-

missions. The converter is designed to meet the requirements

of this test when the current is injected on the input power leads

cable. Consult factory for more information.

CS115: This test measures the ability of the converter to oper-

ate correctly during and after being subjected to 30 ns long

pulses of current injected into bulk cables. Its purpose is to

simulate transients caused by lightning or electromagnetic

pulses. The converter is designed to meet this requirement

when applied to its input power leads cable. Consult factory for

more information.

CS116: This test measures the ability of the converter to oper-

ate correctly during and after being subjected to damped sinu-

soid transients in the 10 kHz to 100 MHz range. Its purpose is

to simulate current and voltage waveforms that would occur

when natural resonances in the system are excited. The con-

verter is designed to meet this requirement when applied to its

input power leads cable. Consult factory for more information.

RE101: This requirement limits the strength of the magnetic

field created by the converter in order to avoid interference with

sensitive equipment located nearby. The measurement is made

from 30 Hz to 100 kHz. The most stringent requirement is for

the Navy. Figure 13 shows the test results when the pickup coil

is held 7 cm above the converter. As can be seen, the converter

easily meets this requirement.

RE102: This requirements limits the strength of the electric

field emissions from the power converter to protect sensitive

receivers from interference. The measurement is made from

10 kHz to 18 GHz with the antenna oriented in the vertical

plane. For the 30 MHz and above range, the standard calls for

the measurement to be made with the antenna oriented in the

horizontal plane as well.

In a typical power converter system setup, the radiated emis-

sions can come from two sources: 1) the input power leads as

they extend over the two meter distance between the LISNs and

the converter, as required for this test, and 2) the converter

output leads and load. The latter is likely to create significant

emissions if left uncovered since minimal EMI filtering is

provided at the converter's output. It is typical, however,

that the power supply and its load would be contained in a

conductive enclosure in applications where this test is applicable.

A metal screen enclosure was therefore used to cover the con-

verter and its load for this test.

Figure 14 shows test results for the vertical measurement and

compares them against the most stringent RE102 requirement;

the horizontal measurement (30 MHz and above) was similar.

As can be seen, the emissions just meet the standard in the

18 MHz28 MHz range. This component of the emissions is

due to common-mode currents flowing through the input power

leads. As mentioned in the section on CE102 above, the level

of common-mode current that flows is dependent on how the

load is connected. This measurement is therefore a good indi-

cation of how well the converter will perform in the final con-

figuration, but the user should confirm RE102 testing in the

final system. (Reference the last section of EMI Considerations

for how to adjust the external components in the test setup

circuit to increase the margin between the specification limit

and the measured results.)

RS101: This requirement is specialized and is intended to check

for sensitivity to low frequency magnetic fields in the 30 Hz to

50 kHz range. The converter is designed to meet this require-

ment. Consult factory for more information.

RS103: This test calls for correct operation during and after the

unit under test is subjected to radiated electric fields in the 10 kHz

to 40 GHz range. The intent is to simulate electromagnetic

fields generated by antenna transmissions. The converter is

designed to meet this requirement. Consult factory for more

information.

Circuit Setup for EMI Test

Figure 15 shows a schematic of the test setup used for the EMI

measurements discussed above. The output of the converter is

connected to a resistive load designed to draw full power. There

is a 0.1

µ

F capacitor placed across this resistor that typifies by-

pass capacitance normally used in this application. At the input

of the converter there are two differential capacitors (the larger

one having a series resistance) and two small common-mode

capacitors connected to case ground. The case itself was con-

nected to the metal ground plane in the test chamber. For the

RE102 test, a metal screen box was used to cover both the con-

verter and its load (but not the two meters of input power lead

cables). This box was also electrically connected to the metal

ground plane.

With regard to the components added to the input power lines,

the 100

µ

F capacitor with its 1

series resistance is required to

achieve system stability when the unit is powered through the

LISNs, as the MIL-STD-461D standard requires. These

LISNs have a series inductance of 50

µ

H at low frequencies,

giving a total differential inductance of 100

µ

H. As explained

earlier in the System Instability section, such a large series

source inductance will cause an instability as it interacts with the

converter's negative incremental input resistance unless some

corrective action is taken. The 100

µ

F capacitor and 1

resis-

tor provide the stabilization required.

It should be noted that the values of these stabilization components

are appropriate for a single converter load. If the system makes

use of several converters, the values of the components will need

to be changed slightly, but not such that they are repeated for

every converter. It should also be noted that most system appli-

cations will not have a source inductance as large as the 100

µ

H

built into the LISNs. For those systems, a much smaller input

capacitor could be used.

Increasing Margin Between Specification Limit and Measured

Results

With regard to the 2

µ

F differential-mode capacitor and the two

82 nF common-mode capacitors, these components were in-

cluded in the test setup to augment the performance of the

ADDC02828SA

REV. 0

14

power supply's internal EMI filter. The values were chosen to

achieve the results shown in Figures 12 and 14. To increase the

margin between the specification limits and the measured emis-

sions, larger external component values could be used.

To do this it is useful to know that most of the emissions below

10 MHz, whether conducted or radiated, are due to differential-

mode currents flowing in the input power leads. To make the

emissions in this frequency range smaller, the differential

capacitor value should be increased above 2

µ

F. Conversely,

most of the emissions above 10 MHz are due to common-mode

currents, and to make them smaller the common-mode capaci-

tors should be increased above the 82 nF value. In both cases it

is important to minimize the parasitic inductance of the capaci-

tors; the use of several smaller capacitors connected in parallel is

one way to achieve this.

Using larger valued capacitors than those shown in Figure 15 is

a good solution if an additional 6 dB10 dB of margin is de-

sired. However, if in an extremely sensitive application it is

desired to increase the margin by 20 dB or more, it may be

better to add both differential- and common-mode inductors to

the external components to make a higher order filter.

RELIABILITY CONSIDERATIONS

MTBF (Mean Time Between Failure) is a commonly used

reliability concept that applies to repairable items in which

failed elements are replaced upon failure. The expression for

MTBF is

MTBF = T/r

where

T = total operating time

r = number of failures

In lieu of actual field data, MTBF can be predicted per

MIL-HDBK-217.

MTBF, Failure Rate, and Probability of Failure: A proper

understanding of MTBF begins with its relationship to lambda

(

), which is the failure rate. If a constant failure rate is assumed,

then MTBF = 1/

, or

= 1/MTBF. If a power supply has an

MTBF of 1,000,000 hours, this does not mean it will last

1,000,000 hours before it fails. Instead, the MTBF describes

the failure rate. For 1,000,000 hours MTBF, the failure rate

during any hour is 1/1,000,000, or 0.0001%. Thus, a power

supply with an MTBF of 500,000 hours would have twice the

failure rate (0.0002%) of one with 1,000,000 hours.

What users should be interested in is the probability of a power

supply not failing prior to some time t. Given the assumption of

a constant failure rate, this probability is defined as

R(t )

=

e

t

where R(t) is the probability of a device not failing prior to some

time t.

If we substitute

= 1/MTBF in the above formula, then the

expression becomes

R(t )

=

e

t

MTBF

This formula is the correct way to interpret the meaning of

MTBF.

If we assume t = MTBF = 1,000,000 hours, then the probability

that a power supply will not fail prior to 1,000,000 hours of use

is e

1

, or 36.8%. This is quite different from saying the power

supply will last 1,000,000 hours before it fails. The probability

that the power supply will not fail prior to 50,000 hours of use is

e

.05

or 95%. For t = 10,000 hours the probability of no failure

is e

.01

or 99%.

Temperature and Environmental Factors: Although the

calculation of MTBF per MIL-HDBK-217 is a detailed process,

there are two key variables that give the manufacturer signi-

ficant leeway in predicting an MTBF rating. These two vari-

ables are temperature and environmental factor. Therefore, for

users to properly compare MTBF numbers from two different

manufacturers, the environmental factor and the temperature

must be identical. Contact the factory for MTBF calculations

for specific environmental factors and temperatures.

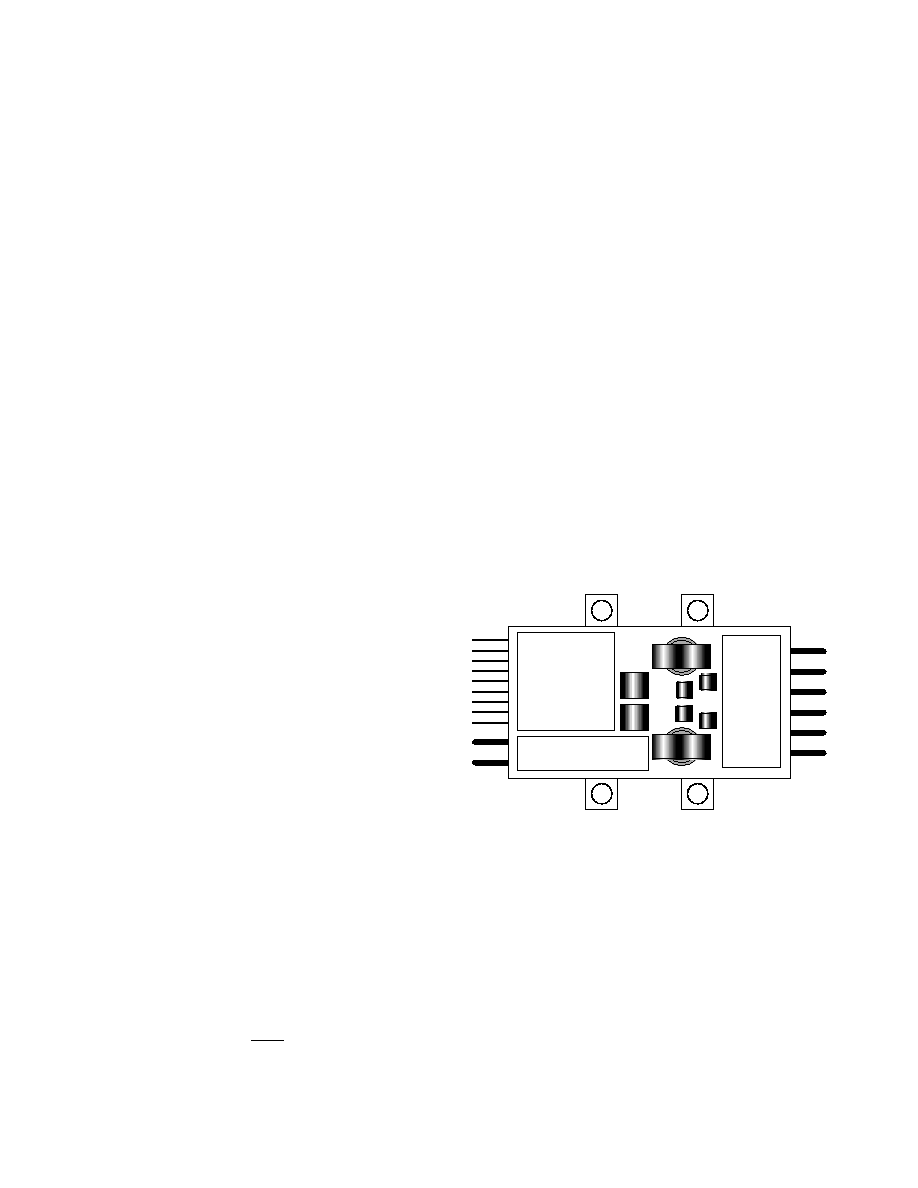

MECHANICAL CONSIDERATIONS

When mounting the converter into the next higher level assem-

bly, it is important to ensure good thermal contact is made

between the converter and the external heat sink. Poor thermal

connection can result in the converter shutting off, due to the

temperature shutdown feature (Pin 9), or reduced reliability for

the converter due to higher than anticipated junction and case

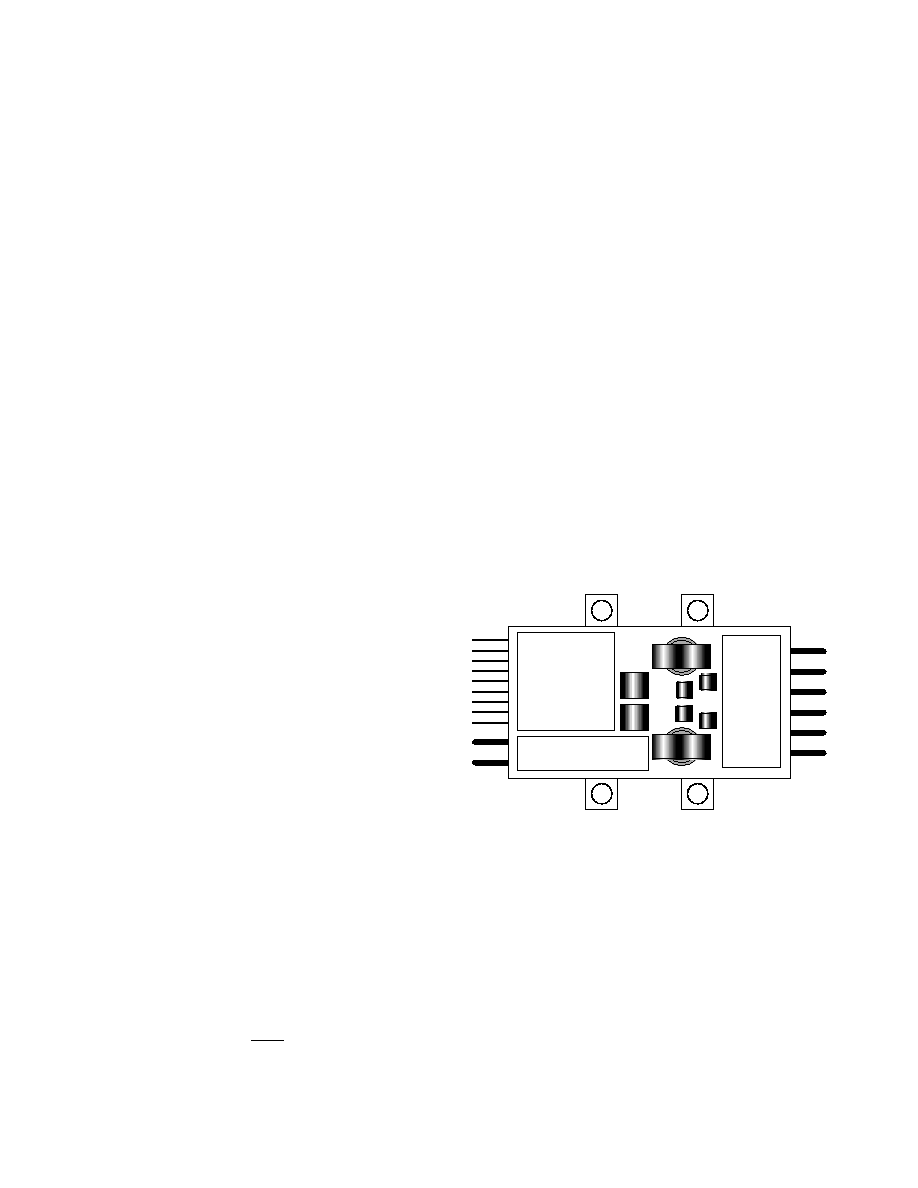

temperatures. For these reasons the mounting tab locations

were selected to ensure good thermal contact is made near the

hot spots of the converter, which are shown in the shaded areas

of Figure 24.

Figure 24. Hot Spots (Shaded Areas) of DC/DC Converter

The pins of the converter are typically connected to the next

higher level assembly by bending them at right angles, either

down or up, and cutting them shorter for insertion in printed

circuit board through holes. In order to maintain the hermetic

integrity of the seals around the pins, a fixture should be used

for bending the pins without stressing the pin-to-sidewall seals.

It is recommended that the minimum distance between the

package edge and the inside of the pin be 100 mils (2.54 mm)

for the 40 mil (1.02 mm) diameter pins; 120 mils (3.05 mm)

from the package edge to the center of the pin as shown in

Figure 25.

ADDC02828SA

REV. 0

15

DISABLE

ENB

GND

V

CC

OUT

HH73R-1MHZ

CONNER/WINFIELD

C1

.1µF

C2

100pF

+5V

SYNC OUT

SYNC 1

V

AUX

SYNC 2

SYNC 10

D2

1N5819

R13

1k

R5

1k

R2

1k

C3

.1µF

D1

1N966B

D3

1N5819

D4

1N5819

C4

100pF

C5

100pF

C13

100pF

R4

51k

OLH5801

(ISOLINK)

R3

357

SYNC IN

SYNC IN

2

3

5

6

8

R1

100k

A

K

A

K

Figure 28. Fault Tolerant, Secondary Side-Powered SYNC

Drive Circuit

NOTES

1. Input to Output Isolation: With the use of the Isolink opto-

coupler, we can use the output of the converters to power the

Conner/Winfield 1 MHz clock (output referenced) and the

Vaux pin (input referenced) to power the opto-coupler.

2. Fault Tolerant: All outputs are capacitively coupled to ensure

that if the master clock stops working the individual units will

continue to operate at their own internal clock frequency,

thereby eliminating a potential single point failure.

3. Radiated Emissions: C2 can be added to slow down the clock

edges (Tr and Tf) for reducing radiated emissions.

4. Table: The following table shows the capacitor and resis-

tor value to be used for the number of converters to be

synchronized.

Resistor

# of

Capacitor

Value

Converters

Value (pF)

(ohms)

1

1000

100

2

470

200

3

330

300

4

270

400

5

220

500

6

180

600

7

150

700

8

120

800

9

100

900

10

100

1K

0.100"

(2.54mm)

0.120"

(3.05mm)

Figure 25. Minimum Bend Radius of 40 Mil (1.02 mm) Pins

1

2

10

11

17

16

15

14

13

12

ADDC02828SA

PS1

C1

+28VDC

28RTN

RLOAD

NOTE: VALUE OF C1 IS DEPENDENT ON SOURCE IMPEDANCE.

REFER TO SECTION ON SYSTEM INSTABILITY CONSIDERATIONS.

Figure 26. Typical Power Connections and External Parts

for Converter (+28 V dc Out)

1

2

8

10

11

17

16

15

14

13

12

ADDC02828SA

1

2

8

10

11

17

16

15

14

13

12

ADDC02828SA

PS2

PS1

I

SHARE

C1

+28VDC

28RTN

+SENSE PS1

+SENSE PS2

RLOAD

+V

OUT

RETURN

NOTE: VALUE OF C1 IS DEPENDENT ON SOURCE IMPEDANCE.

REFER TO SECTION ON SYSTEM INSTABILITY CONSIDERATIONS.

Figure 27. Typical Connections for Paralleling Two

Converters (+28 V dc Out)

ADDC02828SA

REV. 0

16

C29947.52/97

PRINTED IN U.S.A.

Screening Levels for ADDC02828SA

Screening Steps

Industrial (KV)

Ruggedized Industrial (TV)

MIL-STD-883B/SMD (TV/883B)

Pre-Cap Visual

100%

MIL-STD-883, TM2017

Temp Cycle

N/A

N/A

Constant Acceleration

N/A

N/A

Fine Leak

Guaranteed to Meet

Guaranteed to Meet

MIL-STD-883, TM1014

MIL-STD-883, TM1014

Compliant to MIL-PRF-38534

Gross Leak

Guaranteed to Meet

Guaranteed to Meet

MIL-STD-883, TM1014

MIL-STD-883, TM1014

Burn-In

N/A

MIL-STD-883, TM1015,

96 Hrs at +115

°

C Case

Final Electrical Test

At +25

°

C, Per Specification

At +25

°

C, Per Specification

Table

Table

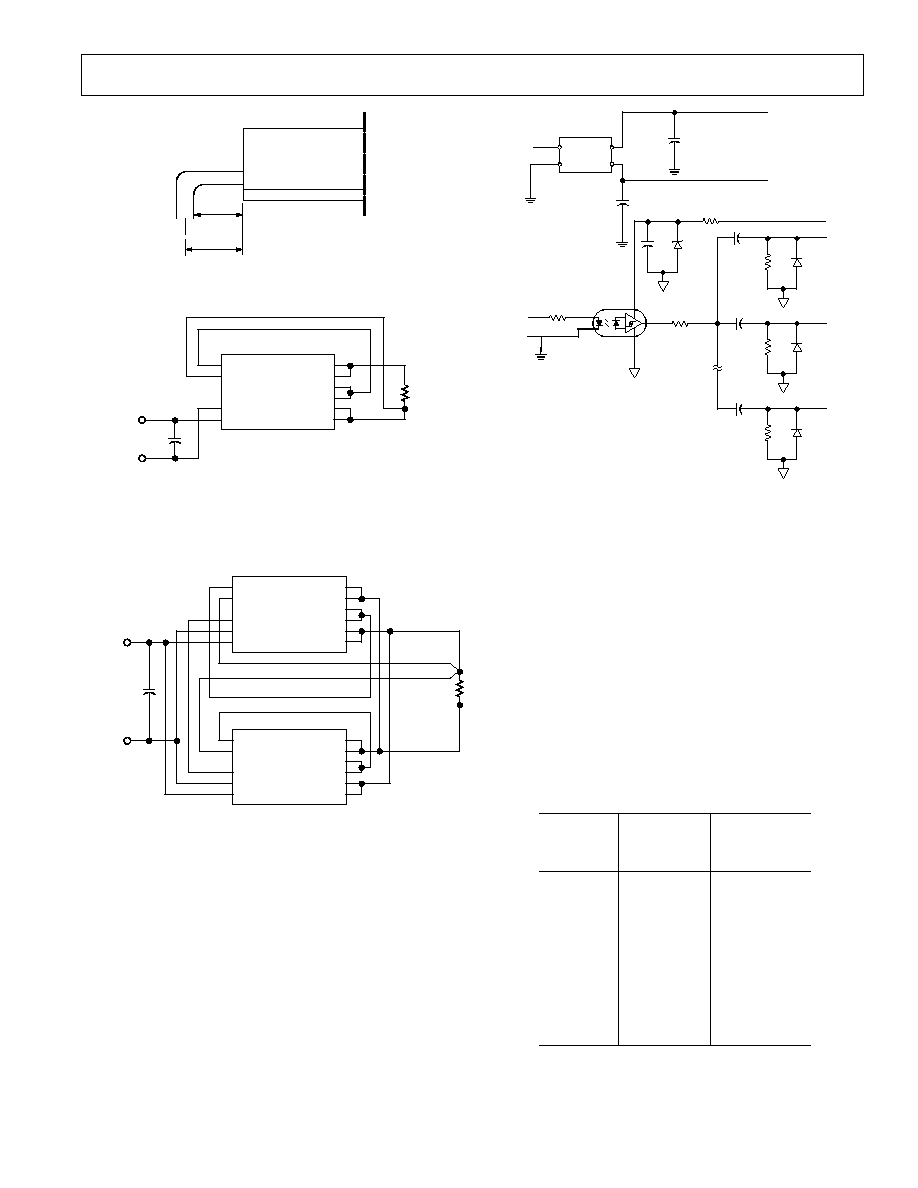

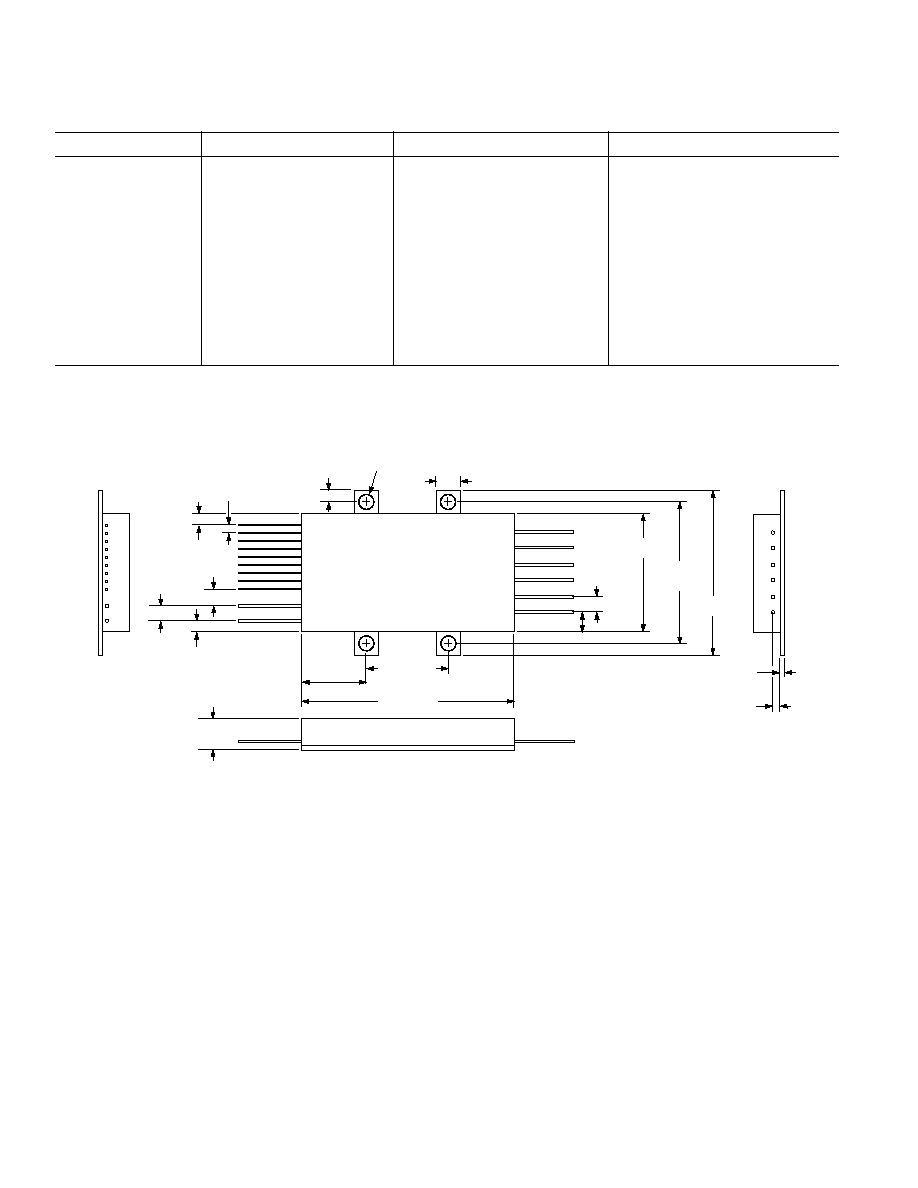

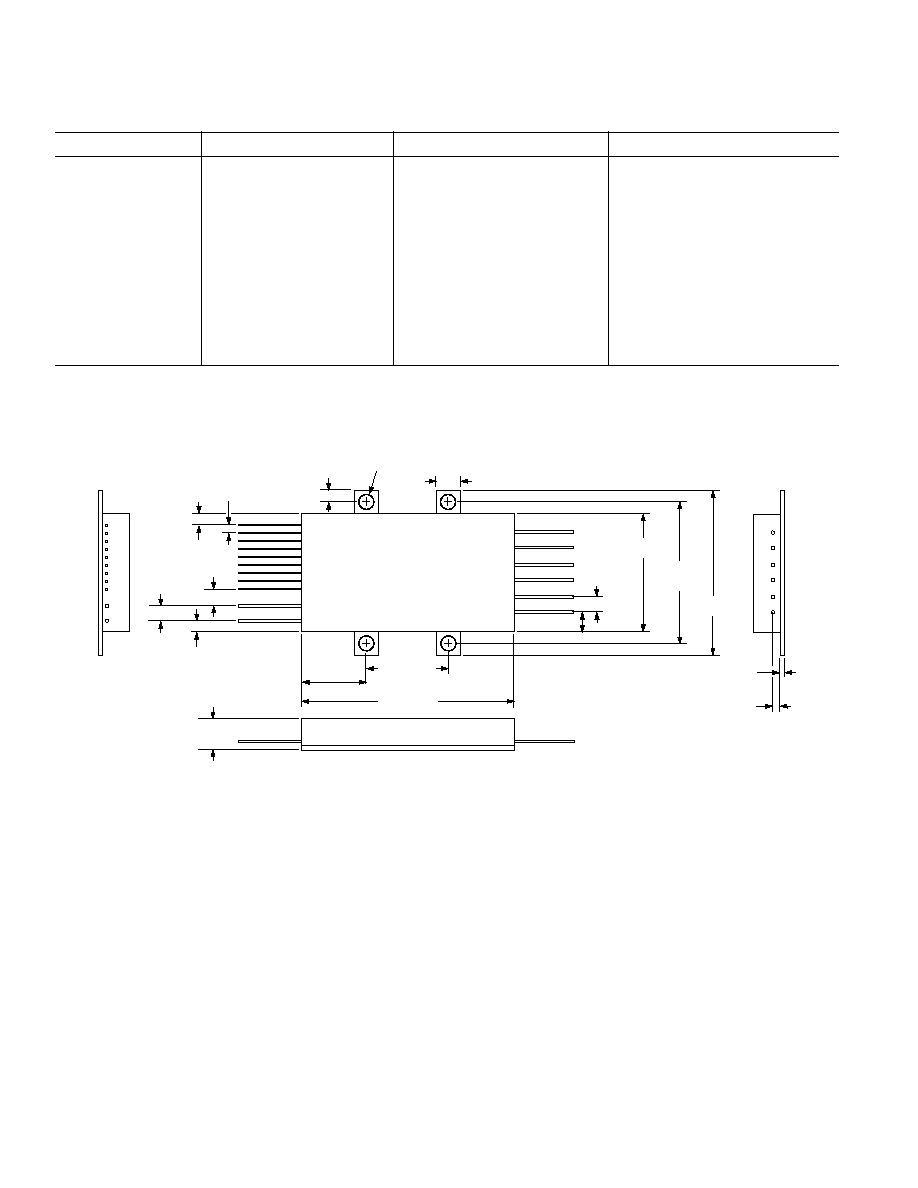

NOMINAL CASE DIMENSIONS IN INCHES AND (mm)

[All tolerances

±

.005" (

±

.13 mm) unless otherwise specified]

0.150 (3.81)

0.100 (2.54)

8 PLCS

0.200 (5.08)

0.150 (3.81)

0.200 (5.08)

0.390

±

0.010

(9.91

±

0.25)

0.800

±

0.010

(20.32

±

0.25)

1.145 (29.08)

2 PLCS

0.150 (3.81)

4 PLCS

TOP VIEW

0.149 (3.78)

DIA TYP

0.300 (7.62) SQ

±

0.010

4 PLCS

0.200 (5.08) 5 PLCS

0.250 (6.35)

2 PLCS

1.500

±

0.010

(38.10

±

0.25)

0.040

±

0.003

(1.02

±

0.08)

0.090

±

0.010

(2.29

±

0.25)

4 PLCS

2.745

±

0.010

(69.72

±

0.25)

1.800

(45.72)

TYP

2.100

±

0.010

(53.34

±

0.25)

5. All pins are a minimum length of 0.740 inches (18.80 mm)

when the product is shipped. The pins are typically bent up

or down and cut shorter for proper connection into the user's

system.

6. All pin-to-sidewall spacings are guaranteed for a minimum of

500 V dc breakdown at standard air pressure.

7. The case outline was originally designed using inch-pound units

of measurement. In the event of conflict between the metric

and inch-pound units, the inch-pound shall take precedence.

NOTES

1. The final product weight is 85 grams maximum.

2. The package base material is made of molybdenum and is

nominally 40 mils (1.02 mm) thick. The "runout" is less

than 2 mils per inch (0.02 mm per cm).

3. The high current pins (1017) are 40 mil (1.02 mm) diameter;

are 99.8% copper; and are plated with gold over nickel.

4. The signal carrying pins (19) are 18 mil (0.46 mm) diam-

eter; are Kovar; and are plated with gold over nickel.